We Protect What You Value

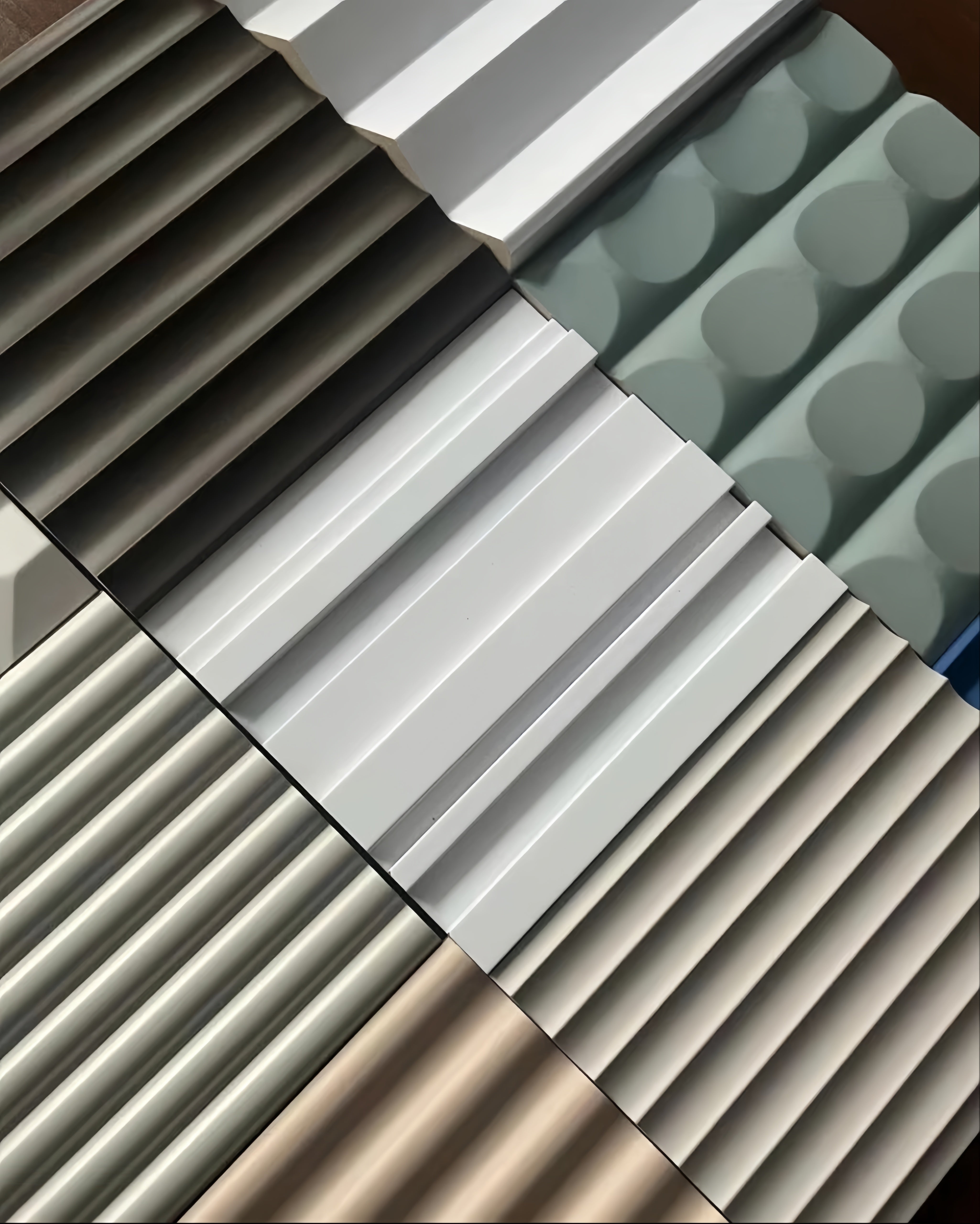

Ansus Metal Collections: Precision Architectural Metal Solutions for Every Surface

At Ansus Metal, we believe that exceptional architecture requires a seamless dialogue between structural performance and aesthetic vision. As a premier provider of architectural metal panels, we bridge the gap between concept and reality, offering a comprehensive ecosystem of metal solutions that span from the building envelope to the finest interior details.

Our collections are engineered to empower architects, designers, and developers. Whether you are defining a skyline with a robust façade or sculpting the acoustic environment of a high-end lobby, our custom metal fabrication capabilities ensure that your design intent is executed with engineering precision. Explore our four core collections below to find the ideal material solution for your project.

Comprehensive Product Collections

We have organized our portfolio into four specialized categories, each optimized for specific architectural applications, load requirements, and environmental conditions.

