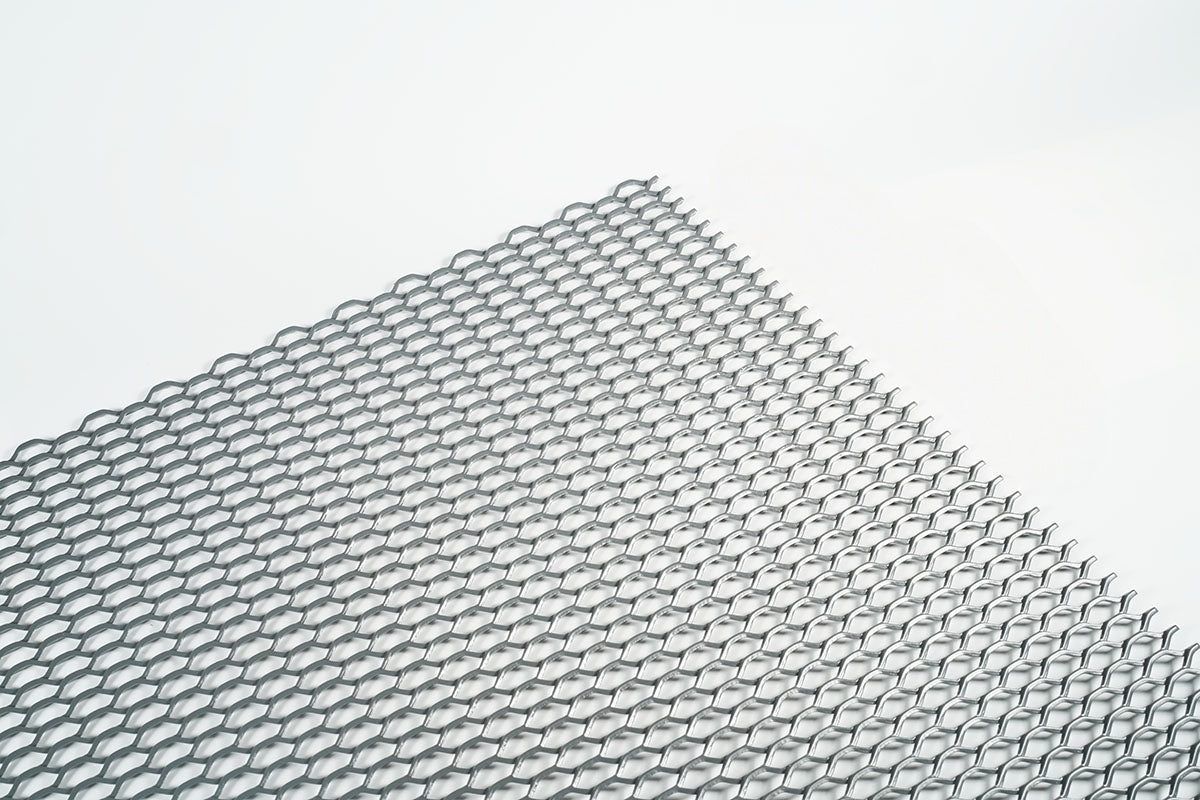

Expanded Mesh Panel Ceiling Plate

High-performance expanded mesh ceiling plates engineered to deliver exceptional visual transparency, superior airflow characteristics, and modern industrial aesthetics for contemporary commercial, institutional, and industrial applications. These precision-manufactured plates combine optimal ventilation properties, acoustic performance, and architectural appeal to create dynamic interior environments with enhanced functionality.

Our expanded mesh ceiling plates are engineered for performance-driven environments where airflow, access, and a modern industrial aesthetic are paramount.

- Technical & Industrial Spaces: Essential for data centers, server rooms, and manufacturing facilities where maximum airflow for cooling and unobstructed access to plenum services are critical.

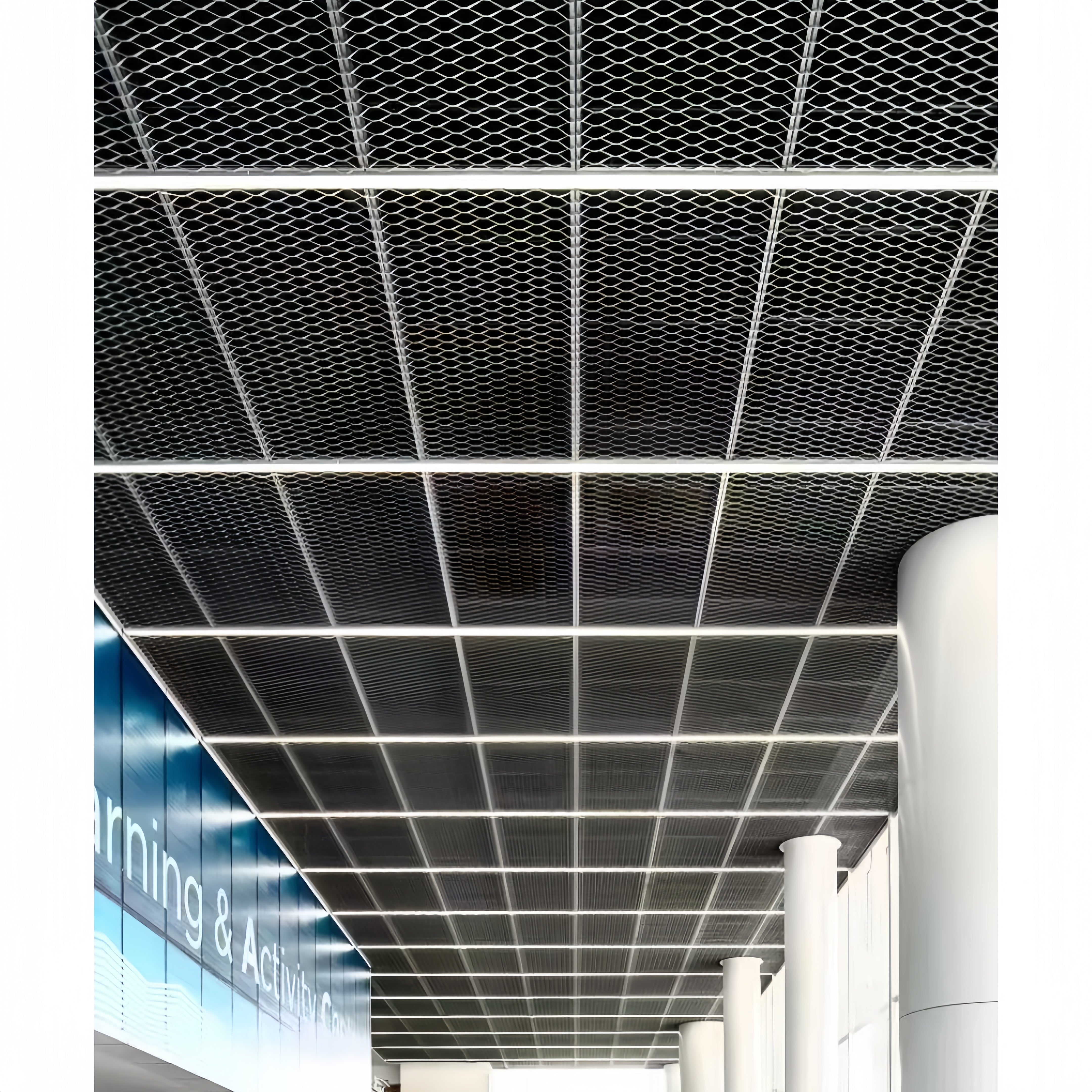

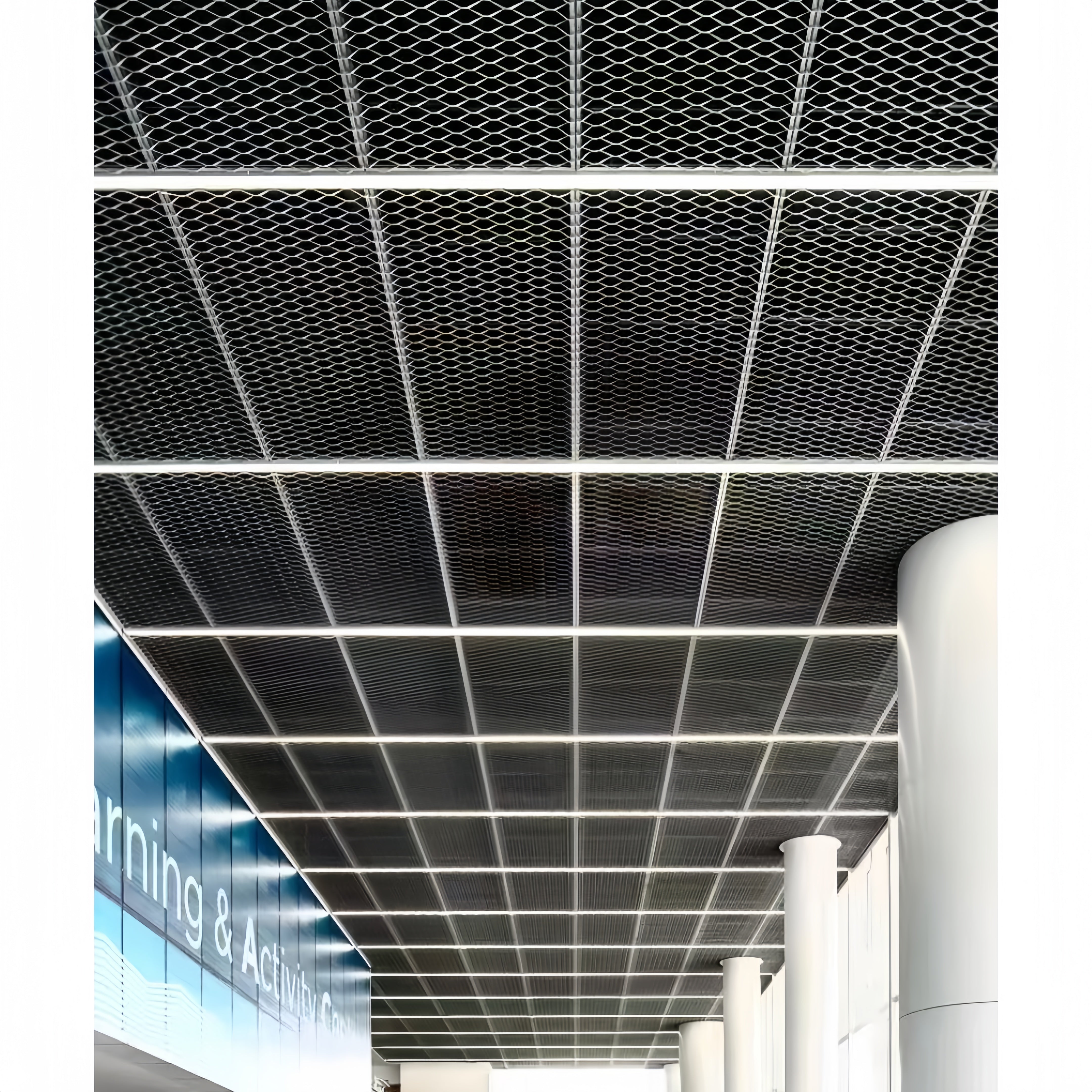

- Transportation & Public Venues: Ideal for airports, train stations, and convention centers, providing durability, easy maintenance, and smoke ventilation capabilities in high-traffic, large-volume spaces.

