Decorative Metal Screen

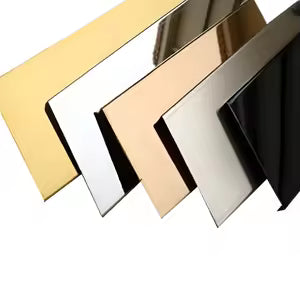

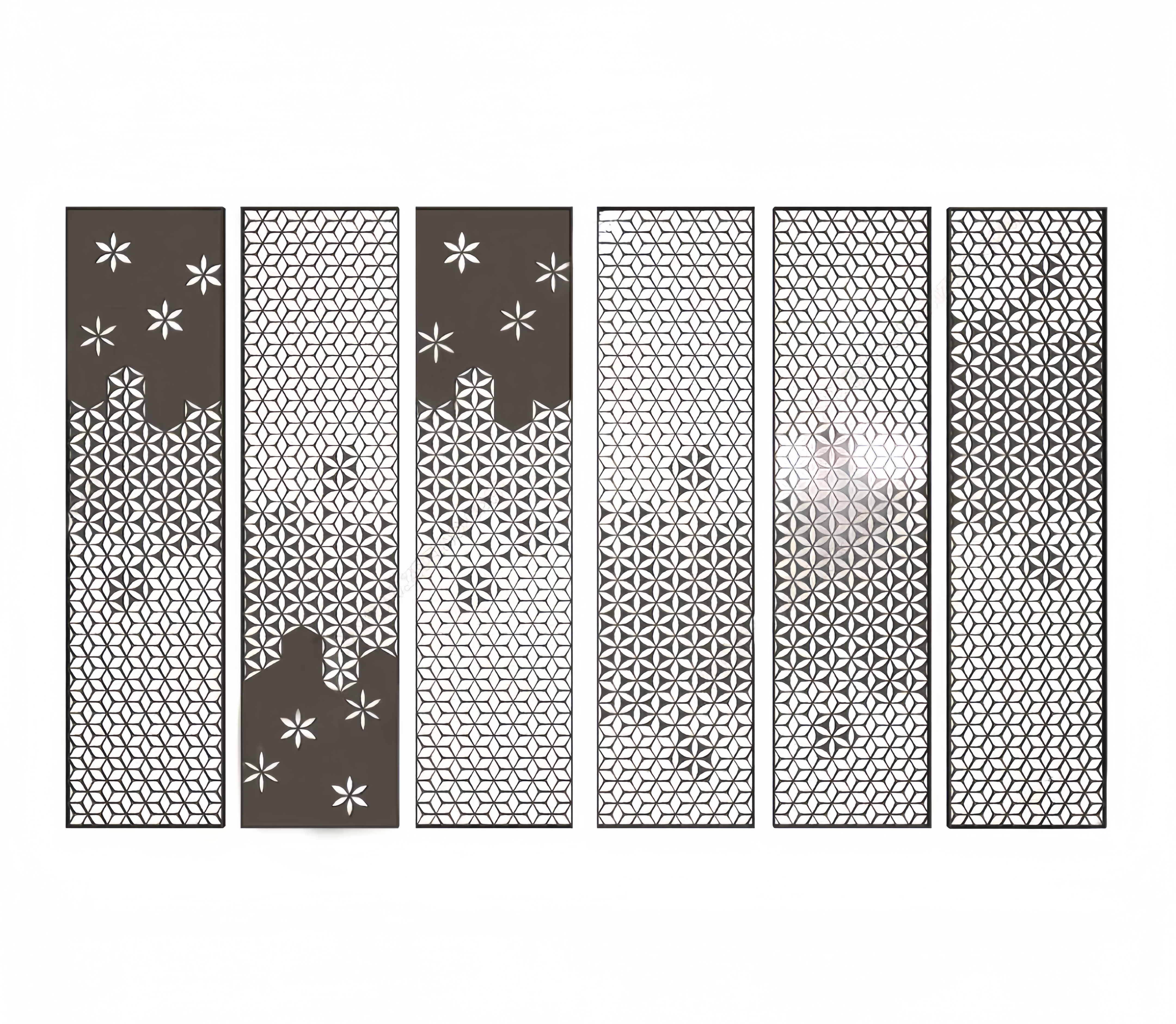

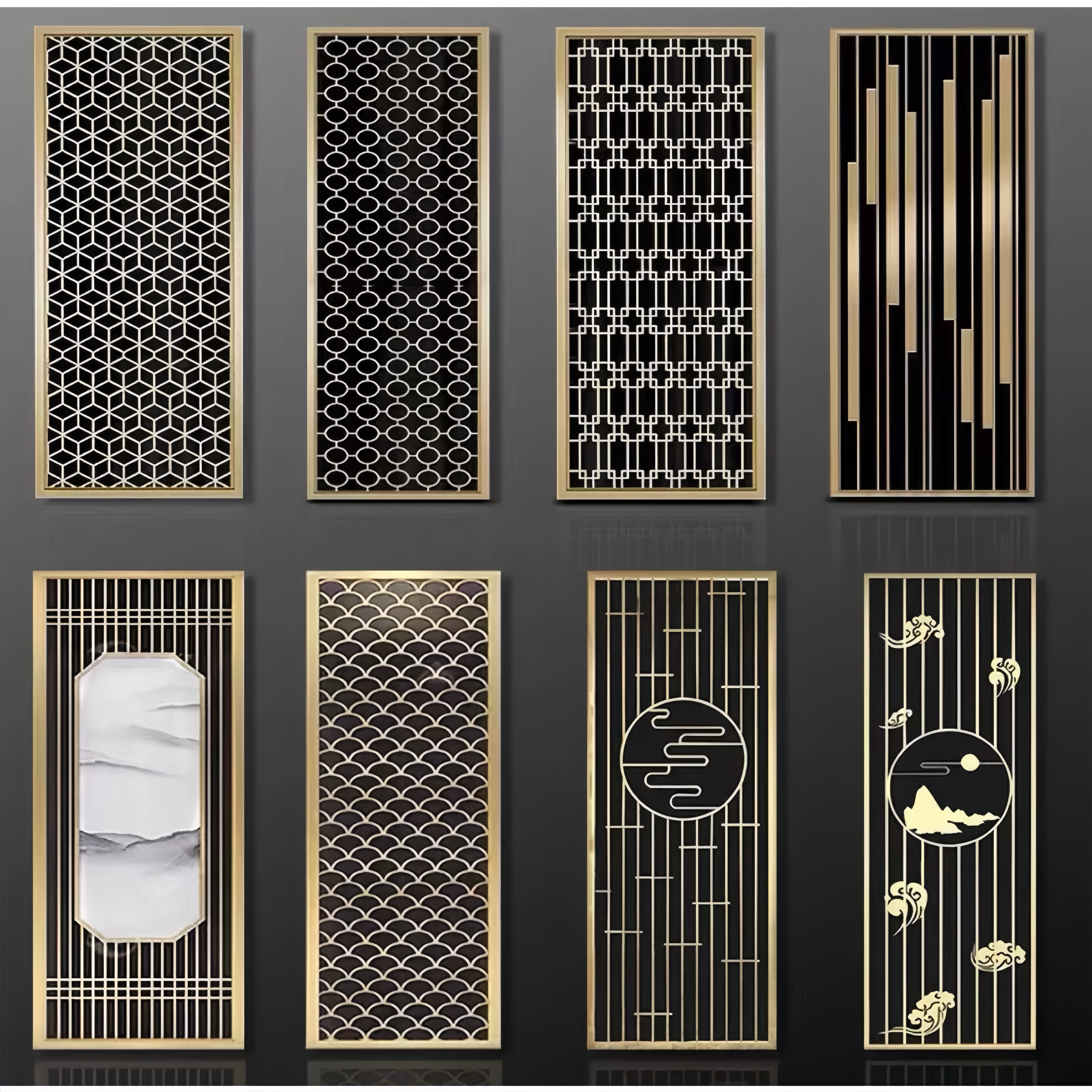

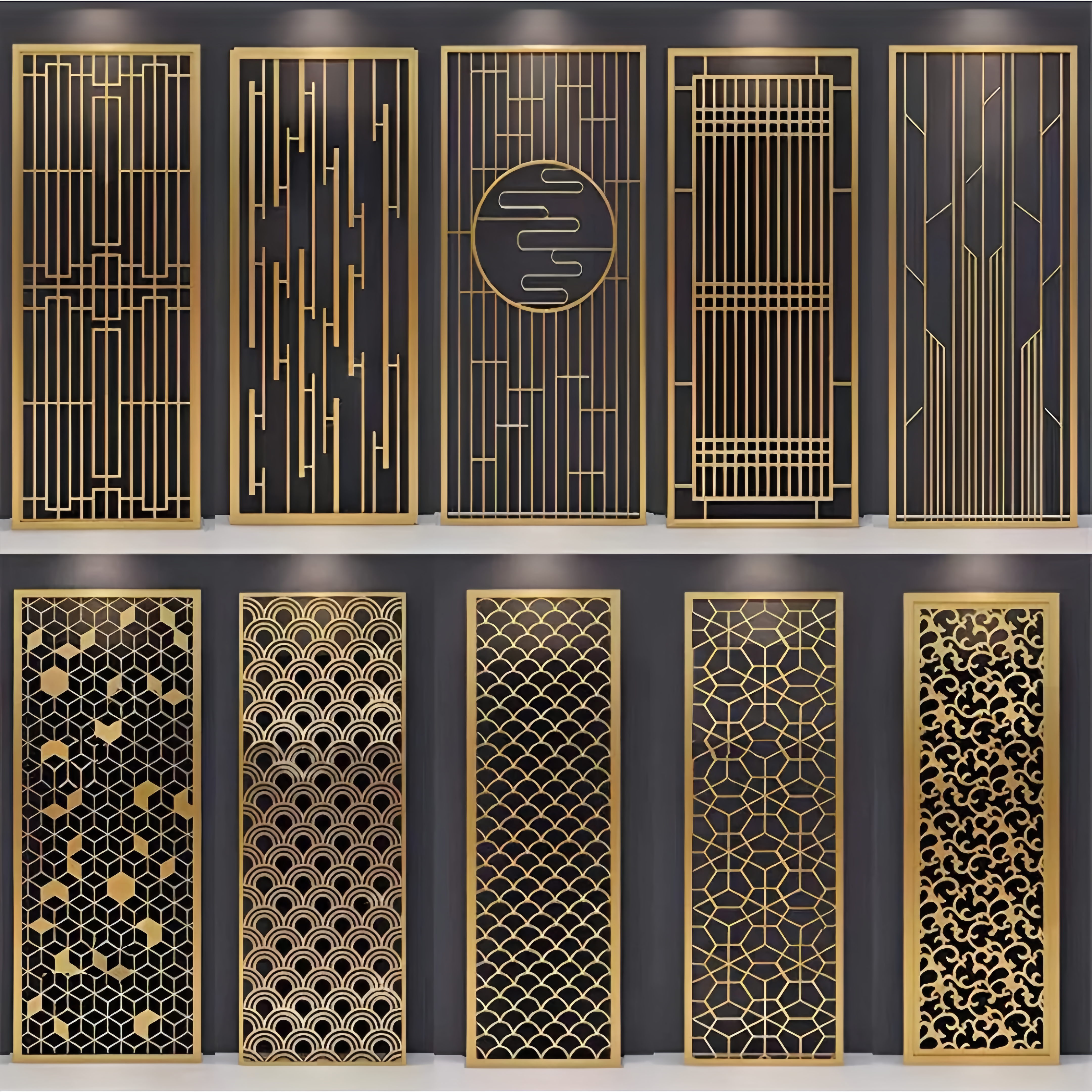

Premium decorative metal screens engineered to transform architectural spaces with sophisticated geometric patterns and luxurious metallic finishes. Our decorative screens combine precision-fabricated stainless steel or aluminum frameworks with advanced PVD (Physical Vapor Deposition) coating technology to create stunning visual elements that serve as room dividers, privacy screens, architectural features, and artistic installations. Each screen is meticulously crafted using laser-cut plates and welded tube construction, finished with durable PVD coatings in elegant gold, rose gold, bronze, and contemporary metallic tones.

