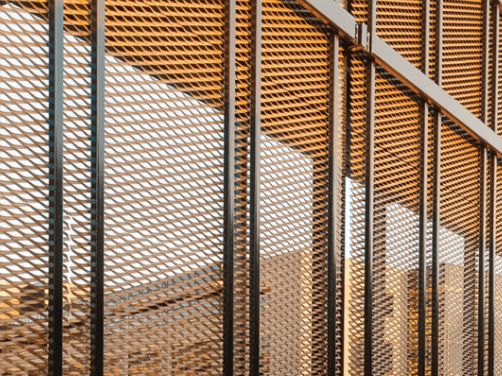

Metal curtain walls are revolutionizing building design through innovative materials. Perforated sheets and expanded sheets have become the go-to choices for modern facades, offering architects unprecedented flexibility in balancing aesthetics, functionality, and sustainability. Custom perforated metal panels and custom expanded sheets are driving this transformation, enabling unique design expressions while meeting performance requirements.

What Are the Advantages of Perforated Metal Panels for Buildings?

The adjustable perforated metal panels are game-changers for modern architecture. Think of them as a canvas where functionality intersects with form, delivering performance without losing aesthetics.

Design Flexibility

What’s useful about this? Various hole sizes regulate airflow differently:

- Small holes (a few millimeters): provide privacy while allowing airflow

- Medium holes (around a centimeter range): balance visibility and ventilation

- Large openings (several centimeters or more): create dramatic shadow effects inside buildings

- Typical size availability spans from a few millimeters up to several centimeters, depending on the supplier and project codes.

Clever designers combine multiple hole sizes in the same panel to achieve precisely the effect they need.

Light & Shadow

This is where perforated sheets excel—literally. By day, light passes through the holes and creates mobile patterns inside the building. Rather than fixed percentages, open-area selection is tailored to the design goal: lower open area emphasizes privacy and shading; mid-range balances shading with daylight; higher open area maximizes daylight and ventilation.

| Open Area | Solar Heat Gain Reduction | Light Transmission | Best Use |

| Lower open area | Greater shading potential (project-dependent) | Lower daylight levels | Maximum privacy, moderate cooling |

| Mid open area | Balanced shading (project-dependent) | Moderate daylight levels | Balanced shading and daylight |

| Higher open area | Less shading, more solar admission | Higher daylight levels | Maximum natural light, high ventilation |

There are projects where computer modeling has been adopted to create patterns that throw definite shadows at definite times.

Energy & Ventilation

Let’s also consider finances. With combined shading and ventilation effects, metal screen solutions deliver measurable energy savings:

- Peak cooling load can be reduced in hot periods when shading is well designed (results vary by climate and orientation).

- Annual HVAC energy can decrease in well-modeled case studies, but actual savings are project-specific.

- Open area is optimized on a case-by-case basis rather than a universal percentage.

- Passive cooling can support natural ventilation in mild weather; mechanical ventilation is still required in many conditions.

Additionally, the holes shade incoming sunlight while allowing views that are impossible for solid walls. Ventilation strategies can leverage the stack effect—exhausting warm air at the top and drawing in cooler air at the bottom—to reduce reliance on mechanical ventilation in suitable climates. The strategic placement of perforations creates natural airflow patterns, saving significant operating costs annually.

These advantages make customized perforated metal panels a wise investment that pays for itself repeatedly.

Why Are Custom Expanded Sheets Popular in 2025?

Custom expanded sheets are totally in right now, and you can totally see why once you get what makes them stand out.

Strength Without Extra Weight

Unlike those perforated sheets where material is actually removed, expanded sheets are stretched out. They cut and pull the metal to create these diamond-shaped holes, minimizing waste. The result is a powerful panel that weighs very little.

This is significant because lighter facades require less structural framing, which reduces construction expenses:

- High-open-area mesh options are commonly available (exact values vary by mesh pattern and gauge)

- Expanded mesh panels are significantly lighter than a solid sheet of the same thickness across the same area

- The process uses the original sheet with minimal scrap compared with punching

- Structural advantage: Inherent ribbing resists bending and shock

However, the fact that it's stretched gives it inherent ribbing that actually resists bending and shocks better than you might believe.

