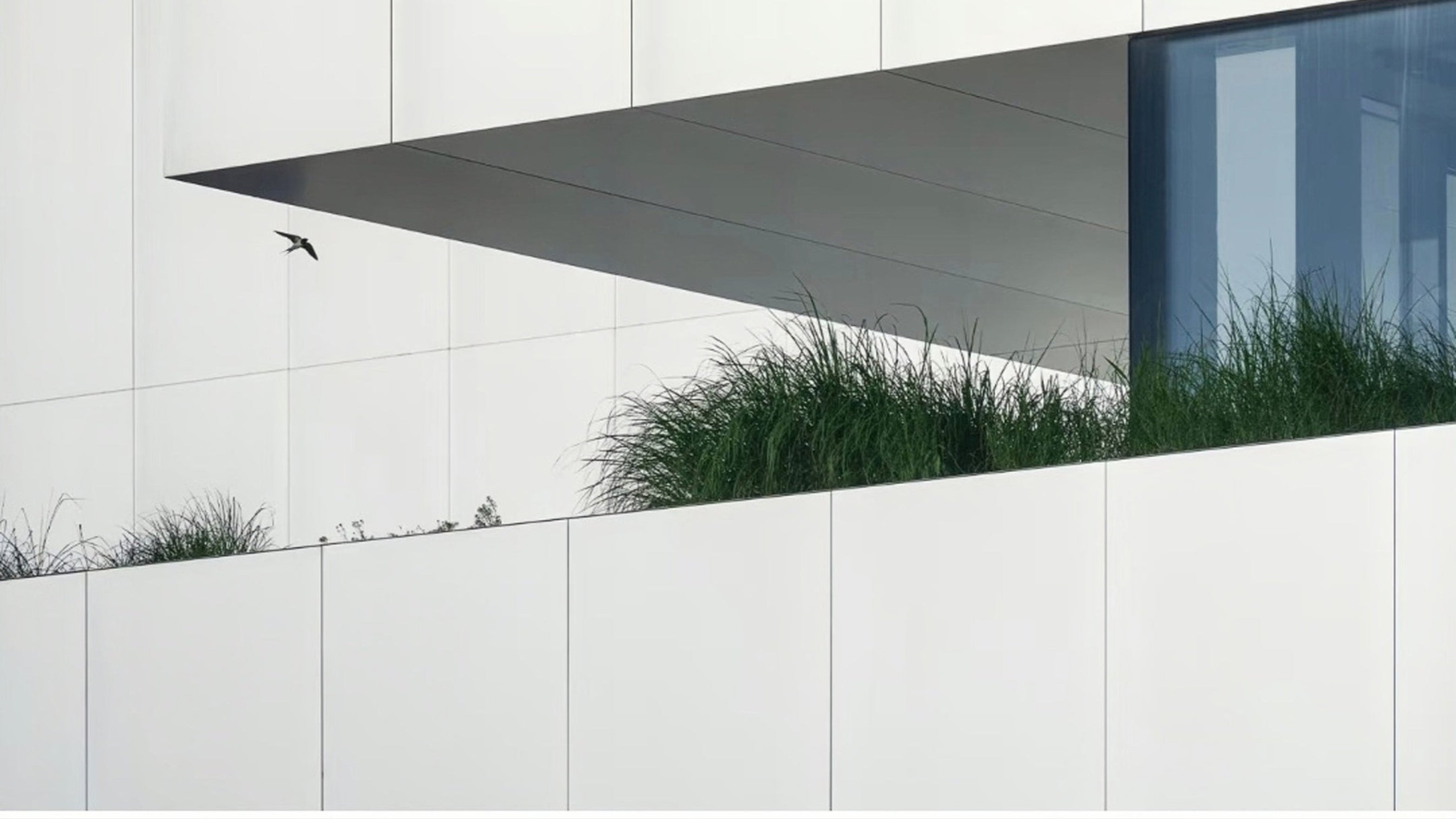

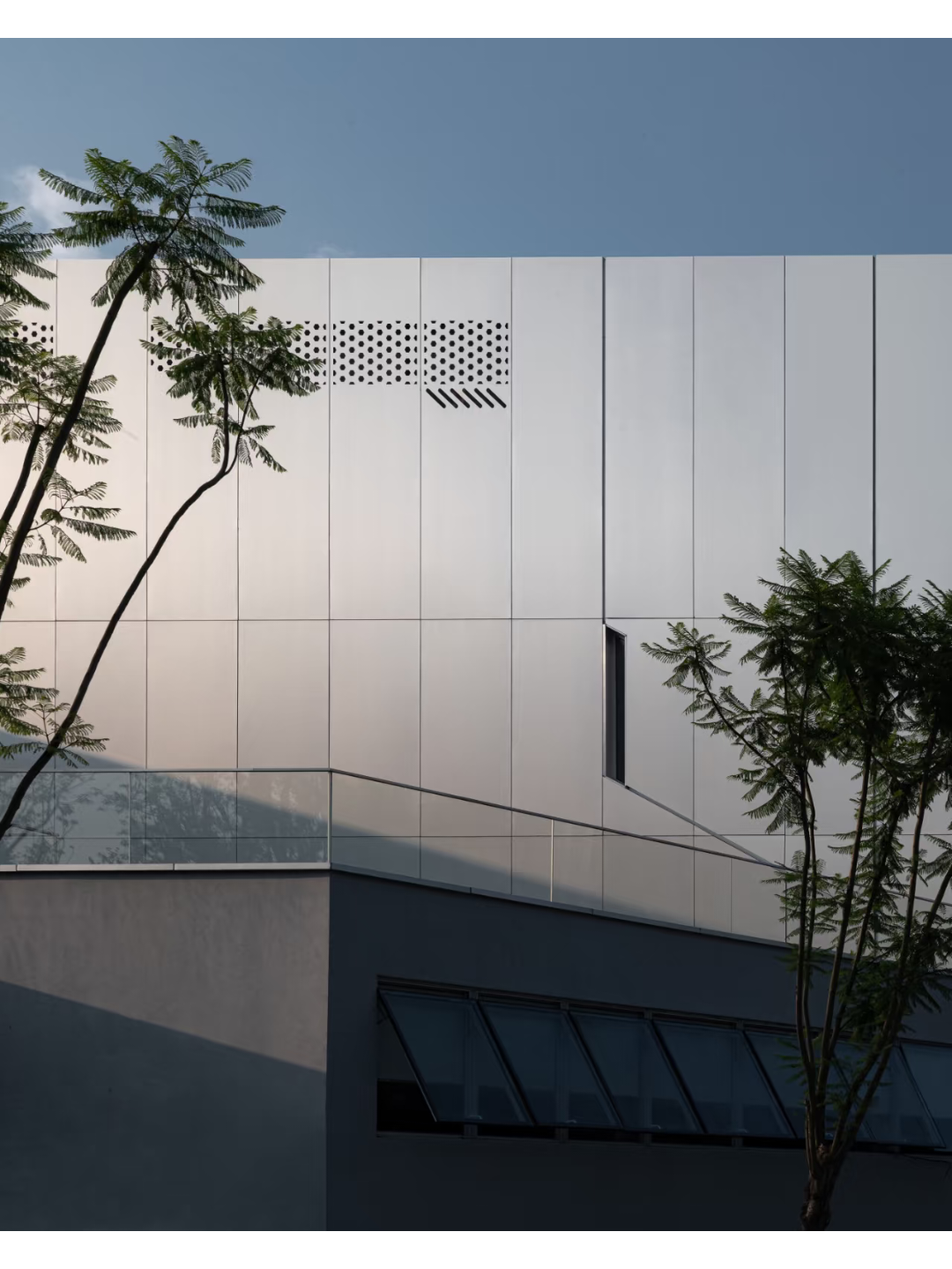

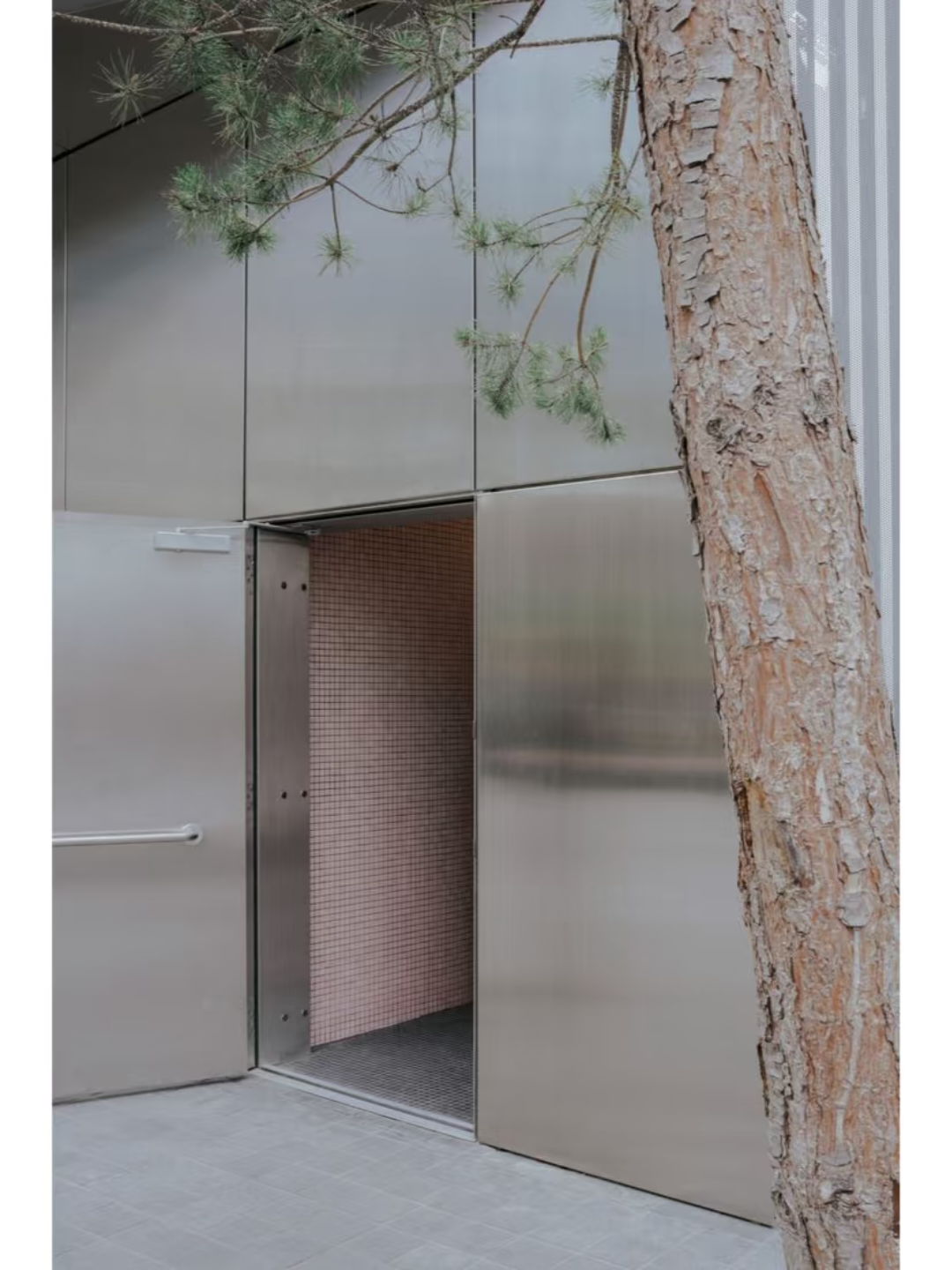

Aluminum Panel for Cladding

Premium solid aluminum panels engineered specifically for architectural cladding applications. These high-performance panels deliver exceptional durability, weather resistance, and aesthetic appeal for commercial and residential building facades. Made from high-grade aluminum alloys with advanced surface treatments, our aluminum cladding panels provide long-lasting protection and striking visual impact.

