- What Are the Common Finish Options for Perforated Sheet and Expanded Sheet?

- How to Choose Perforated Sheet Finishes for Different Applications?

- Coastal and High-Humidity Environments

- Urban and Industrial Areas

- Indoor Versus Exterior Applications

- Climate-Specific Factors

- What Factors Matter When Selecting Finishes for Expanded Sheet?

- Base Material Types

- Perforation Patterns and Coating Adhesion

- Color Retention and UV Resistance

- Maintenance Access and Long-Term Costs

- How Can You Work with a Perforated Sheet Manufacturer to Get Custom Finishes?

- Color Matching and RAL Standards

- Texture and Surface Options

- Sample Testing and Mockups

- Lead Times and Order Minimums

- FAQ

- Q1. Can You Change the Finish on a Perforated Sheet After It’s Installed?

- Q2. What’s the Real Cost Difference Between Finish Types for Expanded Sheet Projects?

- Q3. Do Different Finishes Affect the Structural Strength of Perforated Sheet or Expanded Sheet?

- Conclusion

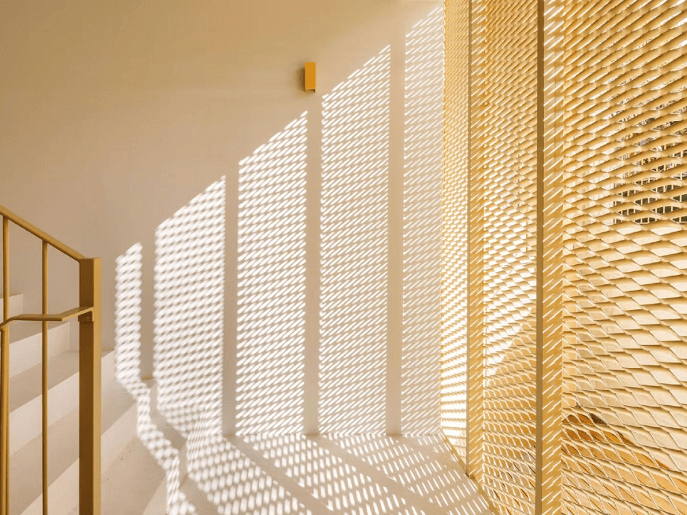

Picking the right finish for your metal mesh facade comes down to three things: where it's going, what it needs to do, and how long you want it to last. Whether you're working with perforated sheet or expanded sheet, the finish affects everything from looks to maintenance costs. This guide walks you through the options so you can make smart choices for custom perforated metal panels and expanded sheet projects.

What Are the Common Finish Options for Perforated Sheet and Expanded Sheet?

A perforated sheet manufacturer will typically offer four main finish types. Each one has different strengths depending on your project needs.

Powder Coating Finishes

Powder coating gives you the most color choices and decent protection. The process sprays dry powder onto the metal, then bakes it in an oven to create a hard shell. It works great on both perforated sheet and expanded sheet because the powder gets into all the edges and holes. You'll see this finish on buildings in downtown areas where color matters but extreme weather isn't a daily battle. Typical dry-film thickness is ~2–5 mils (≈50–125 µm), and long-term performance depends on the coating class.

Anodized Finishes

This one's mainly for aluminum custom perforated metal panels. Anodizing actually changes the metal's surface through an electrical process—it's not just a coating sitting on top. The result is super hard and won't chip or peel. You get metallic colors like bronze, black, or champagne. Class I architectural anodize (≥0.7 mil ≈18 µm) is the exterior workhorse and has a decades-long track record when properly specified and maintained; commercial warranties are often on the order of 5–10 years.

Galvanized Finishes

Hot-dip galvanizing is mainly applied to steel. This process dips your perforated sheet or expanded sheet in molten zinc. It's bulletproof against rust—you'll see this on highway barriers and industrial sites. The downside? It looks pretty industrial. You get that silvery-gray finish that weathers to a matte gray over time. If your project is more about function than fashion, galvanizing makes sense. Using a duplex system (galvanizing + paint/powder) significantly extends service life compared to either alone.

