Aluminium Composite Panel

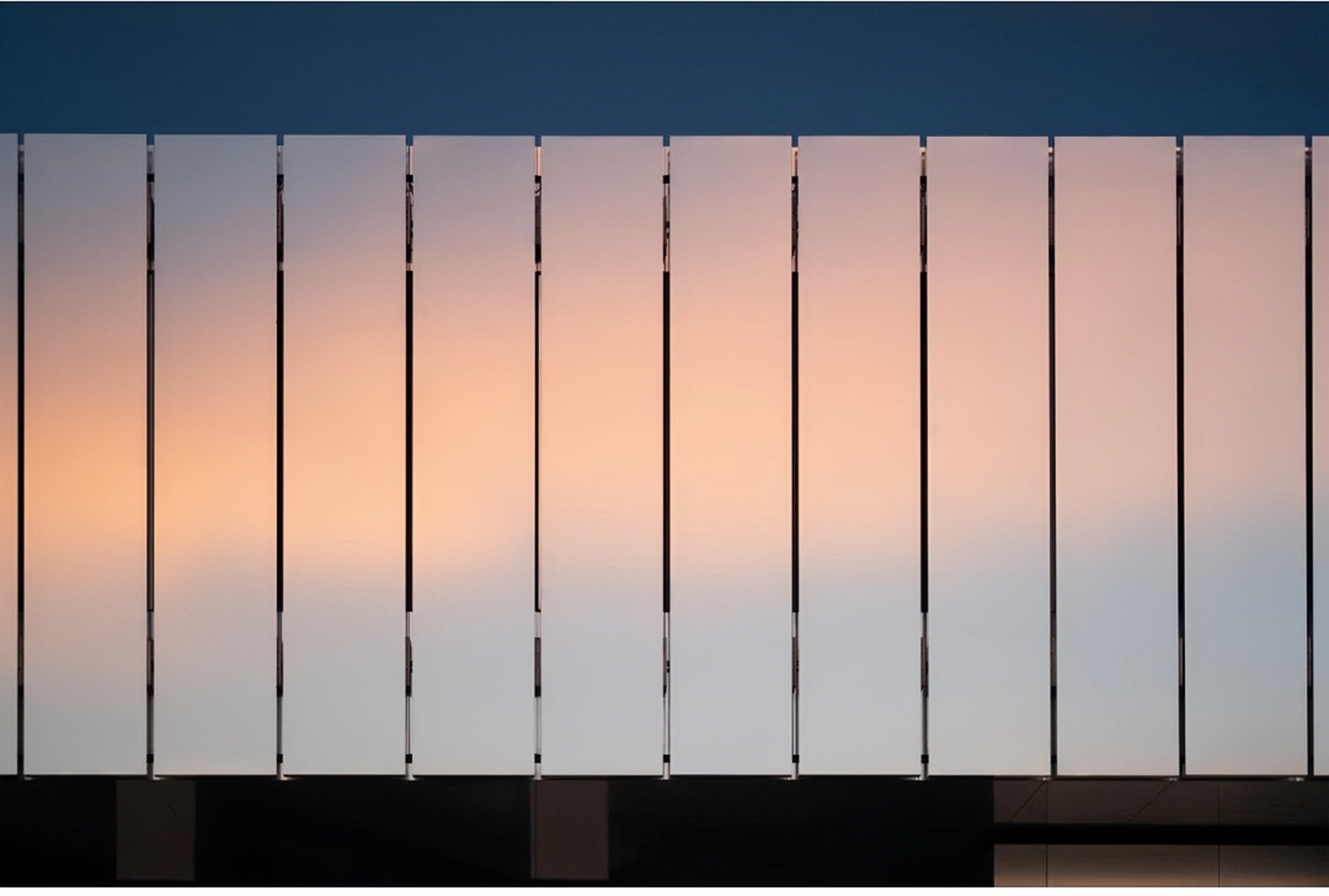

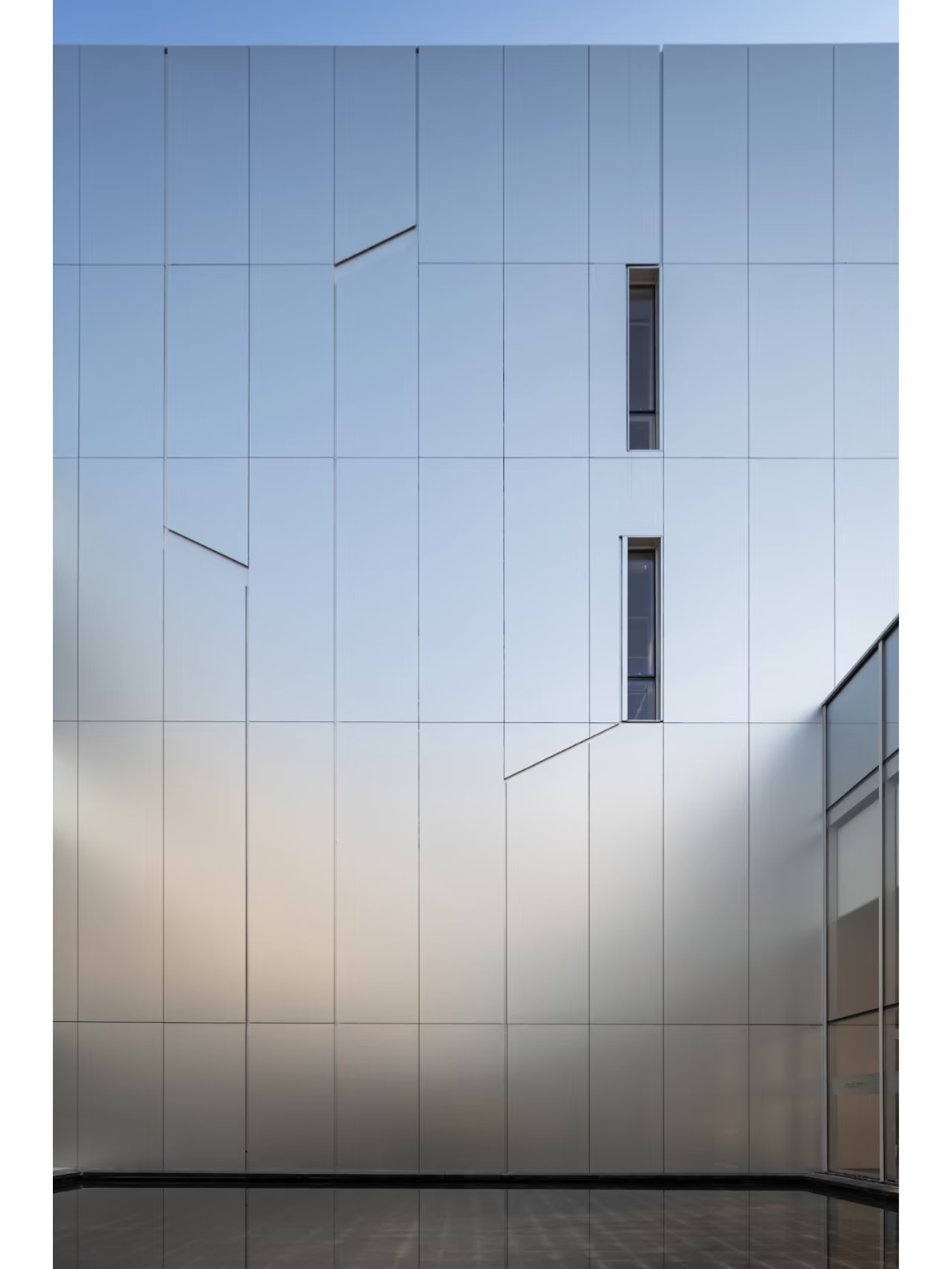

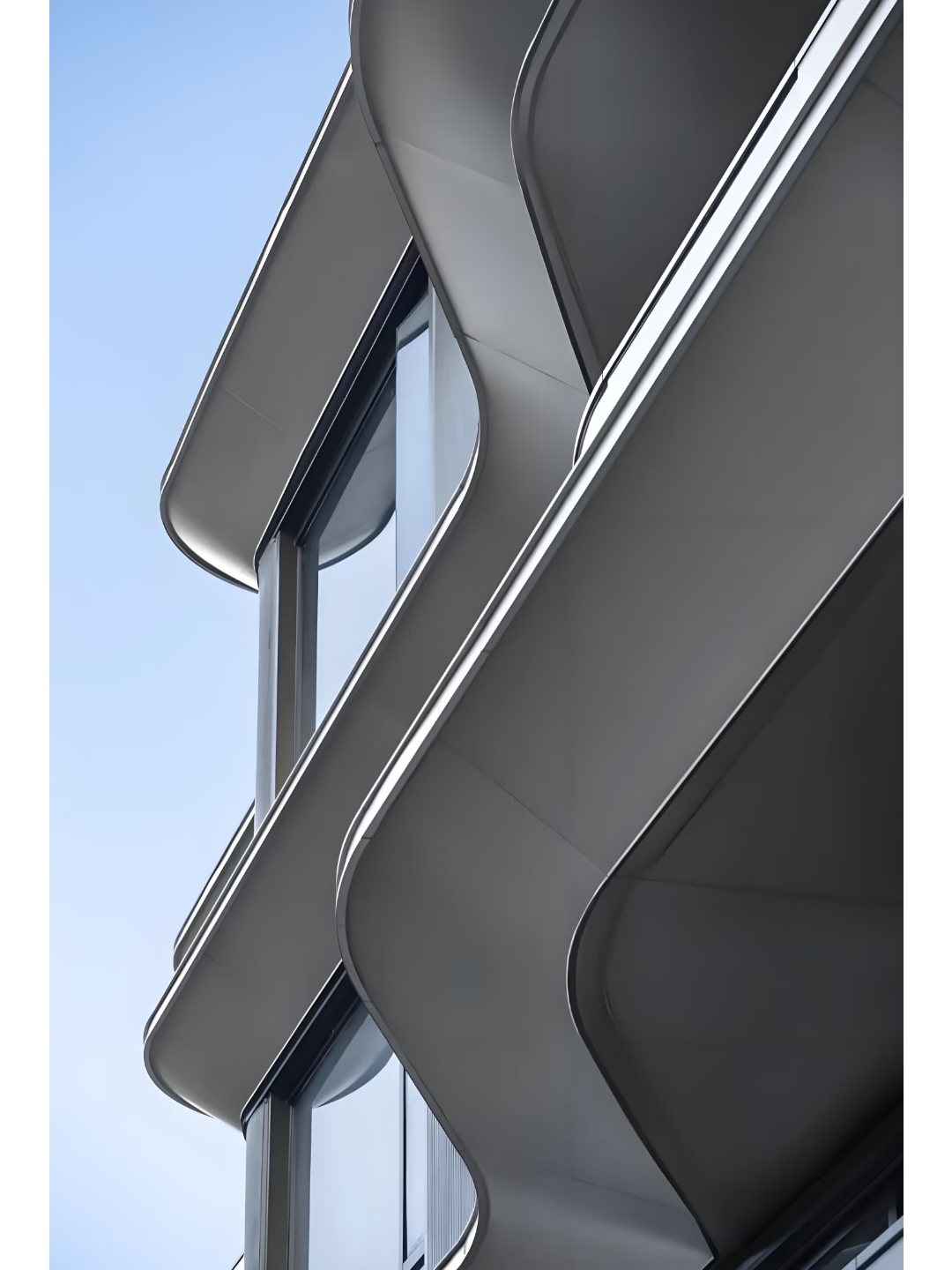

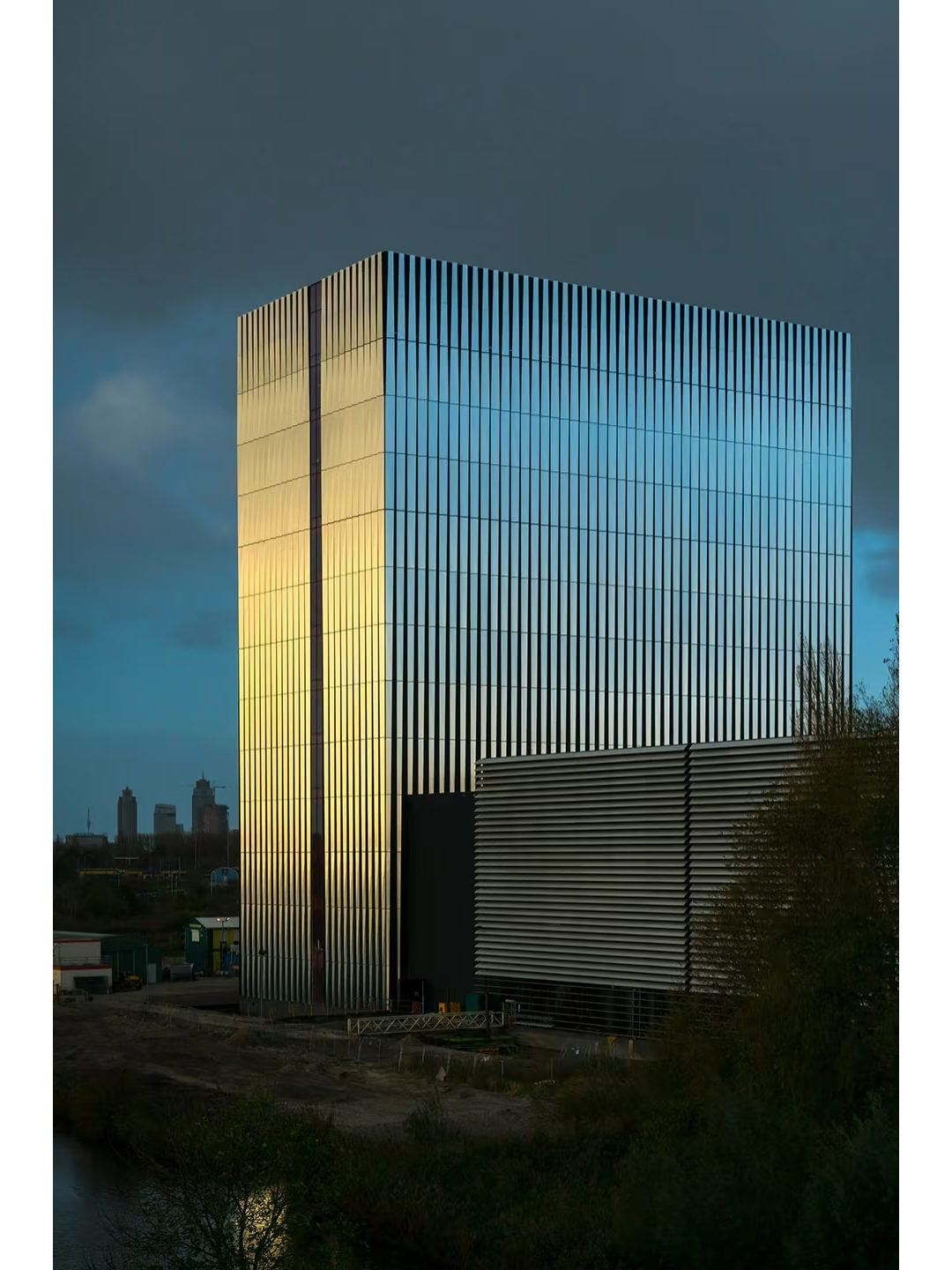

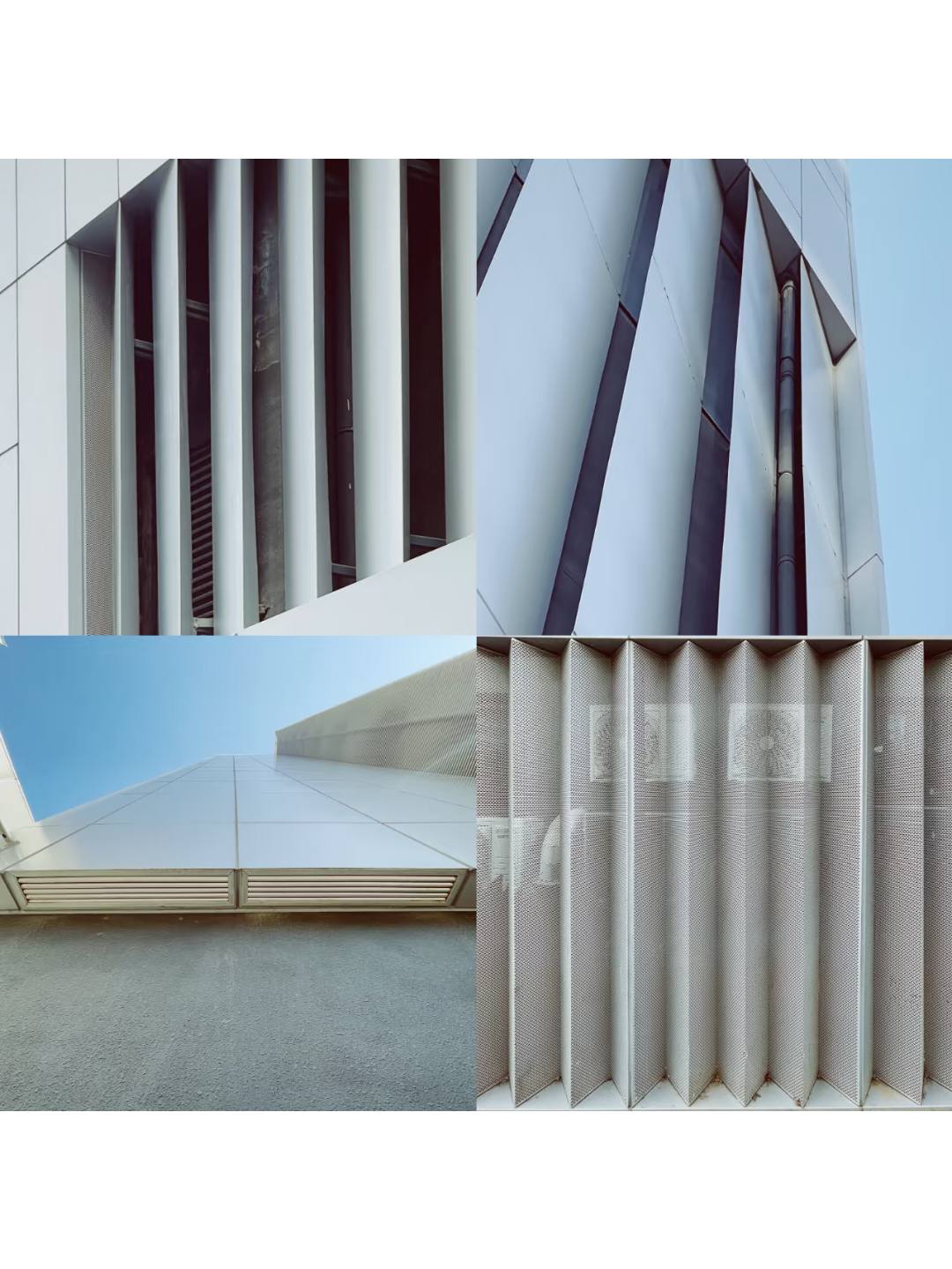

High-performance Aluminium Composite Panels (ACP) engineered for architectural applications that demand superior flatness, light weight, and a modern aesthetic. Manufactured by bonding two aluminum sheets to a central core, these 'sandwich' panels deliver an exceptional strength-to-weight ratio, remarkable rigidity, and outstanding design flexibility for any facade.

Aluminium Composite Panels (ACP) are a highly versatile and cost-effective solution, favored for their flatness, formability, and light weight.