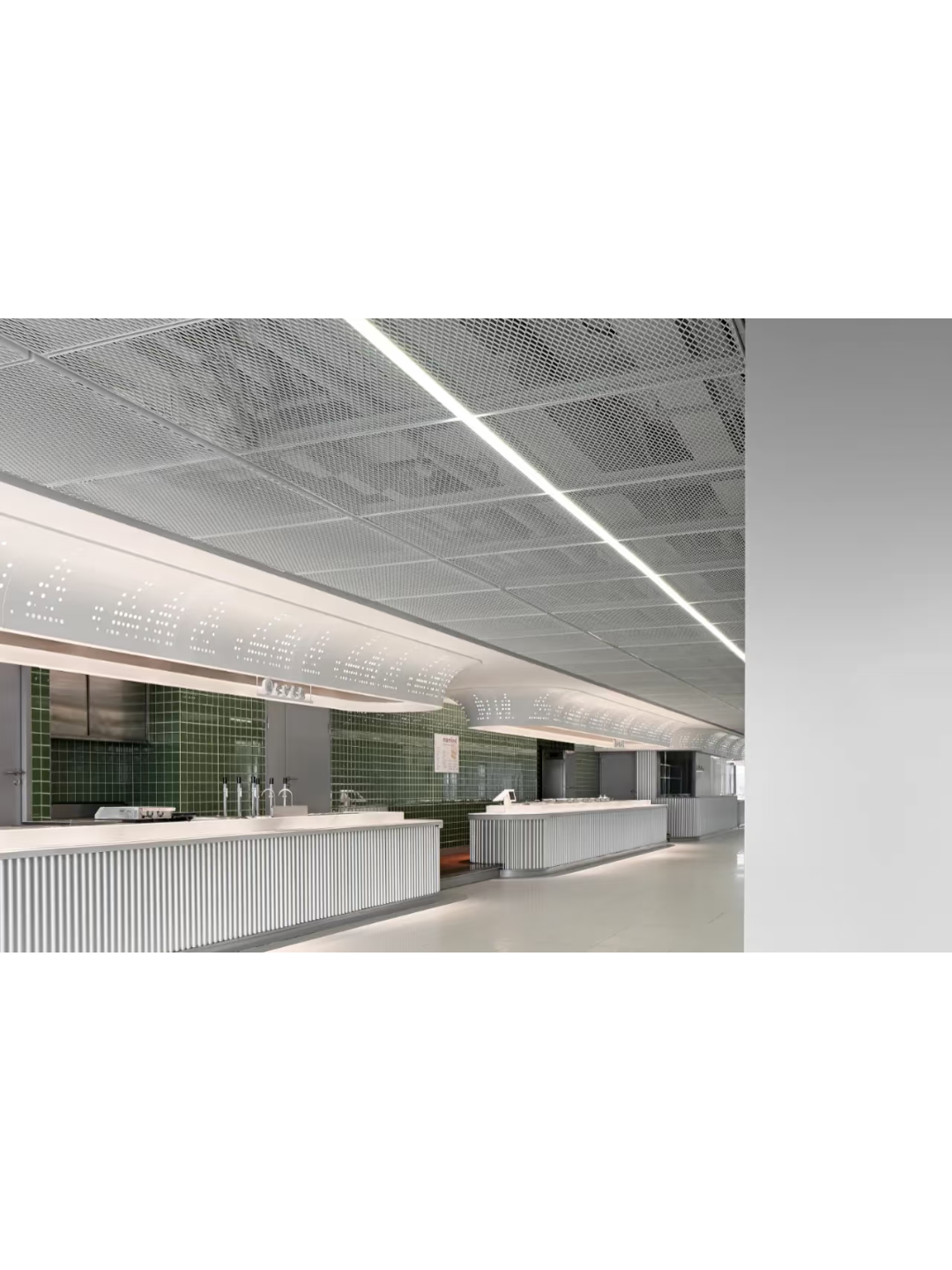

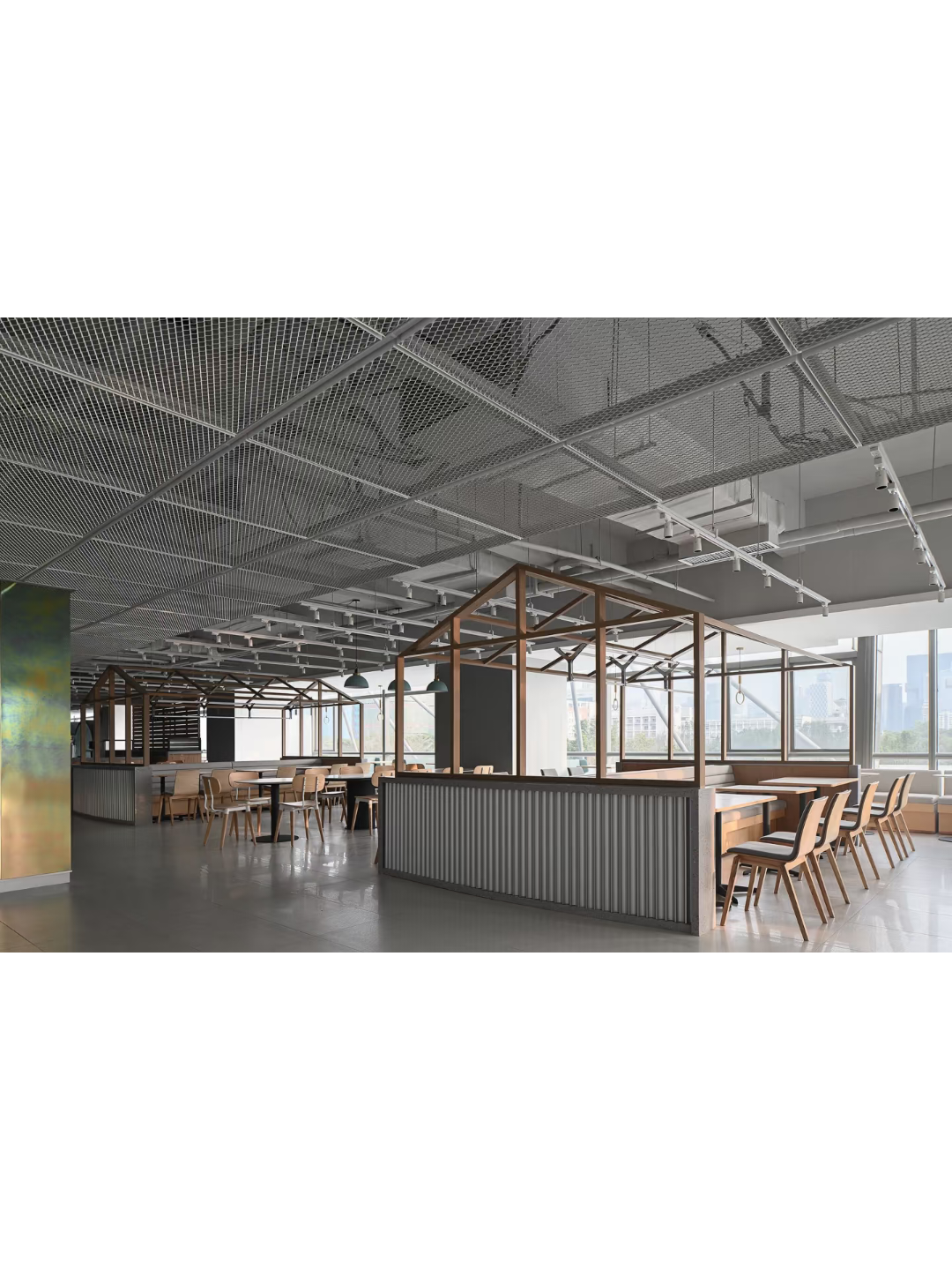

- Commercial & Retail Environments: Delivers a modern, industrial-chic aesthetic to open-plan offices, showrooms, and retail stores, enhancing the sense of volume while supporting HVAC efficiency.

Unmatched Airflow & Transparency

With up to 80% open area, it offers unparalleled ventilation and visual access to the plenum, significantly improving HVAC efficiency and enabling smoke management.

