FAQs

Q1. Why should I choose metal wall panels over traditional drywall or timber?

The primary advantage lies in the balance of form and function. Unlike painted drywall that chips easily or timber that requires frequent maintenance, our metal wall systems offer superior impact resistance and longevity. They are designed to withstand the rigors of high-traffic zones, providing a robust "second skin" that is easily sanitized and maintains its aesthetic appeal for decades without the need for repainting or refinishing.

Q2. How does Ansus Metal ensure a perfect fit and reduce installation time?

We understand that time is money on a construction site. Our panels are engineered for rapid deployment using modular fixing systems that reduce labor hours and complexity. Furthermore, we offer precise custom sizing and fabrication based on your specific elevations. This eliminates the need for on-site cutting, significantly reduces material waste, and ensures a seamless, professional finish right out of the box.

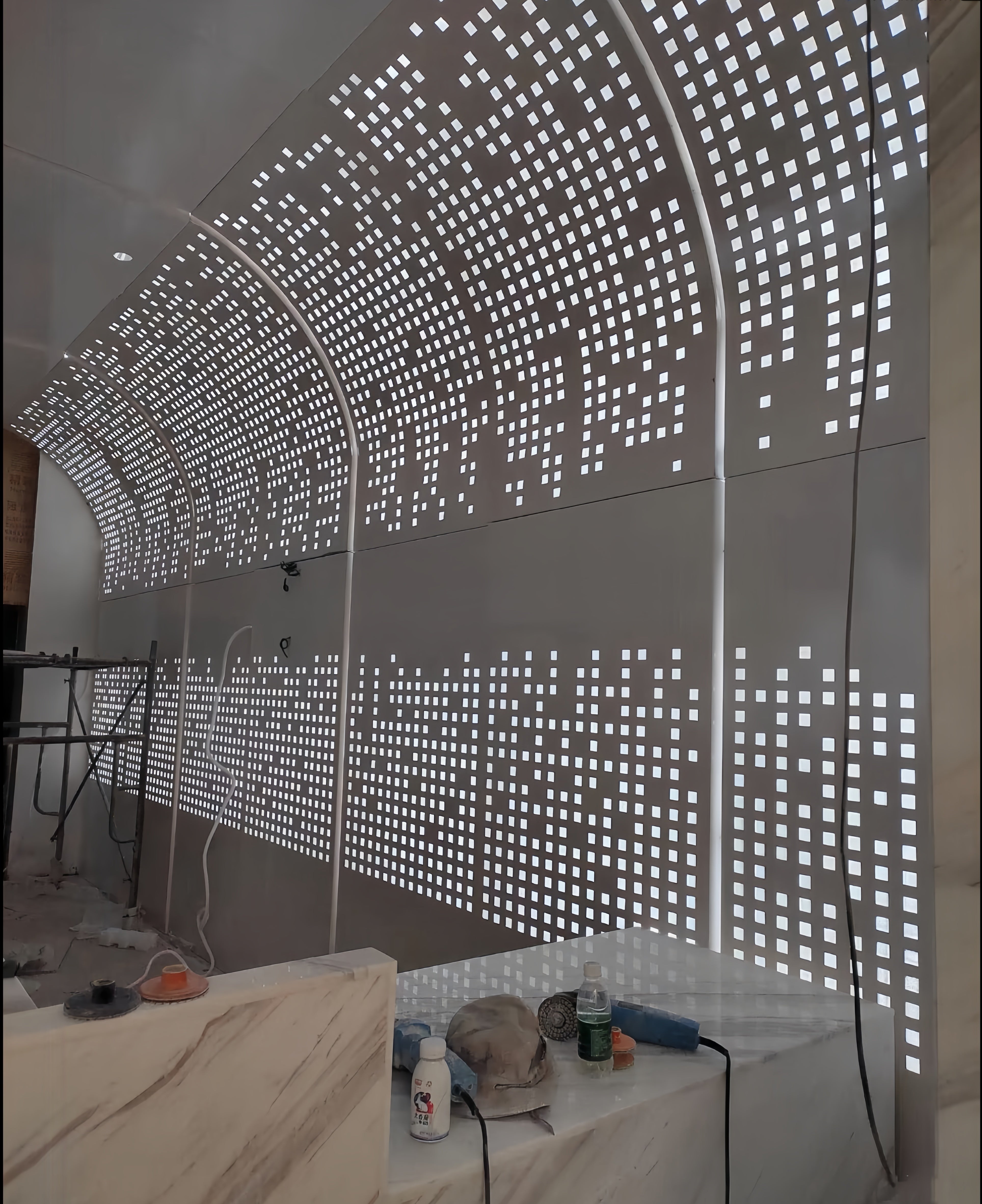

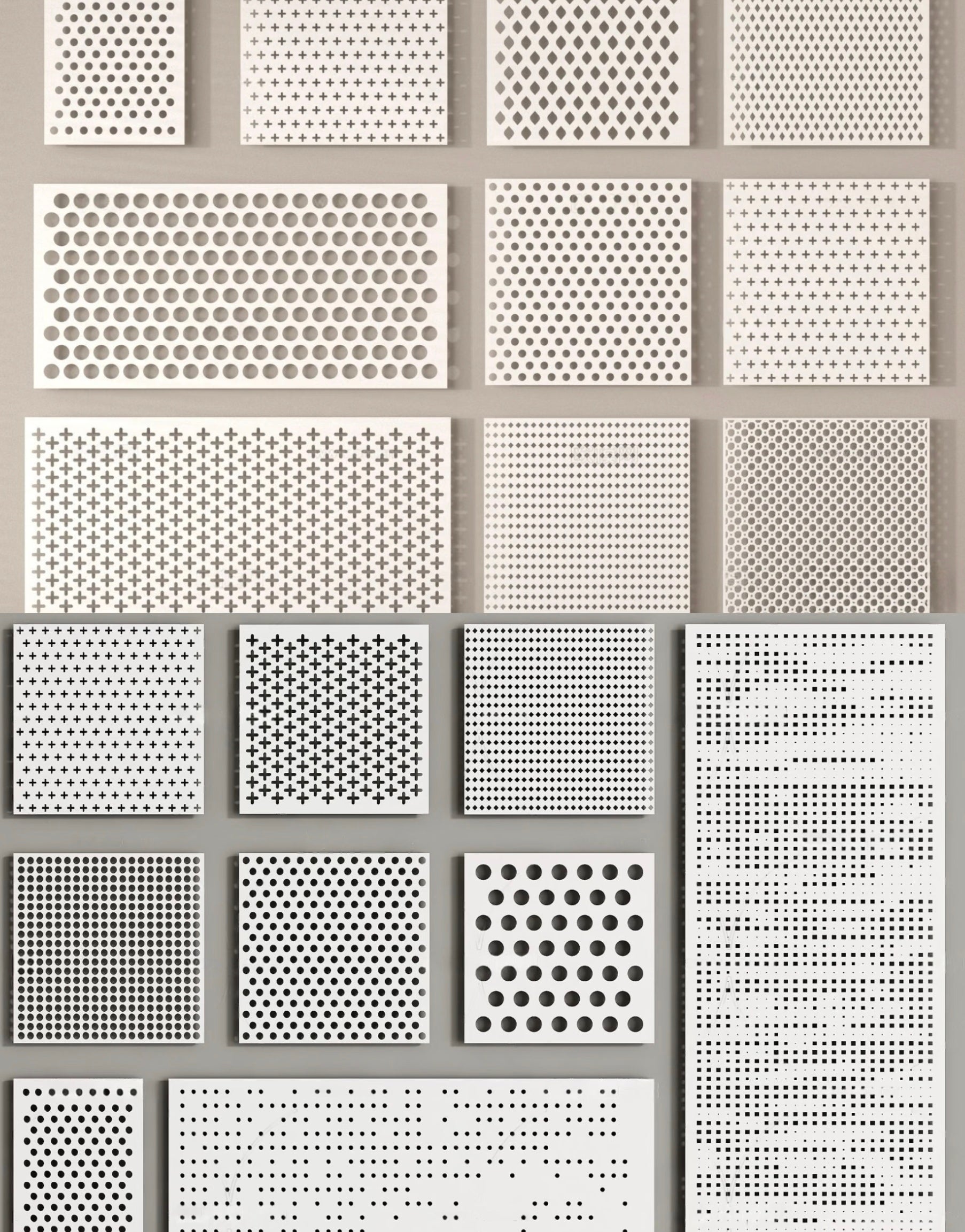

Q3. Can interior metal wall panels improve the acoustic performance of a room?

Yes, specifically our Perforated Series. When visual transparency and sound management are priorities, these panels are the optimal choice. By incorporating acoustic backing materials behind the perforated metal, they function as decorative acoustic wall panels. This setup significantly reduces noise reverberation in busy open atriums and lobbies, turning a hard surface into a sound-absorbing architectural feature.