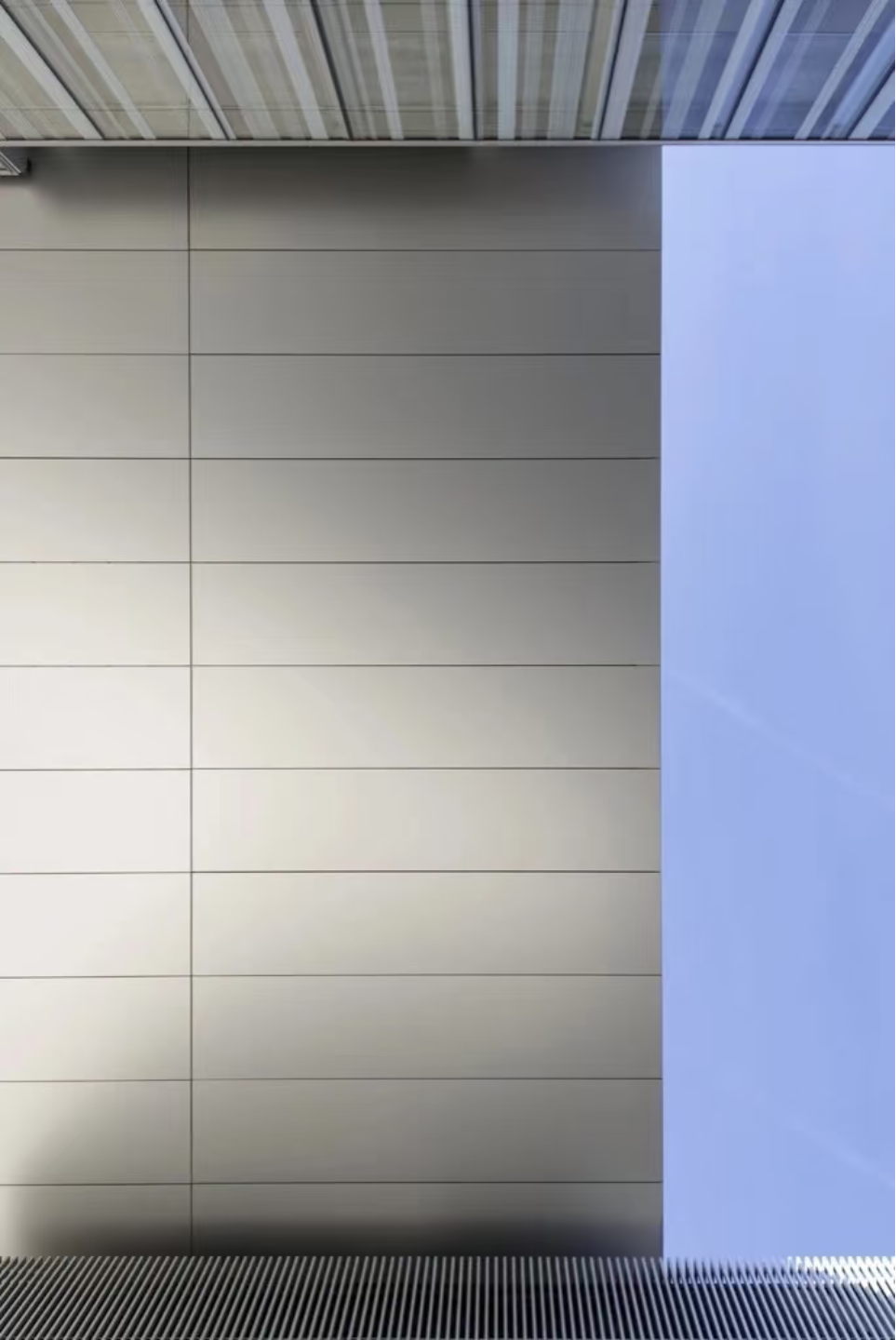

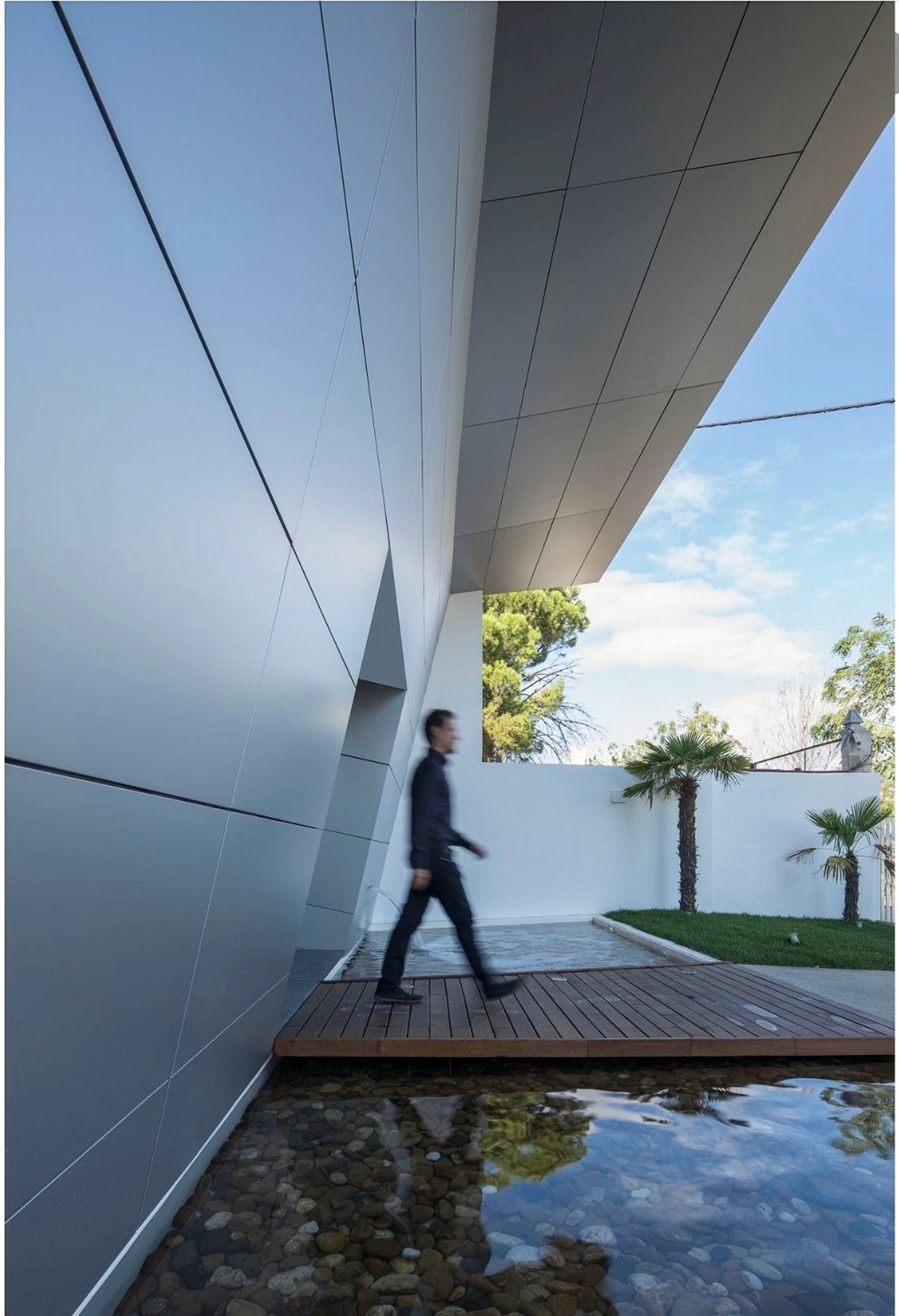

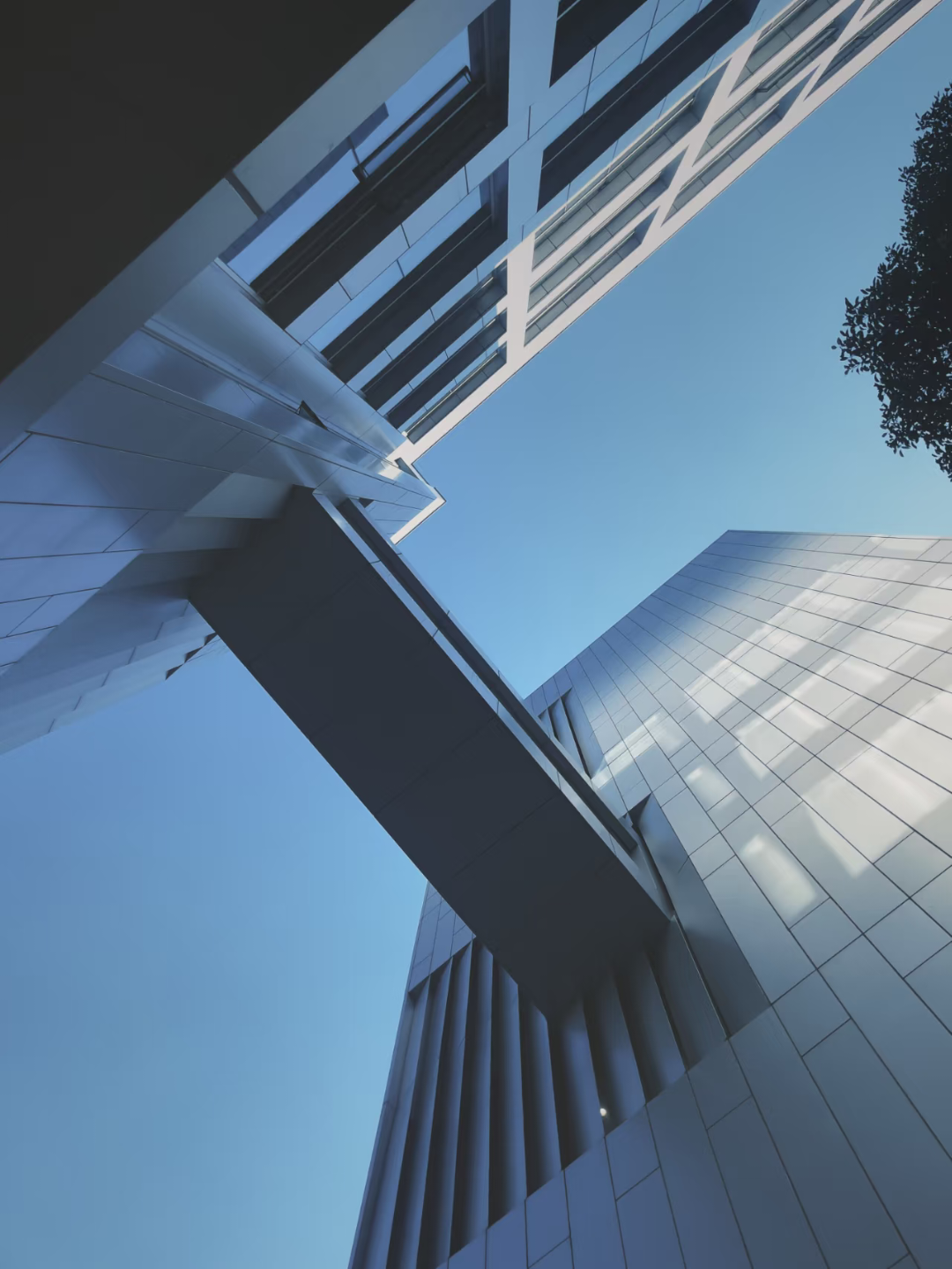

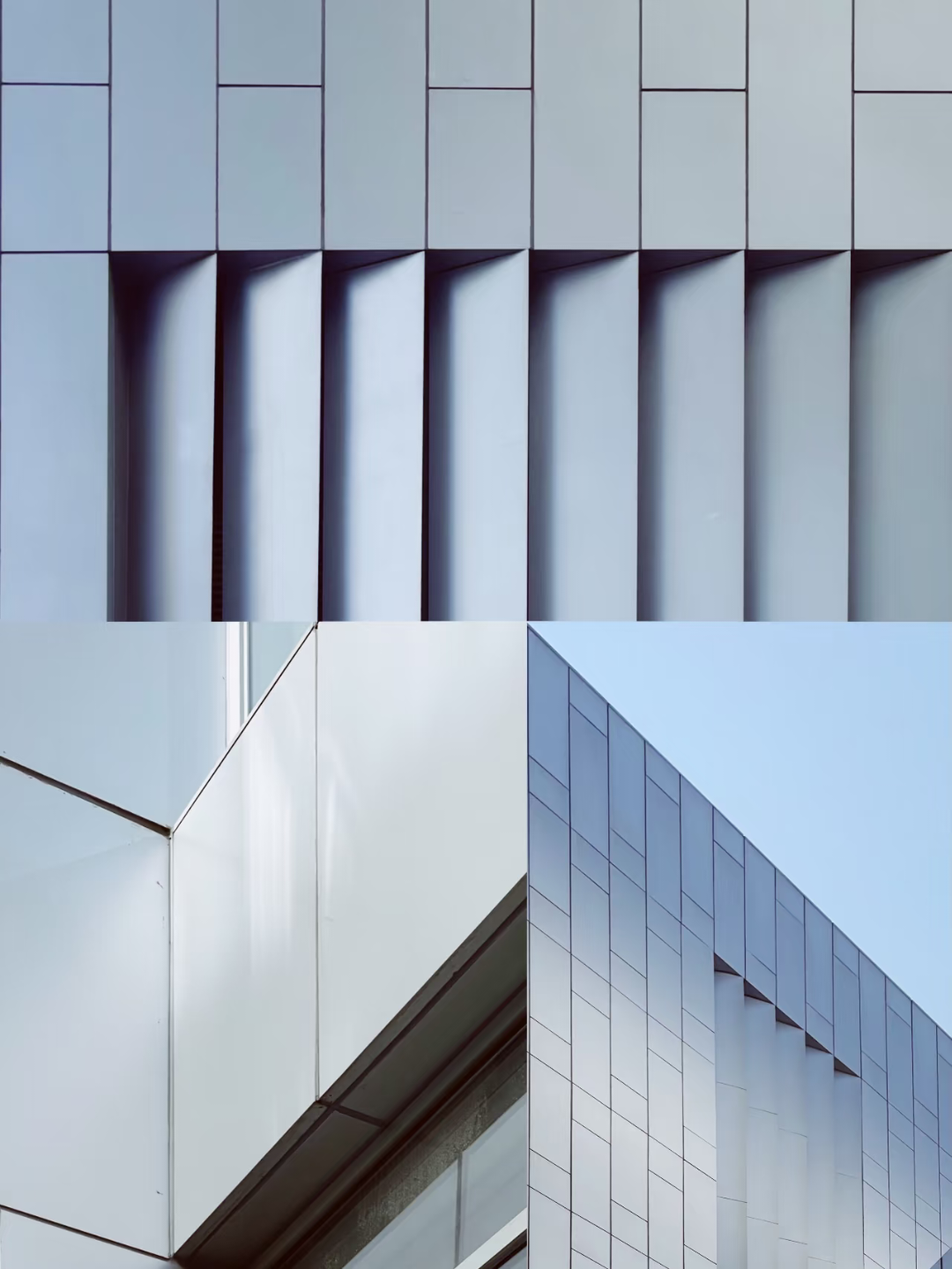

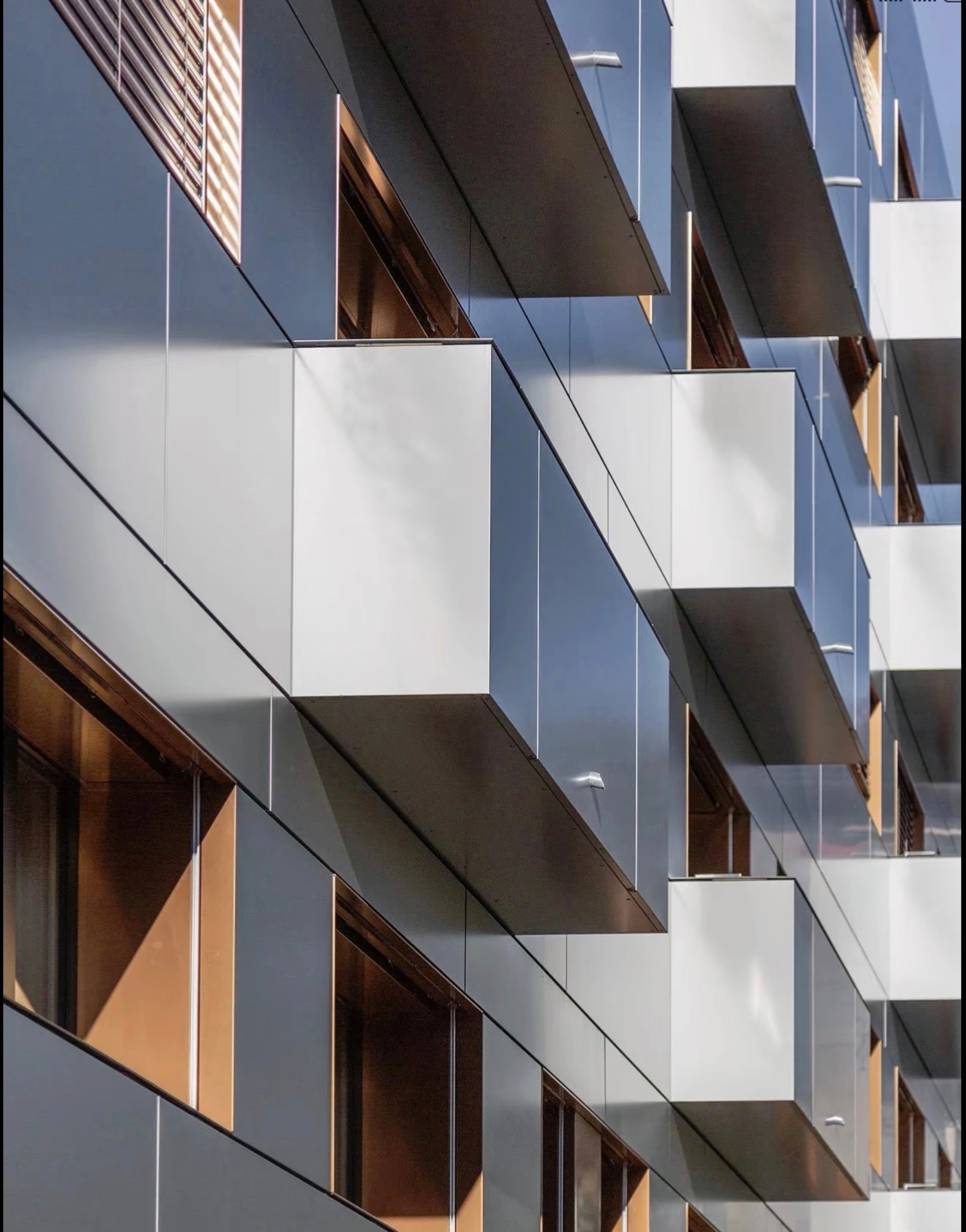

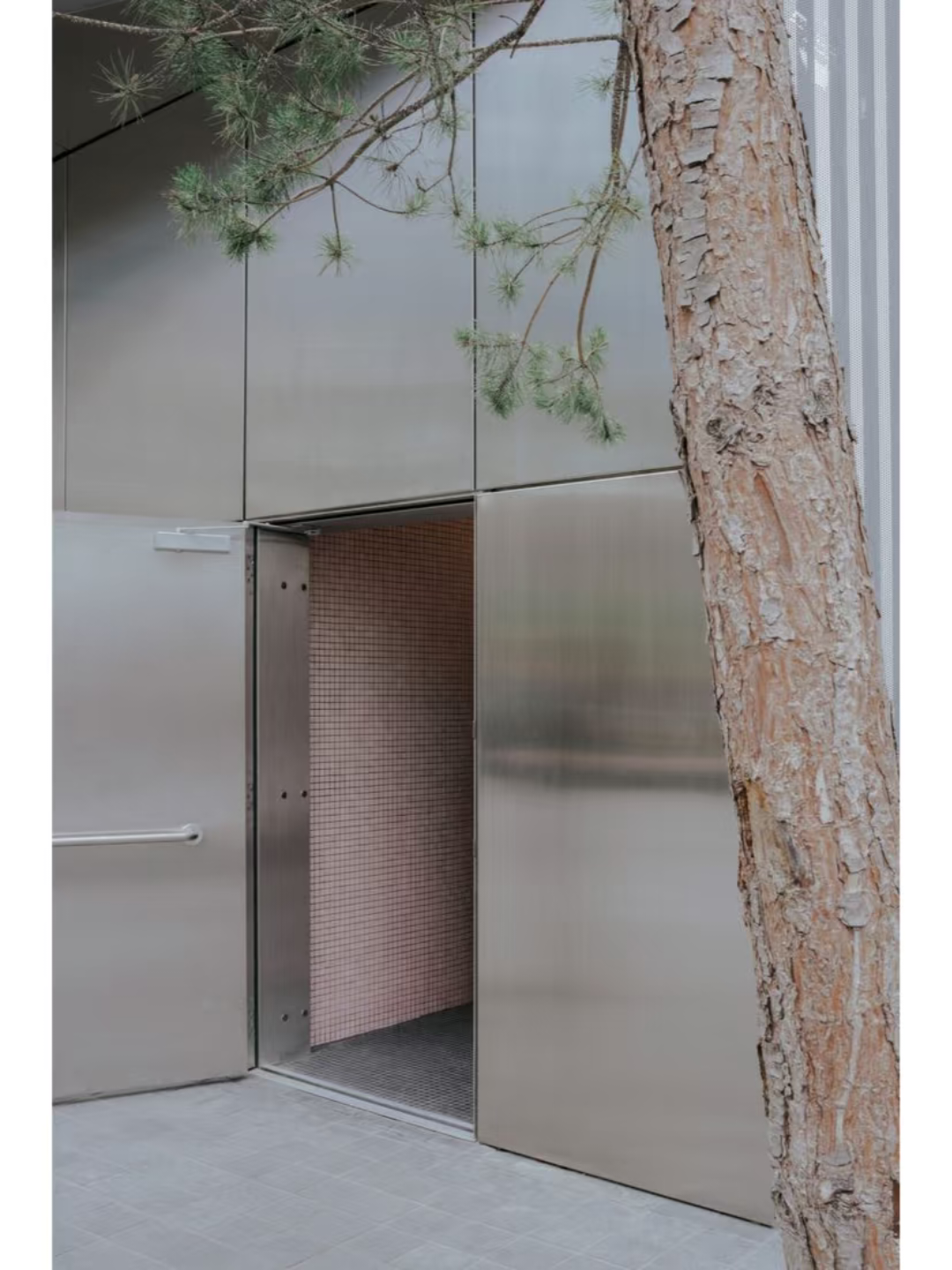