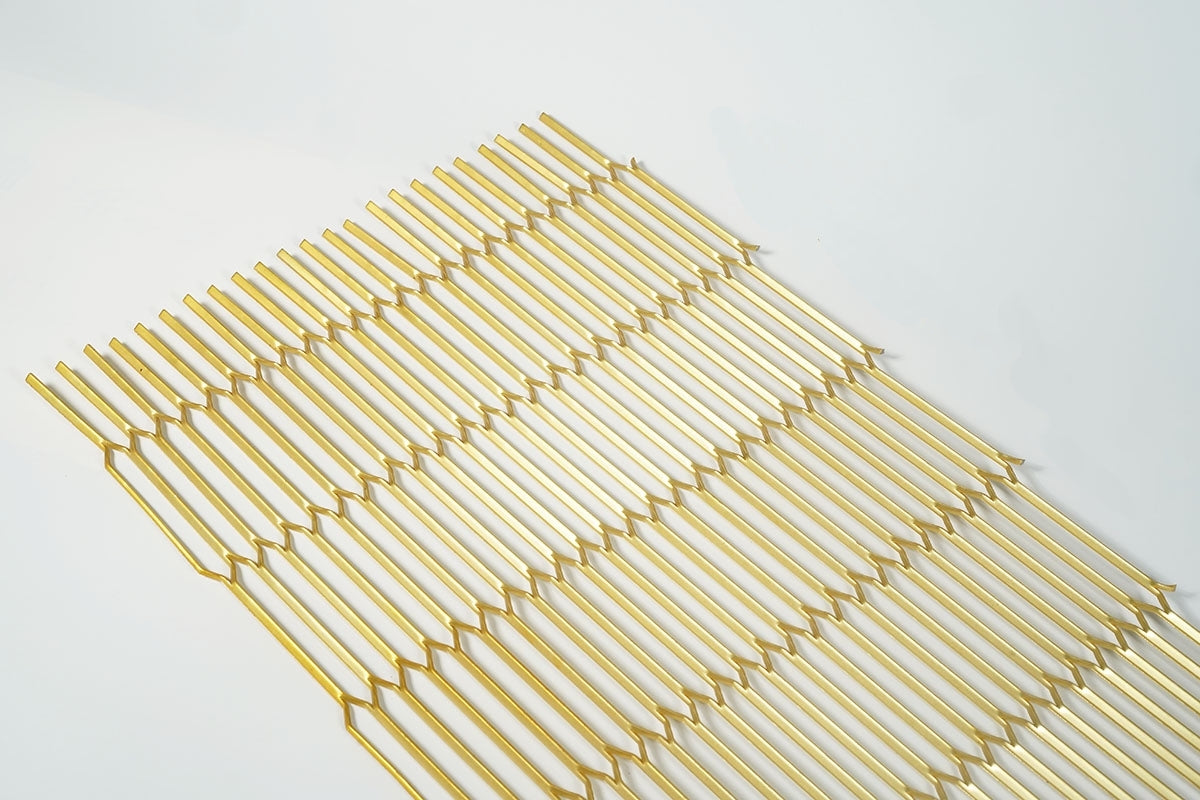

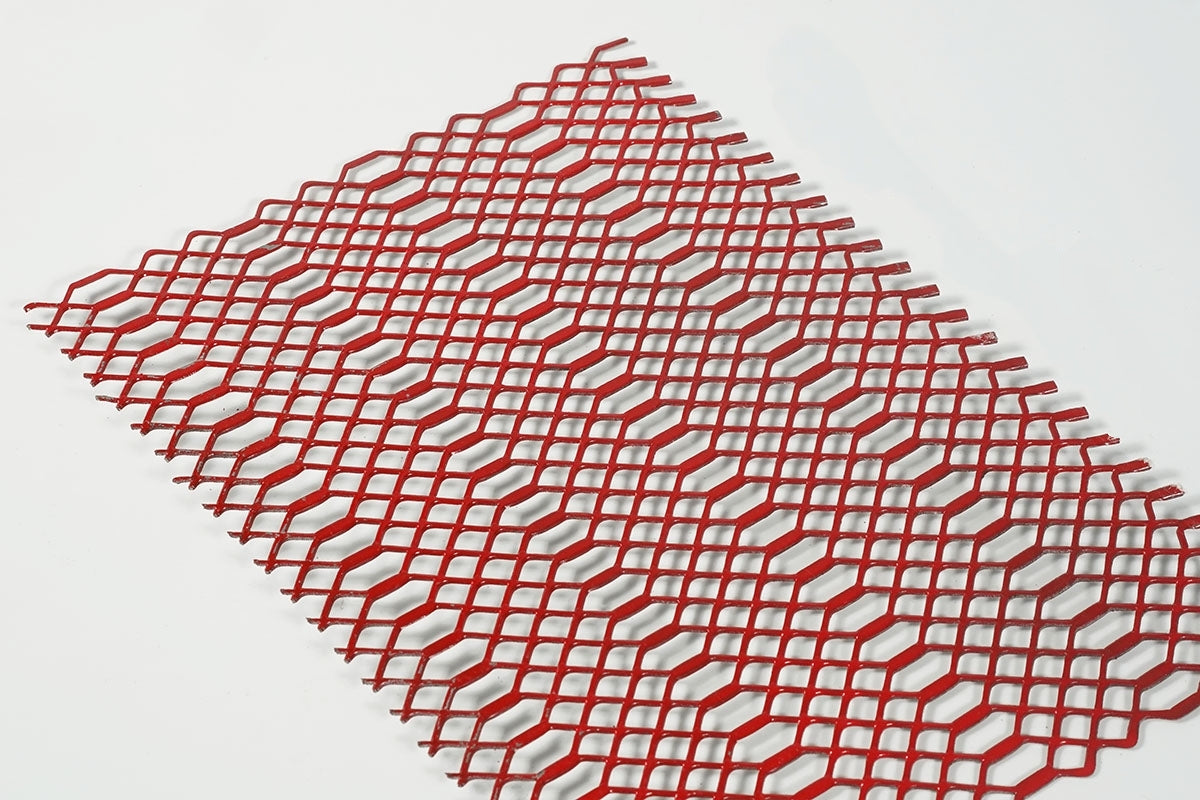

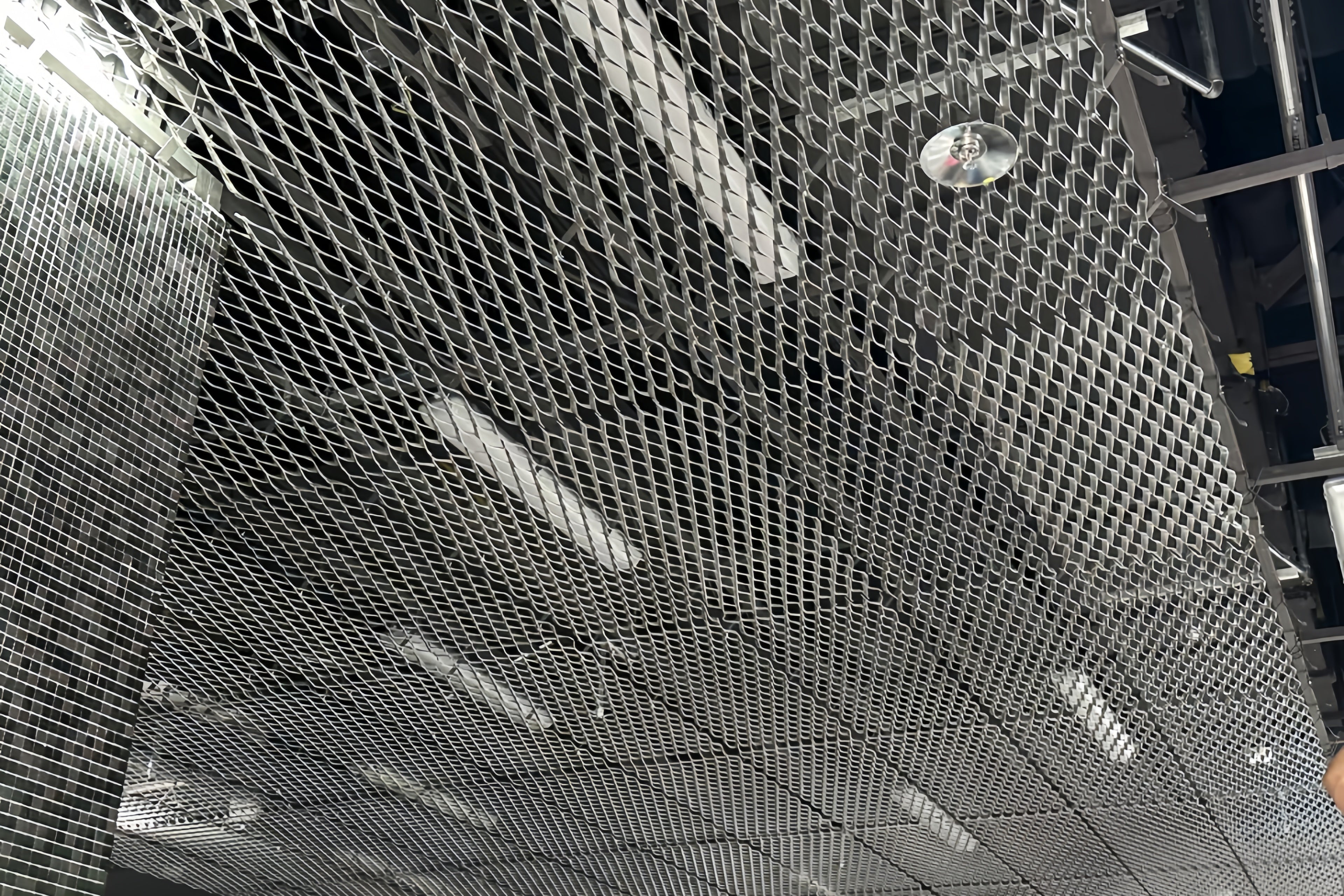

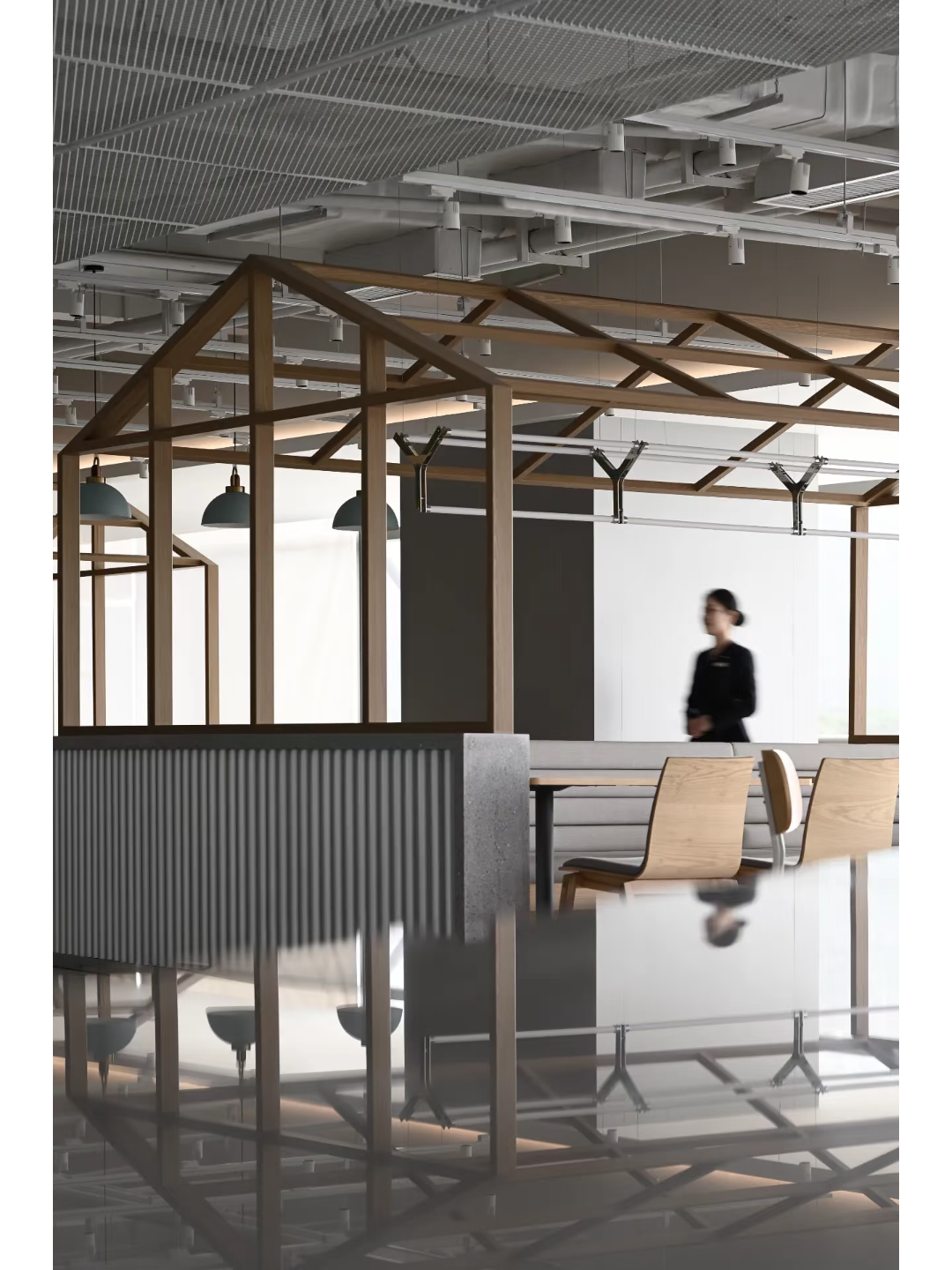

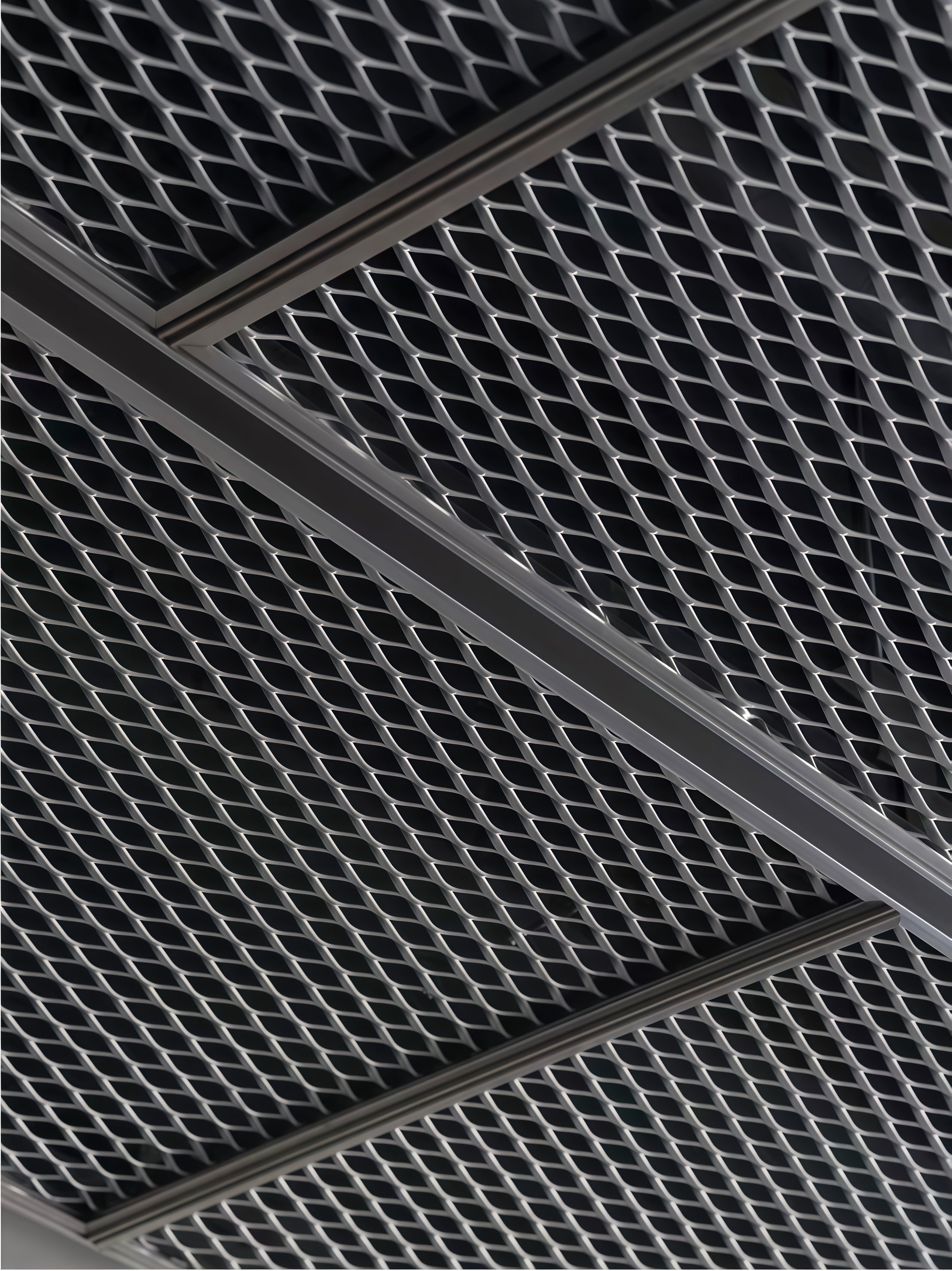

Modern Industrial Aesthetic

The raw, geometric pattern of the mesh delivers a contemporary, industrial-chic look, adding texture and a sense of volume to large interior spaces.

Functional & Accessible Design

These lightweight, non-combustible plates are easy to install on standard grids and provide full, unobstructed access to overhead services without needing to remove panels, simplifying maintenance.

| Material | Alloy/Grade | Properties | Best Applications |

|---|---|---|---|

| Aluminum | 3003-H14, 5052-H32 | Lightweight, excellent corrosion resistance, non-magnetic | Standard commercial, marine environments |

| Steel | Cold-rolled, galvanized | High strength, magnetic properties, cost-effective | Industrial, heavy-duty applications |

| Stainless Steel | 304, 316, 316L | Maximum corrosion resistance, hygienic, premium durability | Food processing, chemical, healthcare |

| Copper | C110, C101 | Antimicrobial properties, premium aesthetics, natural patina | Healthcare, high-end commercial, historic applications |

| Pattern Code | SWD | LWD | Strand Width | Open Area | Weight (Al/Steel) |

|---|---|---|---|---|---|

| XS-13 | 6mm | 13mm | 1.5mm | 65% | 1.8/5.1 kg/m² |

| S-20 | 10mm | 20mm | 2.0mm | 70% | 2.1/6.0 kg/m² |

| M-25 | 12mm | 25mm | 2.5mm | 72% | 2.4/6.8 kg/m² |

| L-32 | 16mm | 32mm | 3.0mm | 75% | 2.7/7.7 kg/m² |

| XL-40 | 20mm | 40mm | 3.5mm | 78% | 3.0/8.5 kg/m² |

| XXL-50 | 25mm | 50mm | 4.0mm | 80% | 3.3/9.4 kg/m² |

| Pattern Code | SWD | LWD | Strand Width | Open Area | Weight (Al/Steel) |

|---|---|---|---|---|---|

| HD-20 | 10mm | 20mm | 3.0mm | 60% | 3.2/9.1 kg/m² |

| HD-25 | 12mm | 25mm | 3.5mm | 62% | 3.6/10.2 kg/m² |

| HD-32 | 16mm | 32mm | 4.0mm | 65% | 4.1/11.7 kg/m² |

