- What's the Difference Between Perforated Sheet and Expanded Sheet for Facades?

- How Are Custom Perforated Metal Panels Used in Building Facades?

- Solar Shading and Heat Control

- Natural Ventilation Enhancement

- Privacy Screening and Security

- Decorative Facades and Branding

- Acoustic Performance Applications

- Multi-Function Design Strategies

- What Can We Learn From Custom Expanded Sheet Facade Projects?

- Case 1: Corporate Office Solar Screen

- Case 2: Cultural Center Decorative Feature

- Case 3: Residential Privacy Solution

- Case 4: Transit Hub Ventilation System

- How Do You Choose the Right Perforated Sheet Manufacturer?

- Customization Capability

- Material and Process Quality

- Technical Support and Engineering Services

- Project Timeline and Production Capacity

- FAQ

- Q1. How Do Building Codes Affect Perforated Metal Panel Design for High-Rise Facades?

- Q2. Can You Integrate Solar Panels or Green Walls Behind Custom Expanded Sheet Facades?

- Q3. What Happens to Perforated Metal Facades in Freezing Climates?

- Conclusion

Perforated metal panels solve real problems while looking sharp. Whether you're working with perforated sheet from a trusted perforated sheet manufacturer or specifying custom perforated metal panels and custom expanded sheet solutions, these materials handle sunlight control, ventilation, privacy, and aesthetics all at once. This guide breaks down how they work in practice through actual projects.

What's the Difference Between Perforated Sheet and Expanded Sheet for Facades?

Choosing between perforated sheet and expanded sheet isn't just about looks—it's about how they're made and what they can do for your building.

| Aspect | Perforated Sheet | Expanded Sheet |

| Manufacturing Process | Starts as solid metal; holes are punched or laser-cut in precise, repeatable patterns (round/square/decorative) or designed custom patterns. Base plate remains intact around the holes. | The metal sheet is slit then stretched to form a diamond-mesh; no material is removed, resulting in a more three-dimensional form. |

| Structural Strength & Durability | Retains much of the base plate’s original rigidity thanks to solid lands between holes. | Diamond-mesh geometry acts like tiny trusses, giving good strength-to-weight; typically lighter at similar coverage and suited to large spans where weight matters. |

| Open Area & Ventilation Performance | Typical architectural open area ~15–70%; “high-ventilation” options ~50–70% for more airflow and daylight. | Offered in wide transparencies; for maximum airflow, designers choose high-open-area meshes rather than a single fixed percentage. |

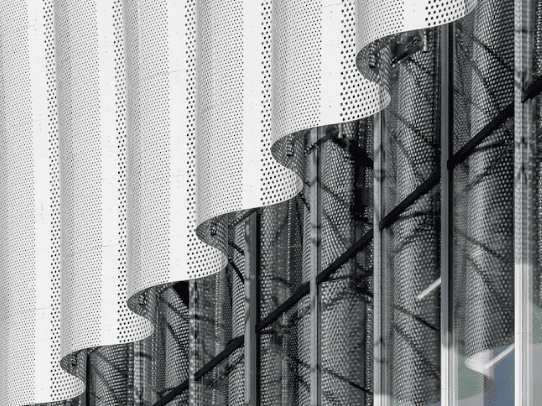

| Visual Effect Differences | Clean, ordered patterns; ideal for corporate/modern residential looks; supports logos/gradients/images via varied hole sizes. | Textured, dynamic surface; angled strands create changing light/shadow throughout the day; more visual “movement.” |

Choose a perforated sheet when you need precise patterns, branding possibilities, and a clean, ordered aesthetic. Choose an expanded sheet when weight, span, and a lively textured look are priorities. Both can deliver durable façades—match the pattern and open area to your airflow, daylight, and visual goals.

How Are Custom Perforated Metal Panels Used in Building Facades?

The best facade systems do multiple jobs at once. Custom perforated metal panels excel at stacking functions without adding bulk.

Solar Shading and Heat Control

Direct sunlight is the enemy of cooling bills. Documented projects with metal mesh/perforated skins report around ~40% solar heat reduction in suitable configurations. The panels block harsh rays while still allowing diffused light through. Instead of fixed percentages, choose denser patterns on sun-exposed elevations in hot climates and more open patterns on shaded faces.

Natural Ventilation Enhancement

Perforated facades create a buffer zone. Air flows through the panels, gets filtered by the pattern, and enters the building more gently. Manufacturers note natural-ventilation facades can cut HVAC energy use on the order of ~15–30% when properly designed. For urban conditions, pair the screen with acoustic build-ups; tested perforated systems can achieve NRC values from roughly ~0.35 up to ~0.95 when backed with absorbers.

Privacy Screening and Security

From inside looking out, even lower-open-area panels can feel transparent. From the street, smaller apertures (rather than a fixed “¼-inch rule”) generally improve screening and security.

Decorative Facades and Branding

Digital fabrication lets you turn any image into a perforation pattern. Corporate headquarters can incorporate logos. Museums can reference collection themes. Ansus production examples list common hole ranges like Ø8–12 mm in architectural sheets—good building blocks for gradients and image work.

Acoustic Performance Applications

The holes allow sound waves to pass into absorption material behind the panel. Perforation/open-area in the ~20–35% range is commonly used for speech-band absorption, and manufacturer data show achievable NRC bands of ~0.35–0.95 with proper backing.

Multi-Function Design Strategies

The smartest projects combine several functions. A south-facing office facade might use custom perforated metal panels that shade the glass, ventilate the cavity behind, display the company brand, and reduce traffic noise—all from one installation.