- Architectural Cladding & Facades: Widely used for exterior curtain walls, building facades, and canopy cladding on commercial and residential buildings.

- Signage & Brand Identity: The ideal substrate for corporate signage, retail storefronts, POS displays, and large-format advertising boards.

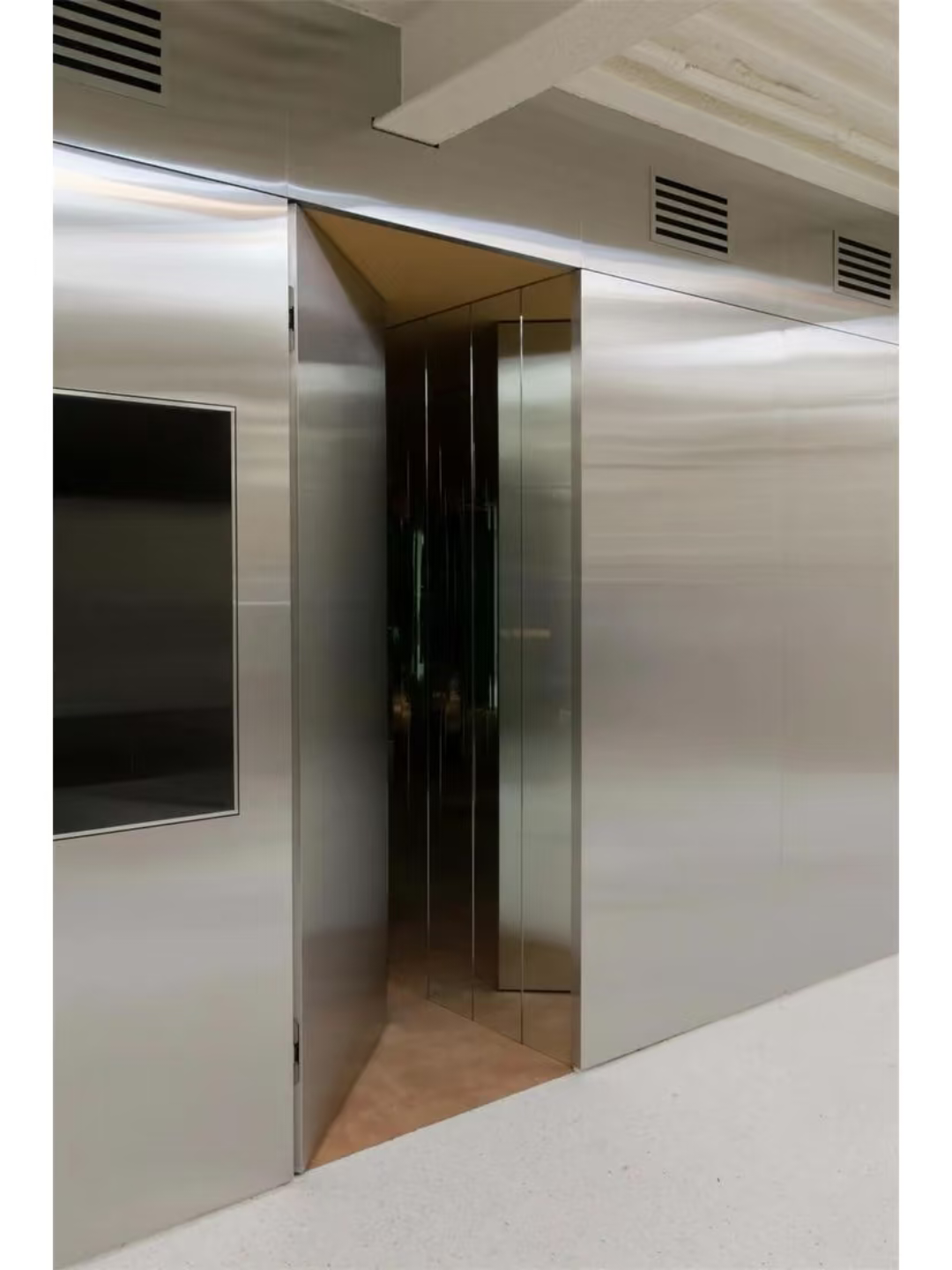

- Interior Decoration & Partitions: Perfect for interior wall finishes, decorative partitions, false ceilings, and column covers in modern spaces.

Excellent Strength-to-Weight Ratio

The composite structure provides outstanding rigidity and flatness while being significantly lighter than solid metal, reducing installation costs and structural load.

Superior Formability & Design Freedom

Easily cut, curved, bent, and folded to achieve complex shapes and dynamic architectural designs that are difficult with other materials.

