Aluminium U-Baffle Ceiling System

High-performance aluminum U-baffle ceiling systems engineered to deliver exceptional acoustic control, superior airflow management, and distinctive linear aesthetics for modern commercial, institutional, and architectural applications. These precision-manufactured baffle systems combine optimal sound absorption, excellent ventilation properties, and contemporary design flexibility to create sophisticated interior environments with enhanced functionality and visual appeal.

Our high-performance U-baffle ceiling systems are engineered for modern architectural spaces that demand superior acoustics, airflow management, and aesthetics. Key applications include:

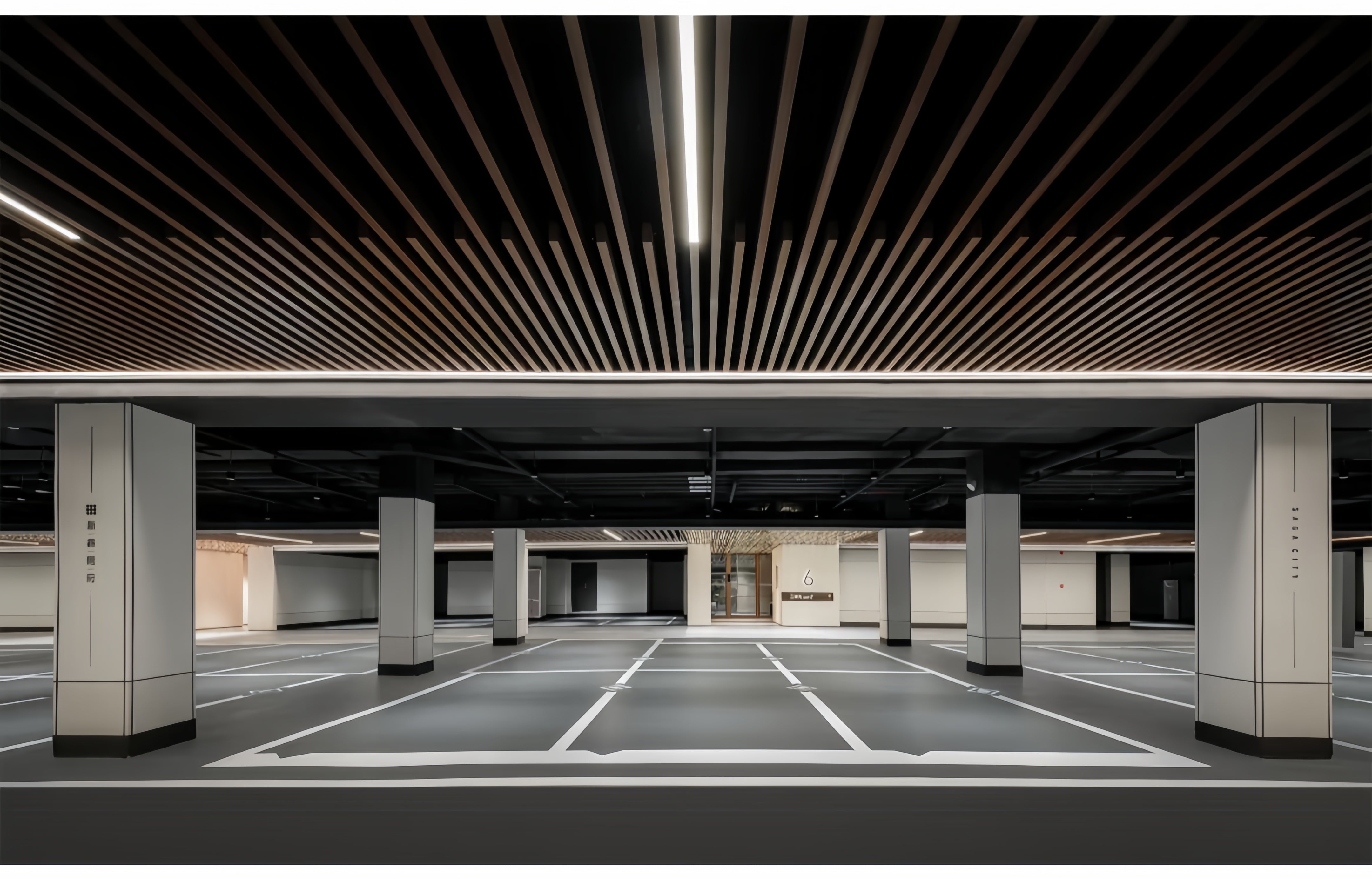

- Commercial & Office Spaces: Modern office buildings, open-planworkspaces, conference centers, and high-end retail stores.

- Transportation Hubs: Airports, subway stations, and high-speed rail terminals where managing airflow and noise in high-traffic areas is crucial.

- Institutional & Public Venues: Schools, libraries, museums, gymnasiums, and hospital lobbies and public corridors.

- Hospitality & Entertainment: Hotel lobbies, signature restaurants, concert halls, and cinemas to create a sophisticated and unique atmosphere.

Superior Acoustic Control

Expertly engineered to absorb and diffuse sound, significantly reducing ambient noise and reverberation for a more comfortable and quieter environment.

