Introduction: The Rise of Perforated Aluminum in Modern Architecture

In today's rapidly evolving architectural landscape, perforated aluminum panels have emerged as one of the most versatile and sought-after building materials. From sleek commercial facades to innovative interior design solutions, these precision-engineered panels are redefining how architects and designers approach both form and function in modern construction.

But what exactly makes perforated aluminum panels so revolutionary? And why are leading architects worldwide choosing them for their most prestigious projects?

What Are Perforated Aluminum Panels?

Definition and Basic Concept

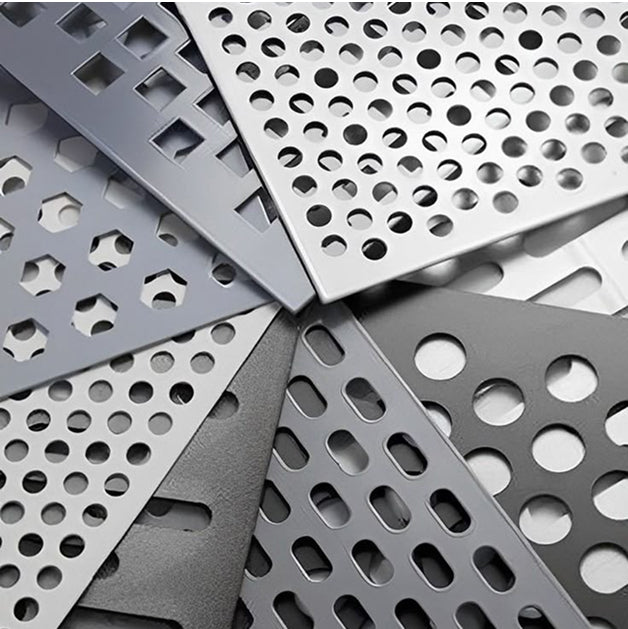

Perforated aluminum panels are sheets of aluminum that have been precision-punched or laser-cut with patterns of holes, creating a mesh-like appearance while maintaining structural integrity. These panels combine the lightweight strength of aluminum with customizable perforation patterns, offering architects unprecedented design flexibility.

Key Characteristics

- Material Base: High-grade aluminum alloys (typically 1100, 3003, or 5052)

- Perforation Methods: CNC punching, laser cutting, or water jet cutting

- Thickness Range: 0.5mm to 6.0mm depending on application

- Panel Sizes: Customizable up to 3000mm x 1500mm standard sheets

- Hole Patterns: Round, square, hexagonal, decorative, or completely custom designs

The Science Behind Perforated Aluminum Excellence

Material Properties That Matter

Aluminum Alloy Selection

- 1100 Series: Pure aluminum (99% minimum) for maximum corrosion resistance

- 3003 Series: Manganese-enhanced for improved strength and formability

- 5052 Series: Magnesium-alloyed for superior strength and marine environment resistance

Perforation Engineering

The perforation process isn't just about creating holes—it's about engineering optimal performance:

- Open Area Percentage: Typically ranges from 15% to 70% depending on application

- Hole Spacing: Calculated for structural integrity while maximizing airflow

- Edge Quality: Precision cutting ensures smooth, burr-free edges

- Pattern Repeatability: Advanced CNC technology ensures perfect consistency

Applications: Where Perforated Aluminum Panels Excel

1. Building Facades and Curtain Walls

Modern Commercial Architecture

Perforated aluminum facades have become the hallmark of contemporary commercial buildings. They offer:

- Solar Control: Reducing heat gain while maintaining natural light

- Visual Privacy: Controlling sight lines without completely blocking views

- Weather Protection: Shielding building interiors from rain and wind

- Aesthetic Appeal: Creating dynamic shadow patterns throughout the day

Residential High-Rise Applications

Luxury residential towers increasingly feature perforated aluminum for:

- Balcony Screening: Privacy without sacrificing airflow

- Decorative Accents: Adding architectural interest to otherwise plain facades

- Energy Efficiency: Reducing cooling costs through passive solar control

2. Interior Design and Space Division

Commercial Interiors

- Room Dividers: Creating visual separation while maintaining open feel

- Ceiling Systems: Acoustic control with modern aesthetic appeal

- Wall Cladding: Adding texture and depth to interior spaces

- Decorative Screens: Functional art pieces that serve practical purposes

Hospitality and Retail

- Restaurant Partitions: Intimate dining spaces without complete enclosure

- Hotel Lobby Features: Dramatic architectural elements

- Retail Display Systems: Flexible, reconfigurable display solutions

3. Industrial and Functional Applications

HVAC and Mechanical Systems

- Air Intake Screens: Protecting equipment while allowing airflow

- Noise Barriers: Reducing sound transmission in industrial settings

- Equipment Enclosures: Ventilated housing for mechanical equipment

Security and Safety

- Perimeter Fencing: Secure boundaries with visibility

- Stair Railings: Safe, modern alternatives to traditional designs

- Machine Guards: Industrial safety applications

Design Possibilities: Perforation Patterns and Customization

Standard Perforation Patterns

Round Holes

- Advantages: Maximum airflow, easy to manufacture, classic appearance

- Typical Sizes: 3mm to 25mm diameter

- Applications: General facade work, acoustic panels, ventilation screens

Square Perforations

- Advantages: Modern aesthetic, efficient material usage

- Typical Sizes: 5mm to 20mm squares

- Applications: Contemporary architecture, interior design features

Hexagonal Patterns

- Advantages: Optimal strength-to-weight ratio, unique visual appeal

- Applications: High-end architectural projects, decorative applications

Custom Design Capabilities

Artistic Perforations

Modern laser cutting technology enables virtually unlimited design possibilities:

- Corporate Logos: Branding integration into building facades

- Cultural Motifs: Reflecting local heritage and traditions

- Abstract Patterns: Creating unique architectural signatures

- Gradient Effects: Varying hole sizes for visual depth

Functional Customization

- Variable Open Areas: Different zones with varying transparency

- Directional Patterns: Controlling light and views from specific angles

- Integrated Mounting: Perforation patterns that incorporate fastening systems

Surface Treatments and Finishes

Standard Aluminum Finishes

Mill Finish

- Characteristics: Natural aluminum appearance, cost-effective

- Applications: Industrial applications, temporary installations

- Durability: Moderate, requires protective coating for longevity

Anodized Finishes

- Process: Electrochemical treatment creating protective oxide layer

- Colors Available: Clear, bronze, black, custom colors

- Benefits: Excellent corrosion resistance, scratch resistance, color stability

- Lifespan: 20+ years in most environments

Premium Coating Systems

PVDF (Polyvinylidene Fluoride) Coatings

- Performance: Superior weather resistance, color retention

- Color Range: Virtually unlimited custom colors

- Warranty: Typically 20-25 years against fading and chalking

- Applications: High-end architectural projects, coastal environments

Powder Coating

- Advantages: Environmentally friendly, excellent durability

- Finish Options: Matte, satin, gloss, textured

- Color Stability: Good to excellent depending on formulation

- Cost-Effectiveness: More economical than PVDF for many applications

Performance Benefits: Why Architects Choose Perforated Aluminum

1. Structural Advantages

Lightweight Strength

- Weight Reduction: 40-60% lighter than solid panels

- Structural Load: Reduced building frame requirements

- Installation Ease: Faster, safer installation processes

- Transportation: Lower shipping costs and environmental impact

Wind Load Performance

- Pressure Reduction: Perforations allow air passage, reducing wind loads

- Structural Efficiency: Less structural support required

- Safety Factor: Improved performance in high-wind environments

2. Environmental Performance

Energy Efficiency

- Solar Heat Gain: Reduced by 30-70% depending on perforation density

- Natural Ventilation: Improved airflow reduces mechanical cooling needs

- Daylighting Control: Optimized natural light while preventing glare

- LEED Contribution: Points toward green building certifications

Sustainability Factors

- Recyclability: 100% recyclable aluminum content

- Longevity: 25+ year lifespan reduces replacement frequency

- Low Maintenance: Minimal cleaning and maintenance requirements

- Energy Savings: Reduced building operational energy consumption

3. Acoustic Performance

Sound Control

- Noise Reduction: Perforations can reduce sound transmission

- Acoustic Tuning: Pattern optimization for specific frequency control

- Reverberation Control: Interior applications for acoustic comfort

- Urban Noise: Effective barrier against traffic and city sounds

Installation and Technical Considerations

Mounting Systems

Curtain Wall Integration

- Structural Glazing: Seamless integration with glass curtain wall systems

- Pressure Plate Systems: Mechanical attachment for easy maintenance

- Cassette Systems: Pre-fabricated units for rapid installation

Direct Attachment Methods

- Through-Fastening: Visible fasteners for industrial applications

- Concealed Fastening: Hidden attachment systems for clean aesthetics

- Clip Systems: Removable panels for maintenance access

Weather Considerations

Thermal Movement

- Expansion Joints: Accommodating thermal expansion and contraction

- Fastener Selection: Materials compatible with aluminum

- Sealant Systems: Weather sealing without restricting movement

Water Management

- Drainage Design: Ensuring proper water runoff

- Ventilation Gaps: Preventing moisture accumulation

- Flashing Integration: Coordinating with building envelope systems

Quality Standards and Manufacturing Excellence

Industry Standards and Certifications

Material Standards

- ASTM B209: Standard specification for aluminum sheet and plate

- ASTM B221: Standard specification for aluminum alloy extruded bars, rods, wire, profiles, and tubes

