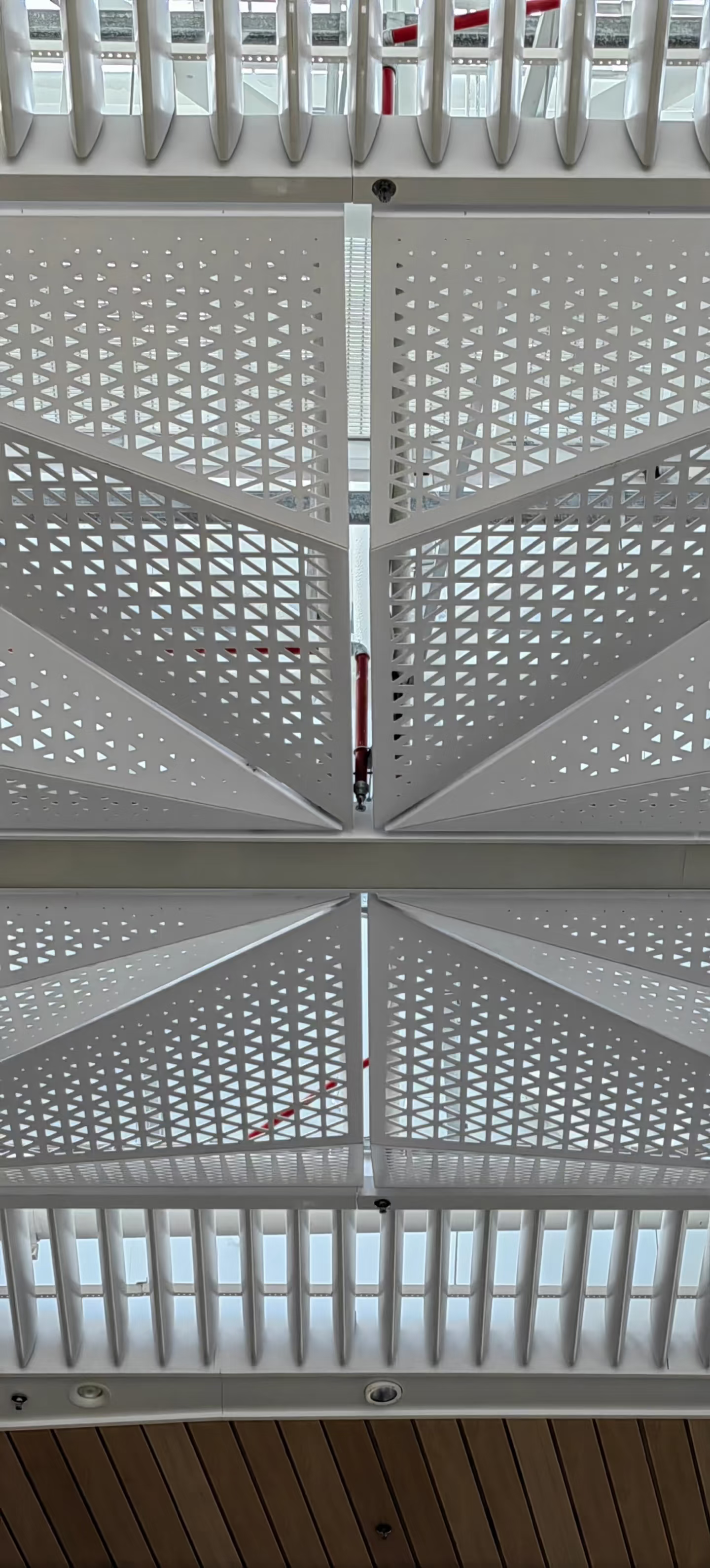

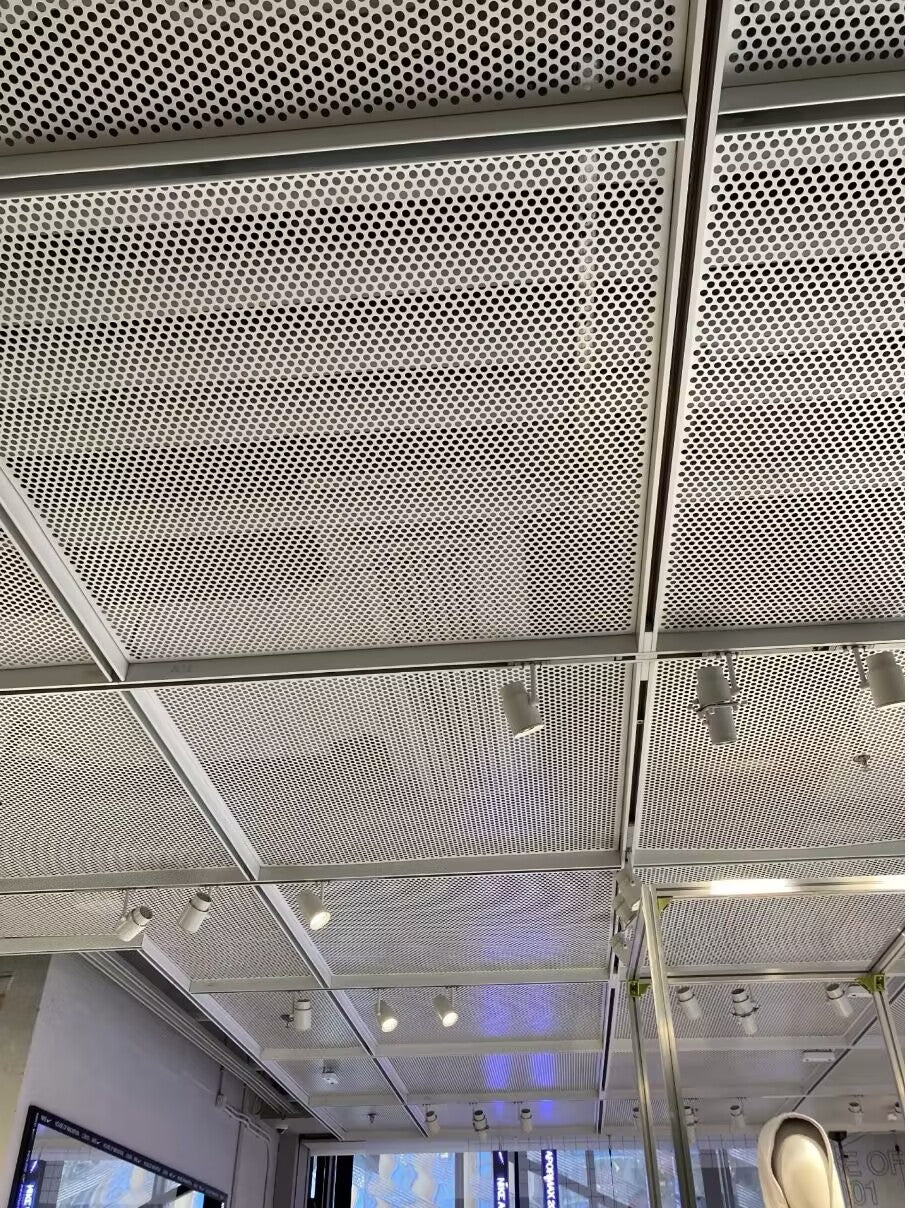

Perforated Metal Ceiling Panel

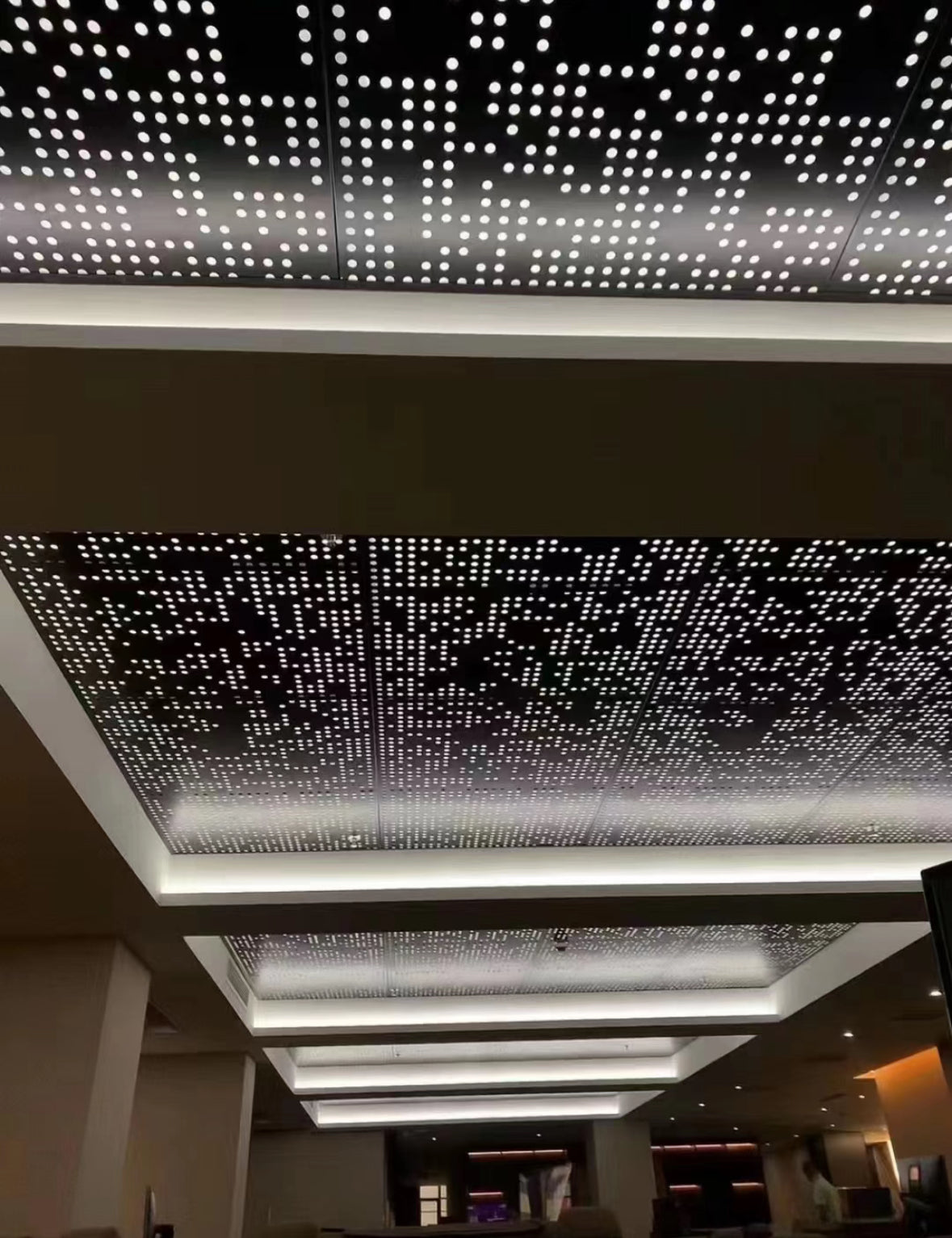

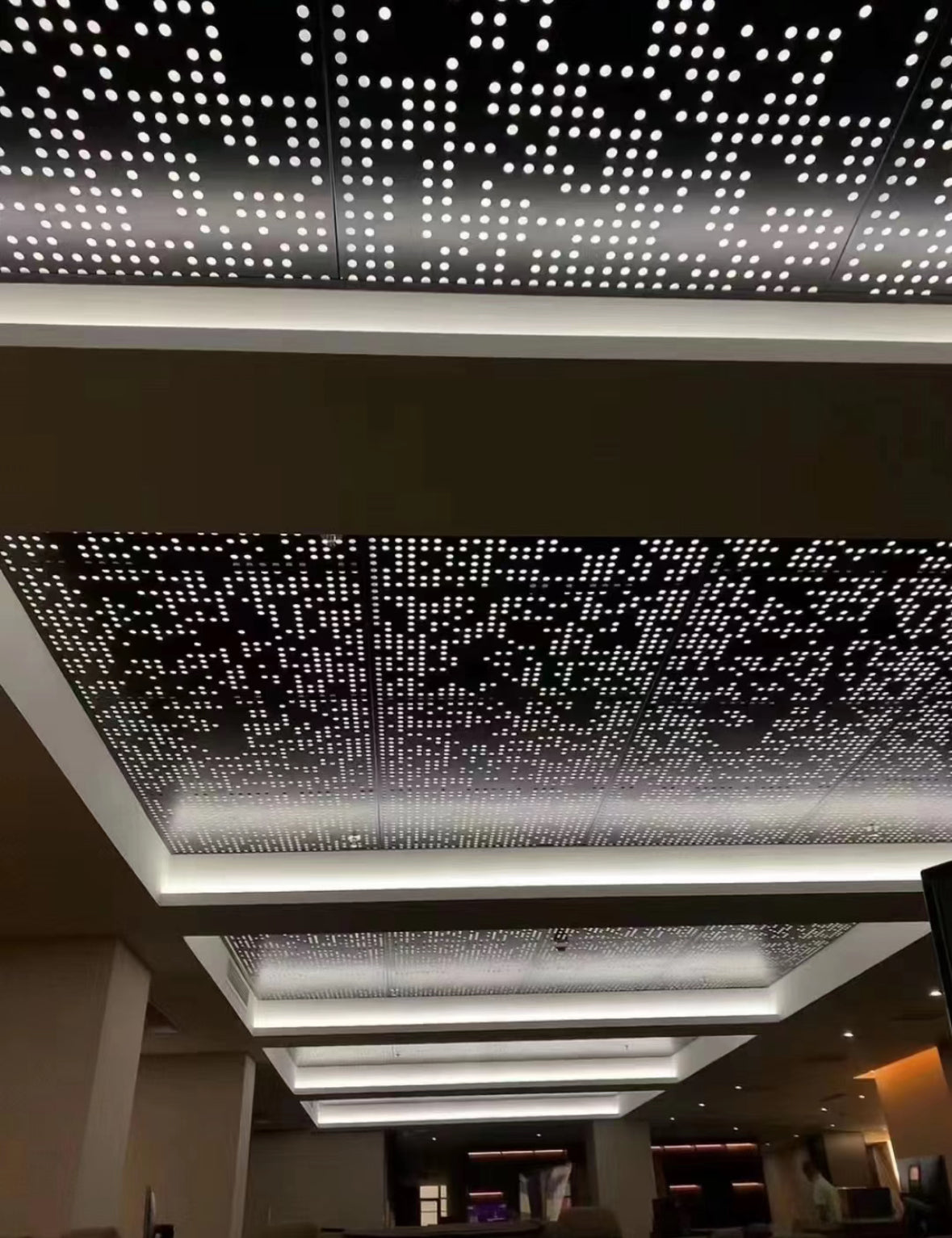

High-performance perforated metal ceiling panels engineered to deliver exceptional acoustic control, aesthetic versatility, and functional performance for modern commercial, institutional, and industrial applications. These precision-manufactured panels combine superior sound absorption, excellent ventilation properties, and contemporary design flexibility to create optimal interior environments.