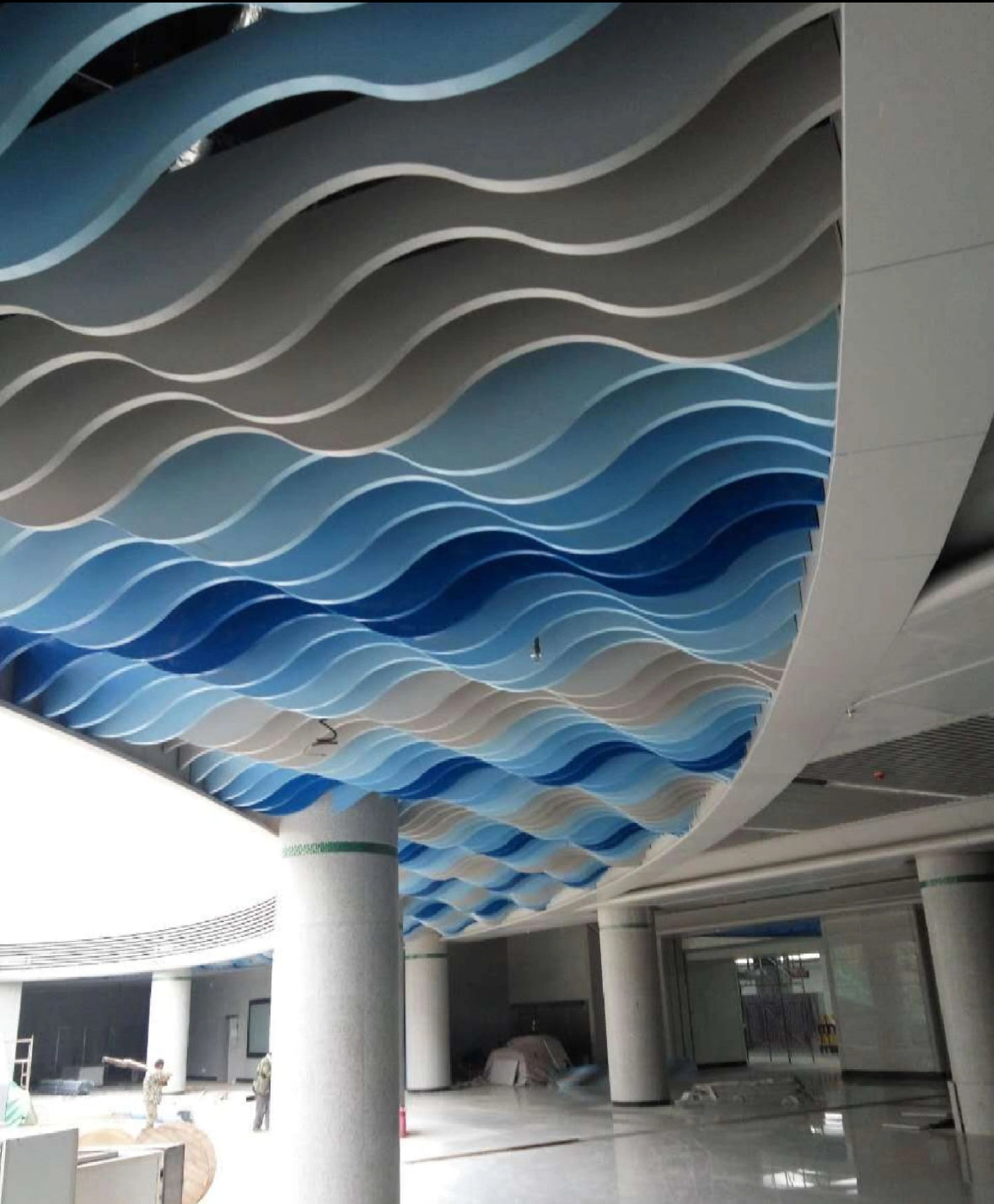

Versatile & Aesthetic Design

A rich selection of finishes (PVDF, Polyester, Anodizing, Wooden Print) and patterns offers endless creative freedom with a distinctive, contemporary linear look.

Functional & Durable

The open design improves airflow and allows easy access for maintenance. Made from high-quality aluminum, it is fire-resistant, moisture-proof, and built to last.

| Alloy | Temper | Composition | Properties | Best Applications |

|---|---|---|---|---|

| 3003 | H14 | 98% Al, 1.2% Mn | Standard strength, excellent formability | Standard commercial applications |

| 5005 | H34 | 99.5% Al, 0.8% Mg | Enhanced strength, superior anodizing | Premium commercial, anodizing applications |

| 5052 | H32 | 97.25% Al, 2.5% Mg | High strength, marine grade corrosion resistance | Harsh environments, coastal installations |

| 6061 | T6 | 97.9% Al, 1.0% Mg, 0.6% Si | Structural grade, excellent strength-to-weight | Heavy-duty, structural applications |

| Profile Code | Width | Height | Thickness | Weight | Moment of Inertia |

|---|---|---|---|---|---|

| U-50 | 50mm | 40mm | 0.8mm | 0.31 kg/m | 2.1 cm⁴ |

| U-75 | 75mm | 60mm | 0.8mm | 0.42 kg/m | 4.8 cm⁴ |

| U-100 | 100mm | 80mm | 1.0mm | 0.68 kg/m | 10.2 cm⁴ |

| U-150 | 150mm | 120mm | 1.0mm | 0.89 kg/m | 28.5 cm⁴ |

| U-200 | 200mm | 160mm | 1.2mm | 1.24 kg/m | 67.8 cm⁴ |

| U-300 | 300mm | 240mm | 1.5mm | 2.15 kg/m | 230.4 cm⁴ |

| Profile Code | Width | Height | Thickness | Weight | Moment of Inertia |

|---|---|---|---|---|---|

| HD-100 | 100mm | 80mm | 1.2mm | 0.82 kg/m | 12.3 cm4 |

| HD-150 | 150mm | 120mm | 1.2mm | 1.07 kg/m | 34.2 cm4 |

| HD-200 | 200mm | 160mm | 1.5mm | 1.55 kg/m | 84.8 cm4 |

| HD-300 | 300mm | 240mm | 2.0mm | 2.87 kg/m | 307.2 cm4 |

| Length | Applications | Handling | Transportation | Installation |

|---|---|---|---|---|

| 600mm | Small spaces, detailed areas | Hand carry | Standard packaging | Easy installation |

| 1200mm | Standard commercial | Two-person lift | Standard shipping | Moderate complexity |

| 1800mm | Large spaces | Equipment assist | Long load shipping | Standard procedures |

| 2400mm | Continuous runs | Mechanical lift | Special transport | Careful handling |

| 3000mm | Maximum spans | Crane required | Oversized load | Professional installation |

| Custom | Architectural features | Variable | Special arrangements | Site-specific procedures |

| Alloy/Temper | Tensile Strength | Yield Strength | Elongation | Hardness | Modulus |