| HD-40 | 20mm | 40mm | 4.5mm | 68% | 4.5/12.8 kg/m² |

| Pattern Code | SWD | LWD | Strand Width | Open Area | Weight (Al/Steel) |

|---|---|---|---|---|---|

| Micro-8 | 4mm | 8mm | 1.0mm | 55% | 2.8/8.0 kg/m² |

| Micro-10 | 5mm | 10mm | 1.2mm | 58% | 2.5/7.1 kg/m² |

| Micro-13 | 6mm | 13mm | 1.5mm | 62% | 2.2/6.3 kg/m² |

| Panel Size | Weight Range | Typical Applications | Grid Compatibility |

|---|---|---|---|

| 300×300mm | 0.2-0.8 kg | Small format, detailed areas | 15mm T-grid |

| 600×600mm | 0.8-3.2 kg | Standard commercial | 15mm/24mm T-grid |

| 600×1200mm | 1.6-6.4 kg | Rectangular layouts | 15mm/24mm T-grid |

| 1200×1200mm | 3.2-12.8 kg | Large format installations | 24mm T-grid |

| 1200×2400mm | 6.4-25.6 kg | Continuous appearance | Structural support |

| Custom Sizes | Variable | Architectural features | Custom systems |

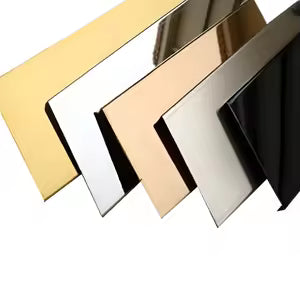

| Material | Finish Type | Details |

|---|---|---|

| Aluminum | Mill Finish | Natural aluminum oxide, economical choice |

| Anodized Clear | 15μm thickness, enhanced corrosion resistance | |

| Anodized Color | Bronze, black, gold - 20μm thickness | |

| Powder Coated | Unlimited colors, 60-80μm thickness | |

| PVDF Coated | Premium weather resistance, 25-30μm thickness | |

| Steel | Galvanized | Natural zinc coating, industrial appearance |

| Powder Coated | Color over galvanized base, 80-120μm thickness | |

| Painted | Baked enamel, standard color range | |

| Zinc-Rich Primer | Enhanced corrosion protection | |

| Hot-Dip Galvanized | Maximum corrosion protection | |

| Stainless Steel | 2B Mill | Standard mill finish, moderate reflectivity |

| #4 Brushed | Directional grain, architectural standard | |

| #8 Mirror | High-gloss polished finish | |

| Bead Blast | Uniform matte finish | |

| PVD Colored | Gold, bronze, black, blue coatings | |

| Specialty | Perforated + Expanded | Combination patterns for unique aesthetics |