1. Cladding & Façade Systems

The First Line of Defense: Durability Meets Design

Our exterior solutions are engineered to withstand the harshest environmental elements while defining the building's visual identity. We specialize in Exterior Cladding Systems that combine lightweight structural properties with superior weather resistance.

- Materials & Technology: We utilize high-grade aluminum alloys and Aluminum Composite Panels (ACP) treated with advanced PVDF fluorocarbon coatings. This ensures color retention and resistance to UV radiation and corrosion for decades.

- Key Configurations: From flat, monolithic Metal Facade Panels to dynamic corrugated profiles, our systems are designed for high wind load capacity and effective rainscreen performance.

- Ideal For: Commercial high-rises, stadium exteriors, and institutional building envelopes.

2. Ceiling Metal Panels

Sculpting the Fifth Wall: Acoustics and Integration

Modern ceiling design goes beyond covering the plenum; it is about managing sound, light, and air. Our Acoustic Ceiling Systems offer the perfect balance of functional integration and visual rhythm.

- Performance: Our systems are designed to accommodate MEP (Mechanical, Electrical, and Plumbing) integration seamlessly. By utilizing perforated patterns backed with acoustic fleece, we significantly reduce reverberation time in open spaces.

- Design Flexibility: Options range from linear U-Baffles that create directional flow to Suspended Metal Ceilings featuring expanded mesh for an industrial, breathable aesthetic.

- Ideal For: Transport hubs, open-plan offices, auditoriums, and retail environments.

3. Interior Wall Panels

Enduring Elegance for High-Traffic Spaces

Note: This collection focuses exclusively on solid metal solutions for superior durability and fire safety.

For interior vertical surfaces, we reject compromise. Our Interior Metal Wall series is crafted strictly from Solid Aluminum Panels and premium Stainless Steel Panels. Unlike composite materials often used externally, our solid interior veneers offer superior impact resistance, non-combustibility, and a refined tactile quality essential for close-up viewing.

- Surface Excellence: Available in anodized, powder-coated, or brushed finishes, these panels provide a pristine, easily maintainable surface.

- Installation System: Engineered for rapid installation using a modular hook-on system, dramatically reducing on-site time for fast-paced commercial fit-outs.

- Ideal For: high-traffic, high-visibility areas such as elevator lobbies, hospital corridors, corporate reception areas, and architectural feature walls.

4. Decorative Screens & Room Dividers

Defining Space with Light and Transparency

Our Decorative Metal Screens allow designers to divide space without sacrificing openness. Utilizing advanced laser-cutting technology, we transform rigid metal sheets into intricate, lace-like patterns that filter light and create privacy.

- Material Purity: We manufacture these screens exclusively from high-quality Stainless Steel and Aluminum to ensure structural rigidity and precise detailing.

- Finish Innovation: While we do not use soft brass alloys, we achieve luxurious metallic tones—including Gold, Rose Gold, and Bronze—through PVD (Physical Vapor Deposition) technology. This provides the classic look of brass with the superior strength and tarnish resistance of steel.

- Application: These laser-cut room dividers serve as functional art, perfect for zoning areas in hospitality and luxury residential projects.

Why Partner with Ansus Metal?

Our reputation is built on architectural metalworks expertise that transcends simple manufacturing.

- Material Integrity: We source only premium-grade raw materials, such as 3003/5052 series aluminum for superior flatness and 304/316 marine-grade stainless steel for corrosion resistance.

- Surface Treatment Experts: We understand that the finish defines the lifespan. We apply PVDF coatings for exterior longevity and utilize PVD, Anodizing, and Powder Coating for interior aesthetics, ensuring the right finish is applied to the right environment.

- Engineering Support: From shop drawings to installation guidance, we assist in solving complex detailing challenges, ensuring corner joints, returns, and transitions are executed flawlessly.

Ready to Realize Your Vision?

Whether you are specifying a high-performance façade or a bespoke interior feature, Ansus Metal provides the technical expertise and manufacturing precision your project demands.

FAQs

1. What are the main differences between your four architectural metal collections?

Our four specialized collections are designed for distinct architectural applications, each optimized for specific performance requirements and aesthetic goals:

Cladding/Facade Collection:

- Exterior building envelope applications with superior weather resistance

- Large-format panels (up to 4000×2000mm) for dramatic architectural impact

- Enhanced structural performance for wind and seismic loads up to 3.5 kPa

- Advanced weatherproof coatings with 20-25 year exterior durability

- Thermal performance optimized for building envelope requirements

- Applications: Building facades, curtain wall infill, architectural cladding, exterior feature walls

Ceiling Collection:

- Suspended ceiling systems with integrated structural support

- Acoustic performance options with NRC ratings up to 0.85

- Lightweight construction to minimize structural loading

- Easy access panels for MEP system maintenance

- Fire-rated assemblies meeting commercial building codes

- Applications: Office ceilings, retail spaces, healthcare facilities, educational institutions