|---|---|---|---|---|---|

| 3003-H14 | 145-185 MPa | 125-165 MPa | 8-16% | 40-50 HB | 69 GPa |

| 5005-H34 | 160-200 MPa | 140-180 MPa | 6-10% | 50-60 HB | 70 GPa |

| 5052-H32 | 230-280 MPa | 165-220 MPa | 12-18% | 60-70 HB | 70 GPa |

| 6061-T6 | 310-380 MPa | 275-310 MPa | 8-12% | 95 HB | 69 GPa |

| Property | 3003-H14 | 5005-H34 | 5052-H32 | 6061-T6 | Units |

|---|---|---|---|---|---|

| Density | 2.73 | 2.70 | 2.68 | 2.70 | g/cm³ |

| Melting Point | 655 | 652 | 607 | 582 | °C |

| Thermal Conductivity | 190 | 201 | 138 | 167 | W/m·K |

| Thermal Expansion | 23.6×10⁻⁶ | 23.8×10⁻⁶ | 23.8×10⁻⁶ | 23.6×10⁻⁶ | /°C |

| Electrical Conductivity | 41 | 52 | 35 | 43 | % IACS |

| Profile | Max Span | Deflection | Load Capacity | Natural Frequency | Safety Factor |

|---|---|---|---|---|---|

| U-50 | 1200mm | L/300 | 50 N/m | 12 Hz | 3.0 |

| U-75 | 1500mm | L/300 | 75 N/m | 15 Hz | 3.0 |

| U-100 | 1800mm | L/300 | 100 N/m | 18 Hz | 3.0 |

| U-150 | 2400mm | L/300 | 150 N/m | 22 Hz | 3.0 |

| U-200 | 3000mm | L/300 | 200 N/m | 25 Hz | 3.0 |

| U-300 | 3600mm | L/300 | 300 N/m | 30 Hz | 3.0 |

| Baffle Size | Spacing | 125 Hz | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 4000 Hz | NRC |

|---|---|---|---|---|---|---|---|---|

| U-100 | 100mm | 0.05 | 0.08 | 0.12 | 0.15 | 0.18 | 0.20 | 0.15 |

| U-100 | 150mm | 0.08 | 0.12 | 0.18 | 0.22 | 0.25 | 0.28 | 0.20 |

| U-150 | 150mm | 0.10 | 0.15 | 0.22 | 0.28 | 0.32 | 0.35 | 0.25 |

| U-200 | 200mm | 0.12 | 0.18 | 0.28 | 0.35 | 0.40 | 0.45 | 0.30 |

| Baffle Size | Spacing | 125 Hz | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 4000 Hz | NRC |

|---|---|---|---|---|---|---|---|---|

| U-100 | 100mm | 0.15 | 0.35 | 0.65 | 0.80 | 0.85 | 0.80 | 0.65 |

| U-100 | 150mm | 0.20 | 0.45 | 0.75 | 0.90 | 0.90 | 0.85 | 0.75 |

| U-150 | 150mm | 0.25 | 0.55 | 0.85 | 0.95 | 0.95 | 0.90 | 0.80 |

| U-200 | 200mm | 0.30 | 0.65 | 0.90 | 1.00 | 0.95 | 0.90 | 0.85 |

| Baffle Size | Spacing | 125 Hz | 250 Hz | 500 Hz | 1000 Hz | 2000 Hz | 4000 Hz | NRC |

|---|---|---|---|---|---|---|---|---|

| U-100 | 100mm | 0.25 | 0.50 | 0.80 | 0.90 | 0.90 | 0.85 | 0.80 |

| U-100 | 150mm | 0.30 | 0.60 | 0.90 | 1.00 | 0.95 | 0.90 | 0.85 |

| U-150 | 150mm | 0.35 | 0.70 | 0.95 | 1.00 | 1.00 | 0.95 | 0.90 |

| U-200 | 200mm | 0.40 | 0.80 | 1.00 | 1.00 | 1.00 | 0.95 | 0.95 |

| Baffle Spacing | Open Area % | Air Velocity | Pressure Drop | HVAC Efficiency |

|---|---|---|---|---|

| 50mm | 33% | 2.0 m/s | 25 Pa | Good |

| 75mm | 43% | 2.5 m/s | 18 Pa | Good |

| 100mm | 50% | 3.0 m/s | 12 Pa | Very Good |

| 150mm | 60% | 3.5 m/s | 8 Pa | Very Good |

| 200mm | 67% | 4.0 m/s | 5 Pa | Excellent |

| 300mm | 75% | 4.5 m/s | 3 Pa | Excellent |

| Property | Performance | Test Standard | Applications |

|---|---|---|---|

| Thermal Conductivity | 190-201 W/m·K | ASTM E1461 | Heat dissipation |

| Thermal Expansion | 23.6×10⁻⁶/°C | ASTM E228 | Dimensional stability |

| Service Temperature | -40°C to +150°C | - | Environmental range |

| Fire Resistance | Non-combustible | ASTM E84 | Fire safety |

| Thermal Shock | Excellent | - | Temperature cycling |

| Property | Performance | Test Standard |

|---|---|---|

| Fire Classification | Class A Non-combustible | ASTM E84 |

| Flame Spread Index | 0 | ASTM E84 |

| Smoke Development | 0-5 | ASTM E84 |

| Heat Release Rate | Zero | ASTM E1354 |

| Toxicity | Non-toxic | ASTM E662 |

| Structural Integrity | Maintains to 500°C+ | - |

| Property | Performance | Test Standard |

|---|---|---|

| Corrosion Resistance | Excellent | ASTM B117 |

| UV Resistance | Excellent (coated) | ASTM G154 |

| Humidity Resistance | 100% RH | ASTM D2247 |

| Chemical Resistance | Good to Excellent | ASTM D543 |

| Freeze-Thaw | No degradation | ASTM C666 |

| Weathering | Excellent (coated) | ASTM D4587 |

| Metric | Performance | Standard |

|---|---|---|

| Recycled Content | 75-95% | ISO 14021 |

| Recyclability | 100% | - |

| Embodied Energy | 155 MJ/kg | ISO 14040 |

| Carbon Footprint | 8.2 kg CO₂/kg | ISO 14067 |

| Service Life | 25-40 years | - |

| VOC Emissions | Zero | GREENGUARD |

| Component | Specification | Load Capacity | Spacing | Hardware |

|---|---|---|---|---|

| Suspension Wire | 12 gauge galvanized | 45 kg | 1200mm max | Eye bolts, clips |

| Carrier System | 24mm T-bar | 14.4 kg/m² | 1200mm | Standard grid |

| Baffle Clips | Spring steel | 15 kg each | Per baffle | Galvanized finish |

| Seismic Bracing | 25mm angle | Seismic loads | Per code | Structural connections |

FAQs

What Are the Key Advantages of U-Baffle Ceiling Systems Over Traditional Ceiling Solutions?

