FAQs

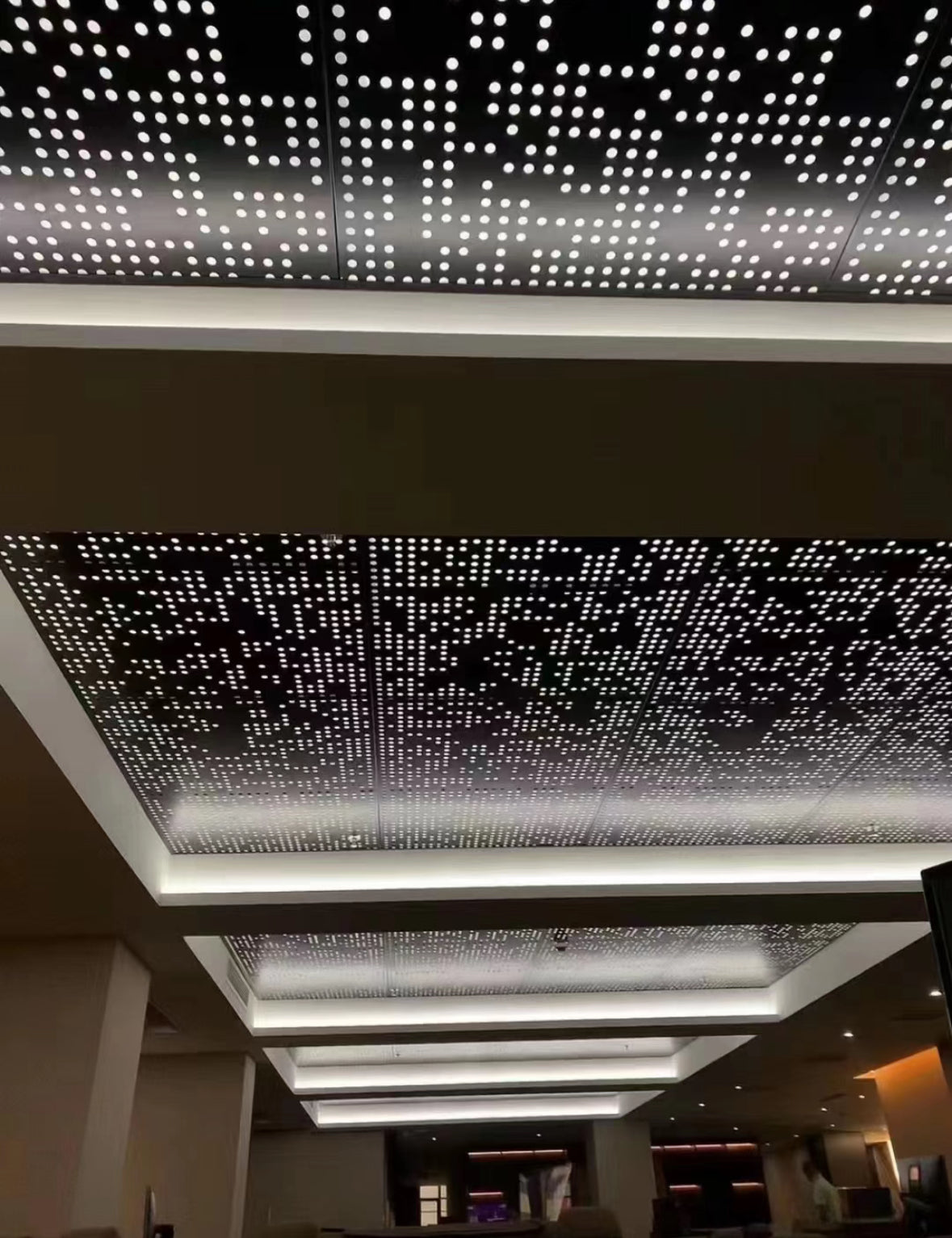

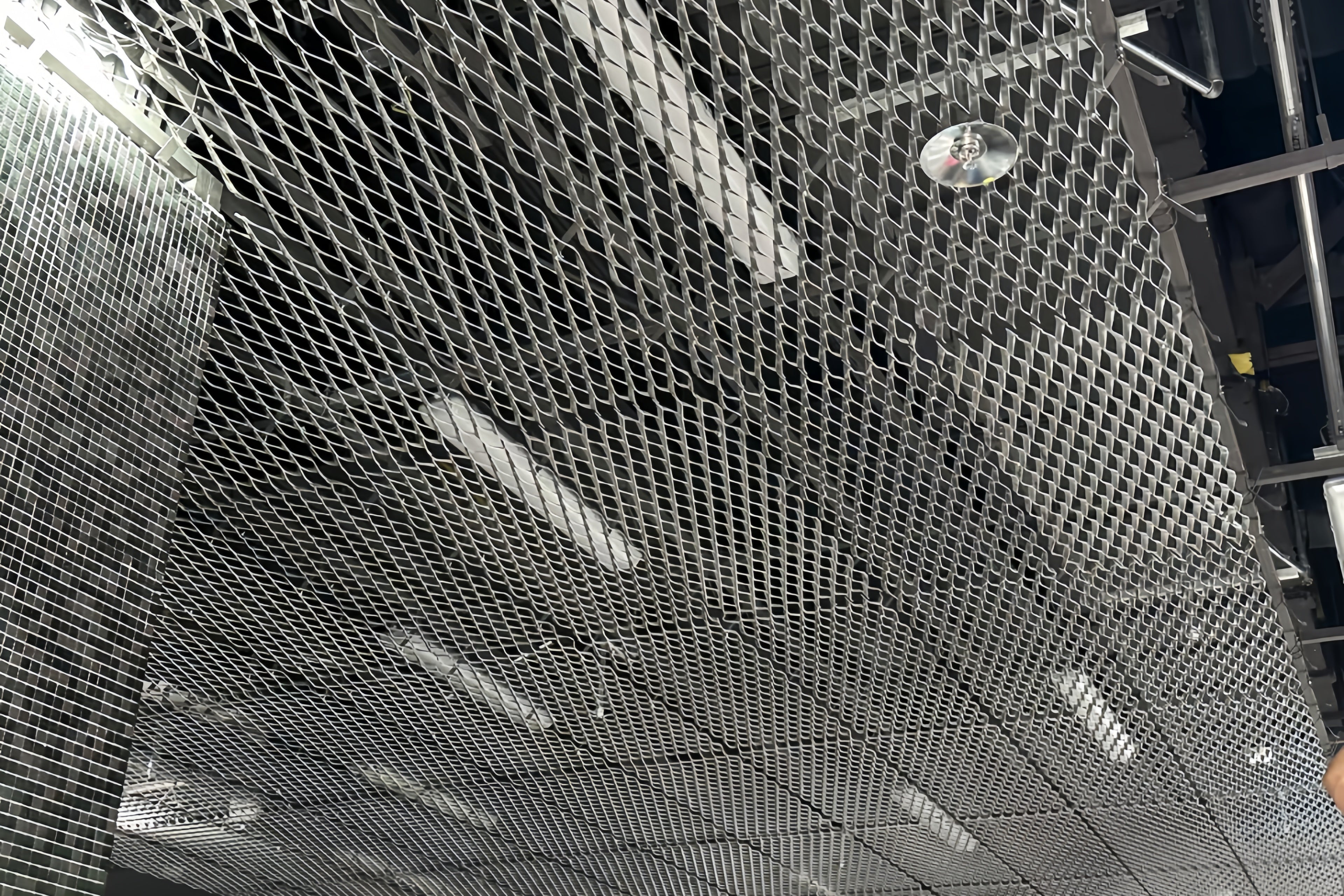

Q1. How do I choose the right type of metal ceiling (baffle, perforated, or expanded) for my space?

The choice depends on your primary goal. For acoustic control, choose Perforated Metal Ceilings. To create a linear direction, add perceived height, and hide plenum services, a Baffle Ceiling is best. For a textured, industrial, and open plenum feel, select an Expanded Metal Ceiling. Our experts can help you evaluate these options in relation to your specific project needs.

Q2. How is the sound absorption of an acoustic ceiling panel achieved?

Sound absorption is achieved through a combination of factors. The perforations in the metal panel allow sound waves to pass through rather than reflecting off the surface. Behind the panel, a non-woven acoustic fleece or mineral wool pad absorbs the sound energy, effectively trapping it and preventing it from re-entering the space. The size of the perforations and the properties of the acoustic backing can be tuned to target specific frequencies.

Q3. How do metal ceiling systems integrate with lighting, sprinklers, and HVAC?

Our systems are designed for seamless integration. Lighting fixtures, sprinkler heads, and air diffusers can be installed within the grid, between baffles, or directly integrated into custom-cut panels. We provide detailed engineering support to ensure all services are accommodated cleanly and precisely, maintaining the integrity of your design.

Q4. What surface finishes and colors are available for Ansus Metal ceilings?

