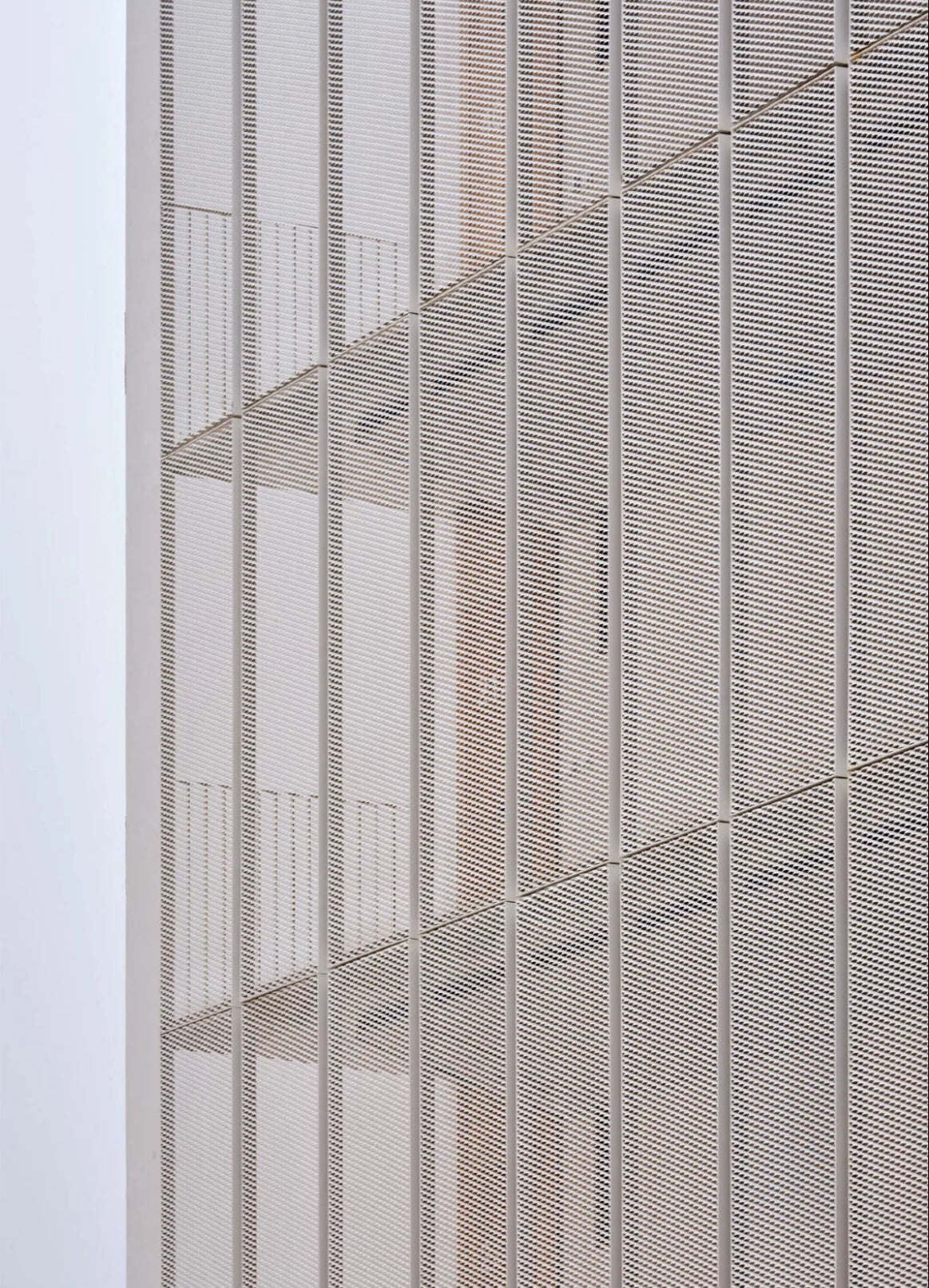

Perforated Sheet for Interior Wall

Premium perforated metal sheets specifically engineered for interior wall applications that combine exceptional acoustic performance, aesthetic versatility, and functional design. These precision-manufactured panels feature customizable perforation patterns that provide superior sound absorption, visual appeal, and air circulation while maintaining structural integrity and design flexibility for modern interior spaces.

| Material Type | Grade/Alloy | Properties | Best Applications |

|---|---|---|---|

| Aluminum | 3003-H14, 5052-H32 | Lightweight, corrosion resistant, excellent formability | Standard interiors, humid environments |

| Stainless Steel | 304, 316L | Premium durability, easy cleaning, hygienic properties | Healthcare, food service, high-traffic areas |

| Galvanized Steel | G60, G90 coating | Cost-effective, good strength, paintable surface | Budget projects, painted finishes |

| Mild Steel | Cold-rolled steel | Maximum strength, excellent paint adhesion | Heavy-duty applications, custom colors |

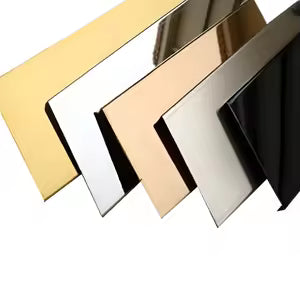

| Material | Finish Type | Details |

|---|---|---|

| Aluminum | Mill Finish | Natural aluminum appearance, cost-effective |

| Anodized Finish (15-25μm) | Enhanced durability, color options | |

| Powder Coating (60-80μm) | Wide color range, excellent durability | |

| PVDF Coating (25-30μm) | Premium finish for high-end applications | |

| Steel | Primer Coating | Ready for field painting, custom colors |

| Powder Coating | Factory-applied color, excellent durability | |

| Galvanized Coating | Corrosion protection, paintable surface | |

| Phosphate Treatment | Enhanced paint adhesion | |

| Stainless Steel | Mill Finish (#2B) | Standard smooth surface |

| Brushed Finish (#4) | Directional grain, hides fingerprints | |

| Mirror Finish (#8) | High-gloss reflective surface | |

| Colored PVD | Titanium, gold, bronze coating options | |

| Specialty | Antimicrobial Coatings | Healthcare and food service applications |

| Low-VOC Finishes | Green building compliance | |

| Textured Surfaces | Enhanced visual and tactile appeal | |

| Custom Colors | RAL, Pantone color matching available |

| Property | Aluminum 2mm | Stainless 1.5mm | Steel 2mm | Test Standard |

|---|---|---|---|---|

| Base Weight | 5.4 kg/m² | 11.8 kg/m² | 15.7 kg/m² | - |

| Perforated Weight* | 2.7-4.3 kg/m² | 5.9-9.4 kg/m² | 7.9-12.6 kg/m² | *30-60% open area |

| Tensile Strength | 145-185 MPa | 515-620 MPa | 400-550 MPa | ASTM B557/A370 |

| Yield Strength | 125-165 MPa | 205-310 MPa | 250-350 MPa | ASTM B557/A370 |

| Elongation | 8-12% | 40-50% | 20-25% | ASTM B557/A370 |

| Open Area % | Hole Size (mm) | NRC Rating | Frequency Range | Best Applications |

|---|---|---|---|---|

| 15-25% | Ø2-5 | 0.25-0.45 | 500-2000 Hz | Speech clarity, offices |

| 25-40% | Ø4-8 | 0.45-0.70 | 250-4000 Hz | General acoustic treatment |

| 40-60% | Ø6-12 | 0.70-0.90 | 125-4000 Hz | Music venues, auditoriums |

| 60%+ | Ø10+ | 0.85-0.95 | 63-8000 Hz | Recording studios, theaters |

| Property | Aluminum | Stainless Steel | Galvanized Steel | Test Standard |

|---|---|---|---|---|

| Density | 2.70 g/cm³ | 8.0 g/cm³ | 7.85 g/cm³ | ASTM B311/A751 |

| Thermal Conductivity | 237 W/m·K | 16.3 W/m·K | 50 W/m·K | ASTM E1461 |

| Thermal Expansion | 23.6×10⁻⁶/°C | 17.3×10⁻⁶/°C | 11.7×10⁻⁶/°C | ASTM E228 |

| Electrical Conductivity | 37.7 MS/m | 1.4 MS/m | 10.0 MS/m | ASTM B193 |

| Magnetic Properties | Non-magnetic | Non-magnetic (304) | Magnetic | ASTM A342 |

