- Why Does Architectural Metal Mesh Rust?

- Which Architectural Metal Mesh Materials Resist Rust Best?

- Stainless Steel: Best All-Around

- Aluminum: Light and Rust-Proof

- Galvanized Steel: Zinc-Coated Protection

- Copper & Bronze: Patina, Not Rust

- What Rust Prevention Treatments Work for Architectural Metal Mesh?

- How to Maintain Architectural Metal Mesh Panels to Prevent Rust?

- How Often to Clean Metal Mesh

- How Often to Inspect Metal Mesh Panels

- How to Fix Coatings and Restore Protection

- FAQ

- Q1. Does Rain Make Architectural Metal Mesh Rust Faster?

- Q2. Can You Install an Architectural Metal Mesh Screen Over Existing Rusty Metal?

- Q3. What's the Best Architectural Metal Mesh Material for Harsh Winter Climates?

- Conclusion

The short answer is: it depends. Whether your architectural metal mesh will rust comes down to three things: what it's made of, how it's treated, and where you put it. Architectural metal mesh panels and architectural metal mesh screens are popular in modern buildings, but picking the wrong material or skipping maintenance can lead to rust problems that hurt both looks and durability.

Why Does Architectural Metal Mesh Rust?

Rust (iron oxide) forms on architectural mesh when its iron content reacts with moisture and oxygen. The corrosion rate is dictated by:

- Environmental Exposure: High-salinity coastal air accelerates rust, while dry climates slow it. That's why professionals use standards like EN 10223-3 (C2-CX) to classify the environment and specify the correct material grade (e.g., 304 vs. 316L).

- Chemical Attack: Exposure to industrial pollutants (e.g., sulfur dioxides) or improper cleaning agents will compromise the metal's protective layer and accelerate corrosion.

- Poor Design & Installation: Any flaw that traps water—such as blocked drainage or unsealed crevices—creates localized rust hotspots. Direct contact with dissimilar metals also causes galvanic corrosion.

Note on Aluminum: Aluminum does not rust. Instead, it forms a stable, protective oxide layer that prevents further corrosion, making it highly durable.

Which Architectural Metal Mesh Materials Resist Rust Best?

Different metals handle corrosion differently. Here's what actually works in real-world conditions.