- ISO 9001: Quality management system certification

Performance Testing

- Wind Load Testing: ASTM E330 structural performance standards

- Water Penetration: ASTM E331 resistance testing

- Air Infiltration: ASTM E283 leakage testing

- Thermal Cycling: ASTM E1131 durability testing

Manufacturing Quality Control

Precision Manufacturing

- CNC Punching: ±0.1mm tolerance on hole placement

- Laser Cutting: Smooth, precise edges with minimal heat-affected zones

- Quality Inspection: Multi-point inspection throughout production process

- Dimensional Accuracy: Consistent panel dimensions for perfect fit

Cost Considerations and Value Engineering

Initial Investment Factors

Material Costs

- Aluminum Grade: Higher grades cost more but offer superior performance

- Panel Thickness: Thicker panels increase material costs but improve durability

- Perforation Complexity: Custom patterns cost more than standard designs

- Surface Finish: Premium coatings increase initial cost but extend lifespan

Installation Considerations

- System Complexity: Simple attachment methods reduce labor costs

- Panel Size: Larger panels reduce installation time and costs

- Access Requirements: Difficult installation locations increase labor costs

Long-Term Value Proposition

Lifecycle Cost Analysis

- Maintenance Savings: Minimal maintenance requirements over 25+ years

- Energy Savings: Reduced HVAC costs through passive solar control

- Durability: No replacement costs for decades with proper specification

- Property Value: Enhanced building aesthetics increase property values

Future Trends and Innovations

Technological Advances

Smart Integration

- Sensor Integration: Embedding environmental sensors within panels

- Automated Control: Motorized panels that adjust to environmental conditions

- LED Integration: Backlighting systems for dynamic facade effects

- Solar Integration: Photovoltaic cells integrated with perforated panels

Advanced Materials

- Recycled Content: Increasing use of post-consumer recycled aluminum

- Composite Systems: Aluminum combined with other materials for enhanced performance

- Nano-Coatings: Self-cleaning and anti-microbial surface treatments

Design Evolution

Parametric Design

- Computational Design: AI-assisted pattern optimization

- Performance-Based Design: Patterns optimized for specific environmental conditions

- Mass Customization: Cost-effective custom patterns through advanced manufacturing

Case Study: ANSUS Quang Ninh Luxury Apartments

Project Overview

Our recent project in Ha Long City, Vietnam, demonstrates the transformative power of perforated aluminum panels in residential architecture.

Project Specifications

- Location: 15 Heng Vinh Street, Ha Long City, Quang Ninh Province

- Scope: 622 precision perforated panels with 162 unique variations

- Material: A5052 H32 Aluminum Sheet with PVDF 4-Layer Metallic Gold finish

- Timeline: 2-month delivery from design to installation

Design Innovation

- Pattern Variety: 156 bespoke perforation patterns optimized for lighting control

- Precision Manufacturing: ±0.1mm tolerances across all panels

- Cultural Integration: Patterns reflecting Vietnamese architectural heritage

- Performance Results: 40% lighting efficiency improvement, 30% energy cost reduction

Project Impact

- Market Recognition: 25% premium property value increase

- Architectural Excellence: Redefined luxury standards in Northern Vietnam

- Industry Leadership: First-of-its-kind complexity in Southeast Asian residential architecture

- Sustainability: Zero maintenance required, 25+ year durability guarantee

Conclusion: The Future is Perforated

Perforated aluminum panels represent more than just a building material—they embody the future of architectural design where form, function, and sustainability converge. As we've explored throughout this comprehensive guide, these innovative panels offer architects and designers unprecedented opportunities to create buildings that are not only beautiful but also highly functional and environmentally responsible.

Key Takeaways

- Versatility: From facades to interiors, perforated aluminum adapts to virtually any architectural application

- Performance: Superior structural, environmental, and acoustic benefits

- Customization: Unlimited design possibilities through advanced manufacturing

- Sustainability: Long-lasting, recyclable, and energy-efficient solutions

- Value: Excellent long-term return on investment through reduced maintenance and energy costs

Looking Ahead

As technology continues to advance and environmental concerns become increasingly important, perforated aluminum panels will undoubtedly play an even more significant role in shaping the built environment. Smart integration, advanced materials, and parametric design will open new possibilities we can only begin to imagine today.

For architects, designers, and developers seeking to create buildings that stand the test of time while pushing the boundaries of what's possible, perforated aluminum panels offer a proven path to architectural excellence.

Share:

Decorative Metal Mesh: The Ultimate Guide to PVD Ti-Coated Stainless Steel Solutions

The Future of Architectural Design: How PVD-Coated Metal Screens Are Revolutionizing Modern Buildings