U-baffle ceiling systems offer unique advantages that make them ideal for applications requiring superior acoustic control, architectural aesthetics, and functional flexibility:

Superior Acoustic Performance:

Enhanced Sound Absorption:

- Three-dimensional absorption - baffles provide sound absorption on multiple surfaces

- Customizable performance - NRC values from 0.15 to 0.95 depending on configuration

- Frequency-specific control - different baffle sizes and spacing target specific frequencies

- Directional absorption - vertical surfaces absorb sound from multiple angles

- Reverberation control - significantly reduces reverberation time in large spaces

Acoustic Design Flexibility:

- Variable spacing - adjust baffle spacing from 50mm to 300mm for different acoustic effects

- Selective treatment - treat only areas requiring acoustic control

- Zoned performance - different acoustic zones within same space

- Integration capability - works with other acoustic treatments for optimal performance

- Future adjustability - easy to modify spacing or add backing materials

Architectural and Aesthetic Benefits:

Linear Design Appeal:

- Contemporary aesthetics - clean, linear appearance enhances modern interiors

- Visual depth - creates three-dimensional ceiling plane with shadow lines

- Directional emphasis - can emphasize room proportions and circulation patterns

- Scale flexibility - works in both intimate and large-scale spaces

- Lighting integration - creates dramatic lighting effects and reduces glare

Design Versatility:

- Multiple profiles - various baffle sizes for different visual impacts

- Unlimited lengths - continuous runs or segmented installations

- Curved applications - custom curved baffles for unique architectural effects

- Color options - unlimited finish colors for design coordination

- Pattern possibilities - varied spacing creates different visual patterns

Functional Performance Advantages:

HVAC Integration:

- Excellent airflow - open design allows natural air circulation

- Plenum access - full access to mechanical systems between baffles

- Pressure equalization - prevents pressure buildup in ceiling plenum

- Energy efficiency - reduces HVAC load through improved air distribution

- System flexibility - easy integration with various HVAC configurations

Maintenance and Access:

- Complete accessibility - full access to all building systems without baffle removal

- Individual replacement - damaged baffles easily replaced without system disruption

- Simple cleaning - accessible surfaces easy to clean and maintain

- System modifications - easy to add or relocate building systems

- Long service life - 25-40 years with minimal maintenance requirements

Installation and Cost Benefits:

Installation Efficiency:

- Modular system - standardized components reduce installation complexity

- Lightweight construction - minimal structural requirements reduce costs

- Standard suspension - works with conventional ceiling grid systems

- Field adjustable - spacing and alignment easily adjusted during installation

- Professional appearance - consistent, high-quality finished appearance

Economic Advantages:

- Material efficiency - less material per square meter than solid ceilings

- Reduced structural loads - lightweight system reduces structural requirements

- Energy savings - improved HVAC efficiency reduces operating costs

- Maintenance savings - easy access reduces service and maintenance costs

- Lifecycle value - long service life and low maintenance provide excellent ROI

Performance Comparison with Other Systems:

vs. Acoustic Ceiling Tiles:

- Superior airflow - unrestricted air movement vs. minimal permeability

- Better access - full plenum access vs. tile removal required

- Higher durability - aluminum construction vs. mineral fiber susceptibility

- Fire safety - non-combustible vs. potential combustible materials

- Design flexibility - unlimited configurations vs. standard tile patterns

vs. Solid Ceiling Panels:

- Acoustic performance - significant sound absorption vs. sound reflection

- System access - complete accessibility vs. no access without removal

- Visual interest - three-dimensional design vs. flat appearance

- Airflow benefits - natural ventilation vs. no air movement

- Weight reduction - lighter system vs. heavier solid construction

vs. Open Ceiling (No Ceiling):

- Acoustic improvement - significant sound absorption vs. hard reflective surfaces

- Aesthetic enhancement - organized linear appearance vs. exposed chaos

- Dust protection - reduces dust accumulation on equipment and surfaces

- Safety improvement - protects against falling objects or debris

- Code compliance - may be required for fire rating or accessibility

Application-Specific Advantages:

Corporate Offices:

- Speech privacy - excellent absorption improves confidentiality

- Professional appearance - sophisticated linear aesthetic

- Flexibility - easy reconfiguration for space changes

- Technology integration - easy access for IT infrastructure modifications

- Brand expression - custom colors and patterns support corporate identity

Educational Facilities:

- Learning environment - optimal acoustics improve student concentration

- Safety compliance - non-combustible construction meets fire codes

- Durability - withstands high-traffic institutional environment

- Maintenance efficiency - easy cleaning and system access

- Future adaptability - easy modification for changing educational needs

Healthcare Facilities:

- Patient comfort - superior acoustics reduce stress and aid healing

- Infection control - smooth aluminum surfaces easy to clean and disinfect

- System access - critical for frequent medical equipment modifications

- Fire safety - non-combustible construction for life safety

- Regulatory compliance - meets healthcare facility requirements

Transportation Hubs:

- Noise control - essential for passenger comfort and safety

- Durability - withstands high-traffic and harsh environments

- Security - visual access for security monitoring between baffles

- Maintenance efficiency - easy access to extensive building systems

- Wayfinding - linear patterns can guide circulation and navigation

Considerations and Limitations:

- Initial cost - higher upfront cost than basic ceiling tiles

- Design coordination - requires careful integration with lighting and HVAC

- Acoustic limitations - may require backing materials for maximum performance

- Cleaning frequency - exposed surfaces may require more frequent cleaning

- Professional installation - requires experienced installers for optimal results

How Do You Design and Specify U-Baffle Spacing for Optimal Acoustic Performance?