| Textured | Embossed or rolled textures | |

| Printed | Digital printing for graphics or patterns | |

| Backlit Compatible | Translucent finishes for LED backlighting |

| Material | Tensile Strength | Yield Strength | Elongation | Hardness | Test Standard |

|---|---|---|---|---|---|

| Aluminum 3003-H14 | 145-185 MPa | 125-165 MPa | 8-16% | 40-50 HB | ASTM B557 |

| Aluminum 5052-H32 | 230-280 MPa | 165-220 MPa | 12-18% | 60-70 HB | ASTM B557 |

| Steel CQ | 270-370 MPa | 140-280 MPa | 20-25% | 70-90 HRB | ASTM A370 |

| Stainless 304 | 515-620 MPa | 205-310 MPa | 40-50% | 92 HRB max | ASTM A240 |

| Property | Aluminum | Steel | Stainless Steel | Units | Test Standard |

|---|---|---|---|---|---|

| Density | 2.68-2.73 | 7.85 | 8.0 | g/cm³ | ASTM B311/A484 |

| Melting Point | 660 | 1510 | 1400-1450 | °C | - |

| Thermal Conductivity | 237 | 50 | 16.3 | W/m·K | ASTM E1461 |

| Thermal Expansion | 23.6×10⁻⁶ | 12×10⁻⁶ | 17.3×10⁻⁶ | /°C | ASTM E228 |

| Electrical Conductivity | 37.7 | 10.4 | 1.4 | MS/m | ASTM B193 |

| Property | Aluminum | Steel | Stainless Steel | Units | Test Standard |

|---|---|---|---|---|---|

| Density | 2.68-2.73 | 7.85 | 8.0 | g/cm³ | ASTM B311/A484 |

| Melting Point | 660 | 1510 | 1400-1450 | °C | - |

| Thermal Conductivity | 237 | 50 | 16.3 | W/m·K | ASTM E1461 |

| Thermal Expansion | 23.6×10⁻⁶ | 12×10⁻⁶ | 17.3×10⁻⁶ | /°C | ASTM E228 |

| Electrical Conductivity | 37.7 | 10.4 | 1.4 | MS/m | ASTM B193 |

| Mesh Pattern | Open Area | Free Area Ratio | Pressure Drop | Airflow Coefficient | Structural Efficiency |

|---|---|---|---|---|---|

| XS-13 | 65% | 0.65 | 12 Pa @ 3 m/s | 0.82 | Good |

| S-20 | 70% | 0.70 | 8 Pa @ 3 m/s | 0.85 | Very Good |

| M-25 | 72% | 0.72 | 6 Pa @ 3 m/s | 0.87 | Very Good |

| L-32 | 75% | 0.75 | 4 Pa @ 3 m/s | 0.89 | Excellent |

| XL-40 | 78% | 0.78 | 3 Pa @ 3 m/s | 0.91 | Excellent |

| XXL-50 | 80% | 0.80 | 2 Pa @ 3 m/s | 0.93 | Maximum |

| Air Velocity (m/s) | XS-13 (65%) | S-20 (70%) | M-25 (72%) | L-32 (75%) | XL-40 (78%) |

|---|---|---|---|---|---|

| 1.0 | 2 Pa | 1.5 Pa | 1.2 Pa | 1.0 Pa | 0.8 Pa |

| 2.0 | 5 Pa | 3.5 Pa | 3.0 Pa | 2.5 Pa | 2.0 Pa |

| 3.0 | 12 Pa | 8 Pa | 6 Pa | 4 Pa | 3 Pa |

| 4.0 | 20 Pa | 14 Pa | 12 Pa | 8 Pa | 6 Pa |

| 5.0 | 32 Pa | 22 Pa | 18 Pa | 14 Pa | 10 Pa |

| Configuration | 125 Hz | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 4000 Hz | NRC |

|---|---|---|---|---|---|---|---|

| Mesh Only | 0.02 | 0.05 | 0.08 | 0.12 | 0.15 | 0.18 | 0.10 |

| 25mm Backing | 0.08 | 0.20 | 0.45 | 0.65 | 0.70 | 0.75 | 0.50 |

| 50mm Backing | 0.15 | 0.40 | 0.75 | 0.85 | 0.80 | 0.75 | 0.70 |

| 75mm Backing | 0.25 | 0.60 | 0.90 | 0.95 | 0.85 | 0.80 | 0.80 |

| Panel Size | Thickness | Max Deflection | Load Capacity | Support Spacing | Safety Factor |

|---|---|---|---|---|---|

| 600×600mm | 0.8mm | L/300 | 150 N/m² | 600mm | 3.0 |

| 600×600mm | 1.0mm | L/350 | 200 N/m² | 600mm | 3.5 |

| 600×1200mm | 1.0mm | L/300 | 175 N/m² | 600mm | 3.0 |

| 1200×1200mm | 1.2mm | L/300 | 225 N/m² | 1200mm | 3.0 |

| 1200×2400mm | 1.5mm | L/300 | 275 N/m² | 1200mm | 3.0 |

| Property | Performance | Test Standard |

|---|---|---|

| Corrosion Resistance | Excellent (coated) | ASTM B117 |

| UV Resistance | Excellent | ASTM G154 |

| Temperature Range | -40°C to +150°C | Service conditions |

| Humidity Resistance | 100% RH compatible | ASTM D2247 |

| Chemical Resistance | Good to excellent | ASTM D543 |

| Freeze-Thaw | No degradation | ASTM C666 |

| Property | Performance | Test Standard |

|---|---|---|

| Fire Rating | Class A Non-combustible | ASTM E84 |

| Flame Spread | 0 (Aluminum/Steel) | ASTM E84 |

| Smoke Development | 0-5 | ASTM E84 |

| Heat Release | Zero | ASTM E1354 |

| Toxicity | Non-toxic combustion products | ASTM E662 |

| Structural Fire | Maintains integrity to 500°C+ | - |

| Metric | Aluminum | Steel | Stainless Steel |

|---|---|---|---|

| Recycled Content | 75-95% | 25-30% | 60-70% |

| Recyclability | 100% | 100% | 100% |

| Embodied Energy | 155 MJ/kg | 25 MJ/kg | 56 MJ/kg |

| Carbon Footprint | 8.2 kg CO₂/kg | 2.3 kg CO₂/kg | 4.1 kg CO₂/kg |

| Service Life | 25-40 years | 20-30 years | 40+ years |

| Mesh Pattern | Visual Transparency | Light Transmission | Shadow Pattern | Viewing Distance |

|---|---|---|---|---|

| XS-13 | 60% | 55% | Fine | >2m |

| S-20 | 65% | 62% | Medium | >3m |

| M-25 | 68% | 65% | Medium | >3m |

| L-32 | 72% | 70% | Coarse | >4m |

| XL-40 | 75% | 73% | Coarse | >5m |

| XXL-50 | 78% | 76% | Very Coarse | >6m |

| Support System | Grid Type | Hanger Spacing | Load Capacity | Seismic Rating |

|---|---|---|---|---|

| Standard T-Grid | 15mm/24mm | 1200mm | 7.2/14.4 kg/m² | Zone 1-4 |

| Heavy-Duty Grid | 32mm | 1200mm | 24.0 kg/m² | Zone 1-4 |

| Direct Mount | Structural | Variable | Structural | Zone 1-4 |

| Cable System | Tension wire | 3000mm | 15.0 kg/m² | Zone 1-3 |

FAQs

What materials are used to make expanded metal mesh ceilings?

Expanded metal mesh ceilings can be made of aluminum, iron, stainless steel or copper. Such considerations as aesthetic appeal, durability, and resistance to corrosion are among many others that allow for specific solutions depending on design and functional needs.

What is an expanded metal mesh ceiling?

An expanded metal mesh ceiling is appealing because of its originality. The suspended ceiling was made of carefully cut and stretched thin metal sheets bearing a mesh pattern with several holes, which added a very distinct touch of craftiness to any space.

What Are the Key Advantages of Expanded Mesh Ceiling Plates Over Other Ceiling Systems?

Expanded mesh ceiling plates offer unique advantages that make them ideal for applications requiring maximum transparency, superior airflow, and modern industrial aesthetics:

Superior Airflow Performance:

Maximum Air Permeability:

- Open area up to 80% - highest airflow capacity of any ceiling system

- Minimal pressure drop - 2-12 Pa at 3 m/s air velocity depending on mesh pattern

- Unrestricted air movement - no blocked areas or flow restrictions

- HVAC efficiency - reduces fan energy consumption by 15-25%

- Natural ventilation - enhances stack effect and natural air circulation

Pressure Drop Comparison:

- Expanded mesh: 2-12 Pa at 3 m/s (depending on pattern)

- Perforated metal: 15-35 Pa at 3 m/s (depending on hole size)

- Acoustic tiles: 25-50 Pa at 3 m/s

- Solid panels: Infinite (no airflow)

Enhanced HVAC Performance:

- Reduced ductwork - ceiling plenum can serve as return air path

- Improved mixing - better air distribution and temperature uniformity

- Energy savings - lower fan power requirements reduce operating costs

- System simplification - fewer diffusers and returns required

- Maintenance access - full access to HVAC systems without panel removal

Exceptional Visual Transparency:

Unobstructed Views:

- Visual transparency 60-78% depending on mesh pattern

- Plenum visibility - allows architectural expression of building systems

- Spatial continuity - maintains visual connection between floor and ceiling

- Light transmission - natural and artificial light passes through freely

- Depth perception - maintains sense of ceiling height and volume

Architectural Benefits:

- Industrial aesthetics - contemporary look popular in modern design

- System integration - showcases mechanical, electrical, and structural systems

- Design flexibility - works with exposed or concealed building systems

- Lighting effects - creates interesting shadow patterns and light play

- Brand expression - can incorporate logos or custom patterns

Cost and Installation Advantages:

Economic Benefits:

- Lower material costs - less material per square meter than solid panels

- Reduced structural loads - lightweight construction reduces support requirements

- Installation efficiency - large panels cover more area quickly

- System simplification - fewer components than complex ceiling systems

- Maintenance savings - easy access reduces service costs

Installation Advantages:

- Standard grid compatibility - works with existing T-grid systems

- Large panel sizes - reduces installation time and labor costs

- Lightweight handling - easier and safer installation

- Field cutting - can be cut and modified on-site if needed

- Flexible mounting - multiple installation options available

Maintenance and Access Benefits:

Complete Accessibility:

- No panel removal required for plenum access

- Full visibility of all building systems from below

- Easy maintenance - all systems accessible without disruption

- Quick repairs - immediate access to problems or failures

- System modifications - easy to add or relocate building systems

Cleaning and Maintenance:

- Self-cleaning design - open structure prevents dust accumulation

- Easy cleaning - simple washing or pressure cleaning

- Durable construction - expanded metal more damage-resistant than perforated

- Long service life - 25-40 years with minimal maintenance

- Replacement ease - individual panels easily replaced if damaged

Performance Comparison with Other Systems:

- Higher open area - 65-80% vs. 15-50% for perforated

- Better airflow - lower pressure drop and higher flow rates

- More transparent - better visual access to plenum space

- Lower cost - less material and simpler manufacturing

- Equal durability - similar service life and maintenance requirements

vs. Acoustic Ceiling Tiles:

- Superior airflow - unrestricted vs. minimal air permeability

- Better access - full plenum visibility vs. tile removal required

- Higher durability - metal vs. mineral fiber or gypsum construction

- Fire safety - non-combustible vs. combustible materials

- Moisture resistance - unaffected by humidity vs. potential sagging/damage

vs. Open Ceiling (No Ceiling):

- Acoustic improvement - some sound absorption vs. hard reflective surfaces

- Dust protection - reduces dust accumulation on equipment and surfaces

- Aesthetic enhancement - organized appearance vs. exposed chaos

- Safety improvement - protects against falling objects or debris

- Code compliance - may be required for fire rating or accessibility

Specific Application Advantages:

Industrial Facilities:

- Heat dissipation - excellent for high-temperature environments

- Contamination control - easy cleaning for food processing or pharmaceuticals

- Equipment access - immediate access to overhead equipment

- Safety compliance - non-combustible construction for hazardous areas

- Cost effectiveness - economical for large areas

Transportation Hubs:

- Smoke management - aids in fire safety and smoke evacuation

- Acoustic performance - reduces noise while maintaining openness

- Durability - withstands high-traffic and harsh environments

- Security - visual access for security monitoring

- Maintenance efficiency - easy access to extensive building systems

Commercial Spaces:

- Modern aesthetics - industrial chic popular in retail and hospitality

- Flexibility - easy to modify for tenant improvements

- Cost control - economical for large retail or office spaces

- HVAC efficiency - reduces operating costs in large spaces

- Brand integration - can incorporate corporate identity elements

Limitations to Consider:

- Acoustic performance - lower sound absorption than dedicated acoustic systems

- Debris protection - larger openings may allow small objects to fall through

- Privacy - visual transparency may not be desired in all applications

- Aesthetic preferences - industrial look may not suit all design styles

- Cleaning frequency - may require more frequent cleaning in dusty environments

How Do You Select the Appropriate Mesh Pattern and Open Area for Different Applications?

Selecting the optimal expanded mesh pattern requires balancing airflow requirements, visual transparency, structural performance, and aesthetic preferences:

Mesh Pattern Selection Criteria:

Airflow Requirements:

Low Airflow Applications (1-2 air changes/hour):

- Recommended patterns: XS-13 (65% open) or S-20 (70% open)

- Applications: Standard offices, retail spaces, residential

- Benefits: Adequate ventilation with good structural strength

- Pressure drop: 8-12 Pa at 3 m/s air velocity

- HVAC compatibility: Works with standard commercial HVAC systems

Moderate Airflow Applications (3-4 air changes/hour):

- Recommended patterns: M-25 (72% open) or L-32 (75% open)

- Applications: Restaurants, laboratories, light industrial

- Benefits: Good airflow with reasonable structural performance

- Pressure drop: 4-6 Pa at 3 m/s air velocity

- HVAC compatibility: Reduces fan energy requirements

High Airflow Applications (5+ air changes/hour):

- Recommended patterns: XL-40 (78% open) or XXL-50 (80% open)

- Applications: Manufacturing, chemical processing, data centers

- Benefits: Maximum airflow with minimal pressure drop

- Pressure drop: 2-3 Pa at 3 m/s air velocity

- HVAC compatibility: Significant energy savings possible

Visual Transparency Requirements:

Minimal Transparency Needed:

- Pattern selection: XS-13 or Micro patterns

- Open area: 55-65%

- Applications: Areas where plenum concealment preferred

- Benefits: Better acoustic performance, more privacy

- Viewing distance: Effective transparency >2m

Moderate Transparency Desired:

- Pattern selection: S-20 or M-25

- Open area: 68-72%

- Applications: Modern offices, retail spaces, restaurants

- Benefits: Balance of openness and structure

- Viewing distance: Effective transparency >3m

Maximum Transparency Required:

- Pattern selection: L-32, XL-40, or XXL-50

- Open area: 75-80%

- Applications: Industrial showcases, modern architecture

- Benefits: Maximum visual access to building systems

- Viewing distance: Effective transparency >4-6m

Structural Performance Considerations:

Light-Duty Applications:

- Panel thickness: 0.8-1.0mm

- Mesh patterns: Any standard pattern acceptable

- Panel sizes: Up to 600×1200mm

- Support spacing: Standard 600mm grid

- Load requirements: Minimal - ceiling weight only

Standard Commercial Applications:

- Panel thickness: 1.0-1.2mm

- Mesh patterns: S-20 through L-32 recommended

- Panel sizes: Up to 1200×1200mm

- Support spacing: 600-1200mm grid

- Load requirements: Standard commercial loads

Heavy-Duty Applications:

- Panel thickness: 1.2-2.0mm

- Mesh patterns: HD series or smaller openings

- Panel sizes: Up to 1200×2400mm

- Support spacing: Structural support required

- Load requirements: High loads, seismic considerations

Application-Specific Selection Guidelines:

Corporate Offices:

- Open plan areas: M-25 or L-32, 1.0mm thickness

- Conference rooms: S-20 or M-25, 0.8-1.0mm thickness

- Reception areas: XS-13 or S-20, 1.0mm thickness

- Data/server rooms: XL-40 or XXL-50, 1.2mm thickness

- Finish: Powder coated in corporate colors

Industrial Facilities:

- Manufacturing areas: XL-40 or XXL-50, 1.5-2.0mm thickness

- Warehouses: L-32 or XL-40, 1.2-1.5mm thickness

- Clean rooms: Micro patterns, stainless steel construction

- Chemical processing: 316L stainless steel, appropriate pattern for airflow

- Finish: Mill finish or specialized coatings

Transportation Hubs:

- Passenger areas: M-25 or L-32, 1.2mm thickness

- Mechanical areas: XL-40 or XXL-50, 1.5mm thickness

- Security areas: S-20 or M-25, 1.2mm thickness

- Outdoor areas: 5052 aluminum or stainless steel

- Finish: PVDF or anodized for durability

Healthcare Facilities:

- Patient areas: S-20 or M-25, stainless steel preferred

- Operating rooms: Micro patterns, 316L stainless steel

- Corridors: M-25 or L-32, easy-clean finishes

- Mechanical rooms: XL-40 or XXL-50, galvanized steel acceptable

- Finish: Antimicrobial coatings where appropriate

Selection Decision Process:

Step 1: Determine Primary Function

- Airflow priority: Select pattern based on ventilation requirements

- Visual priority: Select pattern based on transparency needs

- Acoustic priority: Consider backing materials and smaller openings

- Structural priority: Ensure adequate strength for loads and spans

Step 2: Environmental Assessment

- Corrosion exposure: Select appropriate material and finish

- Temperature conditions: Consider thermal expansion and material limits

- Chemical exposure: Specify compatible materials and coatings

- Cleaning requirements: Select patterns and finishes for maintainability

Step 3: Aesthetic Integration

- Design style: Match mesh pattern to architectural intent

- Scale considerations: Larger patterns for high ceilings, smaller for intimate spaces

- Color coordination: Select finish to complement interior design

- Lighting integration: Consider shadow patterns and light transmission

Step 4: Performance Optimization

- HVAC modeling: Calculate actual pressure drops and energy impacts

- Acoustic modeling: Determine if backing materials needed for sound control

- Structural analysis: Verify panel sizes and support requirements

- Cost analysis: Balance performance requirements with budget constraints

Common Selection Mistakes to Avoid:

- Over-sizing openings: Larger isn't always better - consider structural and acoustic impacts

- Ignoring viewing distance: Pattern appearance changes significantly with distance

- Mismatching materials: Ensure material selection suits environmental conditions

- Inadequate structural design: Large openings require appropriate panel thickness and support

- Poor finish selection: Consider maintenance, durability, and aesthetic longevity

Performance Verification:

- Mock-up testing: Build sample installations for critical applications

- CFD modeling: Use computational fluid dynamics for complex airflow applications

- Acoustic testing: Measure performance if sound control is critical

- Structural testing: Verify deflection and load capacity for large panels

- Maintenance assessment: Evaluate cleaning and access requirements

What Are the Installation Methods and Best Practices for Expanded Mesh Ceiling Plates?

Successful installation of expanded mesh ceiling plates requires proper planning, appropriate support systems, and attention to handling and safety procedures:

Installation System Options:

Standard T-Grid Suspension:

- Grid types: 15mm or 24mm T-grid systems

- Panel compatibility: Standard sizes (600×600mm to 1200×1200mm)

- Load capacity: 7.2 kg/m² (15mm) or 14.4 kg/m² (24mm)

- Advantages: Standard installation, easy access, economical

- Applications: Most commercial and institutional projects

Heavy-Duty Grid Systems:

- Grid types: 32mm heavy-duty T-grid or structural grid

- Panel compatibility: Large panels up to 1200×2400mm

- Load capacity: 24+ kg/m² depending on design

- Advantages: Supports larger panels, higher loads, seismic resistance

- Applications: Industrial facilities, large-span areas

Direct Mount Systems:

- Mounting methods: Clips, brackets, or frame systems attached to structure

- Panel compatibility: Any size, custom shapes possible

- Load capacity: Limited by structural capacity

- Advantages: Clean appearance, maximum structural efficiency

- Applications: Industrial facilities, architectural features

Cable/Wire Suspension:

- System type: Tension cables or aircraft cable suspension

- Panel compatibility: Lightweight panels, artistic installations

- Load capacity: 15 kg/m² typical

- Advantages: Minimal visual impact, flexible layouts

- Applications: Modern architecture, temporary installations

Pre-Installation Requirements:

Structural Assessment:

- Load verification: Confirm structure can support total system weight

- Deflection analysis: Ensure structural movement won't damage ceiling

- Seismic design: Verify compliance with local seismic requirements

- Coordination: Check for conflicts with other building systems

- Access planning: Ensure adequate access for installation equipment

Material Preparation:

- Delivery scheduling: Coordinate delivery with installation sequence

- Storage requirements: Flat storage in clean, dry environment

- Handling equipment: Appropriate lifting and moving equipment

- Quality inspection: Verify materials meet specifications upon delivery

- Protection: Maintain protective packaging until installation

Installation Process:

Phase 1: Support System Installation

- Hanger installation: Install ceiling hangers at specified spacing

- Grid assembly: Assemble T-grid system level and square

- Bracing installation: Install lateral and compression bracing per code

- Utility coordination: Install electrical, HVAC, and other systems

- Quality verification: Check grid level, square, and load capacity

Phase 2: Panel Installation

- Starting point: Begin installation from predetermined corner or centerline

- Panel handling: Use appropriate lifting techniques for panel size and weight

- Sequential installation: Work systematically to maintain alignment

- Cutting and fitting: Field modifications using proper tools and techniques

- Quality control: Verify alignment, fit, and appearance throughout process

Phase 3: Final Adjustments

- Alignment verification: Check overall appearance and consistency

- Integration completion: Install light fixtures, diffusers, and other components

- Cleaning: Remove protective films and clean installation

- Documentation: Record installation details and any field modifications

- Final inspection: Verify compliance with specifications and codes

Handling and Safety Procedures:

Material Handling:

- Panel lifting: Use suction cups or magnetic lifters for large panels

- Team lifting: Minimum two people for panels over 1m²

- Edge protection: Protect panel edges during handling and installation

- Surface protection: Maintain protective films until final cleaning

- Weather protection: Protect materials from rain, snow, and extreme temperatures

Safety Requirements:

- Fall protection: Appropriate fall protection equipment for work at height

- Personal protective equipment: Safety glasses, gloves, hard hats

- Tool safety: Proper use of cutting tools and lifting equipment

- Electrical safety: Lockout/tagout procedures for electrical work

- Emergency procedures: Clear emergency access and communication plans

Installation Best Practices:

Grid SystemOptimization:

- Level installation: Grid level within ±3mm over any 3m span

- Square installation: Diagonals equal within ±6mm

- Proper bracing: Lateral bracing every 3.6m, compression struts as required

- Load distribution: Avoid point loads, distribute weight evenly

- Expansion accommodation: Allow for thermal movement in large installations

Panel Installation Techniques:

- Systematic approach: Work from one corner or center outward

- Consistent gaps: Maintain uniform gaps between panels (typically 3-6mm)

- Proper seating: Ensure panels fully seated in grid system

- Alignment checks: Verify alignment frequently during installation

- Field cutting: Use appropriate tools (shears, plasma, laser) for clean cuts

Quality Control Measures:

Installation Inspection Points:

- Grid installation: Level, square, bracing, load capacity

- Panel fit: Proper seating, consistent gaps, alignment

- Surface quality: No damage, scratches, or contamination

- System integration: Proper coordination with lights, HVAC, etc.

- Safety compliance: Fall protection, electrical safety, code compliance

Performance Verification:

- Visual inspection: Overall appearance and consistency

- Functional testing: Access panels, removable features

- Integration testing: Lighting, HVAC, and other systems

- Documentation: Installation records, warranties, maintenance information

- Training: Facility staff training on system operation and maintenance

Common Installation Challenges:

Dimensional Issues:

- Out-of-square conditions: Building not square affects panel layout

- Level variations: Uneven structure requires grid adjustments

- Interference: Conflicts with other building systems

- Solutions: Careful field measurement, adjustable systems, coordination

Material Challenges:

- Panel warping: Improper storage or handling causes distortion

- Finish damage: Scratches or contamination during installation

- Size variations: Manufacturing tolerances affect fit

- Solutions: Proper handling, quality control, field adjustment capability

System Integration:

- Lighting coordination: Fixture locations don't align with panel layout

- HVAC conflicts: Ductwork interferes with ceiling installation

- Electrical issues: Wiring and junction boxes require panel modifications

- Solutions: Early coordination, flexible systems, skilled field work

Specialized Installation Considerations:

Large Panel Installation:

- Lifting equipment: Crane or hoist required for panels over 2.4m

- Support requirements: Temporary support during installation

- Alignment challenges: Maintaining alignment over large areas

- Safety considerations: Additional fall protection and lifting safety

Industrial Environment Installation:

- Contamination control: Protect materials from industrial processes

- Access limitations: Work around operating equipment and processes

- Safety requirements: Additional safety protocols for industrial environments

- Schedule coordination: Work around production schedules

Retrofit Installation:

- Existing system removal: Safe removal of old ceiling systems

- Structural assessment: Verify existing structure adequate for new loads

- Utility coordination: Work around existing building systems

- Occupied building: Minimize disruption to building occupants

Post-Installation Requirements:

System Commissioning:

- Performance testing: Verify acoustic and airflow performance

- Integration testing: Test all integrated building systems

- Safety inspection: Final safety and code compliance verification

- Documentation: Complete installation records and warranties

Maintenance Planning:

- Access procedures: Document access methods for future maintenance

- Cleaning procedures: Establish appropriate cleaning protocols

- Spare parts: Provide spare panels for future repairs

- Training: Train facility staff on system maintenance and operation

Warranty and Support:

- Installation warranty: Typically 1-2 years on installation workmanship

- Material warranty: 10-25 years depending on material and finish

- Support services: Ongoing technical support and maintenance assistance

- Documentation: Complete system documentation and operating manuals

How Do Expanded Mesh Ceiling Plates Perform in Terms of Acoustics and How Can Performance Be Enhanced?

Expanded mesh ceiling plates provide moderate acoustic performance that can be significantly enhanced through proper design and integration with acoustic backing materials:

Basic Acoustic Performance:

Inherent Acoustic Properties:

- Sound reflection: Expanded mesh reflects most sound energy (85-95%)

- Sound transmission: High sound transmission through large openings

- Sound absorption: Minimal absorption without backing (NRC 0.05-0.15)

- Sound diffusion: Irregular mesh pattern provides some sound scattering

- Frequency response: Minimal effect across all frequency ranges without backing

Mesh Pattern Impact on Acoustics:

- Fine mesh (XS-13): Slightly better acoustic performance, NRC 0.10-0.15

- Medium mesh (M-25): Moderate performance, NRC 0.08-0.12

- Coarse mesh (XXL-50): Minimal acoustic effect, NRC 0.05-0.08

- Strand width: Wider strands provide slightly more sound reflection

- Open area: Higher open area reduces acoustic performance

Enhanced Acoustic Performance with Backing:

Acoustic Backing Material Options:

Polyester Fiber Backing:

- Thickness options: 15mm, 25mm, 40mm, 50mm

- Density range: 60-120 kg/m³

- NRC performance: 0.45-0.85 depending on thickness

- Fire rating: Class A or Class 1 depending on treatment

- Advantages: Lightweight, easy installation, good performance

- Applications: Commercial offices, retail spaces, educational facilities

Mineral Wool Backing:

- Thickness options: 25mm, 50mm, 75mm, 100mm

- Density range: 80-150 kg/m³

- NRC performance: 0.60-0.95 depending on thickness

- Fire rating: Class A non-combustible

- Advantages: Excellent fire safety, superior acoustic performance

- Applications: Healthcare, industrial, high-performance requirements

Melamine Foam Backing:

- Thickness options: 20mm, 30mm, 50mm

- Density range: 8-12 kg/m³

- NRC performance: 0.70-0.90 depending on thickness

- Fire rating: Class B or better depending on formulation

- Advantages: Excellent acoustic performance, lightweight

- Applications: Recording studios, conference rooms, critical listening spaces

Frequency-Specific Performance:

Low Frequency (125-250 Hz):

- Challenge: Expanded mesh provides minimal low-frequency absorption

- Solution: Thick backing materials (50-100mm) improve low-frequency performance

- Applications: Spaces with machinery noise, HVAC noise, traffic noise

- Performance: Can achieve 0.20-0.70 absorption with proper backing

Mid Frequency (500-1000 Hz):

- Performance: Best performance range for expanded mesh systems

- Optimization: 25-50mm backing provides excellent performance

- Applications: Speech frequency range, office environments

- Achievement: NRC 0.60-0.90 readily achievable

High Frequency (2000-4000 Hz):

- Natural performance: Mesh provides some high-frequency absorption

- Enhancement: Backing materials optimize high-frequency performance

- Applications: Computer noise, air handling noise, electronic equipment

- Performance: Excellent absorption (0.75-0.95) with minimal backing

Application-Specific Acoustic Design:

Open Office Environments:

- Target NRC: 0.65-0.80 for good speech privacy and comfort

- Recommended system: M-25 mesh + 50mm mineral wool backing

- Performance: NRC 0.75, excellent speech frequency absorption

- Benefits: Reduces background noise, improves speech intelligibility

- Integration: Works with sound masking systems for enhanced privacy

Industrial Facilities:

- Target NRC: 0.70-0.85 for noise control in high-noise environments

- Recommended system: L-32 mesh + 75mm mineral wool backing

- Performance: NRC 0.80, good broad-spectrum noise reduction

- Benefits: Reduces reverberation, improves communication safety

- Durability: Industrial-grade backing materials for harsh environments

Educational Facilities:

- Target NRC: 0.70-0.85 for optimal learning environments

- Recommended system: S-20 mesh + 50mm polyester backing

- Performance: NRC 0.75, excellent speech clarity

- Benefits: Reduces classroom noise, improves student concentration

- Safety: Class A fire-rated materials for life safety compliance

Healthcare Facilities:

- Target NRC: 0.75-0.90 for patient comfort and privacy

- Recommended system: XS-13 mesh + 75mm mineral wool backing

- Performance: NRC 0.85, superior noise control

- Benefits: Reduces stress, improves healing environment

- Hygiene: Easy-clean surfaces, antimicrobial treatments available

Acoustic Enhancement Strategies:

System Design Optimization:

- Mesh selection: Smaller openings provide slightly better acoustic performance

- Backing thickness: Thicker backing improves low-frequency absorption

- Backing density: Higher density improves performance but adds weight

- Air gap: Space between mesh and backing can enhance performance

- Perimeter sealing: Seal edges to prevent acoustic leaks

Integration with Other Acoustic Treatments:

- Wall treatments: Coordinate ceiling and wall acoustic treatments

- Floor treatments: Carpet and other floor treatments complement ceiling systems

- Sound masking: Electronic sound masking enhances speech privacy

- Space planning: Acoustic zoning and furniture placement optimization

- HVAC noise control: Coordinate with mechanical system noise control

Performance Measurement and Verification:

Testing Methods:

- Reverberation room testing: Laboratory measurement per ASTM C423

- Impedance tube testing: Small sample testing per ASTM E1050

- Field testing: In-situ measurement per ASTM E2235

- Computer modeling: Acoustic simulation software for design optimization

- Mock-up testing: Full-scale testing for critical applications

Performance Monitoring:

- Baseline measurement: Initial acoustic performance documentation

- Periodic assessment: Regular monitoring for performance degradation

- Problem identification: Identify acoustic issues early

- Maintenance impact: Monitor effect of cleaning and maintenance on performance

- Upgrade planning: Plan for acoustic improvements as needs change

Limitations and Considerations:

Acoustic Limitations:

- Low-frequency performance: Limited low-frequency absorption without thick backing

- Sound transmission: High sound transmission through large openings

- Privacy limitations: May not provide adequate speech privacy in sensitive areas

- Flanking paths: Sound transmission through adjacent spaces and structures

- Background noise: May require additional noise control measures

Design Considerations:

- Backing support: Adequate support required for backing materials

- Fire rating: Ensure backing materials maintain required fire ratings

- Moisture resistance: Consider humidity effects on backing materials

- Maintenance access: Balance acoustic performance with access requirements

- Cost optimization: Balance acoustic performance with budget constraints

Acoustic Design Best Practices:

- Early planning: Include acoustic requirements in initial design

- Professional consultation: Engage acoustic consultants for critical applications

- Integrated approach: Consider all acoustic treatments together

- Performance verification: Test actual performance vs. design predictions

- Maintenance planning: Establish procedures to maintain acoustic performance

What Are the Maintenance Requirements and Lifecycle Considerations for Expanded Mesh Ceiling Plates?