Natural Mill Finishes

Sometimes the raw metal look is what you want. A stainless steel perforated sheet often stays unfinished because it already resists corrosion. Mill finish is the cheapest option—you're basically paying for the metal itself. It works indoors or in mild climates, but you'll need to clean it more often to prevent staining. Think of it as the blank canvas option. You can also do brushing, etching, and embossing on the mill finish surface to create various effects.

Each finish type changes how your expanded sheet or perforated sheet performs. The key is matching the finish to your specific conditions, not just picking what looks cool in the sample book.

How to Choose Perforated Sheet Finishes for Different Applications?

Location drives finish selection more than anything else.

Coastal and High-Humidity Environments

Salt air eats through cheap finishes fast. In coastal/salt-spray zones (often defined within roughly 50–2,000 m of the shoreline), specify marine-grade systems. “Standard” interior-grade powders can fail prematurely in these environments; a zinc-rich/pretreatment system and marine-rated topcoat are recommended. Stainless steel (316) with powder coating and aluminum with fluorocarbon painting (3~4 layers) are highly recommended.

Urban and Industrial Areas

Cities mean pollution, and industrial zones add chemical exposure. Powder coating handles urban pollution pretty well, but industrial sites need tougher protection. If you're near factories or refineries, the air contains acids that break down basic finishes. Consider anodized aluminum or fluoropolymer systems meeting AAMA 2605 for superior chemical/UV resistance; AAMA 2604 super-durable powders are common for less aggressive conditions.

Indoor Versus Exterior Applications

Inside buildings, you can use almost any finish on your perforated sheet. The environment stays controlled, so even paint works. Outside, you're fighting sun, rain, temperature swings, and everything else nature throws at you. For exterior mesh with strong sun exposure, prioritize AAMA 2605 for best fade resistance; maintenance intervals depend on exposure and coating class rather than a fixed 10–12-year cycle.

Climate-Specific Factors

Desert heat cracks some finishes while freezing winters cause others to fail. Hot climates need finishes that handle thermal expansion—metal expands and contracts with temperature changes. Cold regions require finishes that stay flexible when it's freezing. A good perforated sheet manufacturer should know which finishes work in your climate zone.

What Factors Matter When Selecting Finishes for Expanded Sheet?

Beyond location, the metal itself and how you use it affect which finish works best.

Base Material Types

Aluminum, steel, and stainless steel each need different approaches. Aluminum takes powder coating and anodizing equally well. Steel needs a protective finish, or it rusts—galvanizing or powder coating are your main options. A stainless steel expanded sheet can go unfinished, but powder coating still helps with color matching and extra protection. The thinner the metal, the more careful you need to be with the finish application. Over-thick coatings on light-gauge expanded mesh can bridge/clog openings and alter airflow—specify target DFT and QA checks.

Perforation Patterns and Coating Adhesion

Here's something most people miss: the hole pattern affects how well finishes stick. Tiny holes mean more edges where the coating can chip. Large openings are easier to coat evenly. Custom perforated metal panels with complex patterns need more prep work before finishing. The perforated sheet manufacturer should blast or etch the surface first so the finish grabs properly. Skipping proper prep dramatically increases the risk of early adhesion failure.

Color Retention and UV Resistance

Not all finishes hold color the same way. Basic polyester powders (AAMA 2603) can chalk/fade faster outdoors; super-durable (AAMA 2604) improve resistance; 70% PVDF systems meeting AAMA 2605 deliver the highest color/gloss retention, verified by a 10-year South Florida exposure requirement. This standard is commonly met by high-performance 70% PVDF (polyvinylidene fluoride) resin-based coatings, as detailed in industry performance guides.

Maintenance Access and Long-Term Costs

Think about how you'll clean the facade. Ground-level perforated sheet is easy to maintain. Twenty stories up? That's expensive. Follow manufacturer cleaning guidance—at least annual washing is recommended, with more frequent cleaning in marine/industrial settings—to maximize coating life.