Our decorative metal screens are engineered to be architectural centerpieces, blending artistry with function to elevate a space's character.

- Luxury Hospitality & Retail: Creating breathtaking focal points and partitions in hotel lobbies, upscale restaurants, and luxury boutiques to define spaces and craft an exclusive ambiance.

- Corporate & Office Environments: Serving as elegant room dividers in open-plan offices or as monumental feature walls in corporate headquarters to convey sophistication and brand identity.

- High-End Residential Interiors: Used as sophisticated privacy screens, artistic staircase enclosures, or decorative partitions that add a layer of bespoke luxury to modern homes.

- Architectural Features & Facades: Employed as striking exterior cladding, decorative balcony screens, or large-scale artistic installations that define a building's unique character.

Exquisite Artistic Statement

Meticulously crafted with intricate laser-cut patterns and luxurious PVD finishes (gold, bronze, etc.), each screen acts as a sculptural centerpiece, creating a stunning interplay of light and shadow.

Fully Customizable Design

From bespoke patterns and integrated logos to custom sizes and unique finishes, we collaborate with architects and designers to transform any creative vision into a precisely fabricated reality.

Premium Craftsmanship & Durability

Constructed from high-grade stainless steel or aluminum with robust welded frames, our screens are finished with exceptionally durable PVD coatings that resist fading and wear, ensuring timeless elegance.

| Grade | Composition | Properties | Applications | Finish Compatibility |

|---|---|---|---|---|

| 304 | 18Cr-8Ni | General purpose, non-magnetic, excellent formability |

Interior applications, standard environments |

All PVD finishes |

| 316 | 18Cr-10Ni-2Mo | Marine grade, superior corrosion resistance | Coastal, high-humidity, exterior applications |

All PVD finishes |

| 316L | Low carbon 316 |

Enhanced weldability, reduced carbide precipitation |

High-end architectural, critical applications |

Premium PVD finishes |

| 430 | 17Cr (Ferritic) | Magnetic, economical, good corrosion resistance |

Budget-conscious projects, interior use |

Standard PVD finishes |

| Alloy | Temper | Strength (MPa) | Applications | Weight Advantage |

|---|---|---|---|---|

| 6061-T6 | T6 | 276 yield | Structural applications, high strength required | 65% lighter than steel |

| 6063-T5 | T5 | 214 yield | Architectural applications, excellent finish | 65% lighter than steel |

| 5052-H32 | H32 | 228 yield | Marine applications, superior corrosion resistance | 65% lighter than steel |

| 1100-H14 | H14 | 110 yield | Decorative applications, maximum formability | 65% lighter than steel |

| Component | Stainless Steel | Aluminum | Welding Method | Finish |

|---|---|---|---|---|

| Perimeter Frame | 25×25×2mm to 50×50×3mm tube | 25×25×2mm to 50×50×3mm tube | TIG welding | Ground smooth |

| Internal Structure | 20×20×1.5mm to 40×40×2mm tube | 20×20×1.5mm to 40×40×2mm tube | TIG welding | Ground smooth |

| Decorative Plates | 1.5–3.0mm thickness | 2.0–4.0mm thickness | Laser cut | Precision edges |

| Connection Hardware | 316 stainless steel | 6061-T6 aluminum | Mechanical fastening | Matching finish |

| Panel Size | Width (mm) | Height (mm) | Thickness (mm) | Weight (kg) | Applications |

|---|---|---|---|---|---|

| Small | 600-800 | 1200-1800 | 25-40 | 8-15 | Residential, small commercial |

| Medium | 800-1200 | 1800-2400 | 30-50 | 15-28 | Standard commercial, offices |

| Large | 1200-1500 | 2400-3000 | 40-60 | 28-45 | Hotels, large commercial spaces |

| Extra Large | 1500-2000 | 3000-4000 | 50-80 | 45-70 | Architectural features, atriums |

| Custom | Up to 3000 | Up to 6000 | 25-100 | Varies | Unique architectural applications |

| Finish | Color Description | Thickness (μm) | Durability | Applications |

|---|---|---|---|---|

| Gold (Au) | Rich, warm gold tone | 0.8-1.2 | Excellent | Luxury retail, hotels, high-end residential |