Installation Speed Advantage

Time is construction money, and custom expanded sheets install fast. Their lightweight means smaller crews and lighter equipment. Key advantages include:

- Can install faster than heavier curtain wall systems (crew and site conditions determine actual speed)

- Larger panel sizes are possible due to the lightweight design

- Fewer connections and alignments are needed

- Reduced crane and equipment requirements

Contractors report schedule gains on some projects when switching to lightweight screen systems.

Long-Term Performance

Expanded sheets hold up incredibly well over time. The stretching process work-hardens the metal, making it more resistant to fatigue:

| Performance Factor | Specification |

| Typical lifespan | Often measured in decades, with proper detailing and maintenance |

| PVDF coating warranty | Commonly around 20–30 years, depending on the manufacturer and the environment |

| Material waste | Lower than perforation processes because the material isn’t punched out |

| Maintenance frequency | Driven by environment and detailing rather than pattern type, establish a site-specific maintenance plan |

| Recyclability | Aluminum and steel panels are widely recyclable |

Cleaning's a lot easier, too. The open diamond pattern doesn't catch debris like some of those perforation designs do. Rain washes right through, and pressure washing takes half the time.

Made-to-order sheets are an excellent option for all projects due to their strength, ease of maintenance, and durability.

What Design Trends Are Shaping Metal Curtain Walls in 2025?

The metal curtain wall business is in motion—the industry is experiencing several significant trends that are defining the look of buildings these days.

Incorporation of Intelligent Technology

New custom-made perforated metal panels are anything but passive screens. Modern systems integrate:

- Programmable LED lighting between panel layers

- IoT sensors monitoring air quality, temperature, and sunlight

- Building automation controls for adaptive shading

- Motorized adjustable screens responding to sun angles

- Electrochromic coatings change opacity via electrical current

One exciting development is the use of electrochromic coatings on perforated sheets. In current practice, it's more common to achieve "dynamic transparency" via motorized/adjustable screens or zoned density strategies to a similar effect. It's like smart glass, but with the added benefits of metal's durability and perforation's ventilation.

Geometric Innovation

2025's designs are getting mathematically complex in the best way. Parametric design software lets architects create patterns that would've been impossible five years ago:

- Voronoi patterns: Organic cellular structures

- Fractal geometries: Self-repeating mathematical designs

- Biomimetic designs: Nature-inspired patterns

- Gradient transitions: Gradually morphing diamond openings

- Custom algorithms: Project-specific pattern generation

Specially expanded sheets excel especially here because their fabrication process translates easily to non-standard patterns. A few facades employ gradually changing geometries—the diamond openings vary in size and proportion across the building's surface, producing a visual flow.

Environment-Friendly Production

A growing environmental conscience is driving a new wave of innovative manufacturing techniques for these products:

| Sustainability Feature | Environmental Benefit |

| Expanded mesh production | Lower scrap than perforation because the material is slit and stretched |

| Recycled content | High percentage in most panels |

| End-of-life recyclability | Metals are readily recyclable; actual rates depend on local recycling streams |

| Powder coating/PVDF | Low VOC emissions, durable finish |

| Lifecycle carbon footprint | Can compare favorably to some glazed systems in certain designs; verify with a project-specific LCA |

Expanded-mesh production slits and stretches the original sheet and fully uses the material, yielding virtually zero scrap. Metal panels usually contain high recycled content and are 100% recyclable (exact share depends on the supply chain). Common finishes such as powder coating and PVDF offer durability and low maintenance.

All these are signposts that metal curtain walls are transforming to address style goals and environmental challenges.

What to Consider When Choosing Custom Metal Panels?

Selecting the right system isn't just about looks—several critical factors need attention to ensure project success.

Project Requirements Analysis

Start with the basics: What's the building's purpose? Office buildings need different solutions than parking structures or residential towers. Climate also plays a significant role—coastal buildings require corrosion-resistant alloys, while desert climates demand high solar reflectivity.

