FAQs

Q1. What are the main differences between solid aluminum panels and aluminum composite panels for exterior cladding?

The primary difference lies in their construction and performance. Solid aluminum panels are a single, monolithic sheet of aluminum, offering the highest level of fire resistance (Class A non-combustible) and structural rigidity. They are best for high-rises and projects where durability is the top priority. Aluminum composite panels (ACP) consist of a core material sandwiched between two thin aluminum skins, making them lighter and more cost-effective, with excellent flatness. Their fire rating depends on the core material chosen.

Q2. How do I choose the right surface finish for my project?

Choosing the right finish depends on your project's location, aesthetic goals, and budget.

- PVDF Coating: Offers the highest level of durability, UV resistance, and color retention, making it ideal for landmark projects and harsh environments. It comes with the longest warranties (20+ years).

- Polyester Coating: A cost-effective solution that provides good performance and a wide range of colors, suitable for standard commercial applications.

- Anodized Finish: Creates a hard, integral layer that enhances the natural metallic look of the aluminum while offering excellent corrosion and abrasion resistance.

Q3. What fire safety ratings do Ansus Metal cladding systems meet?

Safety is paramount in our engineering. Our Solid Aluminum Panels are the definitive choice for high-rise and critical safety projects, achieving a Class A non-combustible fire rating. For projects utilizing Aluminum Composite Panels (ACP), we offer fire-rated (FR) cores designed to enhance safety while maintaining the material's flatness and versatility. All our products are manufactured to meet rigorous international standards to ensure compliance with local building codes.