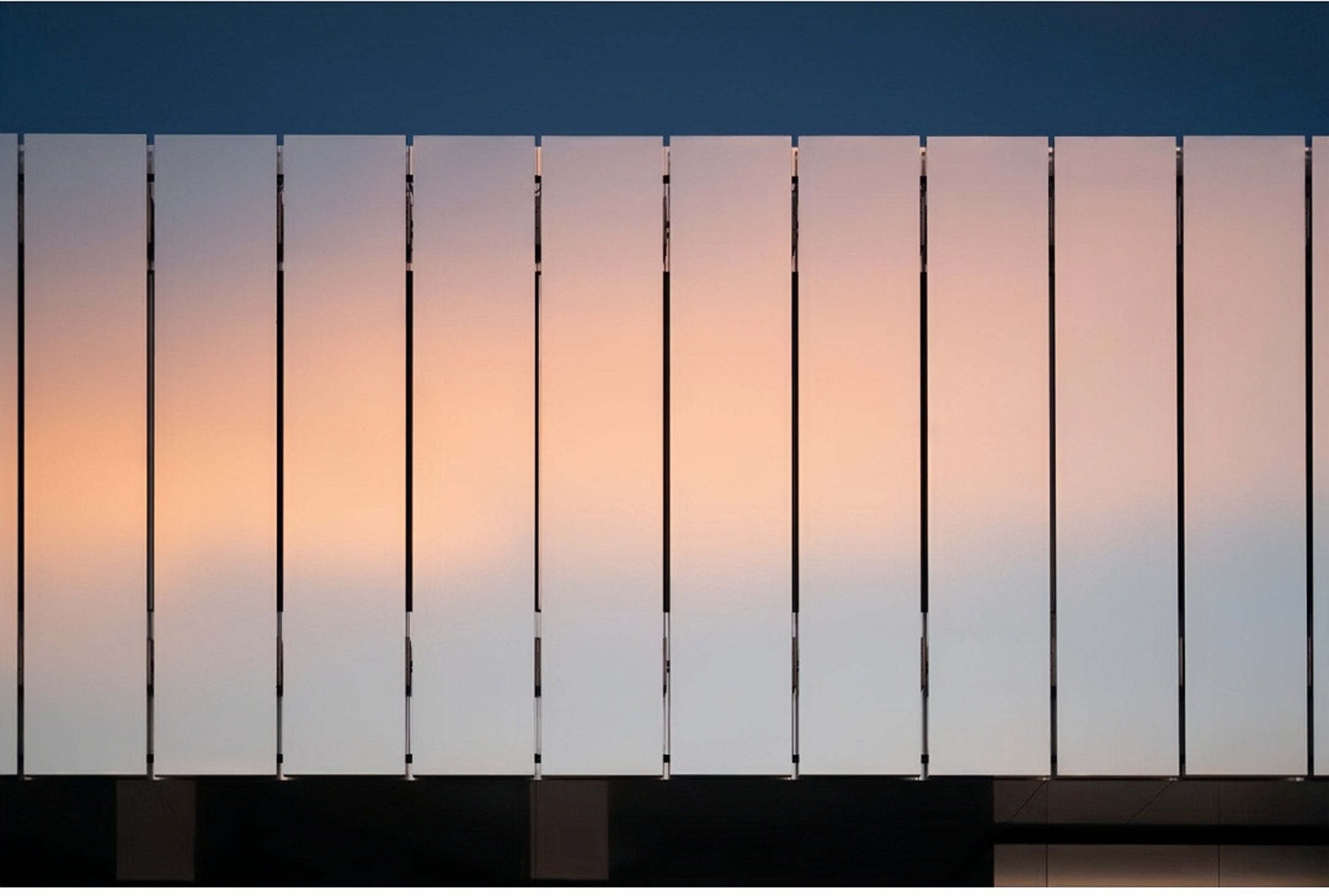

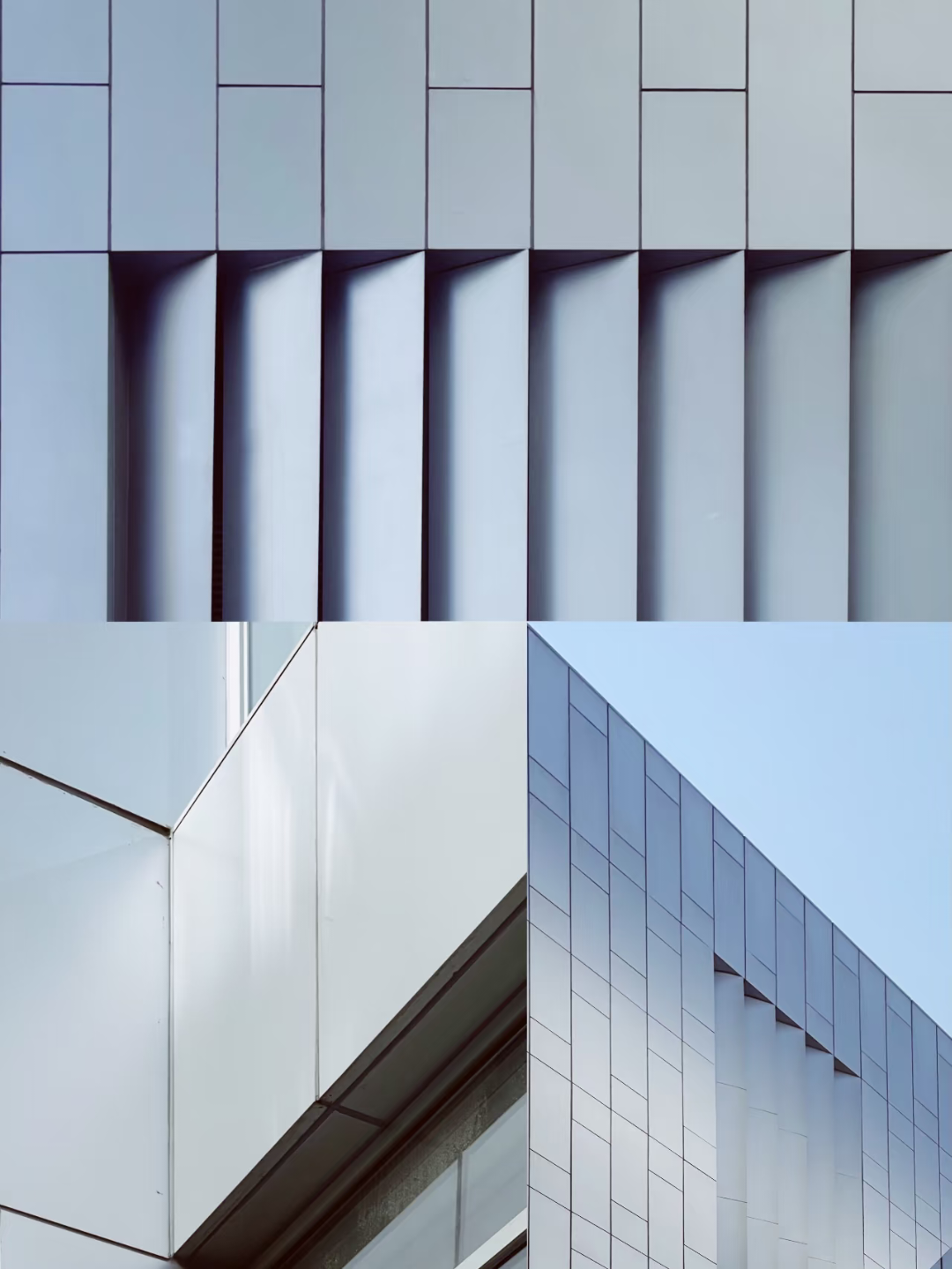

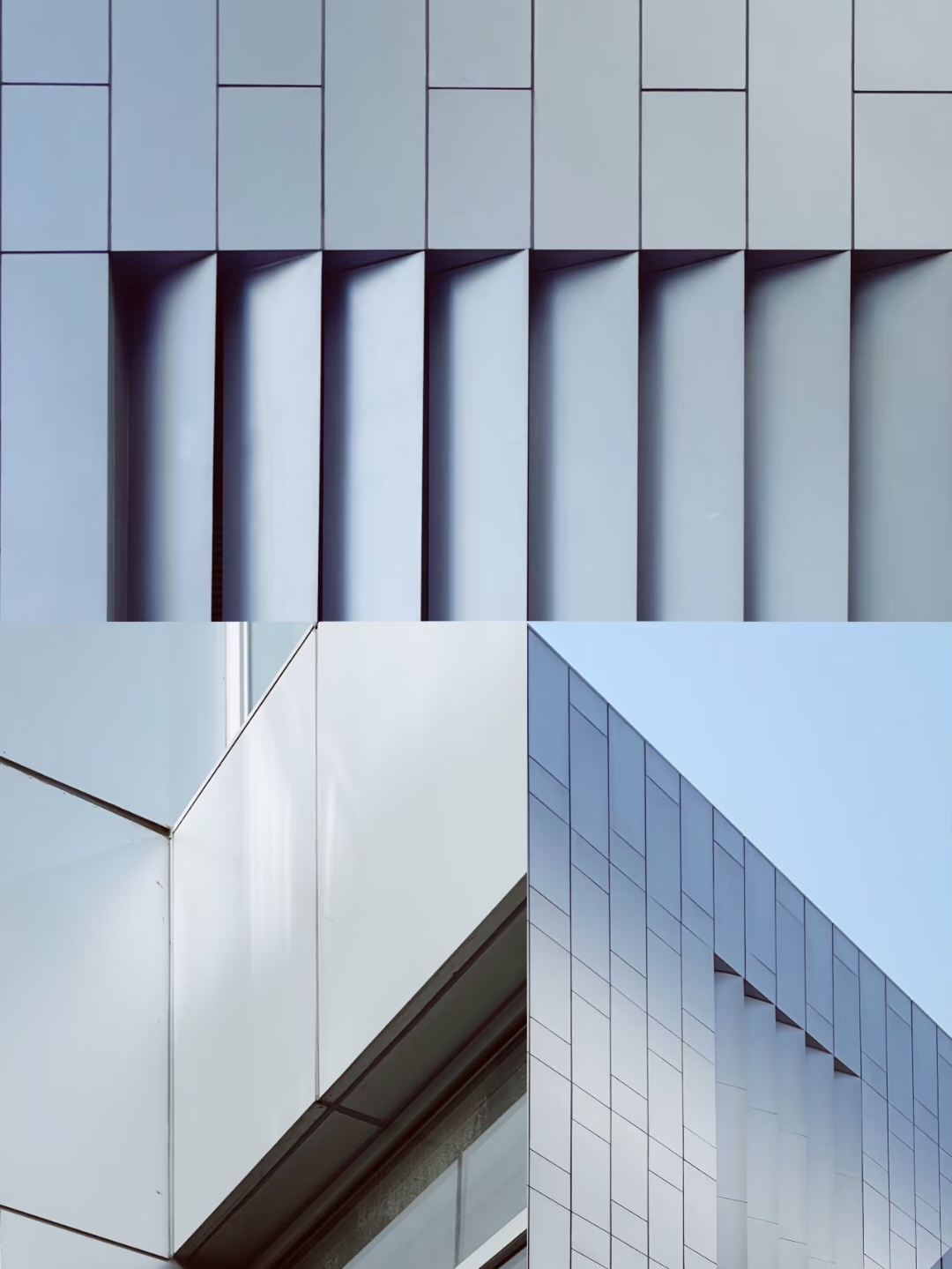