Optimal U-baffle spacing requires careful analysis of acoustic requirements, space function, and aesthetic goals to achieve the desired performance:

Acoustic Performance Fundamentals:

Sound Absorption Mechanisms:

- Surface absorption - sound absorbed by baffle surfaces and backing materials

- Edge diffraction - sound waves diffract around baffle edges, increasing absorption

- Cavity resonance - air spaces between baffles create resonant absorption

- Multiple reflections - sound bounces between baffles, increasing absorption opportunities

- Directional absorption - vertical surfaces absorb sound from multiple angles

Spacing Impact on Performance:

- Closer spacing (50-100mm): Higher absorption, more uniform coverage, increased cost

- Moderate spacing (100-200mm): Balanced performance and cost, most common application

- Wider spacing (200-300mm): Lower absorption, more economical, architectural emphasis

- Variable spacing: Custom acoustic zones with different performance characteristics

Acoustic Design Calculations:

Absorption Coefficient Estimation:

Total Absorption = (Baffle Surface Area × αbaffle) + (Cavity Effect × αcavity)

Where:

- Baffle Surface Area = Perimeter × Length × Number of Baffles

- αbaffle = Material absorption coefficient (0.05-0.15 without backing)

- αcavity = Cavity absorption enhancement (0.10-0.30 depending on spacing)

Reverberation Time Calculation:

RT60 = 0.161 × V / A

Where:

- V = Room volume (m³)

- A = Total absorption (m² sabins)

- Target RT60 varies by application (0.6-1.2 seconds typical)

Application-Specific Spacing Guidelines:

Corporate Offices:

- Open plan areas: 150-200mm spacing, U-150 baffles, 25mm backing

- Target NRC: 0.75-0.85 for speech privacy and comfort

- Conference rooms: 100-150mm spacing, U-100 baffles, 50mm backing

- Target NRC: 0.80-0.90 for excellent speech intelligibility

- Private offices: 200mm spacing, U-100 baffles, 25mm backing

- Target NRC: 0.65-0.75 for comfortable acoustic environment

Educational Facilities:

- Classrooms: 100-150mm spacing, U-150 baffles, 50mm backing

- Target NRC: 0.80-0.90 for optimal learning conditions

- Libraries: 150-200mm spacing, U-100 baffles, 25mm backing

- Target NRC: 0.70-0.80 for quiet study environment

- Gymnasiums: 200-300mm spacing, U-200 baffles, 75mm backing

- Target NRC: 0.85-0.95 for high-noise activity control

Healthcare Facilities:

- Patient rooms: 100-150mm spacing, U-100 baffles, 50mm backing

- Target NRC: 0.75-0.85 for patient comfort and privacy

- Corridors: 150-200mm spacing, U-150 baffles, 25mm backing

- Target NRC: 0.65-0.75 for noise control without over-absorption

- Waiting areas: 150mm spacing, U-150 baffles, 50mm backing

- Target NRC: 0.80-0.90 for stress reduction and comfort

Design Process and Methodology:

Step 1: Acoustic Requirements Analysis

- Measure existing conditions - background noise, reverberation time

- Define target performance - desired NRC and RT60 values

- Identify critical frequencies - speech, machinery, HVAC noise

- Consider space function - privacy, concentration, communication needs

- Review applicable standards - building codes, industry guidelines

Step 2: Preliminary Spacing Selection

Spacing Selection Matrix:

- High Performance (NRC >0.85): 75-125mm spacing

- Standard Performance (NRC 0.65-0.85): 125-175mm spacing

- Moderate Performance (NRC 0.45-0.65): 175-250mm spacing

- Basic Performance (NRC <0.45): 250-300mm spacing

Step 3: Performance Modeling

- Computer acoustic modeling using software like EASE, ODEON, or CATT

- Reverberation time prediction for different frequency bands

- Sound pressure level mapping throughout the space

- Speech intelligibility analysis (STI, RASTI calculations)

- Background noise impact assessment

Step 4: Design Optimization

- Iterative spacing adjustment to meet performance targets

- Backing material selection for frequency

specific control - backing thickness optimized for target frequencies

- Cost analysis: Balance acoustic performance with budget constraints

- Integration planning: Coordinate with lighting, HVAC, and other building systems

Step 5: Final Design Documentation

- Performance specifications: Document expected NRC and RT60 values

- Installation details: Specify mounting, spacing, and integration requirements

- Quality control: Establish testing and verification procedures

- Maintenance planning: Document cleaning and maintenance requirements

Common Spacing Configurations:

High-Performance Acoustic Zones (NRC 0.80-0.95):

- Spacing: 75-125mm between baffles

- Baffle size: U-150 or U-200 profiles

- Backing: 50-75mm mineral wool or melamine foam

- Applications: Recording studios, conference rooms, critical listening spaces

- Cost impact: 40-60% higher than standard configurations

Standard Commercial Applications (NRC 0.65-0.80):

- Spacing: 125-175mm between baffles

- Baffle size: U-100 or U-150 profiles

- Backing: 25-50mm polyester or mineral wool

- Applications: Open offices, retail spaces, educational facilities

- Cost impact: Baseline configuration for cost comparisons

Economic Performance Solutions (NRC 0.45-0.65):

- Spacing: 175-250mm between baffles

- Baffle size: U-100 profiles

- Backing: 15-25mm polyester fiber

- Applications: Warehouses, industrial spaces, basic commercial

- Cost impact: 25-35% less than standard configurations

Architectural Emphasis (NRC 0.30-0.50):

- Spacing: 250-300mm between baffles

- Baffle size: U-200 or U-300 profiles

- Backing: Optional or minimal

- Applications: Lobbies, atriums, architectural features

- Cost impact: Focus on visual impact rather than acoustic performance

Installation and Performance Verification:

Installation Quality Control:

- Spacing verification: Measure actual spacing vs. design requirements

- Alignment check: Ensure baffles are straight and parallel

- Backing installation: Verify proper installation of acoustic backing

- Integration testing: Test lighting, HVAC, and other integrated systems

- Performance measurement: Post-installation acoustic testing if required

Performance Monitoring:

- Baseline measurement: Document initial acoustic performance

- Periodic assessment: Monitor performance over time

- Problem identification: Identify acoustic issues early

- Maintenance impact: Monitor effect of cleaning on acoustic performance

- Upgrade planning: Plan for acoustic improvements as needs change

What Are the Installation Requirements and Best Practices for U-Baffle Ceiling Systems?