We offer a wide array of advanced surface treatments to match your design vision. Our options range from high-performance PVDF and powder coatings available in any custom color to stunningly realistic wood grain transfers. These finishes are not just aesthetic; they are engineered for long-term color stability and texture retention, ensuring that your ceiling maintains its visual impact for years to come without fading.

Q5. Can I achieve a wood-look aesthetic with the durability of metal?

Yes. Our wood grain transfer technology allows you to enjoy the warmth and beauty of natural timber with the superior performance of metal. Unlike real wood, our metal ceiling systems are resistant to warping, rotting, and humidity. This provides a low-maintenance solution that captures the organic feel of wood while delivering the fire safety and structural integrity required for modern commercial and public spaces.

Q6. How do baffle ceilings handle plenum concealment and maintenance access?

Baffle ceiling systems are the ideal solution for balancing aesthetics with functionality in open-plenum environments. The vertical arrangement of the baffles elegantly conceals unsightly HVAC ducts, pipes, and wiring (the plenum) from the viewer's angle, while the open spacing ensures easy access for maintenance teams. This makes them exceptionally suited for corridors, airports, and lobbies where regular service access is required without dismantling the entire ceiling.

Q7. What are the benefits of using expanded metal for ceiling designs?

Expanded metal ceilings offer a unique combination of visual lightness and structural robustness. Formed from a single sheet of metal into a three-dimensional mesh, they create a distinct industrial-chic aesthetic. Functionally, their open structure facilitates the free flow of air and light, making them perfect for areas requiring smoke extraction compliance or creative lighting effects. They add texture and depth to a space while maintaining a sense of "breathable" volume.