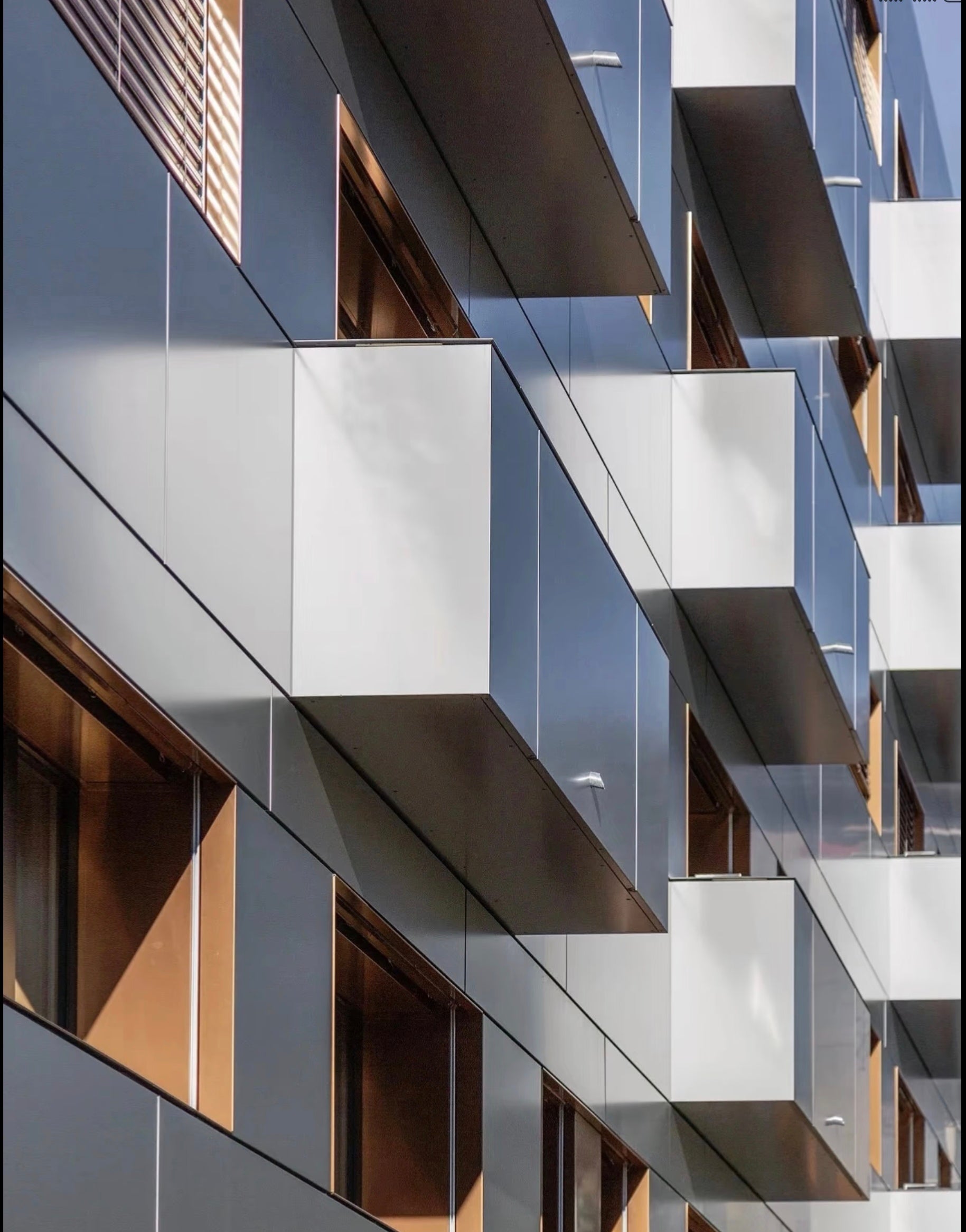

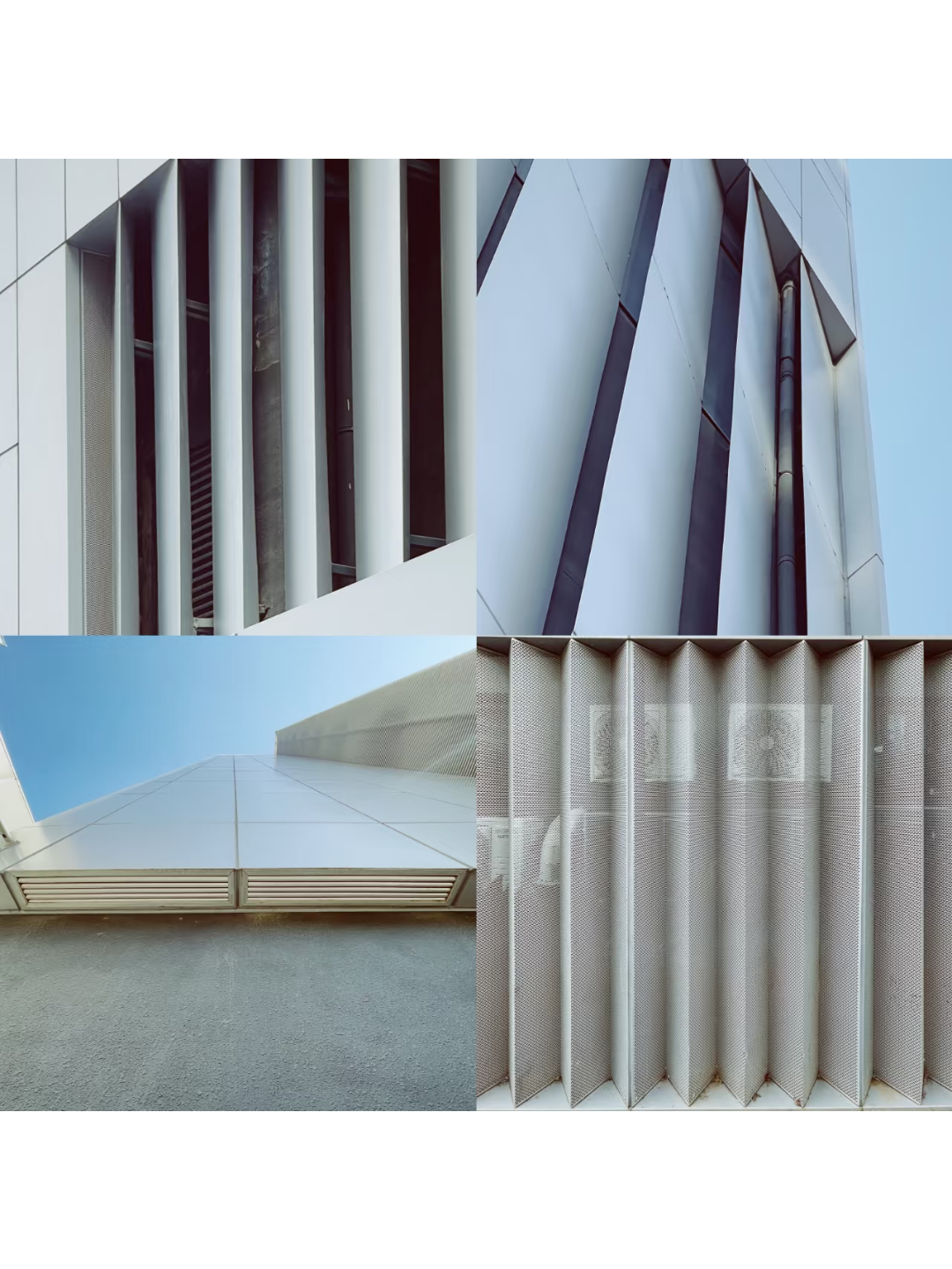

Engineered for creating sleek, modern, and high-performance building exteriors.