Expanded mesh ceiling plates require minimal maintenance while providing excellent long-term performance and value when properly specified and installed:

Routine Maintenance Requirements:

Daily/Weekly Inspection:

- Visual assessment: Check for damaged, displaced, or heavily soiled panels

- System integration: Verify proper operation of integrated lighting and HVAC systems

- Safety inspection: Ensure all panels properly secured with no loose components

- Access verification: Confirm access panels and removable sections function properly

- Documentation: Record any issues or changes for maintenance trending

Monthly Maintenance:

- Surface cleaning: Remove dust and light contamination from visible surfaces

- Perforation cleaning: Ensure mesh openings remain unobstructed for airflow

- Plenum inspection: Visual check of accessible plenum areas through mesh

- Integration check: Verify lighting, HVAC, and other systems operating properly

- Acoustic assessment: Monitor for changes in acoustic performance or complaints

Cleaning Procedures by Material and Environment:

Aluminum Mesh Panels:

- Standard environments: Mild detergent solution and soft brush or cloth

- Industrial environments: Degreasing agents appropriate for aluminum

- Coastal environments: Fresh water rinse to remove salt deposits

- Food service: Food-safe cleaning agents and sanitizers

- Frequency: Monthly in standard environments, weekly in harsh conditions

Steel Mesh Panels:

- Galvanized steel: Mild alkaline cleaners, avoid acidic solutions

- Painted steel: Gentle cleaners compatible with paint system

- Rust prevention: Regular inspection and touch-up of coating damage

- Industrial environments: Appropriate solvents for specific contaminants

- Frequency: Monthly inspection, cleaning as needed based on environment

Stainless Steel Mesh Panels:

- Standard cleaning: Stainless steel cleaner following grain direction

- Healthcare environments: Hospital-grade disinfectants and sanitizers

- Food processing: Food-grade cleaning and sanitizing agents

- Chemical environments: Cleaners compatible with specific chemical exposures

- Frequency: Weekly in healthcare/food service, monthly in standard commercial

Environment-Specific Maintenance:

Industrial Environments:

- Contamination assessment: Regular evaluation of contamination type and level

- Deep cleaning: Periodic pressure washing or steam cleaning

- Coating inspection: Check for chemical attack or physical damage

- Safety protocols: Appropriate PPE and safety procedures for cleaning

- Downtime coordination: Schedule cleaning during production downtime

Healthcare Facilities:

- Infection control: Follow facility infection control protocols

- Disinfection procedures: Regular disinfection with approved agents

- Air quality monitoring: Ensure cleaning doesn't compromise air quality

- Documentation: Maintain cleaning logs for regulatory compliance

- Emergency cleaning: Procedures for contamination events

Food Service/Processing:

- Food safety compliance: Follow HACCP and FDA guidelines

- Sanitization: Regular sanitization with food-safe agents

- Pest control: Coordinate with pest management programs

- Allergen control: Prevent cross-contamination during cleaning

- Regulatory compliance: Maintain documentation for inspections

Transportation Hubs:

- High-traffic cleaning: More frequent cleaning due to high occupancy

- Security coordination: Cleaning procedures that don't compromise security

- Weather protection: Additional cleaning after severe weather events

- Vandalism repair: Procedures for repairing damage from vandalism

- Emergency access: Maintain emergency access during cleaning operations

Acoustic Backing Maintenance:

Polyester Fiber Backing:

- Dust removal: Regular vacuuming to prevent dust accumulation

- Moisture monitoring: Check for water infiltration that could cause mold

- Compression assessment: Verify backing maintains original thickness

- Fire safety: Inspect for damage that could affect fire rating

- Replacement indicators: Replace if compressed >25% or contaminated

Mineral Wool Backing:

- Inspection access: Periodic removal of panels for backing inspection

- Moisture damage: Check for water damage, mold, or deterioration

- Settling assessment: Monitor for settling or compression over time

- Handling safety: Use appropriate PPE when handling mineral wool

- Replacement criteria: Replace if damaged, contaminated, or compressed

Foam Backing:

- Degradation monitoring: Check for crumbling, discoloration, or odors

- Chemical compatibility: Ensure cleaning agents don't attack foam

- UV protection: Protect from UV exposure that can degrade foam

- Moisture sensitivity: Monitor for water damage in humid environments

- Replacement frequency: Typically 8-12 years depending on environment

Preventive Maintenance Schedule:

Monthly Tasks:

- Visual inspection of all accessible panels and systems

- Routine cleaning of high-traffic and high-contamination areas

- HVAC filter maintenance to reduce dust loading on ceiling

- Performance monitoring for acoustic or airflow changes

- Documentation of maintenance activities and findings

Quarterly Tasks:

- Comprehensive cleaning of entire ceiling system

- Detailed inspection including sample panel removal for plenum access

- Backing material assessment for compression, moisture, or contamination

- Integration testing of lighting, HVAC, and other building systems

- Performance measurement if acoustic or airflow performance critical

Annual Tasks:

- Professional assessment by qualified technicians or consultants

- Comprehensive system evaluation including structural and seismic components

- Backing material replacement planning and budgeting

- Warranty compliance documentation and required maintenance

- Lifecycle planning for system upgrades or replacement

Problem Diagnosis and Solutions:

Performance Degradation:

- Symptoms: Reduced airflow, increased noise, poor acoustic performance

- Causes: Clogged mesh, compressed backing, system modifications

- Diagnosis: Airflow measurement, acoustic testing, visual inspection

- Solutions: Cleaning, backing replacement, system adjustment

- Prevention: Regular maintenance, proper HVAC filtration, usage monitoring

Physical Damage:

- Symptoms: Dents, holes, corrosion, coating failure, panel displacement

- Causes: Impact damage, environmental exposure, improper maintenance

- Diagnosis: Visual inspection, structural assessment, material testing

- Solutions: Panel replacement, refinishing, protective measures

- Prevention: Impact protection, proper material selection, environmental control

Integration Issues:

- Symptoms: HVAC problems, lighting failures, access difficulties

- Causes: System modifications, component failures, maintenance neglect

- Diagnosis: System testing, component inspection, performance measurement

- Solutions: Component replacement, system rebalancing, access improvement

- Prevention: Regular testing, controlled modifications, proper maintenance

Lifecycle Considerations:

Expected Service Life:

- Aluminum panels: 25-40 years depending on environment and maintenance

- Steel panels: 20-30 years with proper coating maintenance

- Stainless steel panels: 40+ years in most environments

- Backing materials: 8-20 years depending on type and environment

- Suspension systems: 20-30 years with proper maintenance

Lifecycle Cost Analysis:

- Initial cost: Material, installation, and integration costs

- Operating costs: Energy savings from improved HVAC efficiency

- Maintenance costs: Regular cleaning, inspection, and component replacement

- Replacement costs: Periodic backing replacement, eventual system replacement

- End-of-life value: Scrap value of recyclable materials

Performance Evolution:

- Acoustic performance: Gradual degradation as backing materials age

- Airflow performance: Generally stable unless mesh becomes clogged

- Aesthetic appearance: Gradual dulling or staining depending on environment

- Structural performance: Stable throughout service life with proper maintenance

- Integration performance: May require updates as building systems evolve

Upgrade and Modernization:

Technology Integration:

- LED lighting: Retrofit LED systems for energy efficiency

- Smart building systems: Integrate sensors and controls

- Wireless infrastructure: Add wireless access points and antennas

- Security systems: Integrate security devices and monitoring

- Energy management: Add building automation and energy monitoring

Performance Enhancement:

- Acoustic improvements: Upgrade backing materials for better performance

- Airflow optimization: Modify patterns or add ventilation features

- Aesthetic updates: Refinish or replace panels for updated appearance

- Accessibility improvements: Add or relocate access panels

- Safety upgrades: Update fire protection or emergency systems

Sustainability Considerations:

Environmental Impact:

- Material selection: Choose materials with high recycled content

- Energy efficiency: Systems that reduce building energy consumption

- Recyclability: Plan for end-of-life material recovery

- Transportation: Local sourcing to reduce transportation impacts

- Manufacturing: Choose suppliers with sustainable manufacturing practices

End-of-Life Planning:

- Material recovery: Plan for recycling of metal components

- Disposal requirements: Proper disposal of backing materials

- Deconstruction: Design for easy disassembly and material separation

- Reuse potential: Consider reuse of components in other applications

- Documentation: Maintain records for future material recovery

Maintenance Cost Optimization:

Preventive Maintenance Benefits:

- Cost reduction: Preventive maintenance costs 20-30% of reactive maintenance

- Performance maintenance: Regular maintenance maintains design performance

- Extended life: Proper maintenance extends system life by 25-50%

- Energy savings: Well-maintained systems operate more efficiently

- Problem prevention: Early detection prevents major system failures

Maintenance Best Practices:

- Staff training: Train maintenance staff on proper procedures and safety

- Documentation systems: Maintain comprehensive maintenance records

- Spare parts inventory: Stock critical spare parts for quick repairs

- Vendor relationships: Maintain relationships with qualified service providers

- Performance monitoring: Track system performance over time for optimization