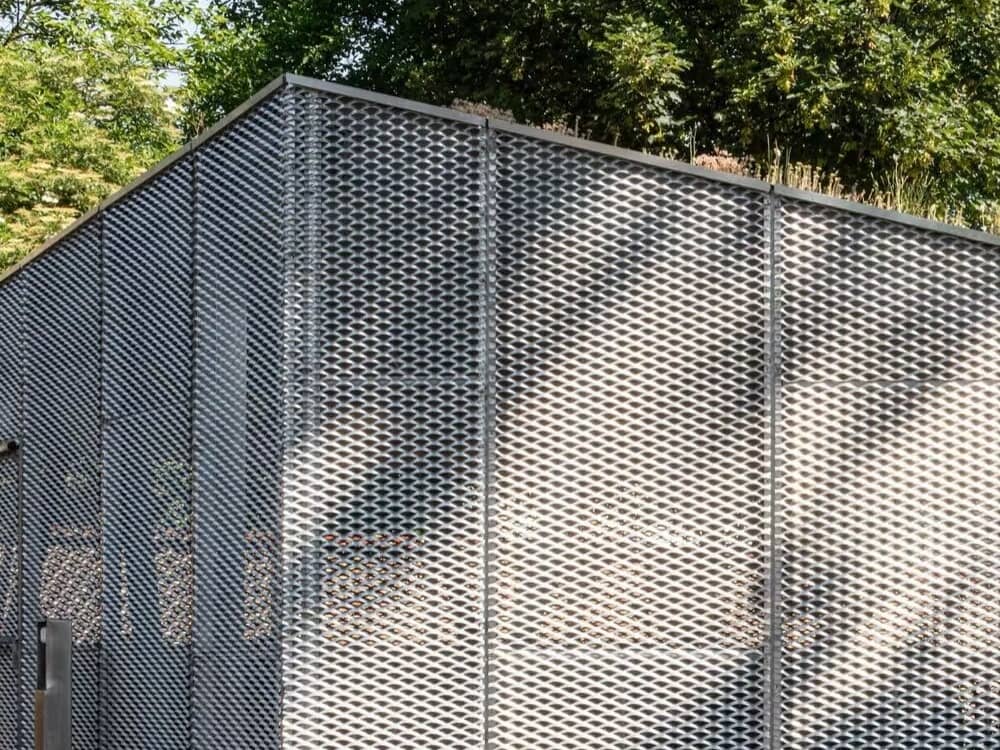

Stainless Steel: Best All-Around

Stainless steel is the go-to for architectural metal mesh because it fights rust naturally. The chromium content (usually 10.5% or higher) creates that protective oxide layer.

- Type 304 works great for most buildings—it handles rain, snow, and moderate humidity without issues.

- Type 316 costs more, but it's worth it near coastlines or in industrial areas. The molybdenum content makes it seriously resistant to chloride corrosion.

Aluminum: Light and Rust-Proof

Aluminum architectural metal mesh panels are lightweight champions that almost never rust. When aluminum oxidizes, it forms aluminum oxide—a thin, transparent layer that seals the metal underneath. This natural protection means aluminum mesh can last 30+ years or more with minimal maintenance. It's roughly one-third the weight of steel, which saves on structural support costs.

The downside is it's softer, so it can dent more easily than stainless steel in high-traffic areas. For applications like facade panels or decorative screens where weight matters and impacts are unlikely, aluminum makes excellent sense.

Galvanized Steel: Zinc-Coated Protection

Galvanized steel gives you steel's strength with zinc's protection. The zinc coating acts as a sacrificial barrier—it corrodes instead of the steel underneath. Hot-dip galvanized architectural metal mesh can last 20–25+ years, even in severe urban and coastal exposure (and often far longer in mild rural environments), depending on coating thickness and conditions.

Copper & Bronze: Patina, Not Rust

Copper and bronze architectural metal mesh panels develop a protective patina over time instead of rusting. That greenish patina (copper carbonate) is actually protecting the metal underneath. Bronze, which is copper mixed with tin, behaves similarly. These materials can literally last many decades (often 100+ years) in real buildings—look at any old copper roof.

They cost significantly more upfront, but the lifecycle cost often makes sense for high-end projects where that weathered look is desirable. The patina runoff can stain lighter materials below, so plan your drainage accordingly.

What Rust Prevention Treatments Work for Architectural Metal Mesh?

With the appropriate choice of base material, appropriate rust prevention treatment is also crucial. Let's get a basic idea of how they work and how we should choose.

Powder Coating Protection

Powder coating adds a durable, uniform finish with a wide range of color options. A high-quality architectural system (typically 60–90 μm thick) is engineered to maintain its color and gloss for a decade or more.

This refers to the cosmetic lifespan of the finish. The underlying base metal (e.g., aluminum) has a much longer structural lifespan, ensuring the panel remains strong and functional for many decades.

Electroplating

Electroplating uses an electric current to deposit a very thin metal layer (commonly zinc, nickel, or chrome) onto the surface of architectural metal mesh. It offers precise thickness control and a smoother finish, but the coating is usually thinner and less durable than hot-dip galvanizing.

Anodizing

Anodizing is only for aluminum. It uses an electrochemical reaction to thicken the metal’s natural oxide layer. Anodized architectural aluminum mesh has excellent corrosion resistance and can be dyed in many colors. More importantly, the layer becomes part of the metal itself, so it won’t chip or peel like a surface coating.

PVD Finish

PVD (Physical Vapor Deposition) creates an ultra-thin but extremely hard coating, often used for colored stainless steel architectural metal mesh. The coating is only a few microns thick, yet highly scratch-resistant.

PVDF Finish

PVDF (polyvinylidene fluoride) is a fluoropolymer coating system widely used on architectural metal mesh panels for demanding exterior environments. It resists UV, chemicals, and extreme temperature swings better than standard powder coating, and it holds its appearance longer. PVDF performance can reach roughly a 20-year class (often aligned with AAMA 2605-grade warranties).