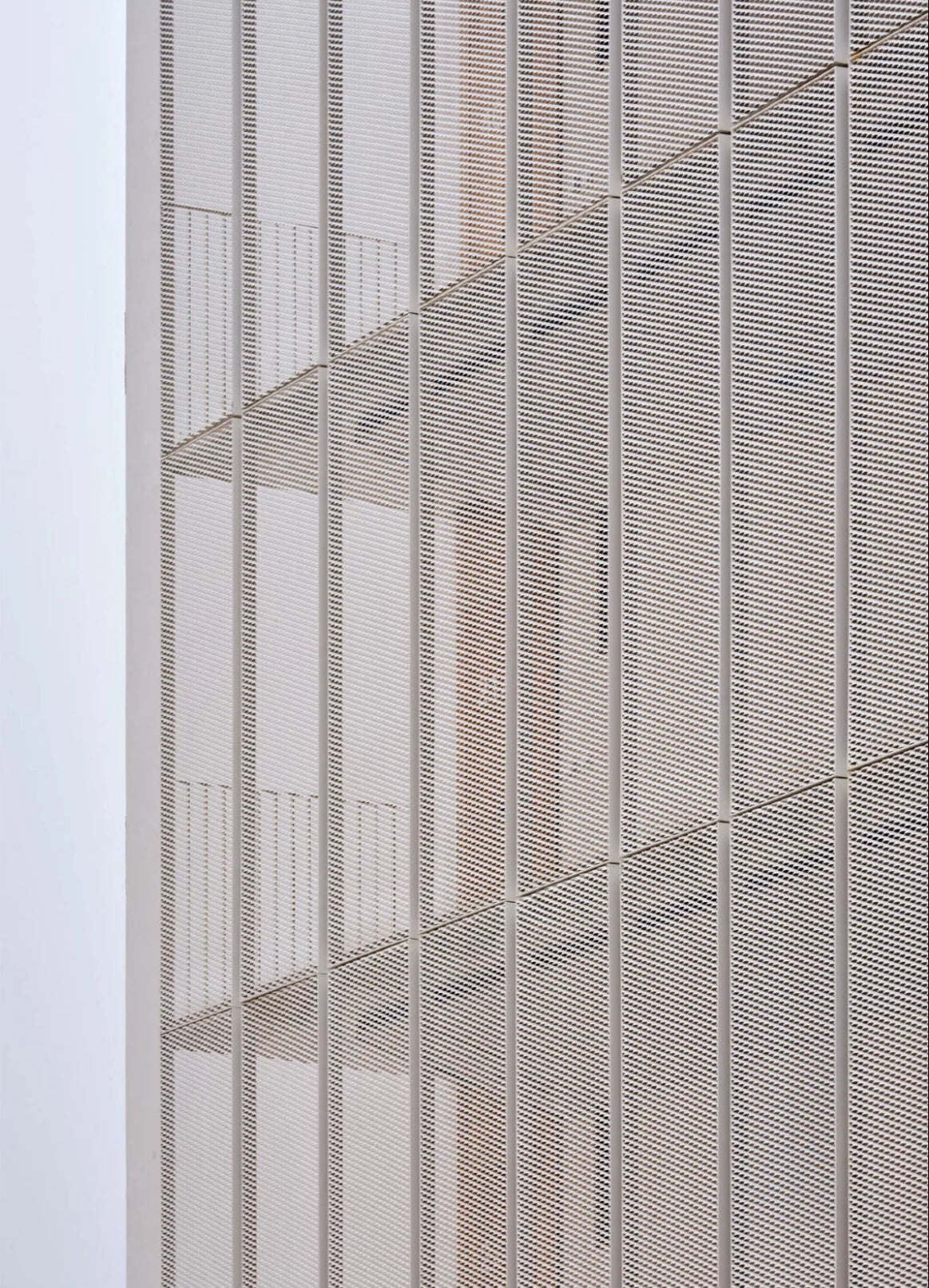

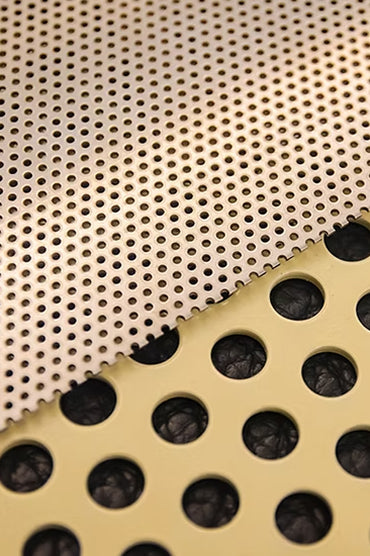

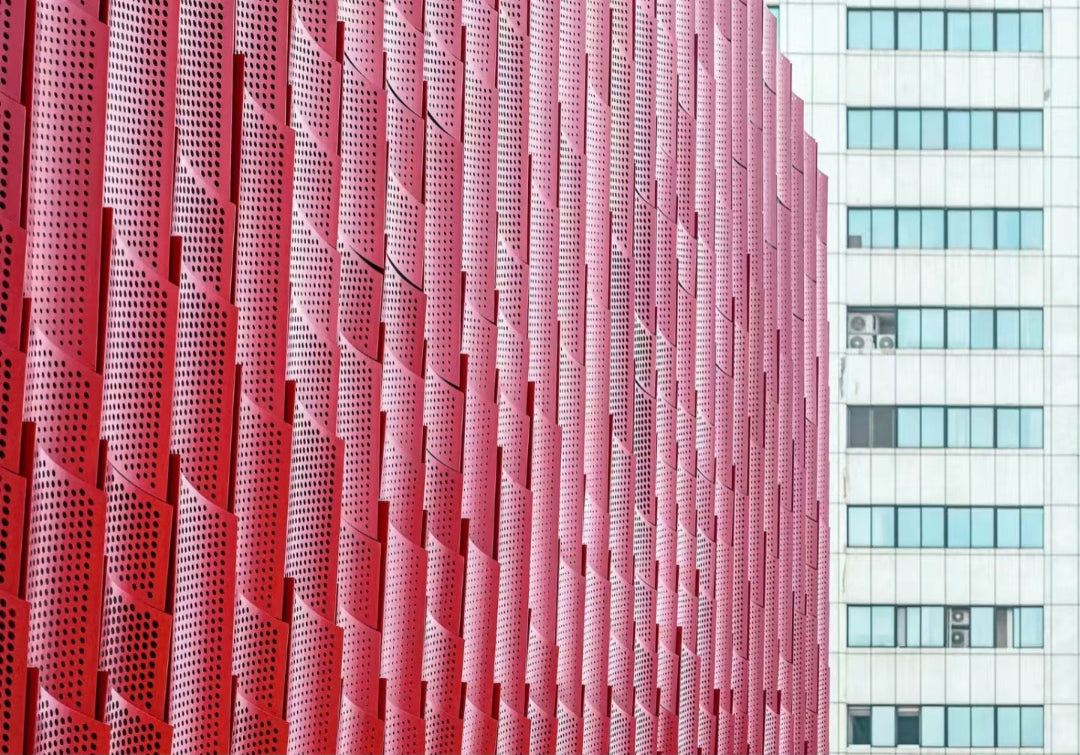

Q4. How do perforated metal facades contribute to building performance?

Beyond their striking visual appeal, perforated metal facades are highly functional. They act as an effective passive solar shading device, allowing you to control light intake and reduce solar heat gain, which can lower energy costs. Additionally, they facilitate natural ventilation while maintaining privacy. Our precision manufacturing allows for custom patterns and variable open-area percentages, giving architects the tools to balance artistic expression with environmental performance.