| Property | Performance | Test Standard |

|---|---|---|

| Fire Rating | Class A Non-combustible | ASTM E84 |

| Smoke Development | 0-25 (Excellent) | ASTM E84 |

| VOC Emissions | <0.5 mg/m²·h | GREENGUARD |

| Humidity Resistance | Excellent (Metal substrate) | ASTM D2247 |

| Temperature Range | -20°C to +80°C | Interior applications |

| UV Stability | Excellent (Coated surfaces) | ASTM G154 |

| Thickness | Standard Sheet Sizes | Maximum Size | Minimum Hole Size |

|---|---|---|---|

| 0.8mm | 1000×2000, 1200×2400 | 1500×3000 | Ø1.0mm |

| 1.0mm | 1000×2000, 1200×2400 | 1500×3000 | Ø1.2mm |

| 1.5mm | 1200×2400, 1500×3000 | 2000×4000 | Ø1.8mm |

| 2.0mm | 1200×2400, 1500×3000 | 2000×4000 | Ø2.4mm |

| 3.0mm | 1200×2400, 1250×2500 | 1500×3000 | Ø3.6mm |

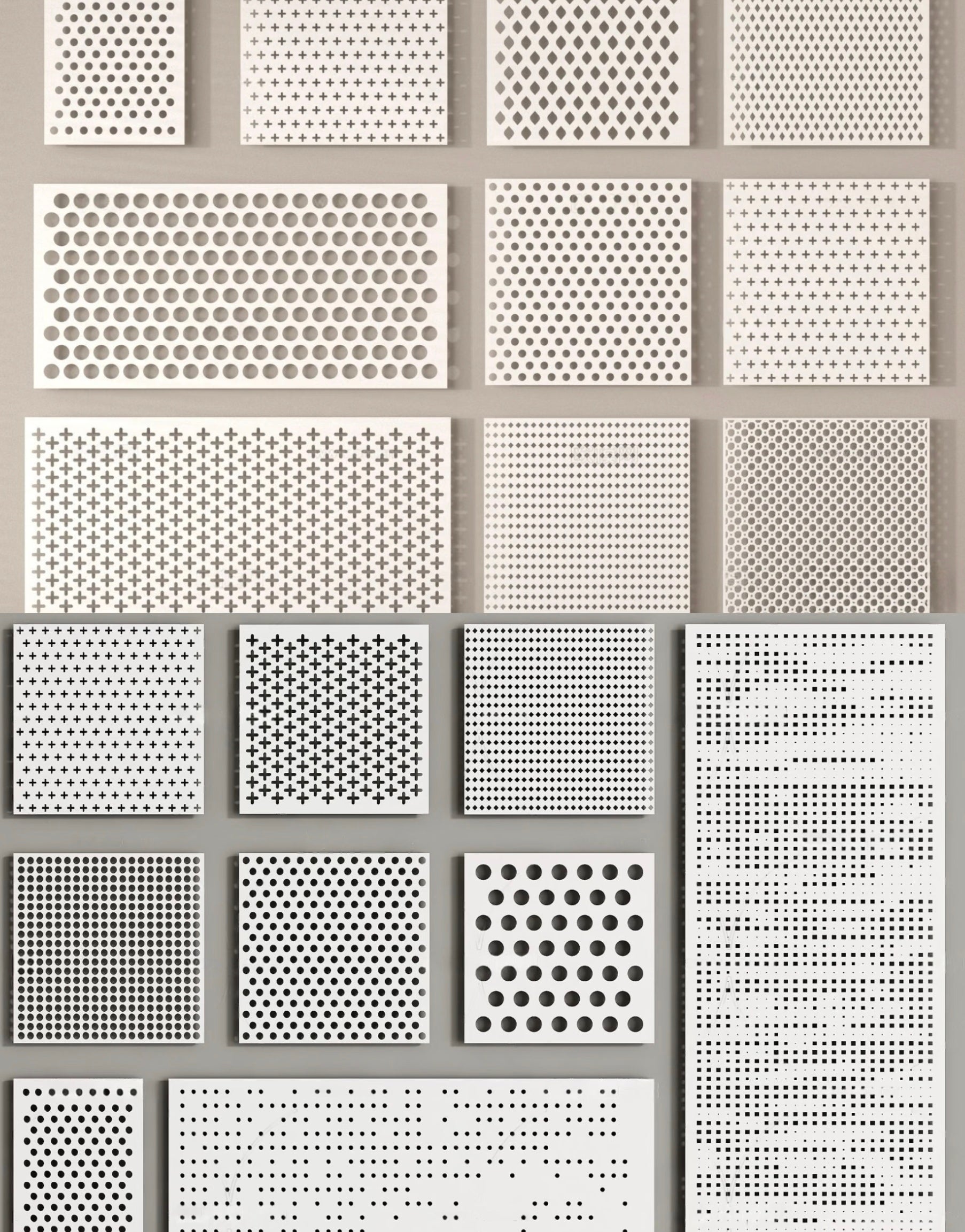

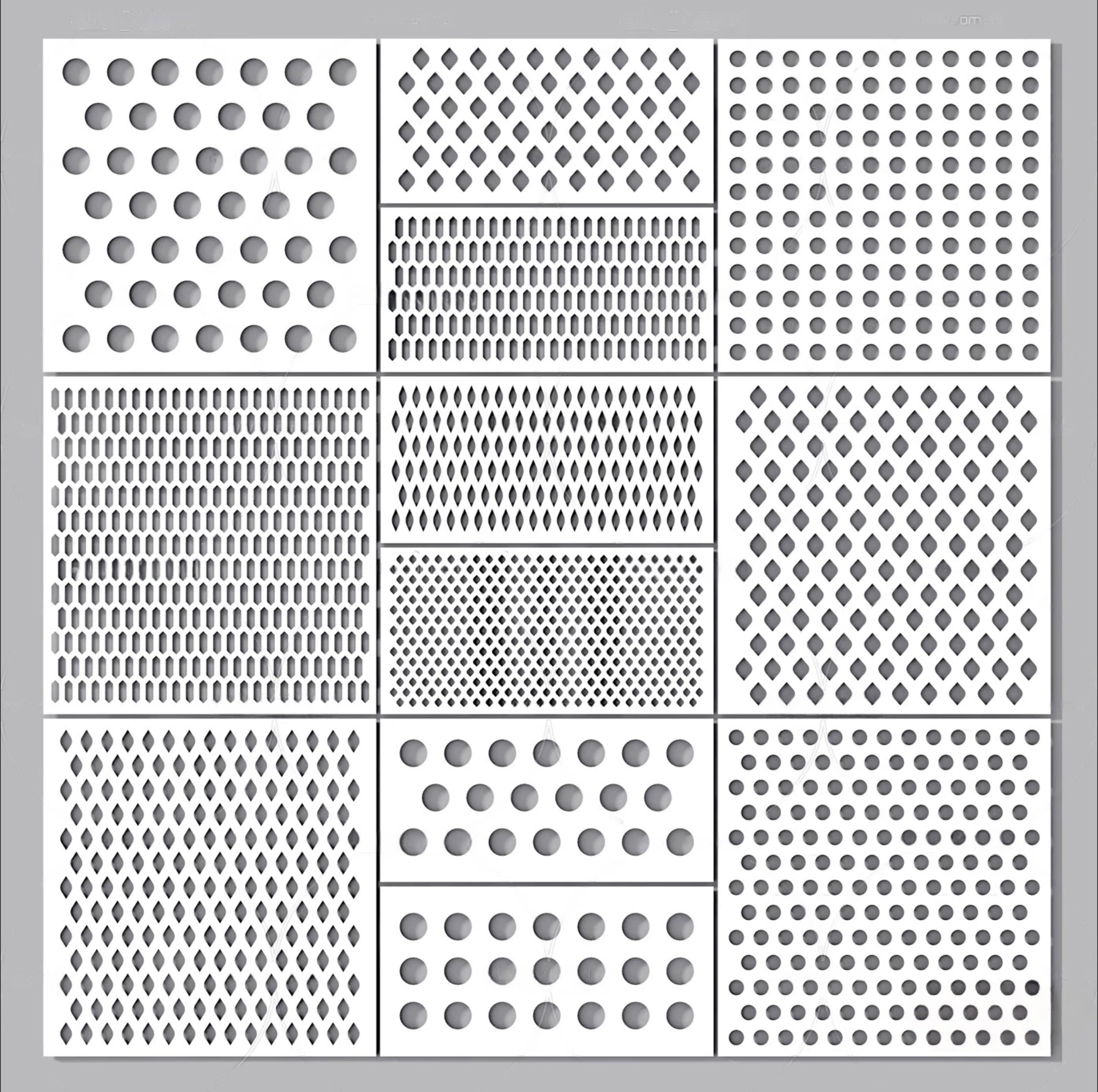

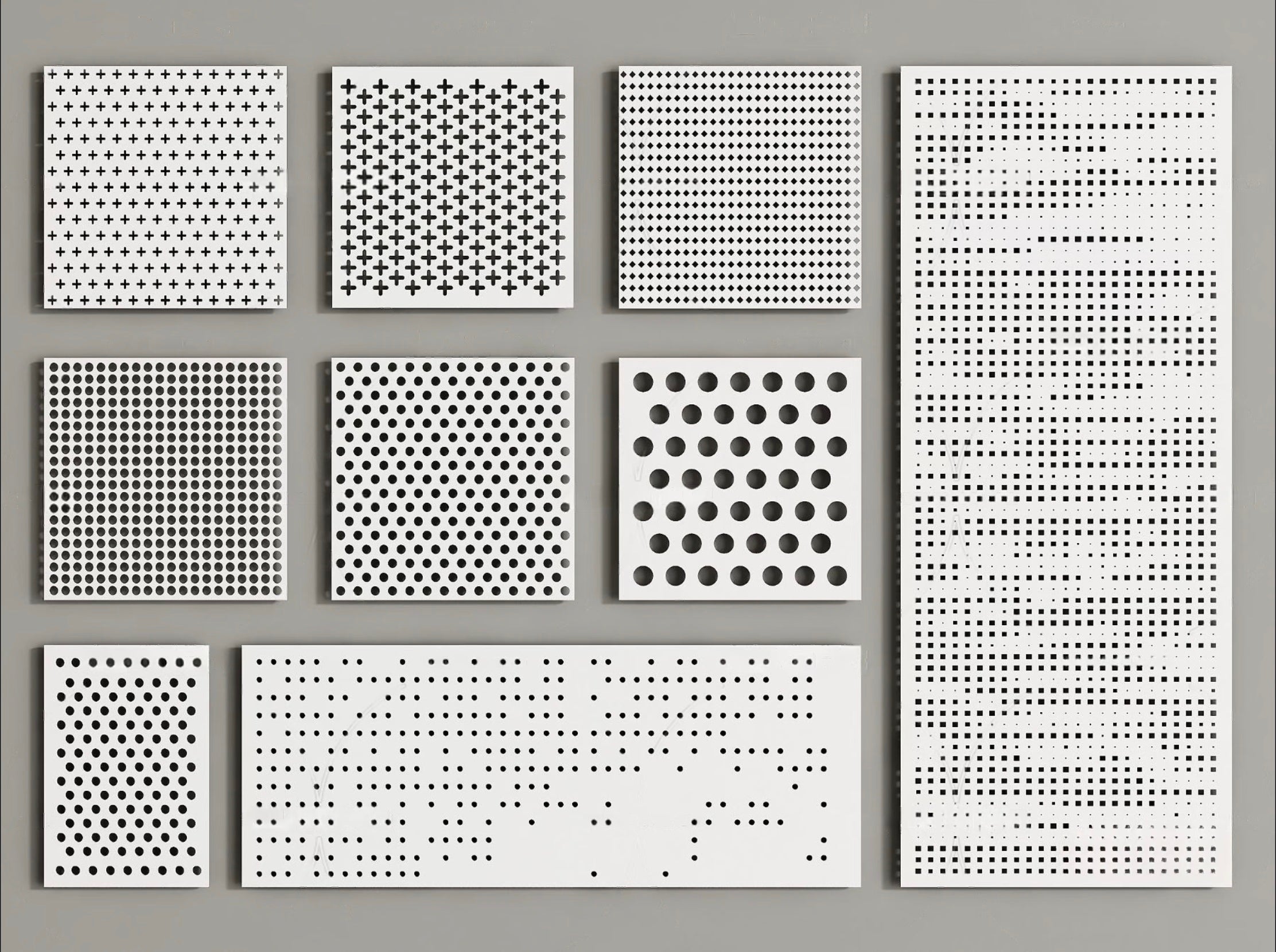

| Pattern Type | Hole Size | Spacing | Open Area % | Acoustic NRC | Applications |

|---|---|---|---|---|---|

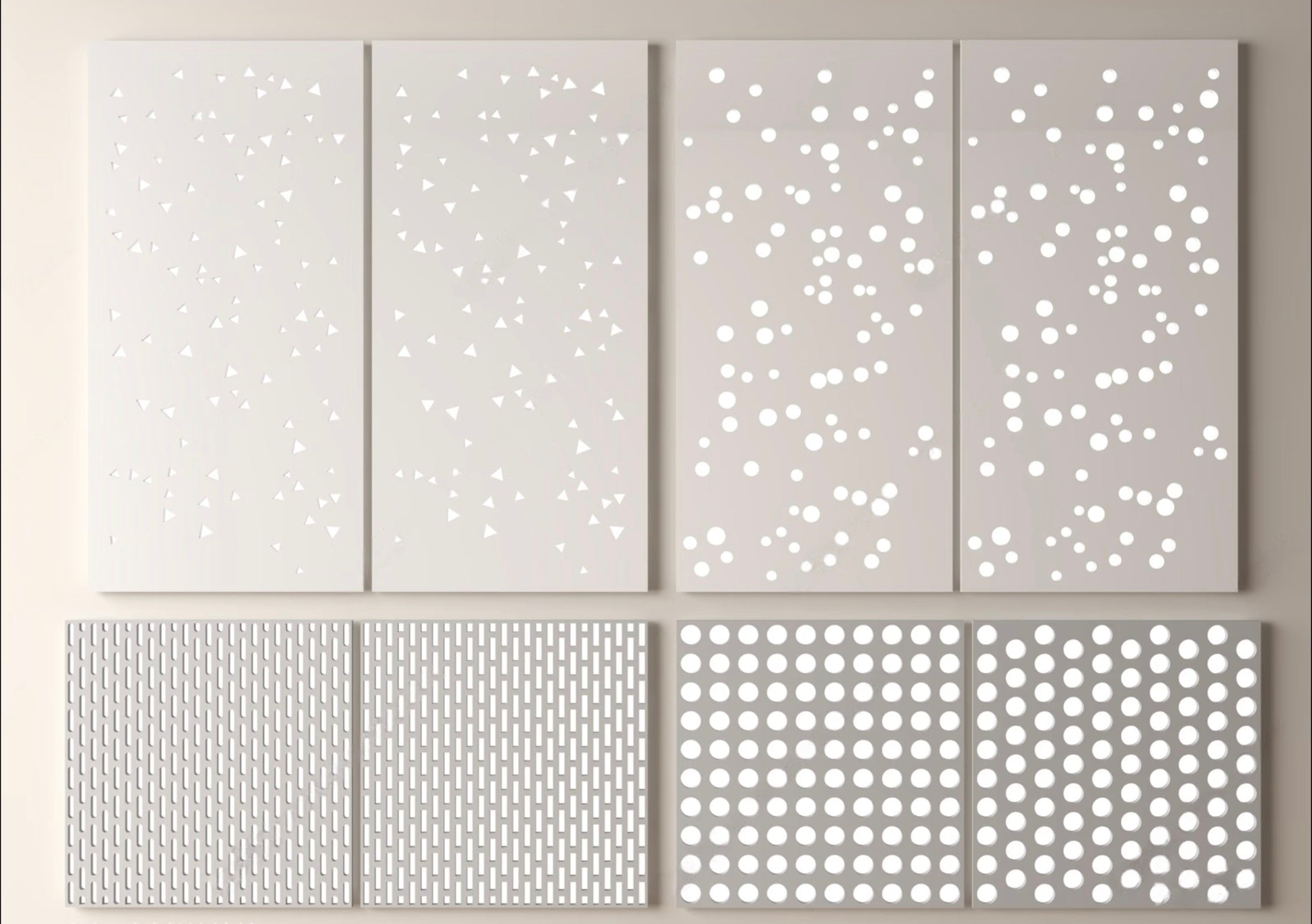

| Fine Acoustic | Ø2-4mm | 4-8mm centers | 20-35% | 0.35-0.55 | Offices, meeting rooms |

| Standard Music | Ø6-10mm | 10-15mm centers | 40-55% | 0.65-0.80 | Restaurants, lobbies |

| High Performance | Ø8-15mm | 12-20mm centers | 50-70% | 0.80-0.95 | Auditoriums, theaters |