Versatile Finishes & Cost-Effective

Offers a vast array of colors, patterns (e.g., wood, stone), and textures, providing a premium look at an economical price point for projects of any scale.

| Property | Standard | Premium | Fire-Rated |

|---|---|---|---|

| Total Thickness | 3mm, 4mm | 4mm, 5mm, 6mm | 4mm, 6mm |

| Aluminum Face Sheet | 0.21mm each side | 0.30mm each side | 0.30mm each side |

| Core Material | LDPE | LDPE | FR Mineral Core |

| Panel Weight | 5.5 kg/m² (4mm) | 6.8 kg/m² (4mm) | 8.2 kg/m² (4mm) |

| Max Panel Size | 1220x2440mm | 1500×4000mm | 1220x2440mm |

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | ≥124 N/mm² | ASTM D638 |

| Flexural Strength | ≥61 N/mm² | ASTM D790 |

| Peel Strength | ≥6.5 N/mm | ASTM D1876 |

| Thermal Expansion | 2.4×10-5/°C | ASTM D696 |

| Fire Rating | Class A2-s1,d0 | EN 13501-1 |

| Weather Resistance | Pass 4000hrs | ASTM G155 |

| Finish Type | Thickness | Colors Available | Warranty |

|---|---|---|---|

| PVDF Coating | 25-30μm | 200+ Standard Colors | 20 Years |

| Polyester | 25μm | 100+ Standard Colors | 10 Years |

| Anodized | 15-25μm | Natural, Bronze, Black | 15 Years |

| Property | Performance | Test Standard |

|---|---|---|

| Fire Rating | Class A Non-combustible | ASTM E84 |

| Weather Resistance | 3000+ hours (Coated) | ASTM G155 |

| Salt Spray Resistance | 1000+ hours (AI/SS) | ASTM B117 |

| UV Stability | Excellent (Metal substrate) | ASTM G154 |

| Thermal Cycling | -40°C to +85°C | ASTM D4329 |

| Wind Load Capacity | Up to 2.5 kPa* | *Engineering required |

FAQs

Are Aluminum Composite Panels Fire Safe for Building Cladding?

Yes, aluminum composite panels can be fire-safe when you choose the right type for your building application. Fire-rated aluminum composite panels with mineral-filled cores meet stringent international fire safety standards, including Class A2-s1,d0 non-combustible rating. These panels are specifically designed for high-rise buildings and commercial cladding applications.

For maximum fire safety in building cladding:

- Choose fire-retardant core ACP panels for buildings over 18 meters

- Ensure compliance with local building codes and fire regulations

- Use proper installation methods with fire-rated mounting systems

- Consider aluminum honeycomb core panels for premium fire resistance

Standard polyethylene core panels may have restrictions in high-rise applications, so always consult building codes and fire safety engineers for your specific project.

How Long Do Aluminum Composite Panels Last on Building Facades?

Aluminum composite panels for cladding typically last 20-30 years with proper installation and minimal maintenance. The lifespan depends on several factors:

PVDF-coated aluminum composite panels offer the longest durability:

- 20-year manufacturer warranty against fading and chalking

- Superior weather resistance in harsh climates

- Excellent UV protection and color retention

Factors affecting ACP panel lifespan:

- Surface coating quality (PVDF lasts longer than polyester)

- Climate conditions and environmental exposure

- Installation quality and proper mounting systems

- Regular maintenance and cleaning schedules

Polyester-coated panels typically last 10-15 years, while anodized aluminum composite panels maintain their appearance for 15-20 years. Proper installation with adequate drainage and ventilation significantly extends panel life.

What is the Cost of Aluminum Composite Panel Cladding per Square Meter?

Aluminum composite panel cladding costs vary by quality, finish, and project size, typically ranging from budget-friendly to premium options. Here's a breakdown of ACP cladding costs:

Cost factors for aluminum composite panel cladding:

- Panel thickness (3mm, 4mm, 5mm, 6mm options)

- Surface finish type (PVDF, polyester, anodized)

- Fire rating requirements (standard vs. fire-rated cores)

- Custom colors vs. standard color options

- Project size and quantity discounts

Additional costs to consider:

- Installation and mounting systems

- Structural support and framing

- Transportation and handling

- Building permits and engineering

ACP offers excellent value compared to solid aluminum panels, natural stone cladding, or high-end fiber cement, providing superior aesthetics and performance at competitive pricing. Contact us for detailed project quotes and cost comparisons.

Can Aluminum Composite Panels Withstand High Winds and Weather?

Yes, aluminum composite panels are engineered to withstand high winds and severe weather conditions when properly installed with appropriate mounting systems. ACP panels offer excellent structural performance for building cladding applications.

Wind resistance capabilities:

- Wind load capacity up to 3.0 kPa or higher with proper engineering

- Lightweight construction reduces structural load on buildings

- High tensile strength (≥124 N/mm²) provides structural integrity

- Thermal expansion control prevents panel distortion

Weather resistance features:

- Corrosion-resistant aluminum construction

- UV-stable coatings prevent fading and degradation

- Moisture resistance with proper drainage systems

- Temperature cycling resistance from -40°C to +80°C

Critical installation requirements:

- Professional structural engineering for wind load calculations

- Proper mounting systems with thermal expansion joints

- Quality sealants and weatherproofing

- Regular inspection of fasteners and connections

For hurricane-prone or high-wind areas, consult with structural engineers to ensure proper panel selection and installation methods.

How Do You Install Aluminum Composite Panels for Building Cladding?

Aluminum composite panel installation requires professional expertise and proper mounting systems to ensure long-term performance and building code compliance. Here's an overview of the ACP installation process:

Common ACP installation methods:

- Rainscreen mounting system - Most popular for ventilated facades

- Cassette system installation - Pre-fabricated panels for faster installation

- Stick system method - Field-assembled for complex geometries

- Structural glazing system - Seamless appearance applications

Key installation steps:

- Structural assessment and engineering calculations

- Mounting framework installation with proper spacing

- Panel cutting and fabrication to precise dimensions

- Weatherproof sealing and joint treatment

- Quality inspection and testing

Professional installation benefits:

- Building code compliance and permit approval

- Proper wind load resistance and structural integrity

- Weatherproof installation preventing water infiltration

- Manufacturer warranty protection

DIY installation limitations: While possible for small projects, building facade installation requires knowledge of structural loads, thermal expansion, and weatherproofing. We strongly recommend professional installation for commercial cladding projects to ensure safety and performance.

What is an aluminium composite panel?

Aluminium Composite Panel (ACP) is Aluminium Composite Material (ACM) manufactured and delivered as a flat sheet. This is super light-weight, versatile, cold workable, easy to fix and install, and highly decorative for creative non-loadbearing applications in the signage, fit-out and building industries.

ACP differs in the type of core material used and the aluminium skins bonded on both sides. They also differ in the paint system, colour and finish that together affect the aesthetic outcomes as well as the longevity influenced by environmental factors such as sunlight, moisture, chemicals and usage.