Successful U-baffle installation requires proper planning, appropriate support systems, and attention to alignment and integration with building systems:

Pre-Installation Planning:

Structural Assessment:

- Load capacity verification: Confirm structure can support total system weight

- Deflection analysis: Ensure structural movement won't affect baffle alignment

- Seismic requirements: Verify compliance with local seismic design requirements

- Coordination drawings: Detailed drawings showing all building system interactions

- Access planning: Ensure adequate access for installation equipment and personnel

System Coordination:

- HVAC integration: Coordinate with ductwork, diffusers, and return air systems

- Lighting design: Plan for recessed, pendant, or track lighting integration

- Fire protection: Coordinate with sprinkler systems and smoke detection

- Electrical systems: Plan for power, data, and communication infrastructure

- Architectural features: Integrate with columns, beams, and other building elements

Installation Methods:Suspension System Options:

Standard T-Grid Suspension:

- Grid type: 24mm heavy-duty T-grid system

- Hanger spacing: 1200mm maximum in both directions

- Load capacity: 14.4 kg/m² distributed load

- Baffle attachment: Spring clips or mechanical fasteners

- Advantages: Standard installation methods, easy access, economical

Cable Suspension Systems:

- Cable type: 3mm aircraft cable, galvanized or stainless steel

- Hanger spacing: 1200-1800mm depending on baffle weight

- Load capacity: 25 kg per suspension point

- Baffle attachment: Threaded rod and clamp assemblies

- Advantages: Minimal visual impact, suitable for long spans

Direct Structural Mounting:

- Mounting method: Brackets attached directly to structure

- Support spacing: 1200mm maximum for standard baffles

- Load capacity: Limited by structural capacity and connection design

- Baffle attachment: Mechanical fasteners or welded connections

- Advantages: Maximum structural efficiency, clean appearance

Track Suspension Systems:

- Track type: Continuous aluminum or steel track systems

- Support spacing: 1500mm maximum for track supports

- Load capacity: 20-30 kg/m depending on track design

- Baffle attachment: Sliding carriers allow spacing adjustment

- Advantages: Adjustable spacing, easy reconfiguration

Installation Process:

Phase 1: Support System Installation

- Layout verification: Confirm dimensions and spacing per drawings

- Hanger installation: Install ceiling hangers at specified locations

- Grid/track assembly: Assemble suspension system level and square

- Bracing installation: Install lateral and compression bracing per seismic requirements

- Quality verification: Check level, square, and load capacity

Phase 2: Building Systems Integration

- HVAC installation: Install ductwork, diffusers, and controls

- Electrical rough-in: Install conduit, boxes, and rough wiring

- Fire protection: Install sprinkler heads and detection devices

- Testing: Test all systems before baffle installation

- Documentation: Record as-built conditions for future reference

Phase 3: Baffle Installation

- Starting point: Begin from predetermined reference point

- Sequential installation: Work systematically to maintain spacing and alignment

- Spacing verification: Check spacing frequently during installation

- Alignment control: Use string lines or laser levels for alignment

- Quality control: Verify appearance and function throughout process

Phase 4: Final Integration

- Lighting installation: Install light fixtures and controls

- System balancing: Balance HVAC systems for proper airflow

- Final adjustments: Fine-tune spacing and alignment

- Cleaning: Remove protective films and clean installation

- Final inspection: Verify compliance with specifications and codes

Installation Best Practices:

Handling and Safety:

- Baffle handling: Use appropriate lifting techniques for baffle length and weight

- Surface protection: Maintain protective films until final cleaning

- Fall protection: Appropriate safety equipment for work at height

- Tool safety: Proper use of cutting and installation tools

- Team coordination: Clear communication and coordination procedures

Quality Control Measures:

- Dimensional verification: Check spacing and alignment frequently

- Level installation: Maintain level installation within ±3mm over 3m span

- Parallel alignment: Ensure baffles are parallel within ±3mm

- Integration testing: Verify proper operation of all building systems

- Appearance inspection: Check for damage, scratches, or contamination

Common Installation Challenges:

Dimensional Issues:

- Building tolerances: Structure may not be perfectly square or level

- Cumulative errors: Small errors accumulate over large installations

- Thermal movement: Account for thermal expansion and contraction

- Solutions: Flexible mounting systems, field adjustment capability

System Integration:

- HVAC conflicts: Ductwork may interfere with planned baffle locations

- Lighting coordination: Fixture locations may not align with baffle spacing

- Structural interference: Beams, columns, or other elements create obstacles

- Solutions: Early coordination, flexible design, field modifications

Access and Logistics:

- Material delivery: Long baffles require special handling and access

- Installation sequence: Coordinate with other trades for efficient installation

- Workspace requirements: Adequate space for installation equipment and materials

- Solutions: Detailed logistics planning, coordination meetings

Specialized Installation Considerations:

Large-Scale Installations:

- Modular approach: Break large areas into manageable sections

- Reference systems: Establish control lines and reference points

- Quality consistency: Maintain consistent appearance across entire installation

- Progress tracking: Monitor installation progress and quality

Curved or Complex Geometries:

- Custom mounting: Special brackets and supports for curved applications

- Field verification: Template or mock-up verification before full installation

- Skilled labor: Experienced installers required for complex geometries

- Quality control: Additional inspection for complex installations

Retrofit Applications:

- Existing system removal: Safe removal of old ceiling systems

- Structural assessment: Verify existing structure adequate for new loads

- Utility coordination: Work around existing building systems

- Occupied buildings: Minimize disruption to building occupants

Post-Installation Requirements:

System Commissioning:

- Performance testing: Verify acoustic and airflow performance meets design

- Integration testing: Test all integrated building systems

- Safety inspection: Final safety and code compliance verification

- Documentation: Complete installation records and warranties

Maintenance Training:

- Access procedures: Train facility staff on safe access methods

- Cleaning procedures: Establish appropriate cleaning protocols

- System operation: Train on any adjustable or removable components

- Emergency procedures: Procedures for emergency access or repairs

Quality Assurance:

- Warranty documentation: Complete warranty registration and documentation

- Performance verification: Verify system meets design performance requirements

- Punch list completion: Address any deficiencies or incomplete items

- Final acceptance: Formal acceptance by owner or representative

How Do U-Baffle Systems Compare to Other Acoustic Ceiling Solutions in Terms of Performance and Cost?