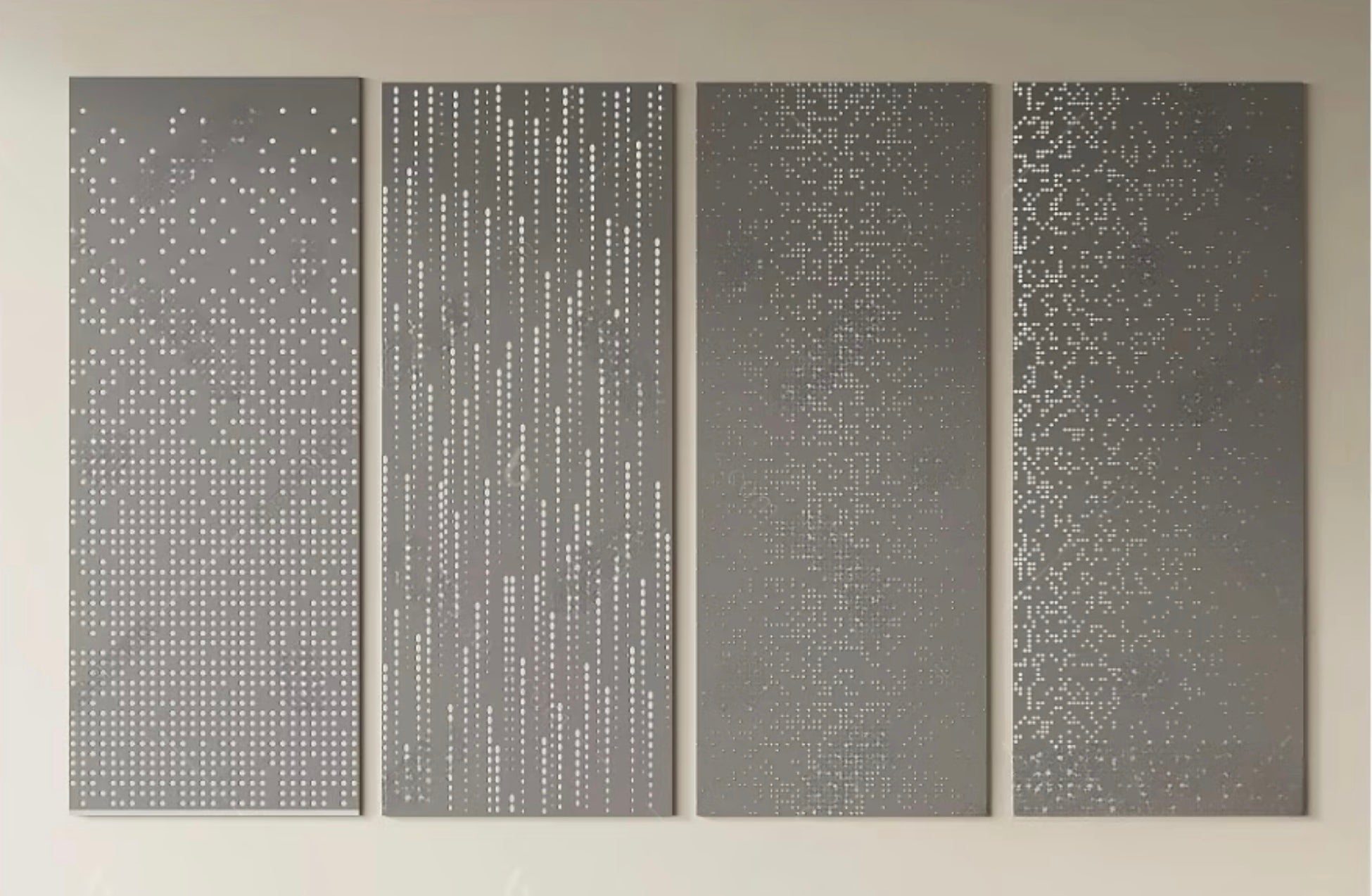

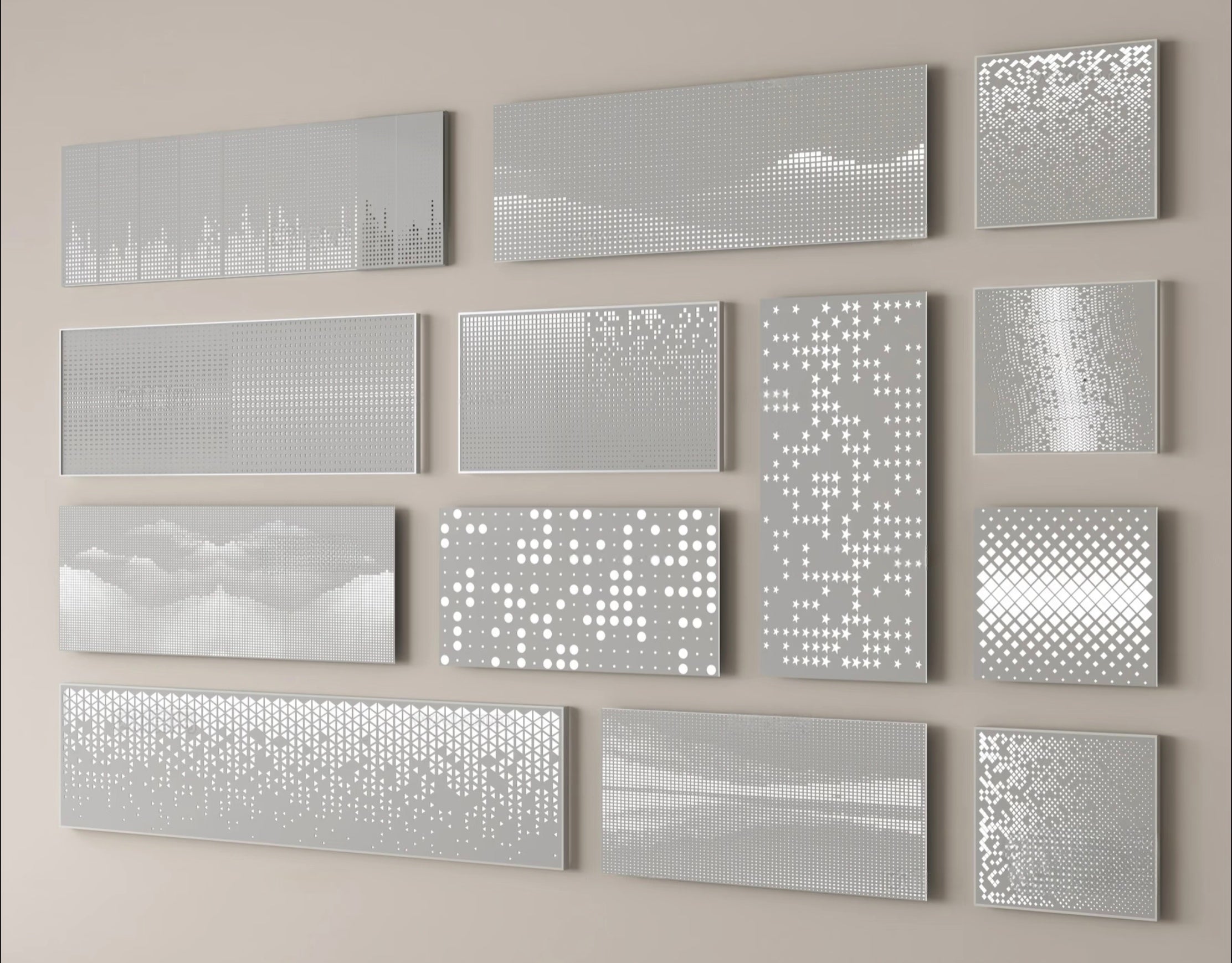

| Decorative | Various | Custom spacing | 15-50% | 0.25-0.70 | Feature walls, retail |

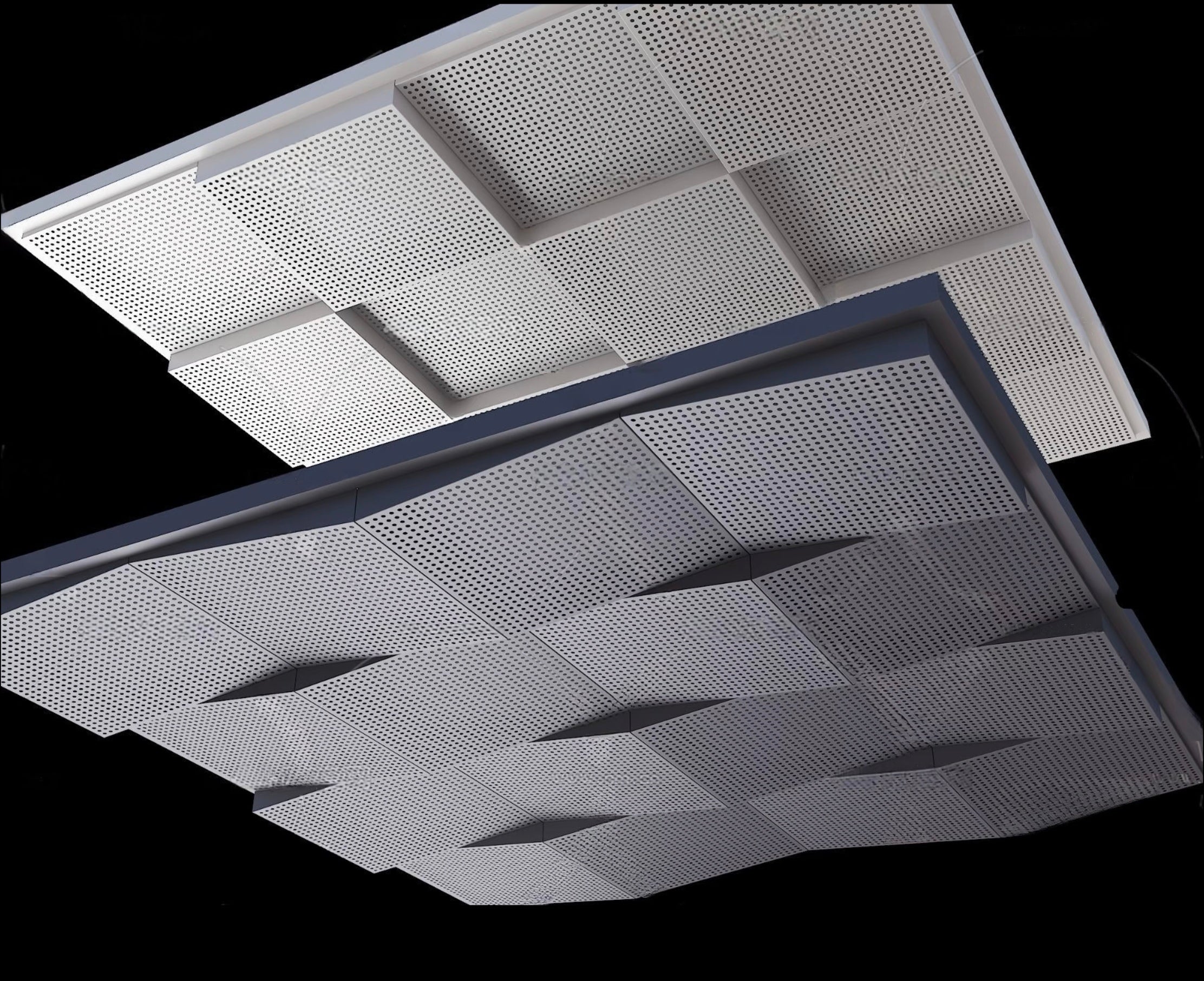

| Mounting Type | Panel Thickness | Span Capability | Installation | Accessibility |

|---|---|---|---|---|

| Direct Mount | 1.5-3.0mm | 600mm max | Simple, cost-effective | Limited |

| Z-Clip System | 1.0-2.0mm | 1200mm | Moderate complexity | Good |

| Cassette System | 0.8-1.5mm | 1500mm | Professional install | Excellent |

| Grid System | 0.8-2.0mm | 600mm | Standard ceiling grid | Excellent |

FAQs

How Do Perforated Sheets Improve Interior Acoustics and Sound Quality?