Getting these factors right means your expanded sheet or perforated sheet looks good and lasts longer. It's not complicated—just match the finish to the real-world conditions your facade will face.

How Can You Work with a Perforated Sheet Manufacturer to Get Custom Finishes?

Custom finishes let you match exact colors and textures. Here’s how we actually run the process at Ansusmetal.

Color Matching and RAL Standards

Most projects specify RAL colors, and we can match any RAL, Pantone, or a physical sample you bring. Photos aren’t reliable—lighting shifts hue—so bring a real swatch if you’re aligning to existing work. We stock 200+ standard powder-coat colors and also support custom matches; for scheduling, plan on about 2–3 weeks for custom powder coats and ~3–4 weeks for custom PVDF, while complex custom colors/patterns typically require ~4–6 weeks from approval to ship.

Texture and Surface Options

You can choose gloss, satin, or matte, and we offer texture add-ons (e.g., brushed/pebbled effects) that help hide minor dings and add visual depth. Beyond powder coat, our finish toolbox includes anodized aluminum, PVDF coating, and premium PVD titanium finishes, plus wood-grain looks—each selected to balance appearance, durability, and budget for perforated metal panels. Textured and specialty finishes involve extra processing and may be priced above smooth coats; we’ll advise which path fits your application.

Sample Testing and Mockups

We never ask you to approve a tiny chip. Instead, we produce project-specific samples—your perforation pattern with the actual finish—so you can review in daylight and under site lighting, both up close and from viewing distance. Check cleanability (fingerprints, water beading) before sign-off. Full-size mockups prevent costly rework, and we provide samples and color verification before production.

Lead Times and Order Minimums

For planning, standard powder colors move fastest; custom powder coats are typically ~2–3 weeks, and custom PVDF ~3–4 weeks after approval. Where applicable, minimums are generally ~200 m² for custom powder colors and ~500 m² for custom PVDF colors; intricate patterns or bespoke textures may extend timelines to ~4–6 weeks. Build your schedule backward from install and keep a buffer for peak construction seasons.

Working directly with us at Ansusmetal gives you tight control over outcome—we know which metal, perforation patterns, and finish systems work together in the field, and we guide you to a specification that installs smoothly and looks right for years.

FAQ

Q1. Can You Change the Finish on a Perforated Sheet After It’s Installed?

Yes, but it's expensive and messy. You'd need to either coat over the existing finish (which only works if the current finish is in good shape) or strip everything and start over. Stripping typically involves abrasive blasting and/or chemical removal—both add significant per-square-foot cost before you even re-finish—so it’s far cheaper to specify the right system up front; some systems can be refreshed with a compatible clear/topcoat, depending on condition.

Q2. What’s the Real Cost Difference Between Finish Types for Expanded Sheet Projects?

Costs vary widely by alloy, thickness, geometry, prep, and performance class (AAMA 2603/2604/2605, anodize class, galvanizing weight). Rather than fixed percentages, request itemized quotes; higher-performance systems often reduce lifetime cost by delaying maintenance cycles.

Q3. Do Different Finishes Affect the Structural Strength of Perforated Sheet or Expanded Sheet?

Not really. Finishes are thin—powder coats are typically a few mils thick (≈2–5 mils)—and don't add meaningful strength or weight. What matters is the base metal thickness and alloy. Some finishes involve cure temperatures that could affect temper if applied too early in the process; confirm forming-then-finishing sequencing with your manufacturer.

Conclusion

The right finish protects your investment and keeps your facade looking sharp for decades. Start by talking to an experienced perforated sheet manufacturer like Ansusmetal about your specific conditions—we've seen what works and what fails. Get samples, compare lifecycle costs, and pick the finish that matches your budget and environment. Don't wait until you're placing the order to think about finishes. Contact us now to review options and get accurate pricing for your custom perforated metal panels or expanded sheet project.

Share:

Metal Curtain Wall Trends: The Future of Architectural Design in 2025

Design and Selection Guide for Metal Interior Wall Panels