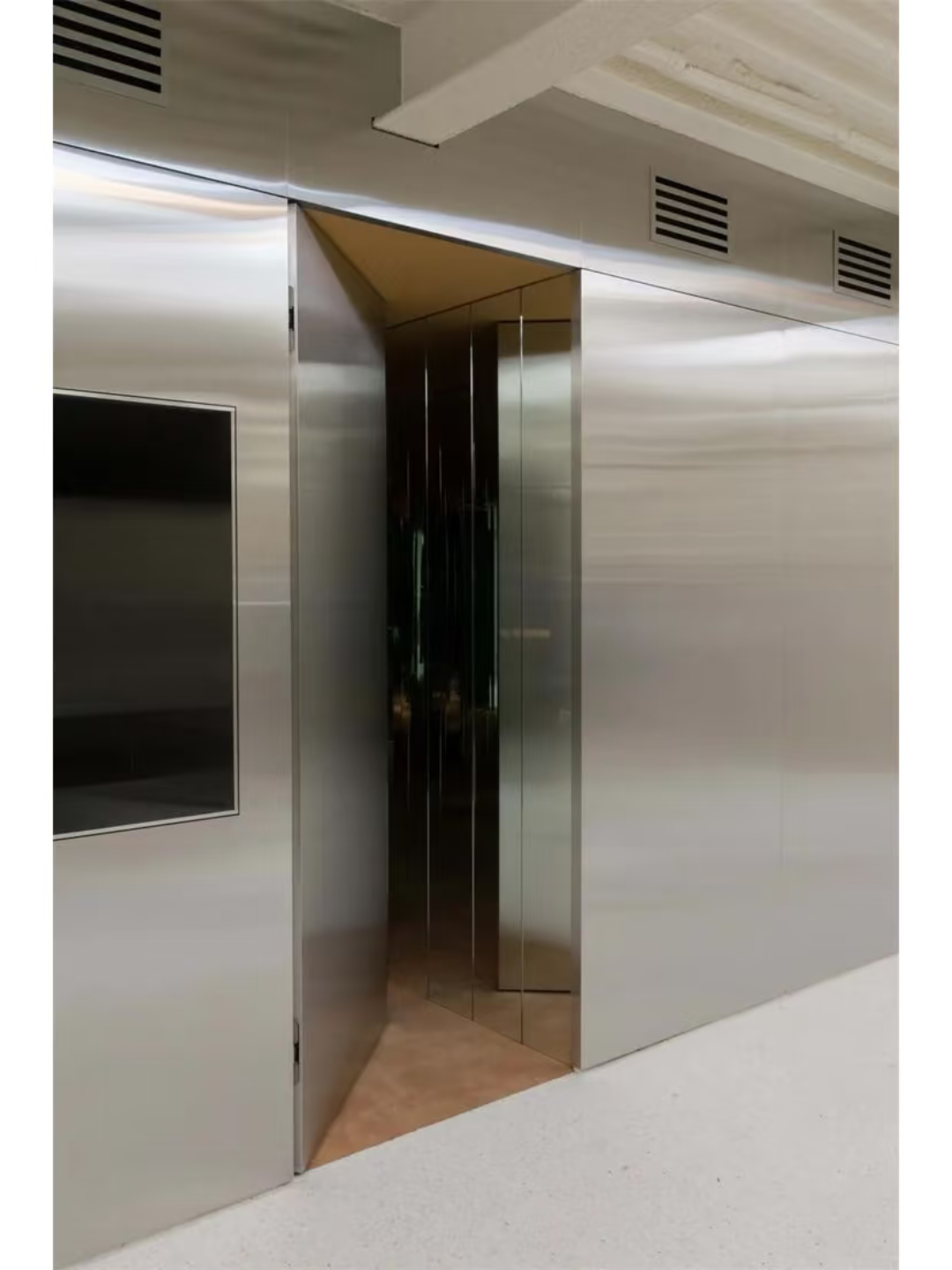

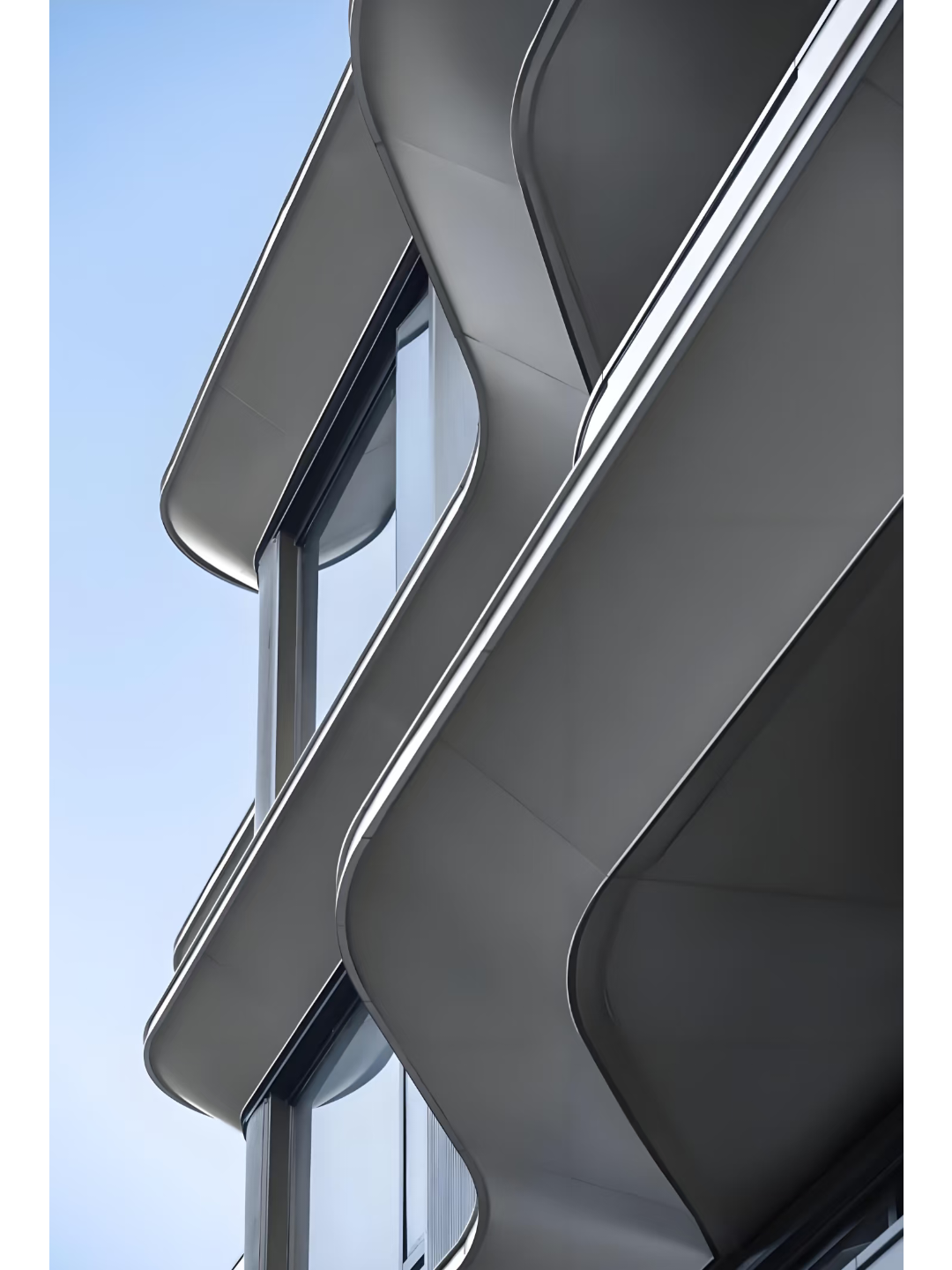

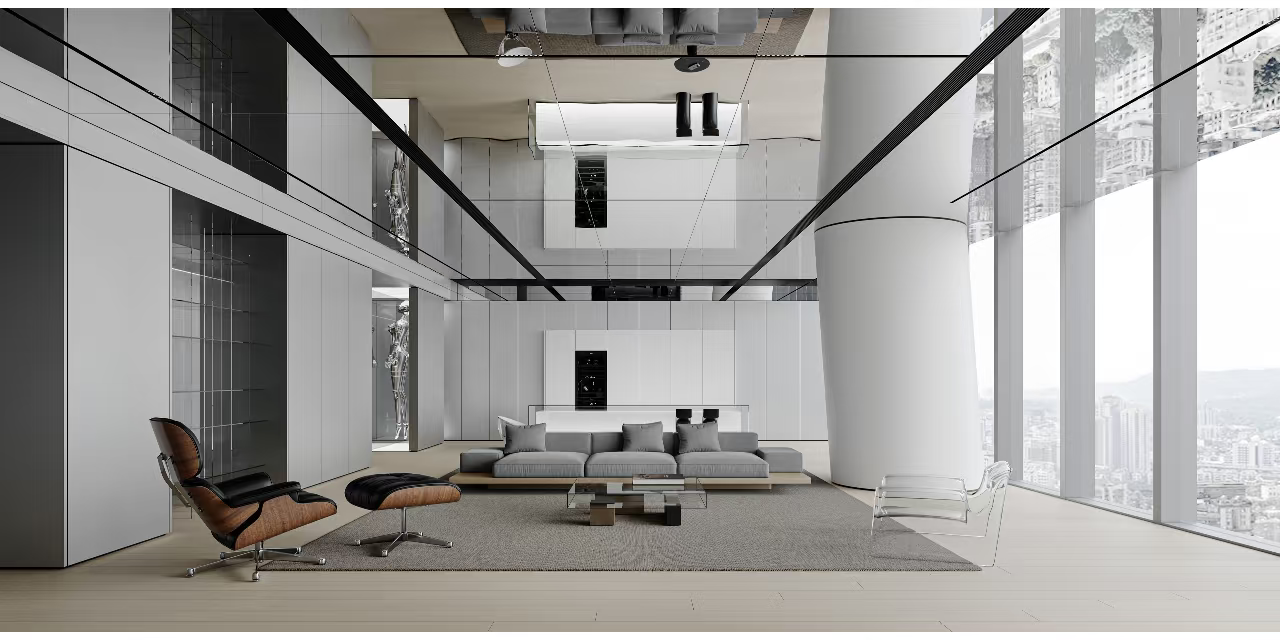

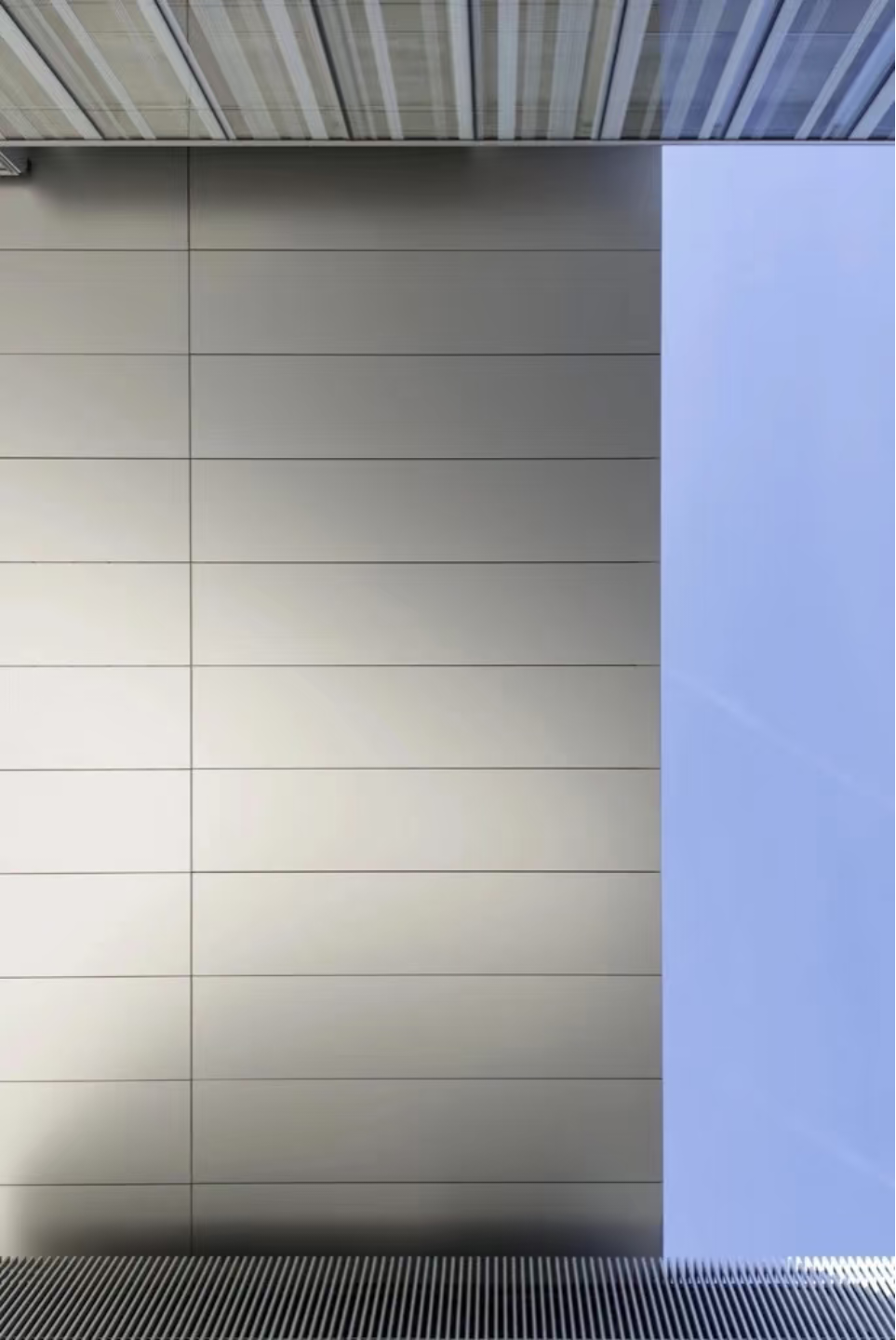

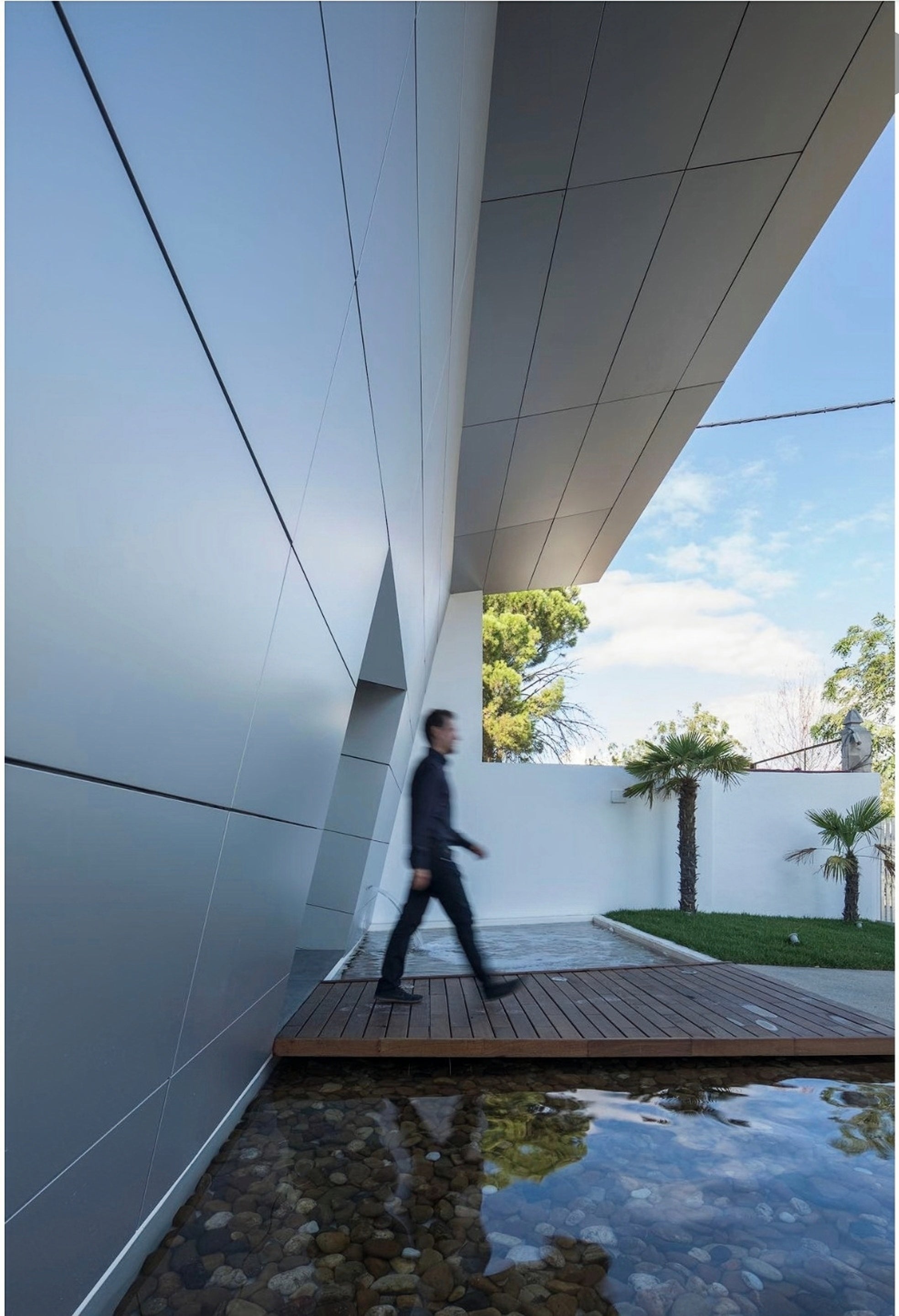

- Architectural Facades: Defining the exterior of premium commercial, public, and residential buildings with a clean, monolithic look.

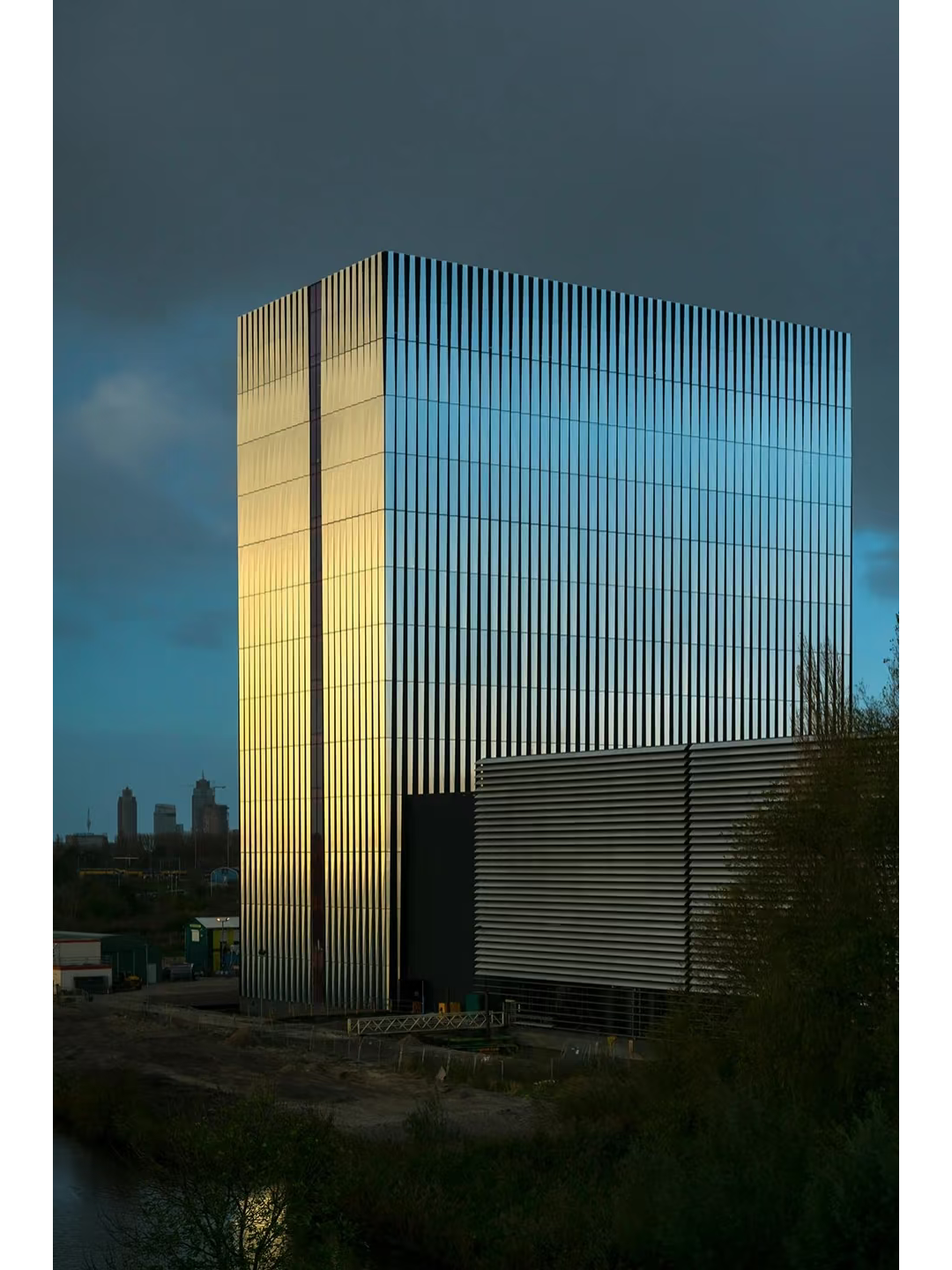

- High-Rise Buildings: Providing a durable, lightweight, and non-combustible cladding solution essential for towers and skyscrapers.

- Modernization Projects: Upgrading existing structures with a contemporary, low-maintenance, and long-lasting new facade.

- High-Profile Venues: Creating impressive and weather-resistant exteriors for airports, museums, and corporate headquarters.

Ultimate Durability

Made from solid aluminum with premium PVDF coatings, it offers a 30-50+ year lifespan with superior resistance to weather, corrosion, and UV.

Uncompromised Fire Safety

As a solid metal panel, it is inherently non-combustible (Class A fire-rated), making it one of the safest choices for any building height.