Key considerations include:

- Building type: Office, residential, parking, industrial

- Climate conditions: Coastal, desert, temperate, tropical

- Vision requirements: Privacy vs. transparency balance

- Security needs: Forced entry resistance levels

Consider the requirements for vision. Perforated metal panels offer greater vision control than expanded sheets, but they have fewer security benefits against forced entry than expanded sheets.

Building Codes and Safety

Each zone has its own requirements. Fire ratings are relevant—all metal construction generally has high ratings; however, fixing techniques and infill materials vary. Wind load calculations are a requirement to ensure that the facade will not delaminate during storms.

Essential compliance factors:

- Fire ratings and material certifications

- Wind load engineering and testing

- Seismic performance requirements

- Ground-level perforation specifications for accessibility

- Local building code variations

A few jurisdictions mandate unique perforation spacings or configurations at the floor level for accessibility or security purposes. Engage your code consultant early to avoid costly redesigns.

Budget and Timing Preparation

Here's the truth: anything custom is initially more expensive than off-the-shelf products. Custom perforations/patterns typically cost more than standard options (the amount varies by process and material).

| Cost Factor | Perforated Sheet | Expanded Sheet |

| Initial material cost | Standard baseline | Often lower than perforated of similar area/spec (process-dependent) |

| Customization premium | Moderate to high | Moderate |

| Installation labor | Standard | Often faster due to lighter weight and fewer attachments |

| Energy payback period | Project-dependent; can occur within a few years in favorable cases | Project-dependent; can occur within a few years in favorable cases |

| Long-term ROI | Excellent | Excellent |

But consider overall project expenditures. More rapid installation reduces labor expenses. Increased efficiency reduces operating costs. For solar-control applications, the typical payback is about 3–7 years (dependent on climate, orientation, and system design).

Spending time upfront evaluating these factors will guarantee that you select the system that most closely meets the needs of your unique project.

FAQ

Q1. What's the Real Difference Between Perforated Sheet and Expanded Sheet?

Perforated metals are manufactured by punching holes from solid metals, while expanded metals are manufactured by slitting and stretching. Perforated metals offer an unlimited range of patterns, including circles, squares, and customized designs. From a cost perspective, expanded mesh often comes in cheaper than a perforated sheet of comparable specs because it uses the original sheet efficiently and minimizes scrap (actual figures vary by material/mesh type). Select perforated metals where appearance is most critical; expanded metals for weight-to-strength ratio and economy.

Q2. How Much Will Such Custom-Perforated Metal Panels Save in Terms of Energy?

It depends on design and context, but well-tuned custom-perforated panels can deliver meaningful savings. By cutting solar heat gain, projects commonly see single- to low-double-digit reductions in cooling energy, with the exact value driven by perforation ratio, depth/stand-off, orientation, glazing, and controls. Paired with natural ventilation and daylight-responsive lighting, they can lower peak cooling demand and annual HVAC use, shorten payback in suitable climates, and extend equipment life while reducing lighting costs through improved daylight distribution.

Q3. Can Custom Expanded Sheets Actually Work on Tall Buildings?

Yes, custom expanded metal can perform on tall buildings when engineered correctly. Panel gauge, strand width, and LWD/SWD must be sized for wind and suction loads, thermal movement, and serviceability, with tested subframes, anchors, and corrosion-resistant finishes. Project mockups and wind-tunnel or CFD studies are common. With fire, fall-protection, and maintenance access addressed, expanded screens deliver durable shading and ventilation at low weight, and can be detailed for acoustics, bird safety, and replaceable modules.

Conclusion

Updated perforated metal paneling and bespoke expanded sheeting are transforming construction. They save money, hasten the process, and look great. Want your project to level up? When you're looking for reliable metal curtain wall solutions, Ansus Metal is a trusted partner. As a specialized manufacturer of custom perforated metal panels and expanded sheets, Ansus Metal provides comprehensive services from design consultation to installation support.

Share:

Guide to Design and Application of Architectural Metal Facades