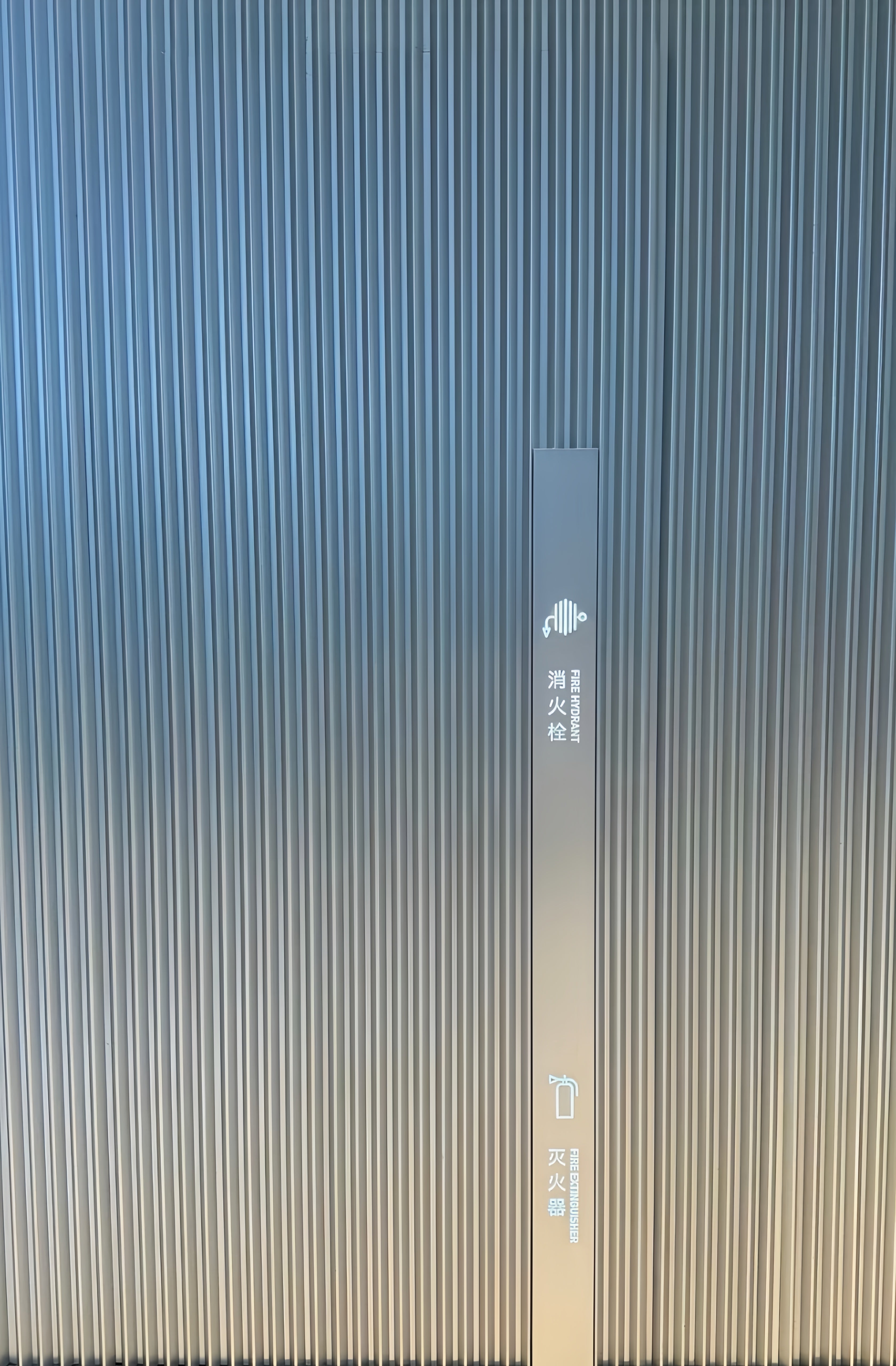

Q5. What are the advantages of using corrugated metal cladding for commercial projects?

Corrugated metal cladding offers a unique combination of structural efficiency and aesthetic character. The corrugated profile naturally increases the panel's strength, allowing for impressive span capabilities and high load-bearing efficiency without adding significant weight to the building structure. Visually, these panels create dynamic facades with distinctive shadow lines, making them an ideal choice for industrial, commercial, and residential projects seeking a robust, modern look.

Q6. What is the expected lifespan of Ansus Metal exterior panels?

Our facade systems are engineered for longevity. Specifically, our Solid Aluminum Panels boast an exceptional lifespan of 25 to 40 years, offering unparalleled long-term value. To ensure this durability, we utilize premium PVDF coatings that provide superior resistance to fading, chalking, and environmental weathering. We back these high-performance finishes with warranties of up to 20 years, ensuring your building's envelope retains its visual identity for decades.

Q7. Can Ansus Metal panels withstand extreme weather and wind loads?

Yes. Our exterior cladding systems are designed as high-performance building envelopes capable of resisting harsh environmental conditions. We specialize in components for rainscreen systems and manufacture our products to exceed ASTM standards for structural performance. Whether facing high-velocity winds or heavy precipitation, our panels provide excellent wind load resistance and proven weatherability, protecting the structural integrity of your building.