Sleek Architectural Finish

Delivers a smooth, premium, and monolithic appearance. Available in a vast range of colors and finishes to achieve any design intent.

| Property | 3mm Thickness | 4mm Thickness | 6mm Thickness | Test Standard |

|---|---|---|---|---|

| Panel Weight | 8.1 kg/m² | 10.8 kg/m² | 16.2 kg/m² | - |

| Tensile Strength | 145-185 MPa | 145-185 MPa | 145-185 MPa | ASTM B557 |

| Yield Strength | 125-165 MPa | 125-165 MPa | 125-165 MPa | ASTM B557 |

| Elongation | 8-12% | 8-12% | 8-12% | ASTM B557 |

| Modulus of Elasticity | 70 GPa | 70 GPa | 70 GPa | ASTM E111 |

| Property | Value | Test Standard |

|---|---|---|

| Density | 2.70 g/cm³ | ASTM B311 |

| Thermal Conductivity | 237 W/m·K | ASTM E1461 |

| Thermal Expansion | 23.6 × 10⁻⁶/°C | ASTM E228 |

| Melting Point | 660°C | - |

| Specific Heat | 0.90 J/g·°C | ASTM E1269 |

| Property | Value | Test Standard |

|---|---|---|

| Fire Rating | Class A (Non-combustible) | ASTM E84 |

| Weather Resistance | Pass 4000+ hours | ASTM G155 |

| Salt Spray Resistance | 1000+ hours no corrosion | ASTM B117 |

| Thermal Shock | Pass -40°C to +80°C | ASTM D4329 |

| Wind Load Capacity | Up to 4.5 kPa* | *Engineering required |

| Flatness Tolerance | ±2mm per 3m length | ASTM B209 |

| Thickness | Standard Sizes (mm) | Maximum Size | Custom Sizes |

|---|---|---|---|

| 2mm | 1220×2440, 1500×3000 | 1500×4000 | Available |

| 3mm | 1220×2440, 1500×3000 | 1500×4000 | Available |

| 4mm | 1220×2440, 1500×3000 | 1500×4000 | Available |

| 5mm | 1220×2440, 1250×2500 | 1500×3000 | Available |

| 6mm | 1220×2440, 1250×2500 | 1500×3000 | Available |

| Finish Type | Thickness | Hardness | Adhesion | Warranty |

|---|---|---|---|---|

| PVDF Coating | 25-30μm | 2H-3H | 5B (ASTM D3359) | 20 Years |

| Polyester | 60-80μm | H-2H | 5B (ASTM D3359) | 10 Years |

| Anodized | 15-25μm | 6-8H | N/A | 15 Years |

FAQs

What is the Difference Between Solid Aluminum Panels and Aluminum Composite Panels for Cladding?

Solid aluminum panels and aluminum composite panels (ACP) serve different cladding needs with distinct performance characteristics:

Solid Aluminum Panels:

- 100% aluminum construction throughout panel thickness

- Superior structural strength and wind load resistance

- Maximum fire safety - Class A non-combustible rating

- Longer lifespan of 30-50+ years

- Higher cost but better long-term value

- Heavier weight requiring stronger structural support

Aluminum Composite Panels:

- Aluminum faces with polymer core (lightweight sandwich construction)

- Cost-effective solution for budget-conscious projects

- Lighter weight reduces structural load requirements

- Fire rating varies by core material (standard vs. fire-rated)

- Shorter lifespan of 20-30 years

- Excellent flatness over large surfaces

Choose solid aluminum panels for: High-rise buildings, extreme weather conditions, maximum durability, and fire-critical applications.

Choose composite panels for: Cost-sensitive projects, lightweight requirements, and standard commercial applications.

How Much Do Aluminum Cladding Panels Cost Per Square Meter?

Aluminum cladding panel costs vary significantly based on specifications, finish quality, and project requirements. Here's a comprehensive cost breakdown:

Factors affecting aluminum panel cladding costs:

- Panel thickness (2mm, 3mm, 4mm, 5mm, 6mm options)

- Surface finish type (PVDF, polyester, anodized, mill finish)

- Aluminum alloy grade (3003, 5005, 6061 specifications)

- Custom vs. standard colors and finishes

- Project size and quantity discounts

- Manufacturing complexity and custom fabrication

Additional cost considerations:

- Installation and labor (professional installation recommended)

- Mounting systems and hardware (rainscreen, cassette, stick systems)

- Structural support modifications if required

- Transportation and handling costs

- Building permits and engineering fees

Long-term value benefits:

- 30-50 year lifespan reduces replacement costs

- Minimal maintenance requirements lower ongoing expenses

- Energy efficiency through thermal performance

- High recyclable value at end of service life

Contact our sales team for detailed project quotes and cost comparisons with other cladding materials.

How Long Do Solid Aluminum Cladding Panels Last on Buildings?

Solid aluminum cladding panels typically last 30-50+ years with proper installation and maintenance, making them one of the most durable cladding materials available.

Aluminum panel lifespan by finish type:

- PVDF-coated aluminum panels: 20+ year coating warranty, 40-50 year total lifespan

- Anodized aluminum panels: 15-20 year finish life, 30-40 year structural life

- Polyester-coated panels: 10-15 year coating warranty, 25-35 year total life

- Mill finish aluminum: 20-30 years depending on environmental conditions

Factors extending aluminum panel lifespan:

- High-quality aluminum alloys (5005, 6061) resist corrosion

- Professional installation with proper drainage and ventilation

- Regular maintenance and annual cleaning

- Quality mounting systems accommodate thermal expansion

- Environmental protection from harsh chemicals or salt spray

Performance advantages:

- No rust or rot like steel or wood materials

- UV stable aluminum doesn't degrade in sunlight

- Thermal cycling resistance handles temperature extremes

- Impact resistance maintains structural integrity

Maintenance requirements:

- Annual cleaning with mild soap and water

- Periodic inspection of sealants and fasteners

- Professional cleaning for high-rise applications

The exceptional longevity of aluminum cladding provides excellent return on investment compared to materials requiring frequent replacement.

Are Aluminum Panels Fire Safe for Building Cladding Applications?

Yes, solid aluminum panels are inherently fire-safe and meet the highest fire safety standards for building cladding applications. Aluminum is classified as Class A non-combustible material, making it ideal for fire-critical buildings.

Fire safety advantages of aluminum cladding:

- Non-combustible construction - aluminum won't ignite or contribute to fire spread

- Class A fire rating meets strictest building codes

- No toxic fume emission during fire exposure

- Structural integrity maintained at high temperatures

- Self-extinguishing properties when heat source is removed

Building code compliance:

- High-rise buildings - approved for unlimited height applications

- Commercial structures - meets fire department requirements

- Educational facilities - safe for schools and universities

- Healthcare buildings - compliant with hospital fire codes

- Mixed-use developments - suitable for complex occupancy types

Fire performance testing:

- ASTM E84 Surface Burning Characteristics

- NFPA 285 Multi-story Building Fire Test

- EN 13501 European Fire Classification

- AS 1530 Australian Fire Testing Standards

Comparison with other materials:

Unlike some composite cladding materials that have faced fire safety concerns, solid aluminum panels provide maximum fire protection without compromising aesthetics or performance.

Installation considerations:

- Use fire-rated sealants and mounting systems

- Ensure proper compartmentalization and fire stops

- Follow manufacturer installation guidelines

- Obtain proper building permits and inspections

Can Aluminum Cladding Panels Withstand High Winds and Severe Weather?

Yes, aluminum cladding panels are engineered to withstand extreme weather conditions including high winds, making them ideal for buildings in hurricane zones, coastal areas, and regions with severe weather.

Wind resistance capabilities:

- Wind load capacity up to 4.5 kPa with proper engineering calculations

- Superior strength-to-weight ratio provides structural efficiency

- Uniform load distribution across panel surface

- Professional engineering required for high-wind applications

- Tested to international standards (ASTM, EN, AS/NZS)

Severe weather performance:

- Hurricane and typhoon resistance when properly installed

- Hail impact resistance - durable aluminum construction

- Thermal cycling stability from -40°C to +80°C

- UV radiation resistance maintains structural properties

- Moisture and humidity tolerance prevents degradation

Installation requirements for high-wind areas:

- Structural engineering analysis for wind load calculations

- Professional mounting systems (rainscreen, cassette, or stick systems)

- Proper fastener spacing and attachment methods

- Thermal expansion joints accommodate movement

- Quality sealants prevent water infiltration

Weather resistance features:

- Corrosion-resistant aluminum alloys for coastal environments

- PVDF coatings provide 20+ year weather protection

- Anodized finishes resist environmental degradation

- Proper drainage design prevents water accumulation

Testing and certification:

- AAMA standards for weather performance

- Salt spray testing (ASTM B117) for marine environments

- Accelerated weathering (ASTM G155) for UV exposure

- Thermal shock testing for temperature extremes

For buildings in extreme weather zones, consult with structural engineers and follow local building codes to ensure proper panel selection, mounting system design, and installation methods.