Perforated metal ceilings are the premier choice for interiors requiring a synthesis of high-performance acoustics, modern aesthetics, and seamless service integration.

- Acoustic & Performance Spaces: Ideal for auditoriums, theaters, and conference rooms to control reverberation and enhance sound clarity, often paired with acoustic backing.

- Transportation & Public Venues: Widely used in airports, train stations, and shopping malls to manage ambient noise and create a clean, modern look while integrating services like lighting and sprinklers.

- Corporate & Educational Environments: Enhances speech intelligibility in open-plan offices, classrooms, and libraries, creating a more focused and productive atmosphere.

- Clean & Architectural Ceilings: Provides a durable, hygienic, and monolithic ceiling solution for healthcare facilities, laboratories, and kitchens where cleanliness and performance are key.

Superior Acoustic Performance

Engineered with various perforation patterns to work with acoustic backing, achieving high Noise Reduction Coefficients (NRC) for excellent sound absorption, reduced echo, and enhanced speech clarity.

Sleek Design & Service Integration

Offers a clean, monolithic appearance with a variety of perforation patterns and colors. Seamlessly integrates lighting, sprinklers, and HVAC elements for a cohesive and uncluttered ceiling plane.

Durable & Easy to Maintain

Constructed from durable metal, these panels are non-combustible, sag-resistant, and easy to clean. They offer a long-lasting, low-maintenance solution for high-traffic commercial interiors.

| Material | Alloy/Grade | Properties | Best Applications |

|---|---|---|---|

| Aluminum | 3003-H14, 5005-H34 | Lightweight, corrosion resistant, excellent formability | Standard commercial, coastal areas |

| Steel | Cold-rolled, galvanized | High strength, cost-effective, magnetic properties | Industrial, heavy-duty applications |

| Stainless Steel | 304, 316 | Maximum corrosion resistance, hygienic, premium appearance | Healthcare, food service, harsh environments |

| Copper | C110, C101 | Antimicrobial, premium aesthetics, natural patina | Healthcare, high-end commercial, historic renovation |

| Thickness | Aluminum Weight | Steel Weight | Typical Applications | Max Panel Size |

|---|---|---|---|---|

| 0.7mm | 1.9 kg/m² | 5.5 kg/m² | Light commercial, residential | 600×600mm |

| 0.8mm | 2.2 kg/m² | 6.3 kg/m² | Standard commercial | 600×1200mm |

| 1.0mm | 2.7 kg/m² | 7.9 kg/m² | Heavy-duty commercial | 600×1500mm |

| 1.2mm | 3.2 kg/m² | 9.4 kg/m² | Industrial applications | 1200×2400mm |

| 1.5mm | 4.1 kg/m² | 11.8 kg/m² | Maximum strength | 1200×3000mm |

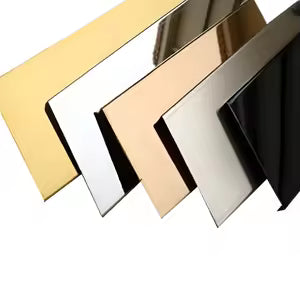

| Material | Finish Type | Details |

|---|---|---|

| Aluminum | Mill Finish | Natural aluminum oxide, economical |

| Anodized | Clear, bronze, black (15-25μm thickness) | |

| Powder Coated | Unlimited colors, 60-80μm thickness | |

| PVDF Coated | Premium durability, 25-30μm thickness | |

| Steel | Galvanized | Natural zinc coating, industrial appearance |

| Powder Coated | Color options over galvanized base | |

| Painted | Baked enamel finishes, standard colors | |

| Specialty | Textured, metallic, custom color matching | |

| Stainless Steel | 2B Mill | Standard mill finish, moderate reflectivity |

| #4 Brushed | Directional grain, architectural standard | |

| #8 Mirror | High-gloss polished finish |

| Material | Tensile Strength | Yield Strength | Elongation | Hardness | Test Standard |

|---|---|---|---|---|---|

| Aluminum 3003-H14 | 145-185 MPa | 125-165 MPa | 8-16% | 40-50 HB | ASTM B557 |

| Aluminum 5005-H34 | 160-200 MPa | 140-180 MPa | 6-10% | 50-60 HB | ASTM B557 |

| Steel CQ | 270-370 MPa | 140-280 MPa | 20-25% | 70-90 HRB | ASTM A370 |

| Stainless 304 | 515-620 MPa | 205-310 MPa | 40-50% | 92 HRB max | ASTM A240 |

| Property | Aluminum | Steel | Stainless Steel | Units | Test Standard |

|---|---|---|---|---|---|

| Density | 2.70-2.73 | 7.85 | 8.0 | g/cm³ | ASTM B311/A484 |

| Melting Point | 660 | 1510 | 1400-1450 | °C | - |

| Thermal Conductivity | 237 | 50 | 16.3 | W/m·K | ASTM E1461 |

| Thermal Expansion | 23.6×10⁻⁶ | 12×10⁻⁶ | 17.3×10⁻⁶ | /°C | ASTM E228 |

| Electrical Conductivity | 37.7 | 10.4 | 1.4 | MS/m | ASTM B193 |

| Hole Type | Diameter/Size | Pitch | Open Area | Acoustic Performance | Airflow |

|---|---|---|---|---|---|

| Round 3mm | 3.0mm | 6mm | 19.6% | NRC 0.25-0.35 | Low |

| Round 6mm | 6.0mm | 10mm | 28.3% | NRC 0.45-0.55 | Moderate |

| Round 10mm | 10.0mm | 15mm | 34.9% | NRC 0.65-0.75 | Good |

| Round 15mm | 15.0mm | 20mm | 44.2% | NRC 0.75-0.85 | High |

| Square 5mm | 5×5mm | 8mm | 39.1% | NRC 0.55-0.65 | Moderate |

| Slot 2×20mm | 2×20mm | 6mm pitch | 33.3% | NRC 0.60-0.70 | Directional |

| Configuration | 125 Hz | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 4000 Hz | NRC |

|---|---|---|---|---|---|---|---|

| No Backing | 0.05 | 0.10 | 0.15 | 0.20 | 0.25 | 0.30 | 0.15 |

| 25mm Fleece | 0.15 | 0.35 | 0.75 | 0.95 | 0.90 | 0.85 | 0.75 |

| 50mm Mineral Wool | 0.25 | 0.65 | 0.95 | 1.00 | 0.95 | 0.90 | 0.85 |

| 75mm Mineral Wool | 0.35 | 0.85 | 1.00 | 1.00 | 0.95 | 0.90 | 0.95 |

| Open Area % | Pressure Drop (Pa) | Air Velocity (m/s) | HVAC Efficiency | Applications |