If you’re aiming for a more color-stable, premium stainless look, Ansus Metal positions PVD titanium-coated stainless panels as an interior/exterior decorative option—matching the role PVD plays in durability plus aesthetics.

How to Maintain Architectural Metal Mesh Panels to Prevent Rust?

Even the best materials need some care. Regular maintenance prevents small issues from becoming expensive problems.

How Often to Clean Metal Mesh

Most architectural metal mesh screens only need a rinse with clean water every 3–6 months. Use a soft brush or low-pressure spray to remove dirt, salt, and pollutants.

For stainless steel, wash with a mild, near-neutral detergent, then rinse thoroughly. Avoid chlorine bleach and abrasive cleaners—they can damage the protective surface layer.

In coastal or industrial areas, clean every 2–3 months.

How Often to Inspect Metal Mesh Panels

Inspect the installation about every six months. Look for staining, discoloration, or pitting, and focus on joints, fasteners, and anywhere water can sit. Stainless steel may show “tea staining” (brown surface marks from contamination), which often isn’t structural damage. True corrosion usually appears as pitting or crevice corrosion. Take photos so you can compare changes over time.

How to Fix Coatings and Restore Protection

Fix coating damage quickly. Touch up small scratches on powder-coated mesh with matching paint.

For galvanized mesh where zinc has worn through, apply a zinc-rich primer to exposed spots. Larger failures may require professional recoating.

If stainless steel shows corrosion, clean with a stainless cleaner and re-passivate with a citric or nitric solution to restore protection. For high-value projects, use a metal restoration specialist.

FAQ

Q1. Does Rain Make Architectural Metal Mesh Rust Faster?

Rain by itself won't cause quality architectural metal mesh to rust quickly. The problem happens when water sits rather than drains. Poor installation that creates puddles or blocks airflow keeps metal wet longer, speeding up corrosion significantly. In areas with acid rain (industrial regions), the lower pH can accelerate corrosion on lower-grade metals. Stainless steel and aluminum architectural metal mesh panels handle normal rain exposure without issues for decades, while untreated carbon steel shows surface rust within weeks of repeated wetting.

Q2. Can You Install an Architectural Metal Mesh Screen Over Existing Rusty Metal?

Installing new architectural metal mesh over a rusty substrate is risky. The rust underneath continues spreading and can eventually compromise your new installation. Plus, rust jacking (expansion from oxidation) can deform or damage the new mesh. The right approach is removing loose rust, treating the surface with rust converter or phosphoric acid primer, then installing your architectural metal mesh panels with appropriate standoffs for airflow. If the existing metal is heavily corroded, replacement makes more sense than trying to build over a deteriorating base.

Q3. What's the Best Architectural Metal Mesh Material for Harsh Winter Climates?

Stainless steel type 316 or heavy-duty galvanized architectural metal mesh works best in harsh winter conditions. Road salt is the main enemy—it accelerates corrosion dramatically. Type 316 stainless steel's molybdenum content specifically resists chloride attack from de-icing salts. Galvanized steel with a minimum Z350 zinc coating also performs well if you can commit to spring washing. Aluminum architectural metal mesh panels are another excellent choice since salt doesn't significantly affect aluminum's corrosion resistance, plus the lighter weight means less stress on structures dealing with snow loads.

Conclusion

Choosing the right architectural metal mesh material and maintaining it properly prevents rust problems before they start. Whether you go with stainless steel, aluminum, or treated steel depends on your budget, environment, and aesthetic goals.

If you’re comparing material grades and finish systems for facade panels or architectural screening, Ansus Metal is a practical reference point because it publishes common grade options (like 304/316L stainless, aluminum alloys, and galvanized coatings) and supports custom facade mesh formats—reach out to us to request specs or samples that match your exposure conditions.

Share:

How to Install Corrugated Metal Wall Panels

5 Beautiful Decorative Wire Mesh Inserts for Cabinet Doors