Interior Wall Collection:

- Interior partition and wall covering solutions

- Sound control properties for privacy and acoustic comfort

- Easy installation systems compatible with standard framing

- Maintenance-friendly surfaces for high-traffic commercial environments

- Design flexibility with modular panel systems

- Applications: Office partitions, retail displays, hospitality interiors, residential feature walls

Screen Collection:

- Space division with transparency and airflow control

- Decorative and functional screening solutions

- Portable and permanent installation options

- High transparency (25-85% open area) depending on design

- Integrated mounting systems for various architectural conditions

- Applications: Room dividers, privacy screens, architectural features, security barriers

2. Can products from different collections be used together in the same project?

Yes, our collections are designed with coordinated aesthetics and compatible specifications to work seamlessly together in comprehensive architectural projects.

Design Coordination Benefits:

- Matching PVD coatings available across all collections for visual continuity

- Consistent material grades (304, 316 stainless steel, 5005, 6061 aluminum)

- Coordinated pattern libraries that work across multiple applications

- Unified color palettes with over 50 standard PVD coating options

- Compatible mounting systems that integrate with various building systems

Common Multi-Collection Applications:

- Corporate headquarters: Facade cladding + interior walls + ceiling systems + screening elements

- Hospitality projects: Exterior screens + decorative ceilings + interior feature walls + room dividers

- Retail environments: Storefront cladding + suspended ceilings + display walls + security screens

- Healthcare facilities: Exterior panels + acoustic ceilings + hygienic wall systems + privacy screens

Technical Compatibility:

- Thermal expansion coordination ensures proper movement joints between systems

- Structural integration with unified load paths and connection details

- Fire rating continuity maintains building code compliance across assemblies

- Maintenance accessibility with coordinated access panels and cleaning requirements

Project Planning Services:

- Integrated design consultation for multi-collection projects

- 3D visualization showing complete architectural integration

- Specification coordination ensuring compatibility across all systems

- Single-source responsibility for design, manufacturing, and installation coordination

3. What stainless steel and aluminum grades do you offer across your collections?

We offer premium-grade materials specifically selected for architectural applications, with grade selection optimized for each collection's performance requirements.

Stainless Steel Grades:

304 Stainless Steel (18Cr-8Ni):

- Standard grade for interior applications and protected exterior locations

- Excellent formability for complex shapes and patterns

- Cost-effective for large-scale commercial projects

- Applications: Interior walls, ceilings, protected facade elements

- Corrosion resistance: Good for standard atmospheric conditions

316 Stainless Steel (18Cr-10Ni-2Mo):

- Marine grade with superior corrosion resistance

- Required for coastal environments and high-humidity applications

- Enhanced chemical resistance for industrial environments

- Applications: Exterior cladding, coastal projects, food service areas

- Corrosion resistance: Excellent for aggressive environments

316L Stainless Steel (Low Carbon 316):

- Enhanced weldability with reduced sensitization risk

- Preferred for complex fabrications requiring extensive welding

- Food-grade applications meeting FDA requirements

- Applications: Healthcare facilities, food processing, critical welded assemblies

- Special properties: Reduced carbide precipitation, superior weld quality

Aluminum Alloys:

5005 Aluminum Alloy:

- Excellent corrosion resistance with natural oxide protection

- Superior anodizing characteristics for decorative finishes

- Good formability for architectural shapes

- Applications: Interior decorative elements, protected exterior applications

- Weight advantage: 65% lighter than stainless steel

6061-T6 Aluminum Alloy:

- High strength-to-weight ratio for structural applications

- Excellent machinability for precision components

- Good weldability with proper techniques

- Applications: Structural frames, high-load facade systems, ceiling supports

- Mechanical properties: 310 MPa tensile strength, excellent fatigue resistance

4. What PVD coating options are available and how do I choose the right finish?

Our comprehensive PVD coating portfolio includes over 50 standard colors and unlimited custom options, with coating selection based on aesthetic preferences, environmental conditions, and performance requirements.