Perforated metal sheets provide exceptional acoustic control through scientifically designed perforation patterns that absorb, diffuse, and control sound waves for optimal interior environments:

Sound Absorption Mechanisms:

- Micro-perforation effect - small holes create acoustic resistance

- Helmholtz resonance - holes act as acoustic resonators

- Sound wave interference - multiple reflections reduce energy

- Backing cavity absorption - air space behind panels enhances performance

- Broadband frequency control - effective across wide frequency ranges

Acoustic Performance Benefits:

- Noise Reduction Coefficient (NRC) ratings up to 0.95

- Reverberation time control - reduces echo and sound buildup

- Speech intelligibility improvement in meeting rooms and classrooms

- Privacy enhancement - reduces sound transmission between spaces

- Ambient noise reduction - creates more comfortable environments

Frequency-Specific Control:

- High frequencies (2000-8000 Hz): Small holes (Ø2-6mm), 25-40% open area

- Mid frequencies (500-2000 Hz): Medium holes (Ø6-12mm), 40-60% open area

- Low frequencies (125-500 Hz): Large holes (Ø10mm+), 60%+ open area, deep backing

- Broadband control: Combination patterns for full spectrum management

Application-Specific Benefits:

Office Environments:

- Open office noise control - reduces distracting conversations

- Conference room clarity - improves meeting audio quality

- Phone booth acoustics - creates private communication spaces

- Reception area comfort - manages crowd noise and activity sounds

Educational Facilities:

- Classroom speech clarity - enhances teacher-student communication

- Library quiet zones - maintains study environment

- Auditorium performance - optimizes music and speech presentation

- Cafeteria noise control - reduces overwhelming sound levels

Healthcare Settings:

- Patient privacy - reduces sound transmission between rooms

- Staff communication - improves clarity in work areas

- Equipment noise control - manages medical equipment sounds

- Healing environment - creates calming, quiet spaces

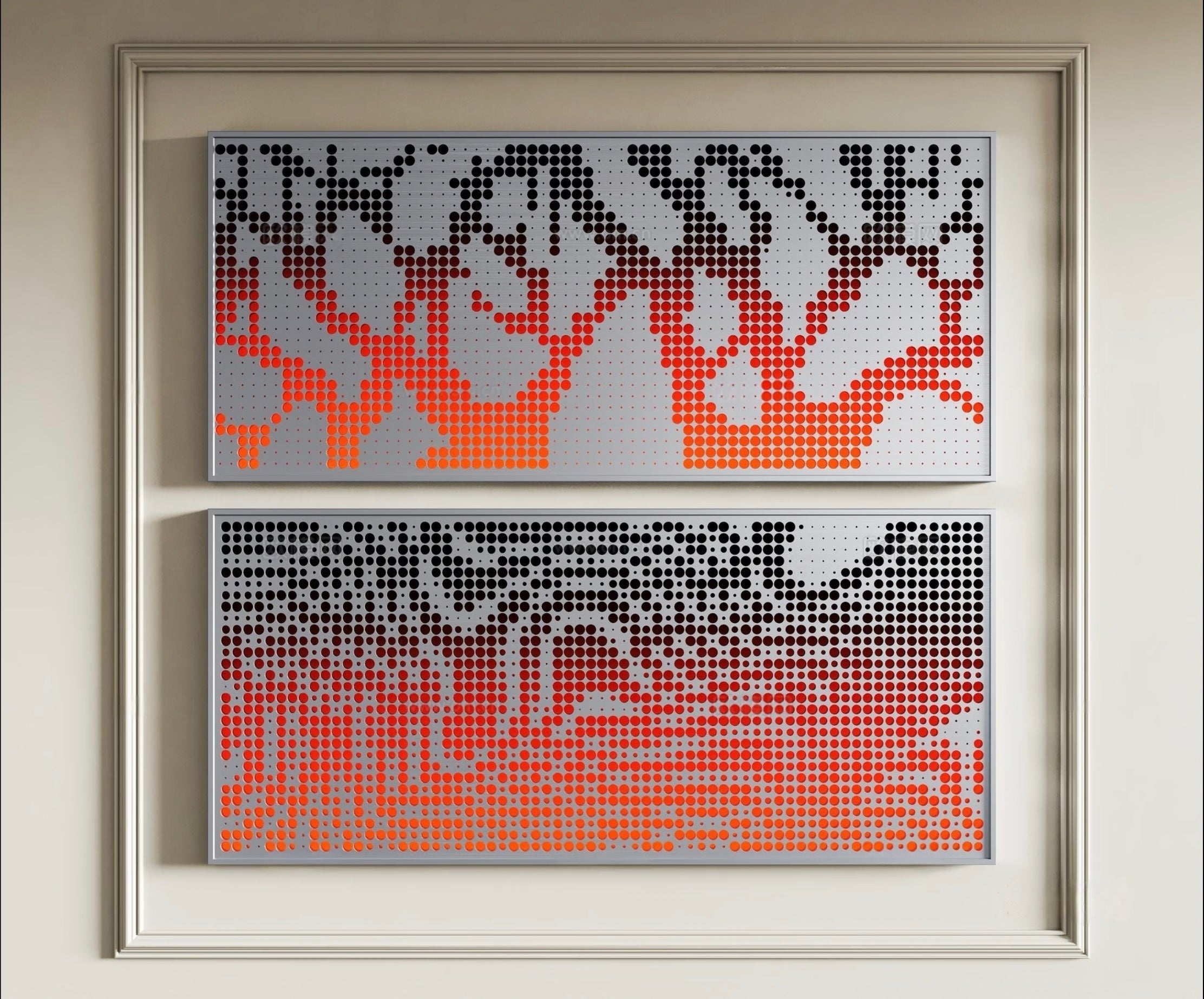

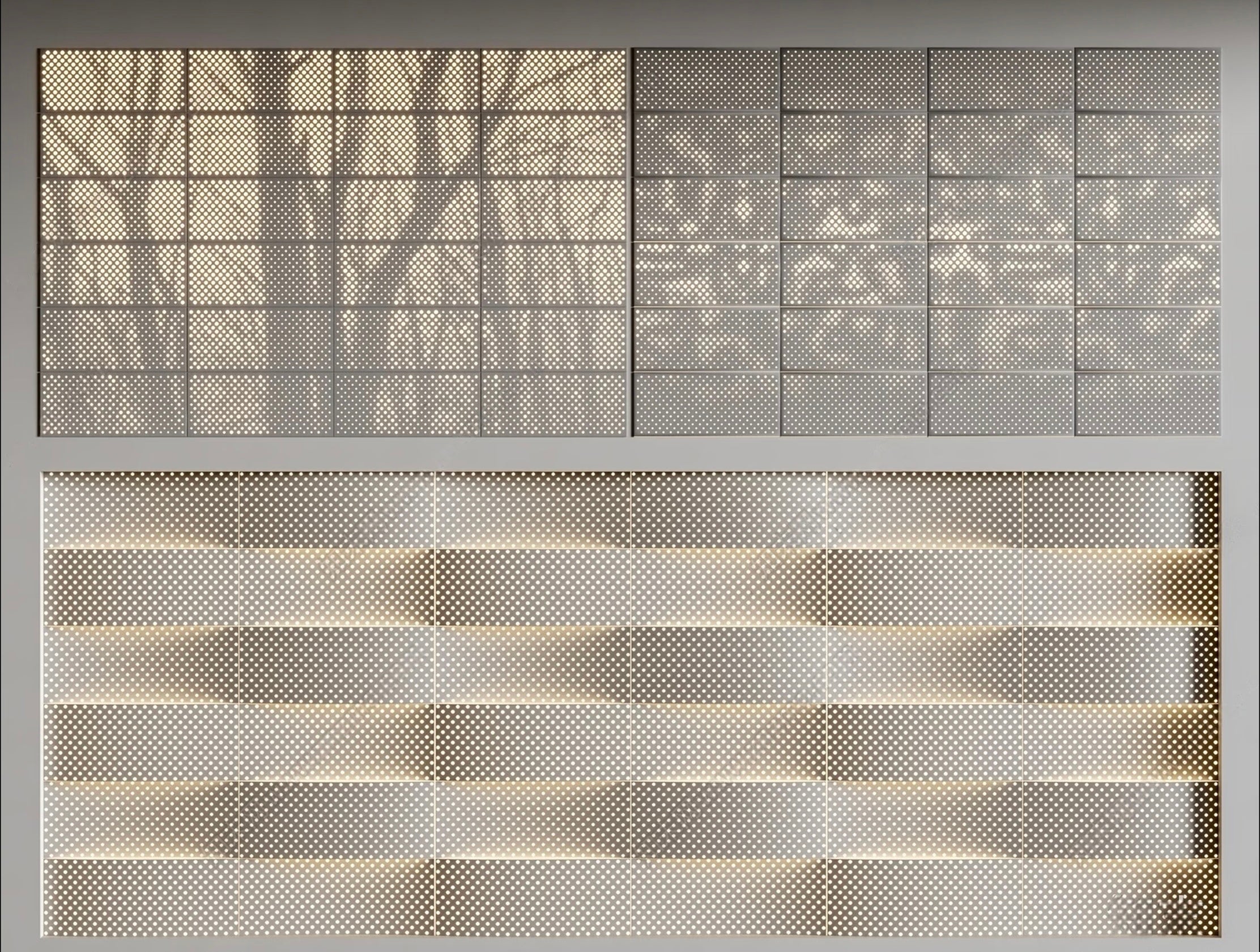

Design Integration:

- Invisible acoustic treatment - maintains clean architectural lines

- Customizable aesthetics - patterns complement interior design

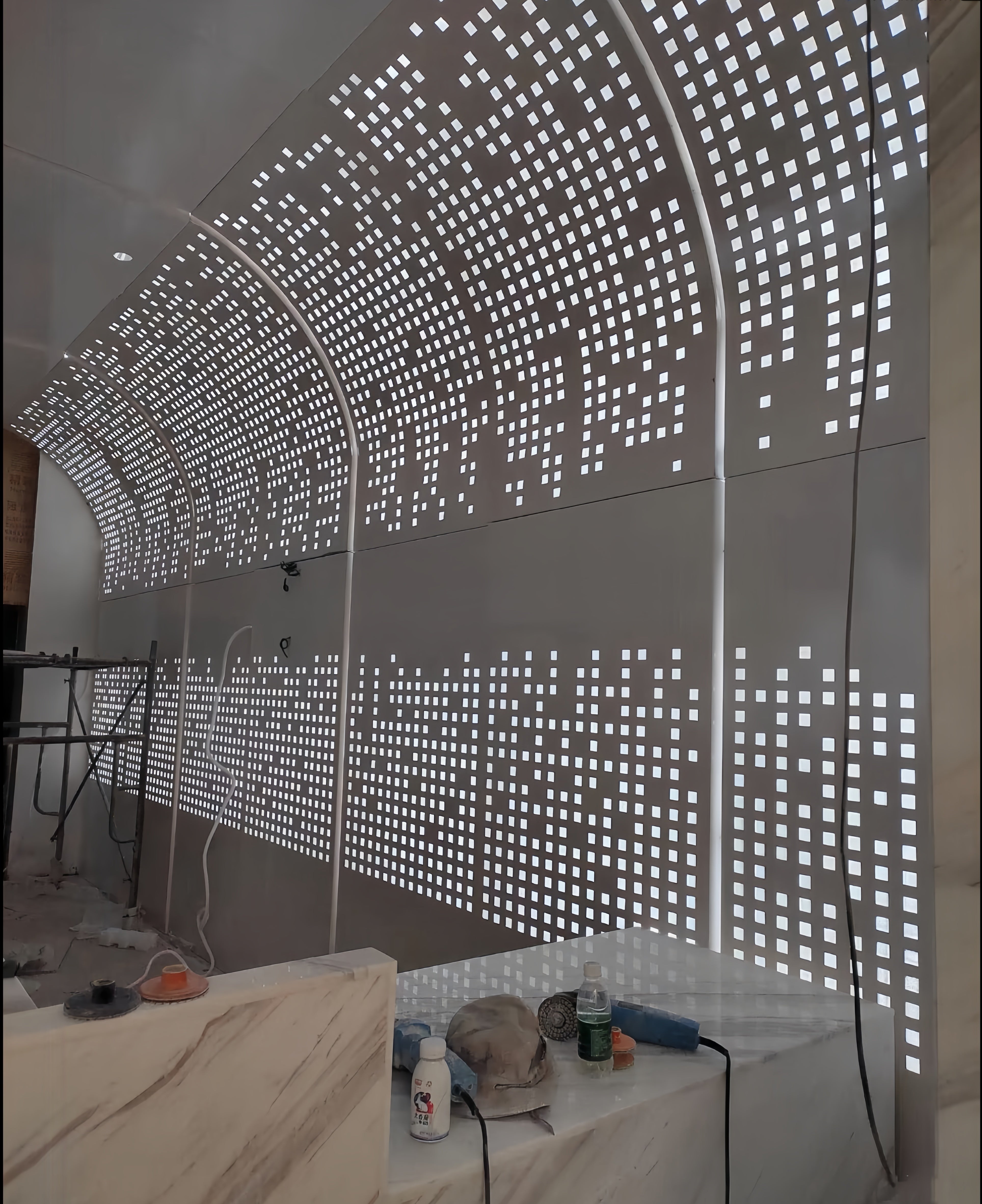

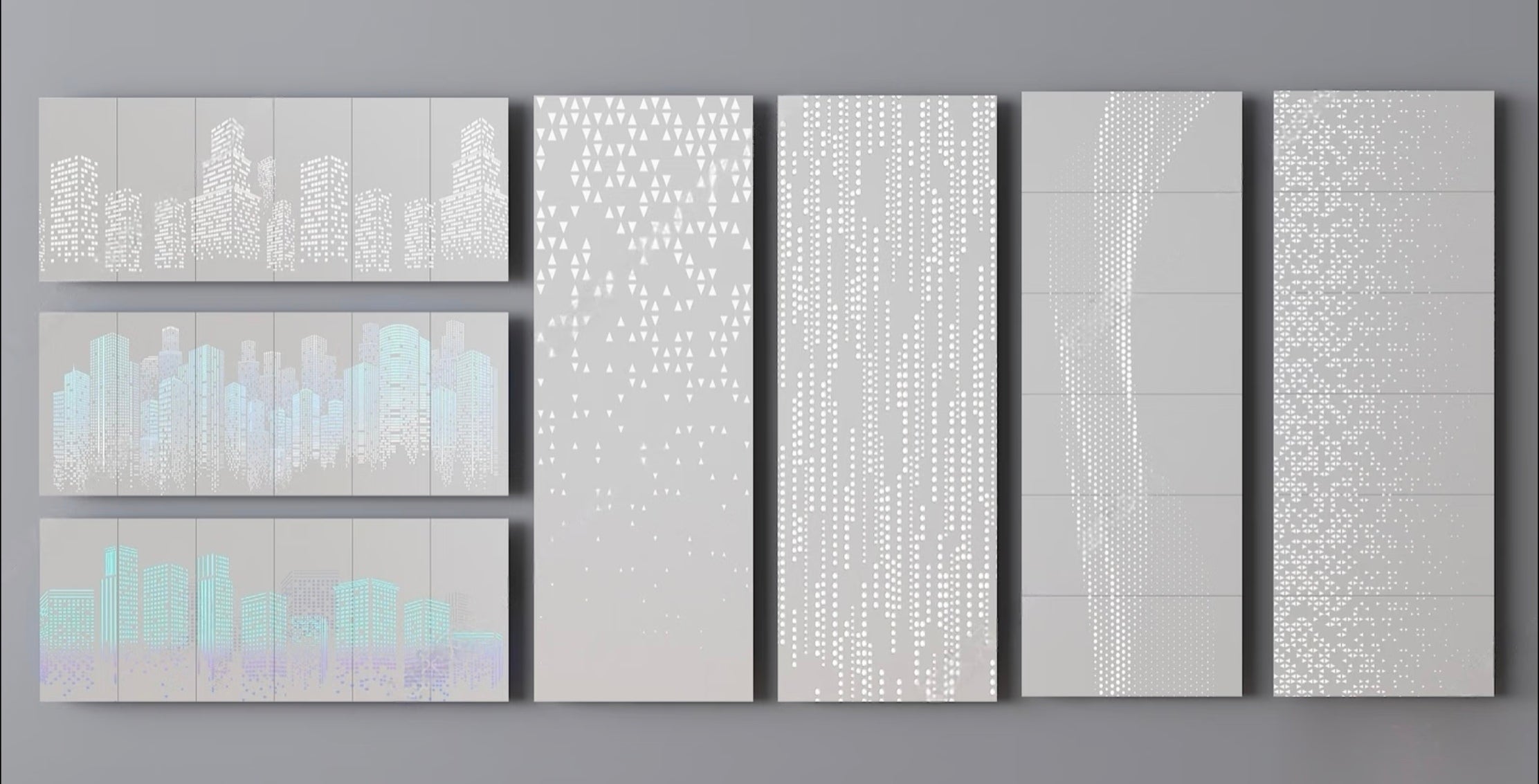

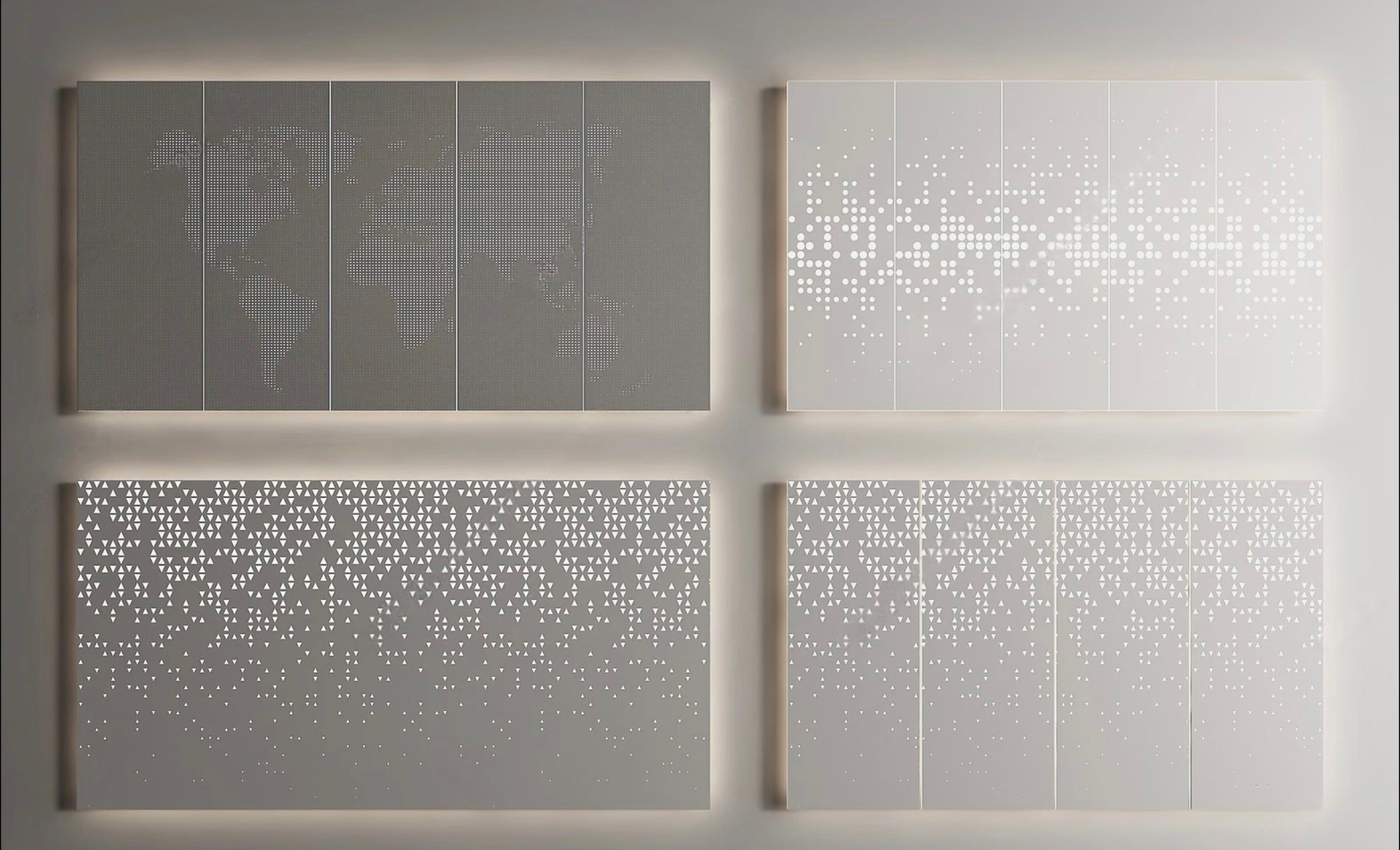

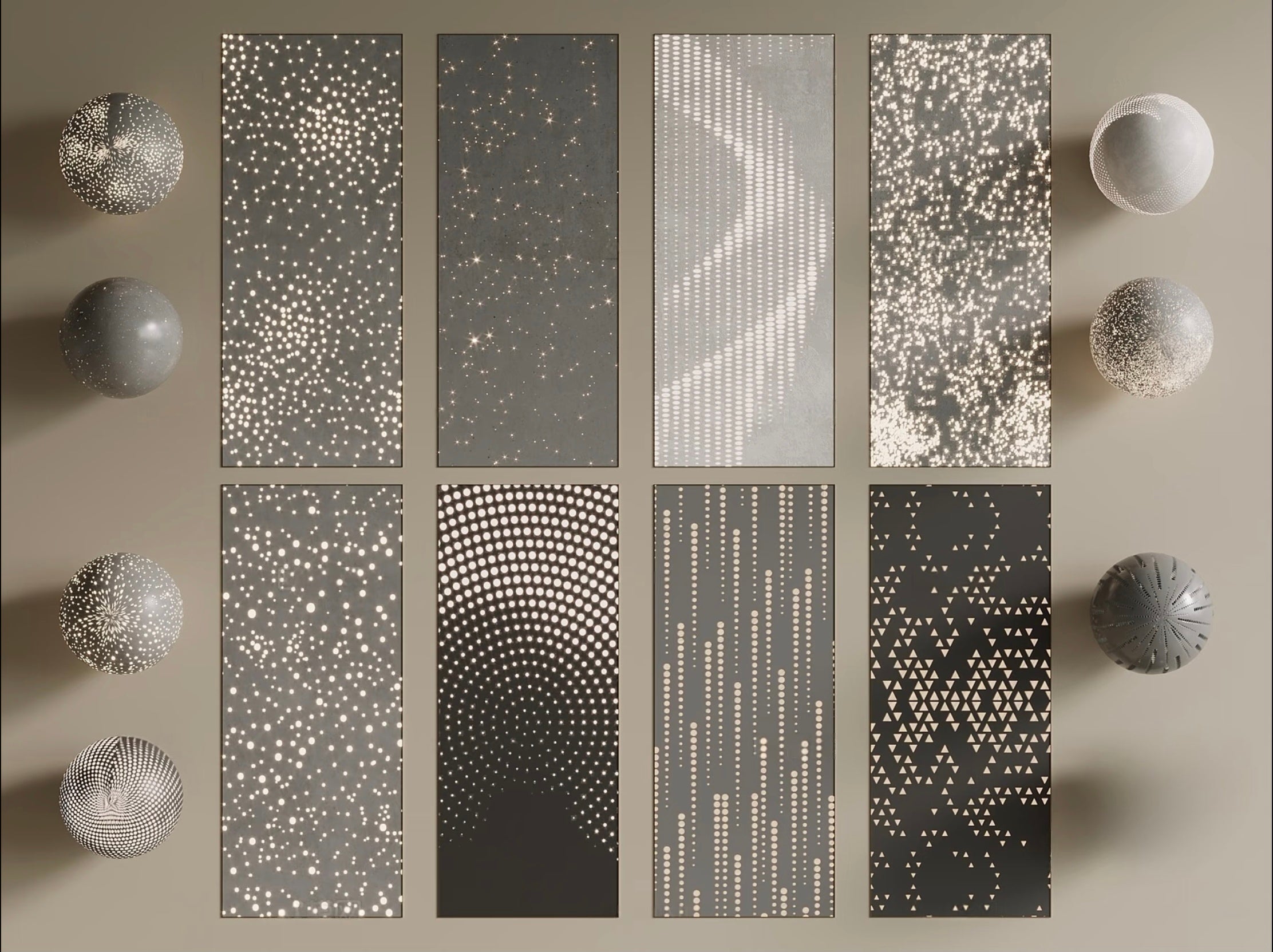