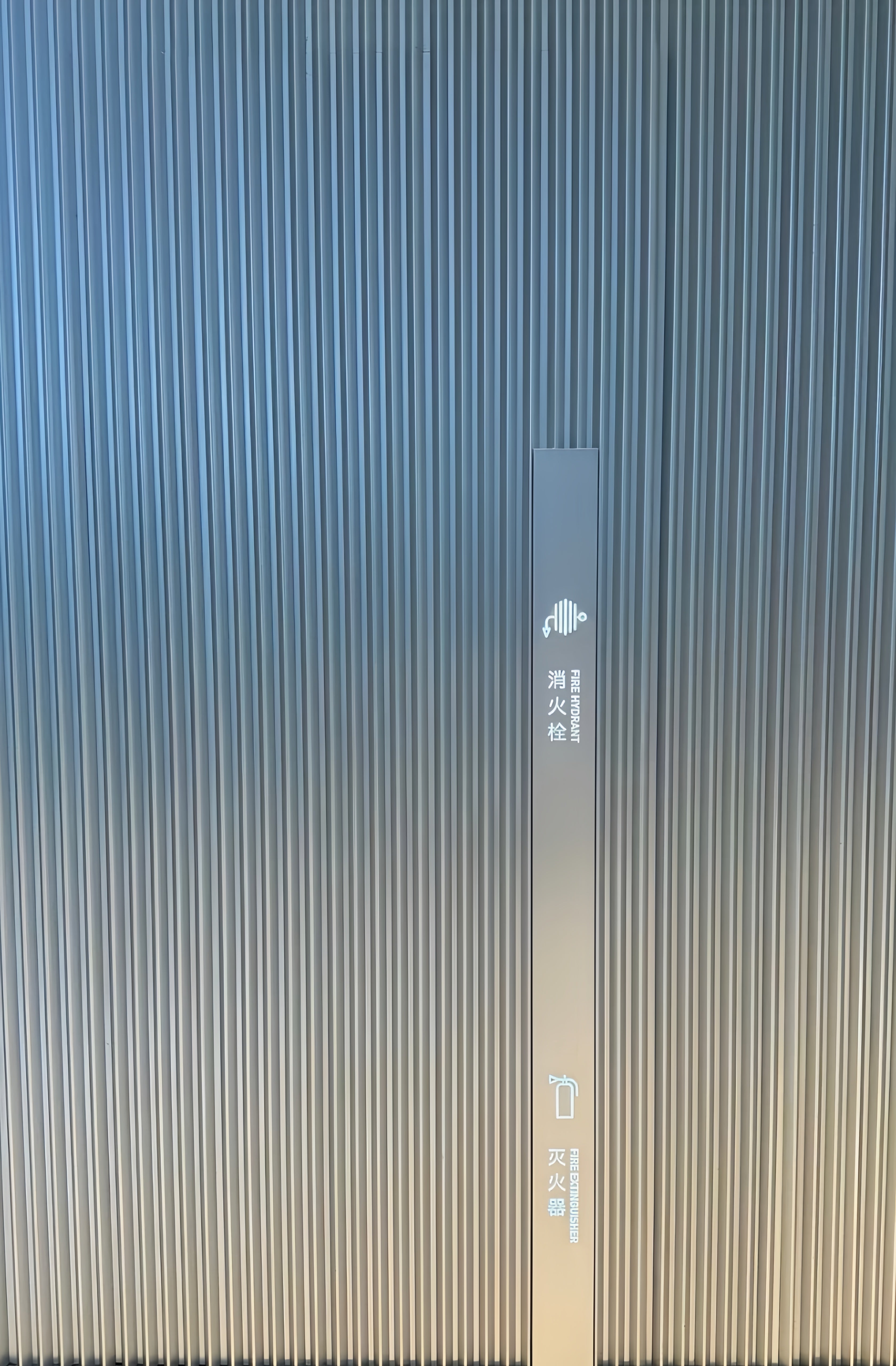

Q4. Which material is best for high-hygiene areas like healthcare facilities or elevators?

For environments demanding the highest standard of cleanliness and physical strength, our Stainless Steel Panel series is the industry standard. Available in brushed or mirrored finishes, stainless steel offers a premium, sterile aesthetic that naturally resists corrosion and heavy wear. It is the ideal specification for healthcare facilities, elevator cabs, and luxury commercial corridors where durability and hygiene are non-negotiable.

Q5. How can I add texture and depth to a flat interior wall?

To create visual drama, we recommend our Corrugated Metal Panel series. The wave-like profile of these panels adds structural rigidity while playing with light and shadow, giving flat walls a dynamic, three-dimensional quality. This series is particularly effective for feature walls in retail spaces and creative offices, where creating an immediate visual impact and industrial character is paramount.

Q6. What are the benefits of using Aluminum panels for large-scale wall cladding?

Solid Aluminum Panels are the superior choice when safety, durability, and weight are driving factors. Unlike composite alternatives, solid aluminum is non-combustible (Class A fire-rated) and eliminates the risk of delamination over time.

For large-scale projects, aluminum is significantly lighter than steel, which reduces the structural load and simplifies installation for floor-to-ceiling designs. Additionally, these panels feature high-performance PVDF coatings that ensure long-lasting color stability and design flexibility.