What Can We Learn From Custom Expanded Sheet Facade Projects?

Real projects teach you what works and what doesn't. Here are four that nailed it.

Case 1: Corporate Office Solar Screen

A tech campus in Austin wrapped three buildings in high-open-area expanded mesh chosen for solar control and weight savings. Post-occupancy monitoring indicated meaningful cooling-load reductions, with performance tied to mesh openness and building orientation.

Case 2: Cultural Center Decorative Feature

A performing arts center in Seattle specified custom expanded sheet in aluminum with a diamond pattern derived from a sound-wave motif. Instead of hole diameters, the team tuned strand width and SWD/LWD to balance transparency, stiffness, and glare control. Behind the mesh sits LED backlighting that washes through the apertures and creates a uniform glow at night

Case 3: Residential Privacy Solution

A 12-unit condo project in San Diego added sliding screens made from custom expanded sheet. The selected mesh delivered high screening at typical street-level viewing angles while maintaining outward visibility for residents; overall project costs reflected scope and finish choices rather than a single universal price.

Case 4: Transit Hub Ventilation System

A rail station outside Chicago needed serious airflow. The solution used custom expanded sheet with a high open-area specification and gauge selected for wind loads. Designers tuned strand width, lay direction, and SWD/LWD to match the ventilation model; post-installation measurements showed improved air-exchange rates and better air-quality metrics compared with baseline.

How Do You Choose the Right Perforated Sheet Manufacturer?

Not all fabricators are created equal. Here's what separates the good ones from the rest.

Customization Capability

Can they actually make what you designed? Ask about equipment. CNC Gantry punching is faster and cheaper for simple patterns, while CNC Turret punching costs relatively higher whereas it is capable of punching different types, sizes, and patterns of holes. Laser-cutting is suitable for complicated patterns and shapes, while the cost is the most expensive. A capable perforated sheet manufacturer should have at least two technologies. Check that the shop routinely delivers architectural cladding panels in standard sheet formats (e.g., up to ~3000 mm × 1500 mm) and in common thickness ranges (about 0.5–6.0 mm for aluminum)

Material and Process Quality

Visit the shop if you can. Ask about material sourcing—do they buy certified metal with mill test reports? For exterior aluminum, look for architectural alloys such as 3003 or 5052 with suitable coatings (e.g., PVDF) for weathering. Check their finishing options too--how many layers do they paint? Normally 3-4 (3 for common purposes and 4 for the highest standards). What the adherance grade of the powder is? Grade 0 is the best, Grade 1 is also acceptable, it shouldn't be lower than Grade 1.

Technical Support and Engineering Services

The best perforated sheet manufacturers act like partners. Will they model your panels for structural loads? Can they detail the attachment system? Some shops employ in-house engineers who can stamp drawings—that's valuable.

Project Timeline and Production Capacity

Standard perforated sheet might ship in 2-3 weeks. Custom perforated metal panels with unique patterns could take 4-8 weeks. Ask about their current backlog and production capacity. Also, check their quality control process.

Standard QC process should at least include:

- material test: mill test report, visual inspection on surface quality, hardness/strength test, precise thickness measurement, panel size measurement

- product test: bending size measurement, perforation size and distance measurement, visual inspection on defects

- surface treatment: thickness of the layer, visual inspection of flaws

FAQ

Q1. How Do Building Codes Affect Perforated Metal Panel Design for High-Rise Facades?

High-rise buildings face strict codes around fire spread and falling debris. Most jurisdictions require non-combustible materials above certain heights—aluminum and steel perforated sheets are offered specifically for cladding/facade applications; verify the chosen finish meets required flame-spread and exterior wall assembly tests. The International Building Code mandates tested assemblies for exterior walls; work with your perforated sheet manufacturer to ensure their custom perforated metal panels integrate with rated systems. At greater heights where wind pressures increase, ensure the attachment is engineered for both positive and negative loads.

Q2. Can You Integrate Solar Panels or Green Walls Behind Custom Expanded Sheet Facades?

Absolutely, and it's becoming popular. Expanded and perforated systems are supplied in high-open-area options that support airflow and plant growth while providing screening. For solar integration, perforated sheet manufacturers often design hybrid panels—solid sections mount photovoltaics while perforated areas handle ventilation. The key is coordinating electrical rough-in during fabrication. Some projects use custom perforated metal panels as both solar mounting and rainscreen, maximizing surface efficiency. Just account for maintenance access; you'll need to clean both the panels and whatever's behind them.

Q3. What Happens to Perforated Metal Facades in Freezing Climates?

Metal expands and contracts with temperature, so proper detailing matters in freeze-thaw regions. Use slotted holes or sliding clips to accommodate thermal movement based on panel span and alloy. Follow the coating supplier’s guidance for flexible thin-film finishes, rather than prescribing a fixed mil thickness. (Project-specific detailing required.) Aluminum and stainless expanded/perforated systems are commonly specified where de-icing salts are present.

Conclusion

Perforated metal facades enhance both the performance and appearance of buildings. Whether you choose a perforated sheet or an expanded sheet, match the product to your functional priorities. Work with a perforated sheet manufacturer who understands architecture. Ready to spec your next facade? Request samples from multiple suppliers—such as Ansus Metal—comparing custom perforated metal panels and custom expanded sheet options side by side.

Share:

Metal Facades: What They Are & Why Use Perforated Sheets

Guide to Design and Application of Architectural Metal Facades