|---|---|---|---|---|

| 15-25% | 15-25 | 2.0-3.0 | Good | Standard offices |

| 25-35% | 8-15 | 3.0-4.0 | Very Good | Open plan offices |

| 35-45% | 4-8 | 4.0-5.0 | Excellent | High-ventilation areas |

| 45-60% | 2-4 | 5.0-6.0 | Maximum | Industrial applications |

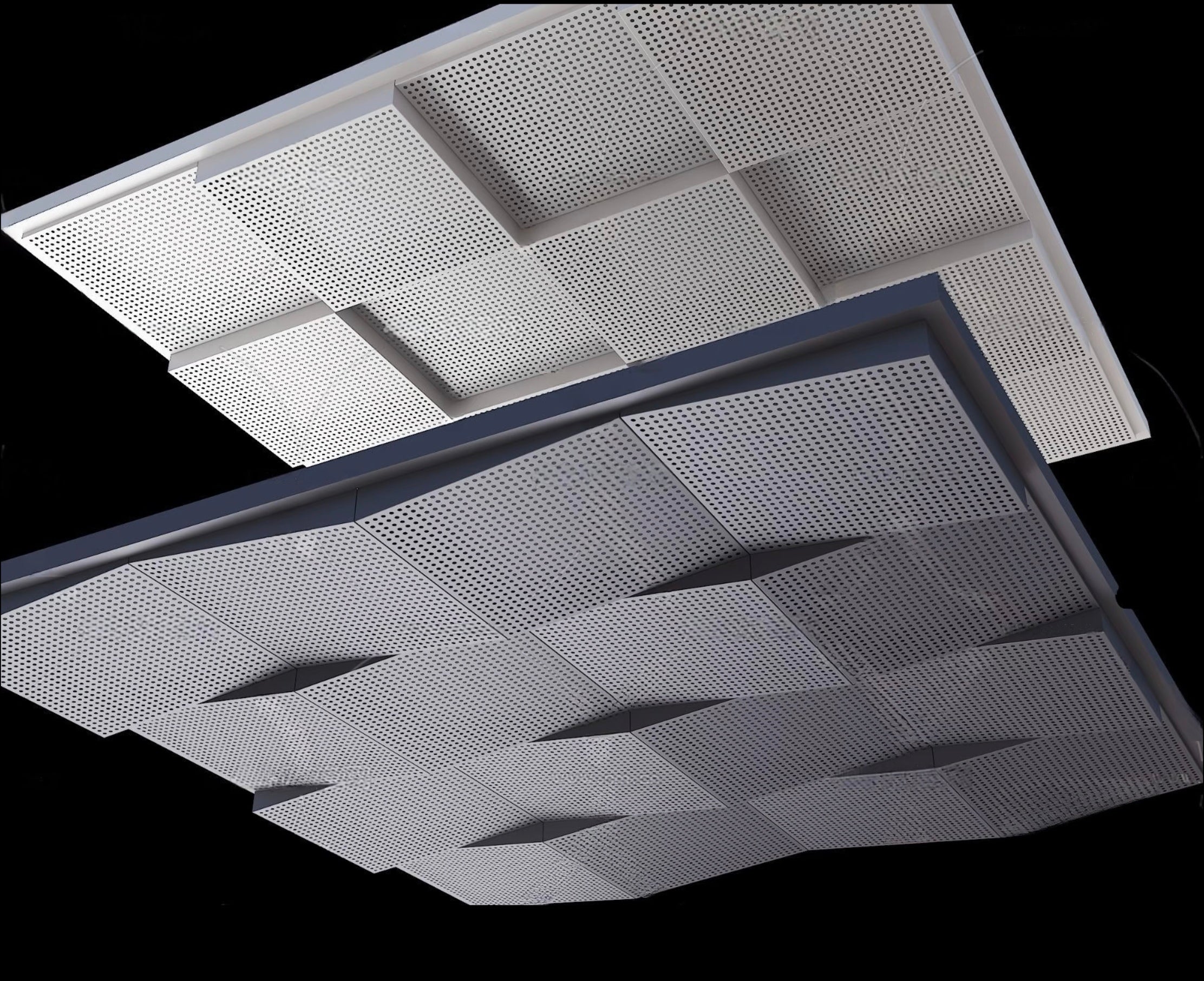

| Panel Size | Weight Range | Deflection | Support Spacing | Applications |

|---|---|---|---|---|

| 600×600mm | 0.7-2.8 kg | <L/300 | 600mm | Standard grid systems |

| 600×1200mm | 1.4-5.7 kg | <L/300 | 600mm | Rectangular layouts |

| 1200×1200mm | 2.8-11.3 kg | <L/300 | 1200mm | Large format |

| 1200×2400mm | 5.7-22.6 kg | <L/300 | 1200mm | Continuous appearance |

| Custom Sizes | Variable | Calculated | Variable | Architectural features |

| Property | Performance | Test Standard |

|---|---|---|

| Fire Rating | Class A Non-combustible | ASTM E84 |

| Flame Spread | 0-5 (Excellent) | ASTM E84 |

| Smoke Development | 0-10 (Excellent) | ASTM E84 |

| Humidity Resistance | Excellent | ASTM D2247 |

| Temperature Range | -40°C to +150°C | Service conditions |

| UV Resistance | Excellent (coated) | ASTM G154 |

| Corrosion Resistance | Excellent | ASTM B117 |

| Grid Type | Panel Sizes | Load Capacity | Seismic Rating | Applications |

|---|---|---|---|---|

| 15mm T-Grid | 600×600, 600×1200 | 7.2 kg/m² | Zone 1-4 | Standard commercial |

| 24mm T-Grid | All standard sizes | 14.4 kg/m² | Zone 1-4 | Heavy-duty applications |

| Concealed Grid | Custom sizes | Variable | Zone 1-4 | Premium installations |

| Direct Mount | Any size | Structural | Zone 1-4 | Industrial applications |

FAQs

What Are the Key Benefits of Perforated Metal Ceiling Panels?

Perforated metal ceiling panels offer exceptional versatility and performance that make them ideal for modern commercial and institutional applications requiring acoustic control, aesthetic appeal, and functional integration:

Acoustic Performance Advantages:

Superior Sound Control:

- Customizable absorption - NRC values from 0.15 to 0.95 depending on backing material

- Frequency-specific control - different perforation patterns target specific sound frequencies

- Reverberation reduction - significantly improves speech intelligibility and comfort

- Noise reduction - reduces ambient noise levels by 3-8 dB depending on configuration

- Echo elimination - prevents sound reflections in large spaces

Acoustic Design Flexibility:

- Variable absorption zones - different areas can have different acoustic properties

- Directional control - slot patterns provide directional sound absorption

- Integration capability - works with other acoustic treatments for optimal performance

- Tunable performance - backing materials can be changed to adjust acoustic properties

- Speech privacy - reduces sound transmission between adjacent spaces

Functional Performance Benefits:

HVAC Integration:

- Air circulation - perforations allow natural air movement and HVAC efficiency

- Plenum access - easy access to mechanical systems above ceiling

- Pressure equalization - prevents pressure buildup in ceiling plenum

- Energy efficiency - reduces HVAC load through improved air distribution

- Temperature control - helps maintain uniform temperature distribution

Lighting Integration:

- Even light distribution - perforations allow light to pass through naturally

- Reduced glare - diffuses harsh lighting for improved visual comfort

- LED compatibility - works excellently with modern LED lighting systems

- Fixture integration - seamless incorporation of light fixtures

- Energy savings - can reduce lighting requirements through light transmission

Maintenance and Accessibility:

- Easy access - removable panels provide full access to plenum space

- Simple cleaning - smooth surfaces easy to clean and maintain

- Individual replacement - damaged panels can be replaced without system disruption

- System flexibility - easy to modify or relocate services above ceiling

- Long service life - 25-40 years typical with minimal maintenance

Design and Aesthetic Advantages:

Visual Appeal:

- Modern appearance - clean, contemporary look enhances any interior

- Pattern variety - extensive perforation options for unique designs

- Finish options - multiple colors and textures available

- Light play - creates interesting shadow and light patterns

- Architectural integration - complements modern building design

Design Flexibility:

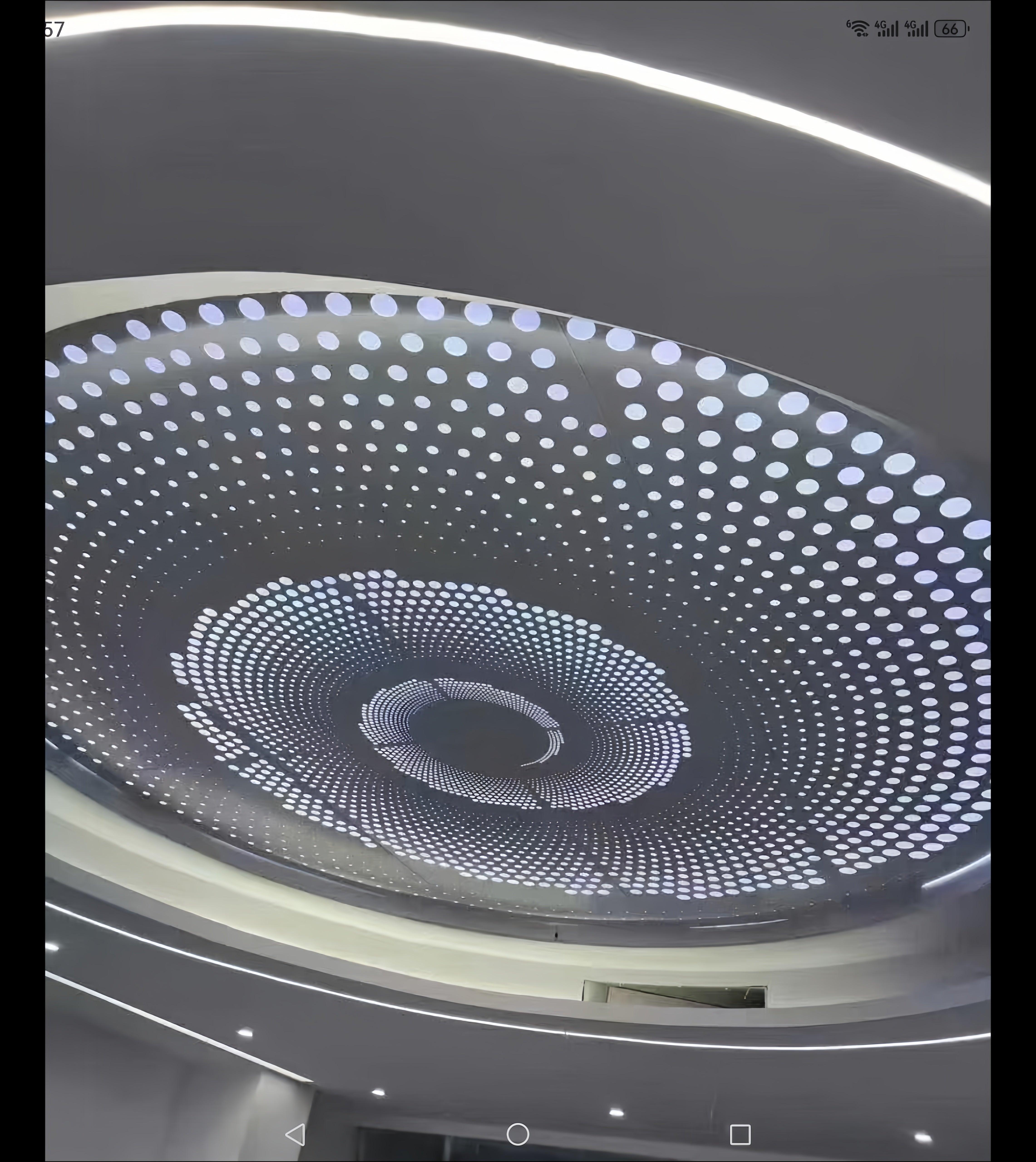

- Custom patterns - logos, geometric designs, artistic patterns possible

- Size variety - from small tiles to large format panels

- Color coordination - unlimited color options to match interior design

- Texture options - smooth, textured, or patterned surfaces available

- Integration capability - works with various architectural styles

Durability and Performance:

Material Advantages:

- Corrosion resistance - aluminum and stainless steel options for harsh environments

- Fire safety - Class A non-combustible rating for life safety

- Structural integrity - maintains strength and appearance over time

- Weather resistance - suitable for semi-exterior applications

- Chemical resistance - withstands cleaning agents and environmental exposure

Economic Benefits:

- Lifecycle value - low maintenance and long service life reduce total cost

- Energy efficiency - HVAC and lighting benefits reduce operating costs

- Installation efficiency - standard grid systems reduce installation time

- Flexibility - easy to modify or expand systems as needs change

- Property value - enhances building value and marketability

Environmental Advantages:

- Recyclable materials - aluminum and steel are infinitely recyclable

- Sustainable manufacturing - high recycled content available

- Energy efficiency - contributes to building energy performance

- Indoor air quality - no off-gassing, GREENGUARD Gold certified options

- LEED credits - contributes to green building certification

How Do You Select the Right Perforation Pattern and Open Area for Specific Applications?

Selecting the optimal perforation pattern requires careful consideration of acoustic requirements, aesthetic goals, and functional needs:

Acoustic Performance Selection:

Low Acoustic Absorption (NRC 0.15-0.35):

- Perforation: Small holes (2-4mm), low open area (15-25%)

- Applications: Areas where sound reflection is desired

- Examples: Lobbies, atriums, spaces with high ceilings

- Benefits: Maintains lively acoustic environment, reduces over-absorption

- Backing: No backing or minimal backing material

Moderate Acoustic Absorption (NRC 0.45-0.65):

- Perforation: Medium holes (5-8mm), moderate open area (25-35%)

- Applications: General office spaces, retail environments

- Examples: Open offices, conference rooms, restaurants

- Benefits: Balanced acoustic environment, good speech clarity

- Backing: 15-25mm acoustic fleece or mineral wool

High Acoustic Absorption (NRC 0.75-0.95):

- Perforation: Large holes (10-20mm), high open area (35-50%)

- Applications: Noisy environments, critical listening spaces

- Examples: Call centers, auditoriums, music rooms, industrial areas

- Benefits: Maximum noise reduction, excellent speech privacy

- Backing: 50-75mm high-density mineral wool

Application-Specific Guidelines:

Corporate Offices:

- Open Plan Areas: 6-10mm holes, 30-40% open area, NRC 0.65-0.75

- Conference Rooms: 8-12mm holes, 35-45% open area, NRC 0.75-0.85

- Private Offices: 4-8mm holes, 25-35% open area, NRC 0.55-0.65

- Reception Areas: 3-6mm holes, 20-30% open area, NRC 0.45-0.55

Educational Facilities:

- Classrooms: 8-12mm holes, 35-40% open area, NRC 0.75-0.85

- Libraries: 6-10mm holes, 30-35% open area, NRC 0.70-0.80

- Gymnasiums: 12-20mm holes, 40-50% open area, NRC 0.80-0.90

- Auditoriums: Variable perforation, 25-45% open area, NRC 0.60-0.85

Healthcare Facilities:

- Patient Rooms: 6-10mm holes, 30-35% open area, NRC 0.65-0.75

- Corridors: 4-8mm holes, 25-30% open area, NRC 0.55-0.65

- Waiting Areas: 8-12mm holes, 35-40% open area, NRC 0.70-0.80

- Treatment Rooms: 10-15mm holes, 35-45% open area, NRC 0.75-0.85

HVAC and Ventilation Considerations:

Standard Ventilation (2-3 air changes/hour):

- Open Area: 20-30%

- Perforation: 4-8mm holes or 2×15mm slots

- Pressure Drop: 10-20 Pa at 3 m/s air velocity

- Applications: Standard office environments

High Ventilation (4-6 air changes/hour):

- Open Area: 30-40%

- Perforation: 8-12mm holes or 3×20mm slots

- Pressure Drop: 5-12 Pa at 4 m/s air velocity

- Applications: Laboratories, clean rooms, industrial areas

Maximum Ventilation (6+ air changes/hour):

- Open Area: 40-50%

- Perforation: 12-20mm holes or 4×25mm slots

- Pressure Drop: 2-8 Pa at 5 m/s air velocity

- Applications: Manufacturing, chemical processing, high-heat areas

Aesthetic and Design Considerations:

Modern/Contemporary Aesthetics:

- Round holes: 6-12mm diameter, regular spacing

- Square holes: 5-10mm square, geometric patterns

- Linear slots: 2-4mm wide, 15-30mm long

- Open area: 25-40% for balanced appearance

Industrial/Utilitarian Aesthetics:

- Large round holes: 15-25mm diameter

- Heavy perforation: 40-60% open area

- Functional appearance: Emphasis on performance over aesthetics

- Durable finishes: Galvanized steel, mill finish aluminum

Decorative/Architectural Aesthetics:

- Custom patterns: Logos, geometric designs, artistic patterns. These custom designs are often realized as decorative metal screens, which serve as both functional and artistic focal points in a space.

- Variable perforation: Different zones with different patterns

- Specialty finishes: Colored, textured, or metallic finishes

- Lighting integration: Patterns designed to work with lighting

Selection Decision Matrix:

Step 1: Acoustic Requirements

- Measure existing noise levels and reverberation times

- Determine target NRC based on space function and comfort requirements

- Consider speech privacy needs and background noise masking

- Evaluate frequency-specific absorption requirements

Step 2: Functional Requirements

- HVAC integration - air flow requirements and pressure drop limits

- Lighting considerations - light transmission and glare control needs

- Access requirements - frequency of plenum access and maintenance

- Fire safety - smoke management and egress considerations

Step 3: Aesthetic Goals

- Design style - modern, traditional, industrial, decorative

- Visual impact - subtle integration vs. architectural feature

- Color coordination - matching or contrasting with interior design

- Pattern preferences - geometric, organic, custom designs

Step 4: Budget and Performance Balance

- Initial cost vs. performance requirements

- Lifecycle value considering maintenance and durability

- Installation complexity and associated labor costs

- Future flexibility for modifications or expansions

Common Selection Mistakes to Avoid:

- Over-absorption - too much acoustic absorption can make spaces feel dead

- Under-ventilation - insufficient open area restricts air flow

- Aesthetic over function - prioritizing appearance over performance

- Ignoring maintenance - difficult-to-clean patterns in high-soil areas

- Poor integration - not considering lighting and HVAC coordination

What Are the Installation Requirements and Best Practices for Perforated Metal Ceiling Panels?

Professional installation of perforated metal ceiling panels requires careful planning, proper equipment, and attention to detail to achieve optimal acoustic performance and aesthetic results:

Pre-Installation Planning:

Structural Assessment:

- Load calculations - verify structure can support panel weight plus suspension system

- Deflection limits - ensure structural deflection won't affect ceiling performance

- Seismic requirements - design for local seismic conditions and building codes

- Coordination with other building systems (HVAC, electrical, plumbing, fire protection)

- Access planning for installation equipment and material handling

Layout and Design:

- Grid layout - optimize panel arrangement for minimal cutting and waste

- Light fixture integration - coordinate panel layout with lighting design

- HVAC integration - plan for diffusers, returns, and access panels

- Acoustic zones - different areas may require different panel specifications

- Expansion joints - plan for thermal movement in large installations

Installation System Selection:

Suspended T-Grid Systems:

- 15mm T-Grid: Standard commercial applications, 7.2 kg/m² load capacity

- 24mm T-Grid: Heavy-duty applications, 14.4 kg/m² load capacity

- Seismic grid: Required in seismic zones, special bracing and connections

- Fire-rated grid: Required for fire-rated ceiling assemblies

- Concealed grid: Premium installations, panels appear to float

Direct Mount Systems:

- Clip systems: Panels attach directly to structure via clips

- Rail systems: Panels hang from wall-mounted or ceiling-mounted rails

- Frame systems: Panels mounted in structural frames

- Applications: Industrial facilities, areas without standard grid systems

Installation Process:

Step 1: Grid Installation

- Hanger installation - proper spacing and load capacity verification

- Grid assembly - level installation within ±3mm tolerance

- Bracing installation - lateral and compression bracing per code requirements

- Utility rough-in - electrical, HVAC, and other systems installed

- Inspection - verify grid meets specifications before panel installation

Step 2: Acoustic Backing Installation (if required)

- Material handling - prevent compression and damage during installation

- Proper fitting - backing material should fit snugly without compression

- Vapor barrier - install if required by design or local codes

- Fire stopping - seal penetrations per fire-rated assembly requirements

- Quality control - verify backing material meets specifications

Step 3: Panel Installation

- Material handling - use proper lifting techniques and protective equipment

- Sequential installation - work from one corner systematically

- Alignment verification - maintain consistent gaps and alignment

- Cutting and fitting - field modifications using proper tools and techniques

- Final adjustment - ensure all panels are properly seated and aligned

Critical Installation Factors:

Handling and Storage:

- Protective packaging - maintain factory protection until installation

- Flat storage - prevent warping and damage during storage

- Clean handling - avoid contamination and surface damage

- Proper lifting - use appropriate equipment for panel size and weight

- Weather protection - protect materials from moisture and temperature extremes

Acoustic Performance Optimization:

- Backing material integrity - prevent compression or gaps that reduce performance

- Plenum sealing - control air leakage that can affect acoustic performance

- Panel fit - proper fit prevents acoustic leaks around panel edges

- System integration - coordinate with other acoustic treatments

- Testing verification - post-installation acoustic testing if required

Quality Control Measures:

Installation Inspection:

- Grid alignment - verify level and square installation

- Panel fit - check for proper seating and consistent gaps

- Surface quality - inspect for damage, scratches, or contamination

- Acoustic backing - verify proper installation and integrity

- System integration - check lighting, HVAC, and other system coordination

Performance Verification:

- Acoustic testing - measure installed performance vs. design requirements

- Air flow testing - verify HVAC performance meets design intent

- Visual inspection - confirm aesthetic requirements are met

- Functional testing - verify access panels and removable features work properly

- Documentation - record installation details and any deviations from design

Common Installation Challenges:

Structural Issues:

- Inadequate support - structure may require reinforcement for panel weight

- Deflection problems - excessive structural movement affects ceiling performance

- Coordination conflicts - interference with other building systems

- Solutions: Structural analysis, reinforcement, careful coordination

Dimensional Challenges:

- Out-of-square conditions - building dimensions don't match drawings

- Level variations - floor or structure not level affects grid installation

- Field modifications - panels require cutting or modification for fit

- Solutions: Careful field measurement, adjustable systems, skilled fabrication

System Integration:

- HVAC conflicts - ductwork or equipment interferes with ceiling installation

- Lighting coordination - fixture locations don't align with panel layout

- Fire protection - sprinkler heads require panel modifications

- Solutions: Early coordination, flexible systems, field adjustment capability

Installation Best Practices:

Planning Phase:

- Detailed coordination drawings showing all systems and interfaces

- Material takeoffs with appropriate waste factors and field cutting allowances

- Installation sequence coordinated with other trades

- Quality control plan with inspection points and acceptance criteria

Installation Phase:

- Skilled installers with experience in perforated metal ceiling systems

- Proper tools and equipment for handling, cutting, and installation

- Clean work environment to prevent contamination and damage

- Regular quality checks throughout installation process

Completion Phase:

- Final cleaning and touch-up work

- System testing and performance verification

- Documentation of installation and warranty information

- Training for facility maintenance staff

Maintenance Access Considerations:

- Removable panels for access to plenum space and building systems

- Access panel locations coordinated with maintenance requirements

- Lifting equipment available for heavy panel removal and replacement

- Spare panels available for future maintenance and repairs

How Do You Maintain Perforated Metal Ceiling Panels for Optimal Performance?

Proper maintenance of perforated metal ceiling panels ensures long-term acoustic performance, aesthetic appeal, and system functionality while maximizing the return on investment:

Routine Maintenance Procedures:

Daily/Weekly Inspection:

- Visual assessment - check for damaged, displaced, or stained panels

- Acoustic performance - monitor for changes in sound quality or noise levels

- System integration - verify lighting, HVAC, and other integrated systems function properly

- Safety inspection - ensure all panels are properly secured and no loose components

- Documentation - record any issues or changes for trend analysis

Monthly Cleaning:

- Dust removal - vacuum or blow out accumulated dust from perforations

- Surface cleaning - wipe panels with appropriate cleaning solutions

- Perforation cleaning - ensure holes remain unobstructed for acoustic and airflow performance

- Grid system - clean suspension grid and check for corrosion or damage

- Plenum inspection - check accessible areas above ceiling for contamination

Cleaning Procedures by Material:

Aluminum Panels:

- Standard cleaning: Mild detergent and water solution

- Stubborn stains: Non-abrasive cleaners specifically designed for aluminum

- Anodized finishes: pH-neutral cleaners to preserve anodized coating

- Powder coated: Mild soap solution, avoid abrasive cleaners

- Frequency: Monthly for high-traffic areas, quarterly for standard areas

Steel Panels:

- Galvanized steel: Mild detergent, avoid acidic cleaners that attack zinc coating

- Painted steel: Gentle cleaners compatible with paint system

- Rust prevention: Regular inspection and touch-up of any coating damage

- Magnetic cleaning: Use magnetic tools carefully to avoid surface scratching

- Frequency: Monthly inspection, cleaning as needed

Stainless Steel Panels:

- Standard cleaning: Stainless steel cleaner following grain direction

- Disinfection: Hospital-grade disinfectants for healthcare applications

- Spot removal: Specialized stainless steel spot removers for stubborn stains

- Passivation: Periodic treatment to restore corrosion resistance

- Frequency: Weekly in healthcare, monthly in commercial applications

Acoustic Backing Maintenance:

Mineral Wool Backing:

- Inspection: Check for compression, moisture damage, or contamination

- Replacement criteria: Replace if compressed >25% or contaminated

- Handling: Use proper PPE when handling mineral wool materials

- Disposal: Follow local regulations for mineral wool disposal

- Performance: Monitor acoustic performance for degradation

Polyester Fleece Backing:

- Cleaning: Vacuum cleaning to remove accumulated dust

- Moisture protection: Ensure no water infiltration that could cause mold

- Compression check: Verify backing maintains original thickness

- Fire safety: Inspect for any damage that could affect fire rating

- Replacement: Typically 10-15 year service life

Foam Backing:

- Degradation monitoring: Check for crumbling, discoloration, or odors

- Moisture sensitivity: Foam particularly sensitive to water damage

- Chemical compatibility: Ensure cleaning agents don't attack foam

- Replacement frequency: 8-12 years depending on environment

- Disposal: Special disposal requirements for some foam types

Preventive Maintenance Schedule:

Monthly Tasks:

- Visual inspection of all accessible panels

- Cleaning of high-traffic and high-soil areas

- HVAC filter check - clogged filters increase dust accumulation

- Documentation of any issues or concerns

- Performance monitoring - acoustic and airflow measurements if required

Quarterly Tasks:

- Comprehensive cleaning of entire ceiling system

- Detailed inspection including removal of sample panels for plenum access

- Acoustic backing inspection for compression, moisture, or contamination

- Grid system inspection for corrosion, loose connections, or damage

- Performance testing if acoustic or airflow performance is critical

Annual Tasks:

- Professional assessment by qualified acoustic consultant if performance critical

- Comprehensive system evaluation including structural support and seismic bracing

- Backing material assessment for replacement needs

- Warranty compliance documentation and any required maintenance

- Budget planning for upcoming maintenance or replacement needs

Problem Diagnosis and Solutions:

Acoustic Performance Degradation:

- Symptoms: Increased noise levels, poor speech intelligibility, complaints

- Causes: Compressed backing, clogged perforations, panel displacement

- Solutions: Backing replacement, perforation cleaning, panel realignment

- Prevention: Regular inspection and cleaning, proper HVAC filtration

Panel Damage:

- Symptoms: Dents, scratches, holes, corrosion, staining

- Causes: Impact damage, improper cleaning, environmental exposure

- Solutions: Individual panel replacement, refinishing, protective measures

- Prevention: Impact protection, proper cleaning procedures, environmental control

System Integration Issues:

- Symptoms: HVAC performance problems, lighting issues, access difficulties

- Causes: Panel displacement, perforation blockage, system modifications

- Solutions: Panel adjustment, cleaning, system coordination

- Prevention: Regular inspection, controlled modifications, proper maintenance

Maintenance Cost Optimization:

Lifecycle Planning:

- Preventive maintenance costs 20-30% of reactive maintenance

- Regular cleaning extends panel life by 25-40%

- Early problem detection prevents major system failures

- Documentation enables trend analysis and predictive maintenance

- Training reduces maintenance costs and improves effectiveness

Maintenance Best Practices:

Staff Training:

- Proper cleaning techniques to avoid damage

- Safety procedures for working at height and with materials

- Problem recognition to identify issues early

- Documentation requirements for warranty and performance tracking

- Emergency procedures for system failures or safety issues

Equipment and Supplies:

- Appropriate cleaning materials for each panel type and finish

- Proper tools for panel removal and installation

- Safety equipment for working at height

- Testing equipment for acoustic and airflow measurement

- Spare panels for emergency replacement

Documentation Requirements:

- Maintenance logs with dates, procedures, and findings

- Performance data tracking acoustic and airflow performance over time

- Warranty information and compliance documentation

- Problem reports with causes and solutions

- Cost tracking for budget planning and lifecycle analysis

What Are the Design Considerations for Integrating Perforated Metal Ceiling Panels with Building Systems?