U-baffle systems offer unique advantages in specific applications while having different cost and performance characteristics compared to alternative acoustic ceiling solutions:

Performance Comparison:

Acoustic Performance Analysis:

U-Baffle Systems:

- NRC range: 0.15-0.95 depending on spacing and backing

- Frequency response: Excellent mid and high-frequency absorption

- Directional absorption: Vertical surfaces absorb sound from multiple angles

- Reverberation control: Significant RT60 reduction in large spaces

- Speech intelligibility: Excellent improvement in open environments

Acoustic Ceiling Tiles:

- NRC range: 0.50-0.95 depending on material and thickness

- Frequency response: Good across all frequencies, some low-frequency limitations

- Coverage: 100% ceiling coverage provides uniform absorption

- Installation density: Higher absorption per square meter of ceiling

- Cost efficiency: Lower cost per unit of absorption

Suspended Acoustic Panels:

- NRC range: 0.80-1.00 for high-performance panels

- Frequency response: Excellent across all frequencies

- Flexibility: Can be positioned for optimal acoustic effect

- Visual impact: Floating panels create architectural interest

- Selective treatment: Treat only areas requiring acoustic control

Open Cell Ceiling Systems:

- NRC range: 0.70-0.90 depending on cell size and backing

- Frequency response: Good mid and high-frequency performance

- Visual depth: Three-dimensional appearance similar to baffles

- Airflow: Excellent HVAC integration

- Maintenance: Easy access to plenum space

Functional Performance Comparison:

Cost Analysis:Initial Cost Comparison (per m² of ceiling area):

U-Baffle Systems:

- Material cost: $45-85/m² depending on spacing and material

- Installation cost: $25-40/m² for standard applications

- Total installed cost: $70-125/m²

- Cost variables: Spacing, baffle size, backing material, finish

Acoustic Ceiling Tiles:

- Material cost: $15-45/m² depending on performance level

- Grid system: $8-15/m² for suspension system

- Installation cost: $15-25/m² for standard installation

- Total installed cost: $38-85/m²

Suspended Acoustic Panels:

- Material cost: $35-75/m² depending on size and performance

- Suspension hardware: $10-20/m² for cables and connectors

- Installation cost: $20-35/m² for custom installation

- Total installed cost: $65-130/m²

Open Cell Ceiling Systems:

- Material cost: $25-55/m² depending on cell size and material

- Suspension system: $12-20/m² for grid or track system

- Installation cost: $18-30/m² for standard installation

- Total installed cost: $55-105/m²

Lifecycle Cost Considerations:

Maintenance and Operating Costs:

U-Baffle Systems:

- Cleaning frequency: Monthly to quarterly depending on environment

- Access advantage: Full plenum access without system removal

- Component replacement: Individual baffle replacement possible

- Service life: 25-40 years with proper maintenance

- Energy impact: Natural ventilation may reduce HVAC costs

Acoustic Ceiling Tiles:

- Replacement frequency: 10-20% annually in high-traffic areas

- Cleaning limitations: Some tiles cannot be cleaned effectively

- System access: Tile removal required for plenum access

- Service life: 15-25 years depending on material and environment

- Energy impact: Minimal impact on HVAC systems

Performance Over Time:

Acoustic Performance Stability:

- U-baffles: Stable performance, backing material may compress over time

- Ceiling tiles: Performance degrades with soiling and damage

- Suspended panels: Stable performance with quality materials

- Open cell: Generally stable, backing materials may degrade

Aesthetic Durability:

- U-baffles: Excellent appearance retention with quality finishes

- Ceiling tiles: Susceptible to staining, sagging, and damage

- Suspended panels: Good appearance retention

- Open cell: Good appearance retention, may collect dust

Application-Specific Recommendations:

When U-Baffles Are Optimal:

- Large open spaces: Warehouses, manufacturing, retail big box

- High ceilings: Spaces over 4m ceiling height

- HVAC integration critical: Spaces requiring excellent air circulation

- Maintenance access important: Facilities with extensive building systems

- Architectural emphasis desired: Spaces where linear aesthetics enhance design

When Alternatives May Be Better:

- Maximum acoustic performance: Critical listening spaces may need ceiling tiles

- Budget constraints: Ceiling tiles provide lower-cost acoustic treatment

- Low ceiling heights: Spaces under 3m may not accommodate baffles effectively

- 100% coverage needed: Some applications require complete ceiling coverage

- Frequent reconfiguration: Suspended panels offer maximum flexibility

Hybrid Solutions:Combined Systems:

- Baffle + tile combination: Baffles in main areas, tiles in private spaces

- Selective treatment: Baffles where needed, open ceiling elsewhere

- Zoned performance: Different acoustic treatments for different functions

- Phased installation: Start with baffles, add other treatments as needed

Cost-Benefit Analysis Framework:

Performance Weighting:

- Acoustic requirements: Weight based on criticality of acoustic performance

- Functional needs: Consider HVAC, access, and maintenance requirements

- Aesthetic goals: Factor in architectural and design objectives

- Future flexibility: Consider potential for future modifications

Total Cost of Ownership:

- Initial investment: Material, installation, and integration costs

- Operating costs: Energy, maintenance, and replacement expenses

- Performance value: Quantify benefits of superior performance

- End-of-life value: Consider recyclability and reuse potential

What Are the Maintenance Requirements and Expected Service Life of U-Baffle Ceiling Systems?

U-baffle ceiling systems require minimal maintenance while providing excellent long-term performance and value when properly specified and installed:

Routine Maintenance Requirements:

Daily/Weekly Inspection:

- Visual assessment: Check for damaged, displaced, or heavily soiled baffles

- Alignment verification: Ensure baffles remain straight and properly spaced

- Integration check: Verify proper operation of lighting and HVAC systems

- Safety inspection: Confirm all baffles securely mounted with no loose components

- Access verification: Ensure access panels and removable sections function properly

Monthly Maintenance:

- Surface cleaning: Remove dust and light contamination from baffle surfaces

- Spacing verification: Check that baffle spacing remains consistent

- Plenum inspection: Visual check of accessible plenum areas

- System integration: Verify lighting, HVAC, and other systems operating properly

- Acoustic assessment: Monitor for changes in acoustic performance

Cleaning Procedures by Material:

Aluminum Baffles:

- Standard cleaning: Mild detergent solution with soft brush or microfiber cloth

- Heavy soiling: Non-abrasive cleaners appropriate for aluminum and finish type

- Anodized finishes: pH-neutral cleaners to preserve anodized coating

- Painted finishes: Cleaners compatible with specific paint system

- Frequency: Monthly in standard environments, weekly in harsh conditions

Steel Baffles:

- Galvanized steel: Mild alkaline cleaners, avoid acidic solutions

- Painted steel: Gentle cleaners compatible with paint system

- Rust prevention: Regular inspection and touch-up of any coating damage

- Industrial environments: Appropriate solvents for specific contaminants

- Frequency: Monthly inspection, cleaning as needed based on environment

Stainless Steel Baffles:

- Standard cleaning: Stainless steel cleaner following grain direction

- Healthcare environments: Hospital-grade disinfectants and sanitizers

- Food processing: Food-grade cleaning and sanitizing agents

- Harsh environments: Cleaners appropriate for specific chemical exposures

- Frequency: Weekly in healthcare/food service, monthly in standard commercial

Environment-Specific Maintenance:

Industrial Environments:

- Contamination assessment: Regular evaluation of contamination type and severity

- Deep cleaning: Periodic pressure washing or steam cleaning as appropriate

- Coating inspection: Check for chemical attack or physical damage to finishes

- Safety protocols: Appropriate PPE and safety procedures for cleaning operations

- Downtime coordination: Schedule cleaning during production downtime

Healthcare Facilities:

- Infection control: Follow facility infection control protocols during maintenance

- Disinfection procedures: Regular disinfection with approved antimicrobial agents

- Air quality protection: Ensure cleaning procedures don't compromise air quality

- Documentation requirements: Maintain cleaning logs for regulatory compliance

- Emergency procedures: Rapid response procedures for contamination events

Food Service/Processing:

- Food safety compliance: Follow HACCP and FDA guidelines for cleaning

- Sanitization: Regular sanitization with food-safe antimicrobial agents

- Pest control coordination: Integrate with facility pest management programs

- Allergen control: Prevent cross-contamination during cleaning operations

- Regulatory documentation: Maintain records for health department inspections

Acoustic Backing Maintenance:

Polyester Fiber Backing:

- Dust removal: Regular vacuuming to prevent dust accumulation

- Moisture monitoring: Check for water infiltration that could promote mold growth

- Compression assessment: Monitor backing thickness for compression over time

- Fire safety inspection: Verify backing maintains fire-rated properties

- Replacement indicators: Replace if compressed >25% or contaminated

Mineral Wool Backing:

- Access inspection: Periodic baffle removal for backing inspection

- Moisture damage assessment: Check for water damage, mold, or deterioration

- Settling evaluation: Monitor for settling or compression over time

- Safety procedures: Use appropriate PPE when handling mineral wool

- Replacement criteria: Replace if damaged, contaminated, or significantly compressed

Melamine Foam Backing:

- Degradation monitoring: Check for crumbling, discoloration, or unusual odors

- Chemical compatibility: Ensure cleaning agents don't attack foam material

- UV protection: Protect from UV exposure that can degrade foam

- Moisture sensitivity: Monitor for water damage in humid environments

- Replacement schedule: Typically 8-12 years depending on environment

Preventive Maintenance Schedule:

Monthly Tasks:

- Visual inspection of all baffles and mounting systems

- Routine cleaning of high-traffic and high-contamination areas

- HVAC filter maintenance to reduce dust loading on baffles

- Performance monitoring for changes in acoustic or visual performance

- Documentation of maintenance activities and observations

Quarterly Tasks:

- Comprehensive cleaning of entire baffle system

- Detailed inspection including sample baffle removal for plenum access

- Backing material assessment for compression, moisture, or contamination

- Integration system testing of lighting, HVAC, and building automation

- Performance measurement if acoustic performance is critical

Annual Tasks:

- Professional assessment by qualified technicians or acoustic consultants

- Comprehensive system evaluation including structural and seismic components

- Backing material replacement planning and budgeting

- Warranty compliance documentation and required maintenance activities

- Lifecycle planning for system upgrades or major maintenance

Expected Service Life:Baffle Components:

- Aluminum baffles: 25-40 years depending on environment and maintenance

- Steel baffles: 20-30 years with proper coating maintenance

- Stainless steel baffles: 40+ years in most environments

- Suspension systems: 20-30 years with proper maintenance and inspection

- Mounting hardware: 15-25 years, may require periodic replacement

Acoustic Backing Materials:

- Polyester fiber: 12-20 years depending on environment and quality

- Mineral wool: 15-25 years with proper installation and protection

- Melamine foam: 8-15 years depending on environmental conditions

- Replacement scheduling: Plan for backing replacement at mid-life

Factors Affecting Service Life:

- Environmental conditions: Temperature, humidity, chemical exposure, UV radiation

- Maintenance quality: Regular, proper maintenance significantly extends life

- Installation quality: Proper installation prevents premature failure

- Material selection: Higher-grade materials provide longer service life

- Usage intensity: High-traffic areas may require more frequent maintenance

Lifecycle Cost Optimization:

Preventive Maintenance Benefits:

- Cost reduction: Preventive maintenance costs 20-30% of reactive maintenance

- Performance maintenance: Regular care maintains design acoustic performance

- Extended service life: Proper maintenance extends system life by 25-50%

- Energy efficiency: Well-maintained systems support optimal HVAC performance

- Problem prevention: Early detection prevents major system failures

Maintenance Best Practices:

- Staff training: Train maintenance personnel on proper procedures and safety

- Documentation systems: Maintain comprehensive maintenance records and schedules

- Quality suppliers: Use quality cleaning materials and replacement components

- Professional services: Engage qualified contractors for specialized maintenance

- Performance monitoring: Track system performance trends for optimization

End-of-Life Considerations:

- Material recovery: Plan for recycling of aluminum and steel components

- Disposal requirements: Proper disposal of backing materials per regulations

- Reuse potential: Consider reuse of components in other applications

- Upgrade opportunities: Plan for system upgrades during major renovations

- Documentation: Maintain records for future material recovery and disposal

Warranty and Support:

- Material warranties: Typically 10-25 years depending on material and finish

- Installation warranties: 1-2 years on installation workmanship

- Maintenance support: Ongoing technical support and maintenance guidance

- Replacement parts: Availability of replacement components throughout service life

- Technical updates: Access to updated maintenance procedures and best practices