| Rose Gold | Warm pink-gold blend | 0.8-1.2 | Excellent | Contemporary design, hospitality, residential |

| Bronze | Deep bronze with copper undertones | 1.0-1.5 | Excellent | Traditional, rustic, industrial chic |

| Champagne | Light gold with silver highlights | 0.8-1.2 | Excellent | Elegant commercial, upscale residential |

| Black Gold | Dark gold with black undertones | 1.2-1.8 | Excellent | Modern luxury, dramatic contrast |

| Titanium | Blue-gray metallic | 0.5-1.0 | Superior | Contemporary, high-tech aesthetic |

| Copper | Pure copper appearance | 1.0-1.5 | Excellent | Industrial, rustic, artistic applications |

| Pattern Code | SWD | LWD | Strand Width | Open Area | Weight (Al/Steel) |

|---|---|---|---|---|---|

| XS-13 | 6mm | 13mm | 1.5mm | 65% | 1.8/5.1 kg/m² |

| S-20 | 10mm | 20mm | 2.0mm | 70% | 2.1/6.0 kg/m² |

| M-25 | 12mm | 25mm | 2.5mm | 72% | 2.4/6.8 kg/m² |

| L-32 | 16mm | 32mm | 3.0mm | 75% | 2.7/7.7 kg/m² |

| XL-40 | 20mm | 40mm | 3.5mm | 78% | 3.0/8.5 kg/m² |

| XXL-50 | 25mm | 50mm | 4.0mm | 80% | 3.3/9.4 kg/m² |

FAQs

What Are the Main Advantages of Expanded Metal Panels for Cladding?

Expanded metal panels offer unique advantages that make them ideal for architectural cladding applications requiring strength, ventilation, and cost-effectiveness:

Structural Advantages:

- Superior strength-to-weight ratio - up to 70% weight reduction with maintained structural integrity

- Excellent load distribution through interconnected diamond pattern

- Impact resistance - expanded structure absorbs and distributes forces

- Dimensional stability - minimal thermal expansion stress

- Fatigue resistance - flexible structure handles dynamic loads

Functional Benefits:

- Outstanding ventilation - up to 80% open area for maximum airflow

- Security with visibility - restricts access while maintaining sight lines

- Self-cleaning properties - open structure prevents debris accumulation

- Acoustic transparency - allows sound transmission when required

- Lightning and EMI protection - conductive metal mesh properties

Economic Advantages:

- Material efficiency - expanded process uses 100% of original sheet

- Reduced transportation costs - lightweight panels lower shipping expenses

- Easy installation - standard mounting systems and lightweight handling

- Low maintenance - durable construction requires minimal upkeep

- Cost-effective manufacturing - efficient production process

Design Flexibility:

- Multiple mesh patterns - from fine security to coarse architectural

- Various orientations - diamond pattern can be rotated for different effects

- Custom sizing - panels can be fabricated to specific dimensions

- Finish options - wide range of coatings and surface treatments

- Integration capability - combines well with other cladding materials

Environmental Benefits:

- High recycled content - made from recycled metal materials

- 100% recyclable - panels can be fully recycled at end of life

- Energy efficient - natural ventilation reduces HVAC requirements

- Sustainable manufacturing - minimal waste production process

How Do You Select the Right Expanded Metal Mesh Pattern for Cladding?

Selecting the optimal expanded metal mesh pattern requires balancing functional requirements, aesthetic goals, and structural performance:

Functional Requirements Analysis:

Ventilation Needs:

- High airflow (70-80% open area): Parking garages, equipment screening - use Heavy Duty or Architectural mesh

- Moderate airflow (60-70% open area): General building ventilation - use Standard mesh

- Controlled airflow (45-55% open area): Security applications - use Fine mesh

Security Requirements:

- Maximum security: Fine mesh (6×12mm SWD) prevents small object penetration

- Standard security: Standard mesh (12×25mm SWD) balances security and cost

- Visual security: Larger mesh maintains visibility while providing barrier

Structural Considerations:

- High wind loads: Smaller mesh patterns provide better structural efficiency

- Large spans: Heavy-duty mesh with wider strands for maximum strength

- Seismic zones: Consider dynamic loading and flexibility requirements

Aesthetic Preferences:Visual Impact:

- Fine texture: Small mesh patterns create subtle surface texture

- Bold pattern: Large mesh creates dramatic shadow effects

- Directional emphasis: Mesh orientation affects visual flow

Light and Shadow:

- Dynamic effects: Larger openings create more pronounced shadow patterns

- Consistent shading: Smaller, uniform patterns provide even light filtration

- Seasonal variation: Consider sun angle changes throughout the year

Material Selection Guidelines:

Aluminum Expanded Metal:

- Best for: Lightweight applications, corrosive environments

- Mesh range: All patterns available

- Finishes: Anodized, powder coat, PVDF options

Galvanized Steel:

- Best for: High-strength requirements, cost-sensitive projects

- Mesh range: Standard to heavy-duty patterns

- Finishes: Galvanized, painted, powder coated

Stainless Steel:

- Best for: Premium applications, extreme environments

- Mesh range: Fine to standard patterns typically

- Finishes: Mill, brushed, mirror options

Application-Specific Recommendations:

- Parking structures: 20×40mm or 25×50mm mesh, 65-75% open area

- Equipment screening: 25×50mm or larger, 70-80% open area

- Security barriers: 6×12mm to 12×25mm mesh, 45-65% open area

- Architectural features: Custom patterns based on design intent

What Is the Cost Difference Between Expanded Metal and Other Cladding Materials?

Expanded metal panels typically offer excellent value compared to other cladding materials, with significant cost advantages in many applications:

Initial Cost Comparison:

Expanded Metal Advantages:

- Material efficiency - 100% of original sheet metal is used (no waste)

- Lightweight construction reduces shipping and handling costs

- Simple manufacturing process keeps production costs low

- Standard tooling available for common mesh patterns

- Bulk availability from multiple suppliers ensures competitive pricing

Cost Factors:

- Base material type: Aluminum > Stainless Steel > Galvanized Steel > Carbon Steel

- Mesh pattern complexity: Standard patterns most economical

- Panel thickness: Heavier gauges cost more per square meter

- Surface finish: Mill finish < Galvanized < Powder Coat < PVDF

- Custom sizing: Standard sizes most cost-effective

Comparison with Other Materials:

vs. Perforated Panels:

- Expanded metal typically 20-40% less expensive

- No material waste vs. 30-70% waste in perforation process

- Faster production reduces manufacturing costs

- Better strength-to-weight ratio

vs. Solid Metal Panels:

- 60-80% material savings due to expanded structure

- Lower shipping costs due to reduced weight

- Reduced structural support requirements

- Natural ventilation reduces HVAC costs

vs. Mesh/Wire Systems:

- Integrated structure eliminates separate framing

- Single-piece installation reduces labor costs

- Better durability than wire mesh systems

- Lower maintenance requirements

Lifecycle Cost Benefits:

- Durability: 25-40 year lifespan with proper material selection

- Low maintenance: Self-cleaning, corrosion-resistant construction

- Energy savings: Natural ventilation reduces operating costs

- Recyclable value: High scrap value at end of service life

Cost Optimization Strategies:

- Choose standard mesh patterns when possible

- Consider galvanized steel for non-corrosive environments

- Plan for standard panel sizes to minimize cutting waste

- Evaluate total project costs including installation and maintenance

How Does Expanded Metal Perform in Different Weather Conditions?

Expanded metal panels excel in all weather conditions due to their unique structural properties and material characteristics:

Wind Performance:

- Excellent wind resistance - open structure reduces wind loads by 40-60%

- Pressure equalization prevents panel flutter and stress concentration

- Flexible structure accommodates wind-induced movement

- Lower structural loads on building framework

- Self-stabilizing diamond pattern distributes forces evenly

Rain and Moisture Management:

- Superior drainage - open structure prevents water accumulation

- Self-cleaning action - rain washes debris through openings

- Rapid drying - excellent air circulation prevents moisture retention

- Reduced ice formation - airflow prevents ice buildup

- Corrosion resistance varies by material and coating selection

Temperature Extremes:

Hot Weather Performance:

- Excellent heat dissipation through natural convection

- Reduced thermal expansion stress - flexible structure accommodates movement

- Solar heat gain control - provides shading while maintaining airflow

- No thermal bridging issues common with solid panels

Cold Weather Performance:

- No brittleness - metal construction maintains flexibility

- Thermal shock resistance - gradual temperature transitions

- Snow and ice shedding - open structure prevents accumulation

- Freeze-thaw stability - no water entrapment issues

UV and Solar Exposure:

- UV-stable materials - metals don't degrade under UV exposure

- Coating protection - PVDF and anodized finishes provide long-term UV resistance

- Dimensional stability - minimal UV-induced expansion or contraction

- Color retention - quality finishes maintain appearance

Coastal and Marine Environments:

- Aluminum and stainless steel excel in salt spray conditions

- Enhanced drainage prevents salt accumulation

- Air circulation helps dissipate corrosive vapors

- Galvanic corrosion resistance with proper material selection

Extreme Weather Events:

- Hurricane resistance - flexible structure survives high winds

- Hail impact resistance - expanded structure absorbs impact energy

- Seismic performance - flexible mounting accommodates building movement

- Tornado debris resistance - open structure allows debris passage

Material-Specific Performance:

- Aluminum: Best overall weather resistance, lightweight

- Stainless steel: Maximum corrosion resistance, premium durability

- Galvanized steel: Good performance with proper coating maintenance

- Weathering steel: Develops protective patina, minimal maintenance

Installation Considerations:

- Proper drainage design behind panels essential

- Quality fasteners and mounting systems critical

- Thermal expansion joints for large installations

- Professional installation recommended for optimal performance

What Are the Security and Safety Benefits of Expanded Metal Cladding?

Expanded metal panels provide excellent security and safety features while maintaining functionality and aesthetic appeal:

Security Advantages:Visual Deterrent:

- Barrier appearance discourages unauthorized access attempts

- Maintained visibility allows security monitoring and surveillance

- Tamper resistance - difficult to cut or breach without specialized tools

- No loose components that could be used as weapons or projectiles

Access Control:

- Controlled opening sizes prevent passage of people or large objects

- Fine mesh options (6×12mm) restrict small object penetration

- Climbing deterrent - diamond pattern difficult to grip

- Integration capability with electronic security systems

Structural Security:

- High strength-to-weight ratio resists impact and forced entry

- Flexible structure absorbs impact energy without catastrophic failure

- Continuous construction - no weak points or joints

- Vandal resistance - difficult to damage with common tools

Safety Features:

Fire Safety:

- Non-combustible construction - Class A fire rating

- No toxic fume emission during fire exposure

- Maintained ventilation during emergency situations

- Emergency egress - doesn't impede evacuation routes when properly designed

Fall Protection:

- Barrier function prevents accidental falls from elevated areas

- Maintained visibility allows supervision and monitoring

- Impact absorption - flexible structure reduces injury severity

- Code compliance meets safety barrier requirements

EnvironmentalSafety:

- Non-toxic materials - safe for occupied buildings

- No sharp edges when properly finished and installed

- Slip resistance - textured surface provides grip

- Lightning protection - conductive mesh provides Faraday cage effect

Application-Specific Benefits:

Parking Structures:

- Suicide prevention barriers with maintained visibility

- Vehicle containment while allowing ventilation

- Pedestrian protection from vehicle areas

- Crime deterrent through improved visibility

Industrial Facilities:

- Equipment protection from unauthorized access

- Maintained ventilation for safe operation

- Personnel protection from moving machinery

- Containment barriers for hazardous areas

Educational Facilities:

- Perimeter security with maintained supervision capability

- Playground protection from unauthorized access

- Sports facility barriers for spectator and player safety

- Stairwell protection preventing falls and objects dropping

Design Considerations:

- Mesh size selection based on security requirements

- Proper mounting height and extension for effectiveness

- Integration with lighting for nighttime security

- Maintenance access for cleaning and inspection

- Emergency access provisions where required by code

Compliance Standards:

- Building codes for barrier height and strength requirements

- Security standards for detention and high-security facilities

- Safety regulations for industrial and commercial applications

- Accessibility requirements for public buildings