Successful integration of perforated metal ceiling panels requires careful coordination with all building systems to optimize performance, aesthetics, and functionality:

HVAC System Integration:

Air Distribution Design:

- Plenum design: Adequate space above ceiling for air distribution and mixing

- Pressure balancing: Perforated panels help equalize pressure across ceiling plenum

- Air velocity control: Panel open area affects air velocity through perforations

- Temperature stratification: Perforations help prevent temperature layering

- Energy efficiency: Proper integration reduces HVAC energy consumption by 10-15%

Diffuser and Return Integration:

- Diffuser placement: Coordinate with panel layout to maintain aesthetic continuity

- Return air: Perforated panels can serve as return air path, reducing ductwork

- Pressure drop calculations: Include panel resistance in HVAC system design

- Access requirements: Ensure adequate access for HVAC maintenance

- Noise control: Coordinate acoustic design with HVAC noise generation

Ventilation Performance:

- Natural ventilation: Perforations enhance natural air movement

- Mechanical ventilation: Reduced pressure drop improves fan efficiency

- Air quality: Enhanced air mixing improves indoor air quality

- Humidity control: Improved air circulation helps control humidity levels

- Contaminant removal: Better air mixing enhances contaminant dilution

Lighting System Integration:

Fixture Coordination:

- Layout planning: Coordinate panel grid with lighting layout for optimal aesthetics

- Fixture types: Recessed, surface-mounted, and pendant fixtures all compatible

- Access requirements: Plan for fixture installation and maintenance access

- Structural support: Ensure adequate support for lighting fixtures

- Emergency lighting: Coordinate with life safety lighting requirements

Light Distribution Optimization:

- Light transmission: Perforations allow light to pass through naturally

- Glare reduction: Panels help diffuse harsh lighting and reduce glare

- Uniformity: Perforated panels help create more uniform light distribution

- Energy savings: Improved light distribution can reduce lighting energy by 5-10%

- Color rendering: Panel finishes affect color appearance of lighting

LED Integration:

- Heat management: Perforations help dissipate LED heat to plenum space

- Driver placement: Plenum space accommodates LED drivers and controls

- Dimming compatibility: Coordinate panel layout with dimming zones

- Color temperature: Panel finishes affect perceived color temperature

- Maintenance access: Easy access for LED replacement and maintenance

Fire Protection System Integration:

Sprinkler System Coordination:

- Sprinkler placement: Coordinate head locations with panel layout

- Water distribution: Perforations may affect sprinkler spray patterns

- Access panels: Provide removable panels at sprinkler head locations

- Pipe routing: Plan sprinkler piping to avoid interference with panels

- Seismic bracing: Coordinate sprinkler and ceiling bracing systems

Smoke Management:

- Smoke exhaust: Perforations can assist in smoke removal strategies

- Compartmentalization: Plan panel layout to support smoke control zones

- Detection systems: Coordinate smoke detector placement with panel layout

- Emergency access: Ensure fire department access to plenum space

- Code compliance: Verify system meets local fire and building codes

Fire Rating Considerations:

- Assembly rating: Coordinate panel system with required fire rating

- Penetration sealing: Seal all penetrations per fire-rated assembly requirements

- Material specifications: Ensure all components meet fire rating requirements

- Testing compliance: Verify system has appropriate fire test certifications

- Inspection requirements: Plan for fire department and code official inspections

Electrical and Technology Integration:

Power Distribution:

- Electrical routing: Plan electrical distribution through plenum space

- Panel access: Provide access panels at electrical connection points

- Load calculations: Include lighting and other electrical loads in panel support design

- Emergency power: Coordinate emergency electrical systems with ceiling design

- Code compliance: Meet electrical code requirements for plenum wiring

Technology Systems:

- Data/telecommunications: Route cabling through plenum space efficiently

- Audio/visual: Coordinate AV equipment placement and access

- Security systems: Plan for security device placement and wiring

- Building automation: Integrate sensors and controls with ceiling system

- Future flexibility: Design for easy modification and expansion

Wireless Infrastructure:

- Signal transmission: Perforations generally don't interfere with wireless signals

- Antenna placement: Coordinate wireless access point locations

- Cable management: Plan for wireless infrastructure cabling

- Maintenance access: Ensure access for wireless equipment maintenance

- Performance optimization: Coordinate with IT department for optimal coverage

Structural Integration:

Load Distribution:

- Dead loads: Calculate panel weight plus suspension system and integrated equipment

- Live loads: Include maintenance loads and equipment access requirements

- Seismic loads: Design for lateral forces and building movement

- Thermal loads: Account for thermal expansion and contraction

- Dynamic loads: Consider vibration from building systems and occupancy

Suspension System Design:

- Hanger spacing: Optimize for panel size and load distribution

- Bracing requirements: Lateral and compression bracing per building codes

- Connection details: Coordinate with structural engineer for proper connections

- Deflection limits: Ensure structural deflection doesn't affect ceiling performance

- Construction tolerances: Design for realistic construction tolerances

Coordination with Other Trades:

- Installation sequence: Plan installation to minimize trade conflicts

- Access requirements: Ensure adequate access for all trades during construction

- Quality control: Coordinate inspection and testing requirements

- Change management: Process for handling field changes and conflicts

- Documentation: Maintain coordination drawings and specifications

Design Process Best Practices:

Early Coordination:

- Design team meetings including all affected disciplines

- Performance requirements clearly defined for all systems

- Coordination drawings showing all systems and interfaces

- Specification coordination ensuring compatibility between systems

- Value engineering opportunities identified early in design

Performance Optimization:

- Integrated design approach considering all systems together

- Performance modeling using appropriate software tools

- Mock-up testing for critical or complex installations

- Commissioning planning for system performance verification

- Lifecycle considerations for maintenance and operation

Documentation Requirements:

- Coordination drawings showing all systems and clearances

- Performance specifications for acoustic, thermal, and airflow performance

- Installation details for system interfaces and connections

- Maintenance requirements for integrated systems

- Warranty coordination between different system components

Common Integration Challenges:

Space Constraints:

- Plenum depth insufficient for all required systems

- Structural conflicts limiting ceiling height or layout options

- Equipment access difficult due to space limitations

- Solutions: Early coordination, compact equipment selection, creative routing

Performance Conflicts:

- Acoustic vs. airflow requirements conflicting

- Lighting vs. acoustic performance trade-offs

- Fire safety vs. access requirements conflicting

- Solutions: Performance modeling, compromise solutions, alternative approaches

Coordination Issues:

- Trade conflicts during installation

- Change orders affecting multiple systems

- Quality control challenges with multiple systems

- Solutions: Detailed coordination, experienced project management, clear communication

Success Factors:

- Early involvement of all design disciplines

- Clear performance requirements and priorities

- Experienced design team with integration expertise

- Adequate design time for proper coordination

- Quality construction management during installation

- Comprehensive commissioning to verify performance