Standard PVD Coating Categories:

Metallic Finishes:

- Stainless Steel Natural: Uncoated 304/316 for industrial aesthetic

- Brushed Stainless: Linear brush pattern with clear protective coating

- Mirror Stainless: High-polish reflective finish with fingerprint resistance

- Titanium: Natural titanium color with superior hardness

- Chrome: Bright chrome appearance with excellent durability

Gold Tones:

- Gold (TiN): Classic gold color, most popular decorative finish

- Light Gold: Subtle gold tone for understated elegance

- Rose Gold: Warm pink-gold tone trending in contemporary design

- Champagne Gold: Muted gold with bronze undertones

- Antique Gold: Aged gold appearance with subtle color variation

Bronze and Copper Tones:

- Bronze: Rich brown-bronze color for traditional applications

- Light Bronze: Subtle bronze tone with gold highlights

- Copper: Natural copper color with protective coating

- Antique Copper: Aged copper appearance with patina effects

- Coffee Bronze: Dark bronze with coffee undertones

Contemporary Colors:

- Black Titanium: Deep black with metallic undertones

- Sapphire Blue: Vibrant blue with high color saturation

- Emerald Green: Rich green with metallic depth

- Purple: Royal purple with color-shift properties

- Custom Colors: RAL, Pantone, or sample matching available

Coating Selection Criteria:

By Application Environment:

- Interior protected: All coating types suitable, focus on aesthetics

- Interior high-traffic: Harder coatings (TiN, TiCN) for wear resistance

- Exterior protected: Standard coatings with UV stability

- Exterior exposed: Enhanced coatings with superior weather resistance

- Coastal/marine: Specialized coatings with salt spray resistance

By Performance Requirements:

- High durability: TiN, TiCN, TiAlN for maximum hardness (2000-3500 HV)

- Color stability: Titanium-based coatings for UV resistance

- Corrosion protection: Multi-layer systems for aggressive environments

- Easy maintenance: Smooth finishes resist soiling and clean easily

- Fingerprint resistance: Specialized topcoats for high-touch applications

Coating Specifications:

- Thickness range: 1.0-4.0 μm depending on coating type

- Adhesion strength: >50 N/mm² per ASTM D4541

- Hardness range: 1800-3500 HV depending on coating chemistry

- Temperature stability: -40°C to +400°C continuous service

- Warranty coverage: 10-year limited warranty on coating performance

5. Do you offer custom patterns and how does the design process work?

Yes, we specialize in custom pattern development with advanced design capabilities and comprehensive support throughout the creative process.

Custom Design Capabilities:

Pattern Development Process:

- Initial consultation - Discuss project vision, functional requirements, and aesthetic goals

- Concept development - Our design team creates initial pattern concepts and variations

- 3D visualization - Photorealistic renderings and virtual reality previews

- Pattern refinement - Iterative design process with client feedback integration

- Engineering optimization - Structural analysis and manufacturing feasibility review

- Prototype creation - Physical samples from 150×150mm to full-size panels

- Final approval - Client sign-off before full production begins

Design Inspiration Sources:

- Corporate branding - Logos, brand elements, and company identity integration

- Architectural themes - Building geometry, historical references, cultural motifs

- Natural patterns - Organic forms, botanical elements, geological structures

- Geometric designs - Mathematical patterns, parametric designs, optical effects

- Artistic collaboration - Work with artists for unique sculptural installations

Technical Design Capabilities:

- Parametric design software - Advanced CAD tools for complex pattern generation

- Structural optimization - FEA analysis ensures patterns maintain structural integrity

- Manufacturing constraints - Design within laser cutting and forming capabilities

- Modular coordination - Patterns that work across multiple panel sizes

- Scale adaptation - Patterns that maintain visual impact at various viewing distances

Pattern Categories by Collection:

Cladding/Facade Patterns:

- Large-scale geometric - Bold patterns visible from street level

- Gradient effects - Varying density for light and shadow play

- Directional patterns - Emphasize building height or horizontal movement

- Functional integration - Patterns incorporating ventilation or shading requirements

- Landmark designs - Signature patterns for iconic buildings

Ceiling Patterns:

- Acoustic optimization - Patterns designed for sound absorption performance

- Lighting integration - Patterns coordinated with LED lighting systems

- Maintenance access - Patterns that conceal or highlight access points

- Perspective effects - Patterns optimized for overhead viewing angles

- Modular systems - Repeating patterns for large ceiling areas

Interior Wall Patterns:

- Human-scale details - Patterns optimized for close viewing distances

- Privacy gradients - Varying opacity for functional privacy control

- Brand integration - Subtle incorporation of corporate identity elements

- Tactile considerations - Patterns safe for incidental human contact

- Maintenance friendly - Patterns that don't trap dust or debris

Screen Patterns:

- Transparency control - Patterns balancing privacy with visual connection

- Airflow optimization - Patterns designed for specific ventilation requirements

- Security integration - Patterns providing security while maintaining aesthetics

- Flexible configurations - Patterns that work in various panel arrangements

- Interactive elements - Patterns designed for changing light conditions

Custom Pattern Pricing:

- Simple modifications: 10-15% premium over standard patterns

- Moderate complexity: 25-40% premium for engineered custom designs

- High complexity: 50-100% premium for artistic or highly complex patterns

- Prototype development: $500-2000 depending on pattern complexity

- Volume discounts: Available for large projects (>100 panels)