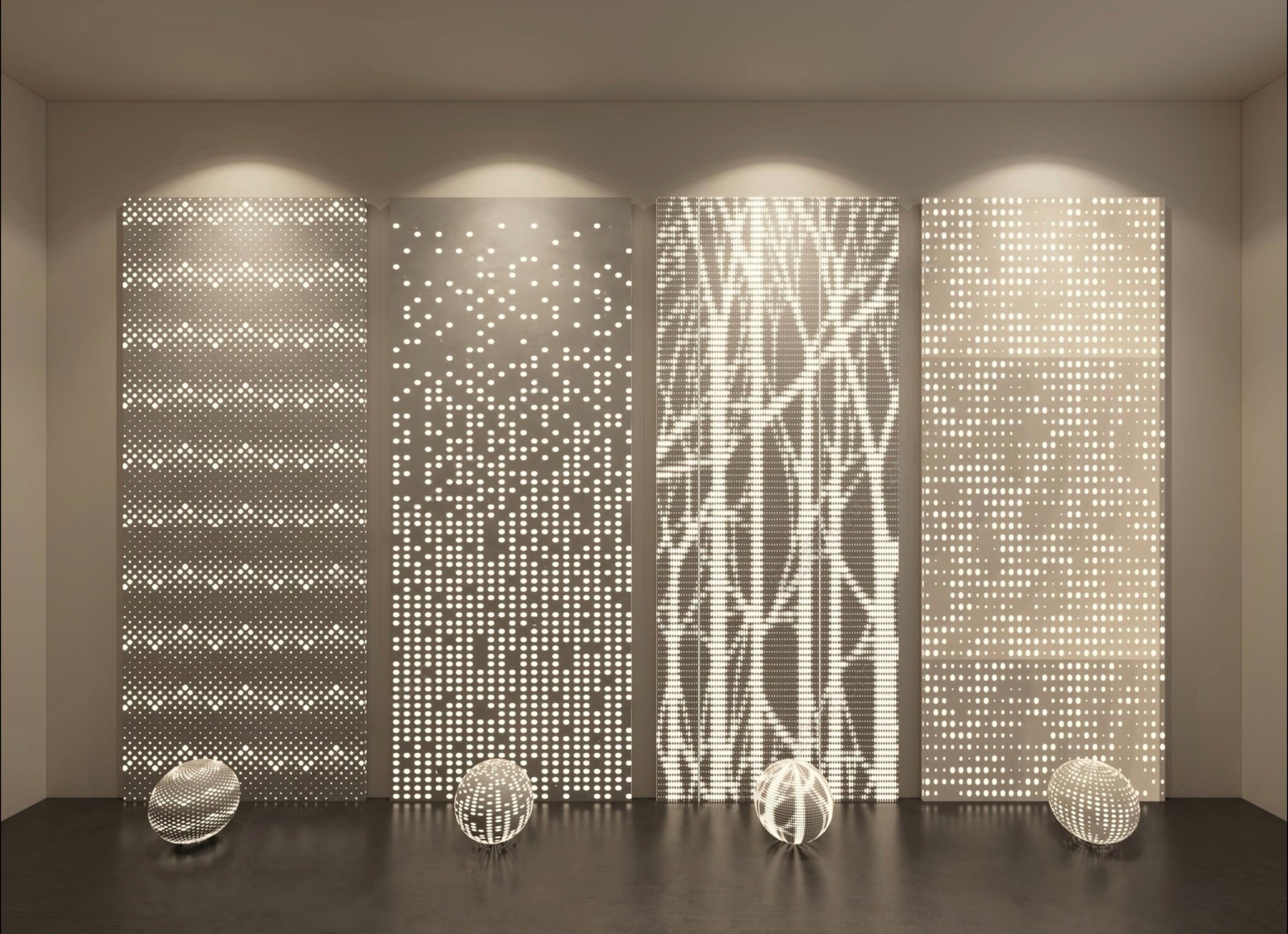

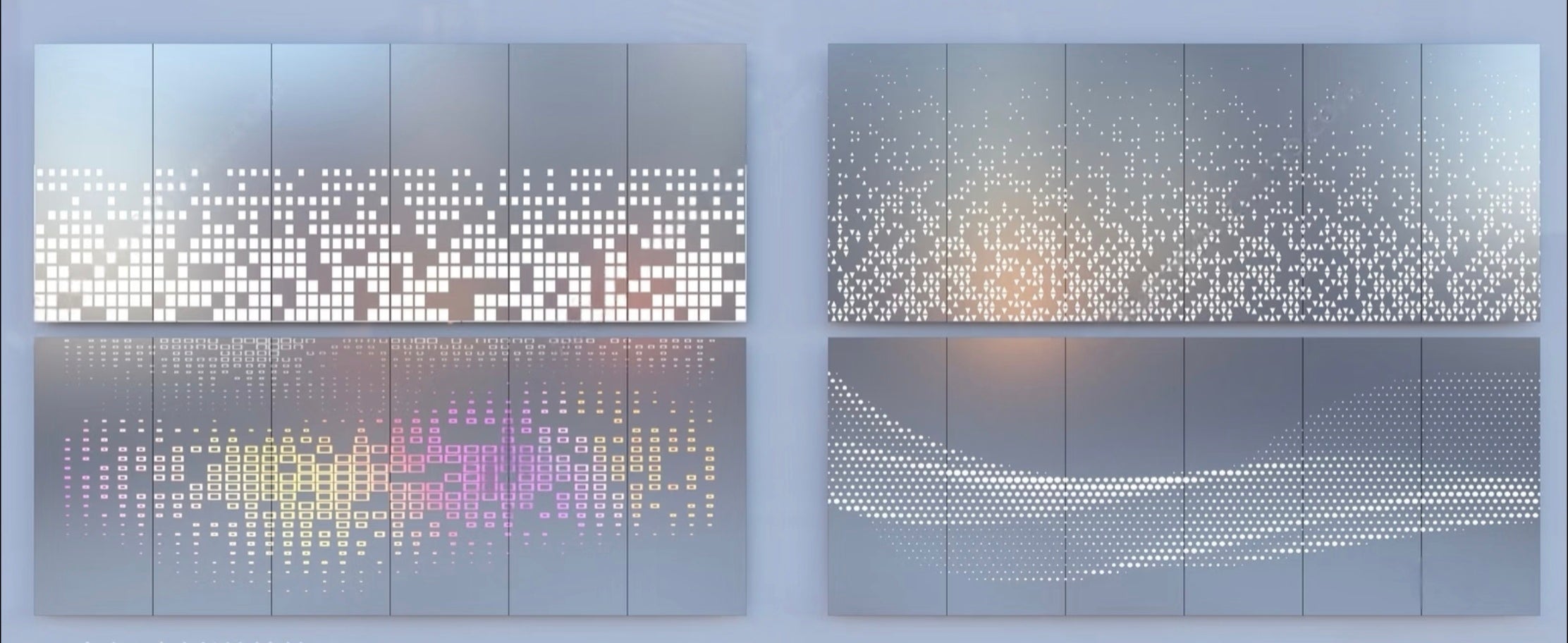

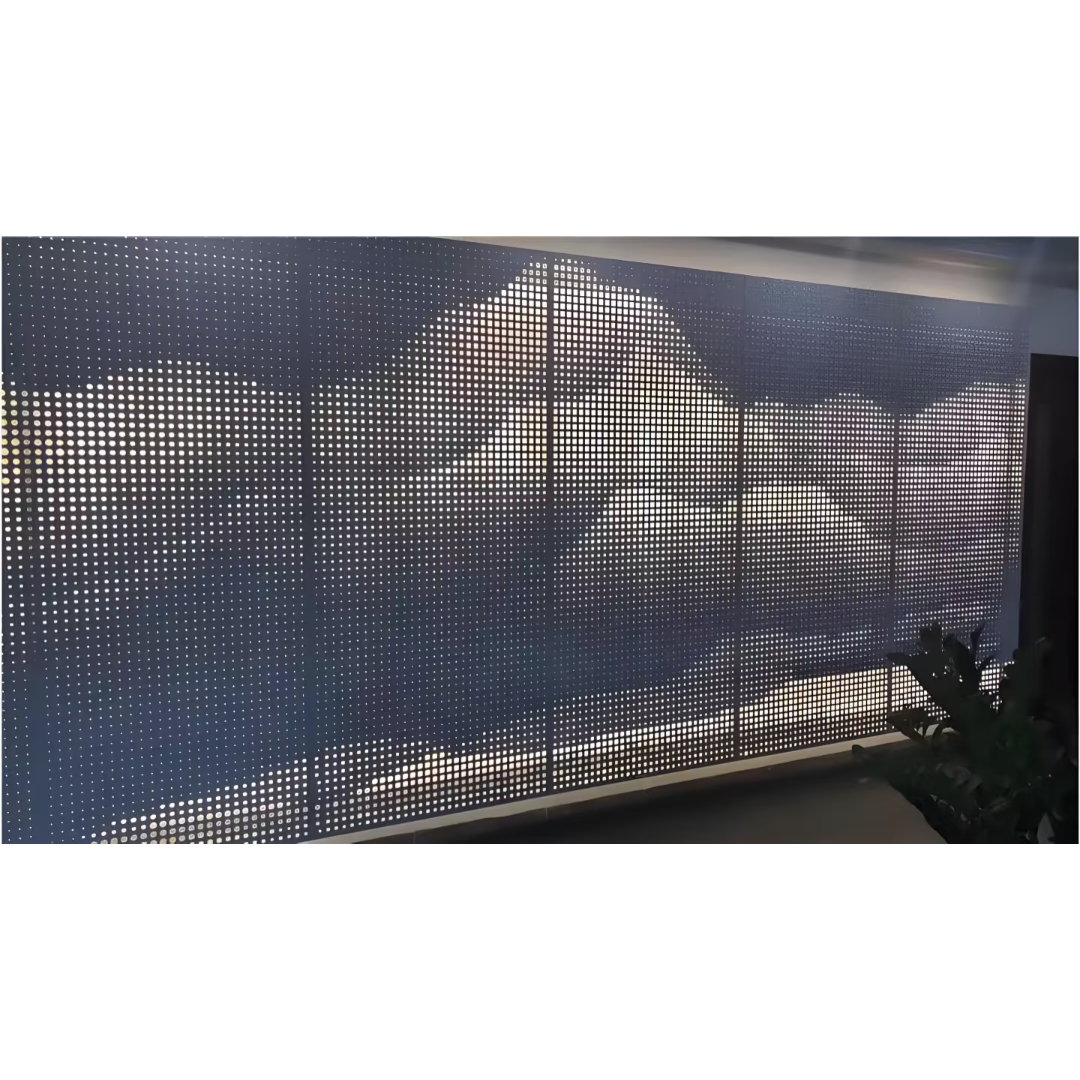

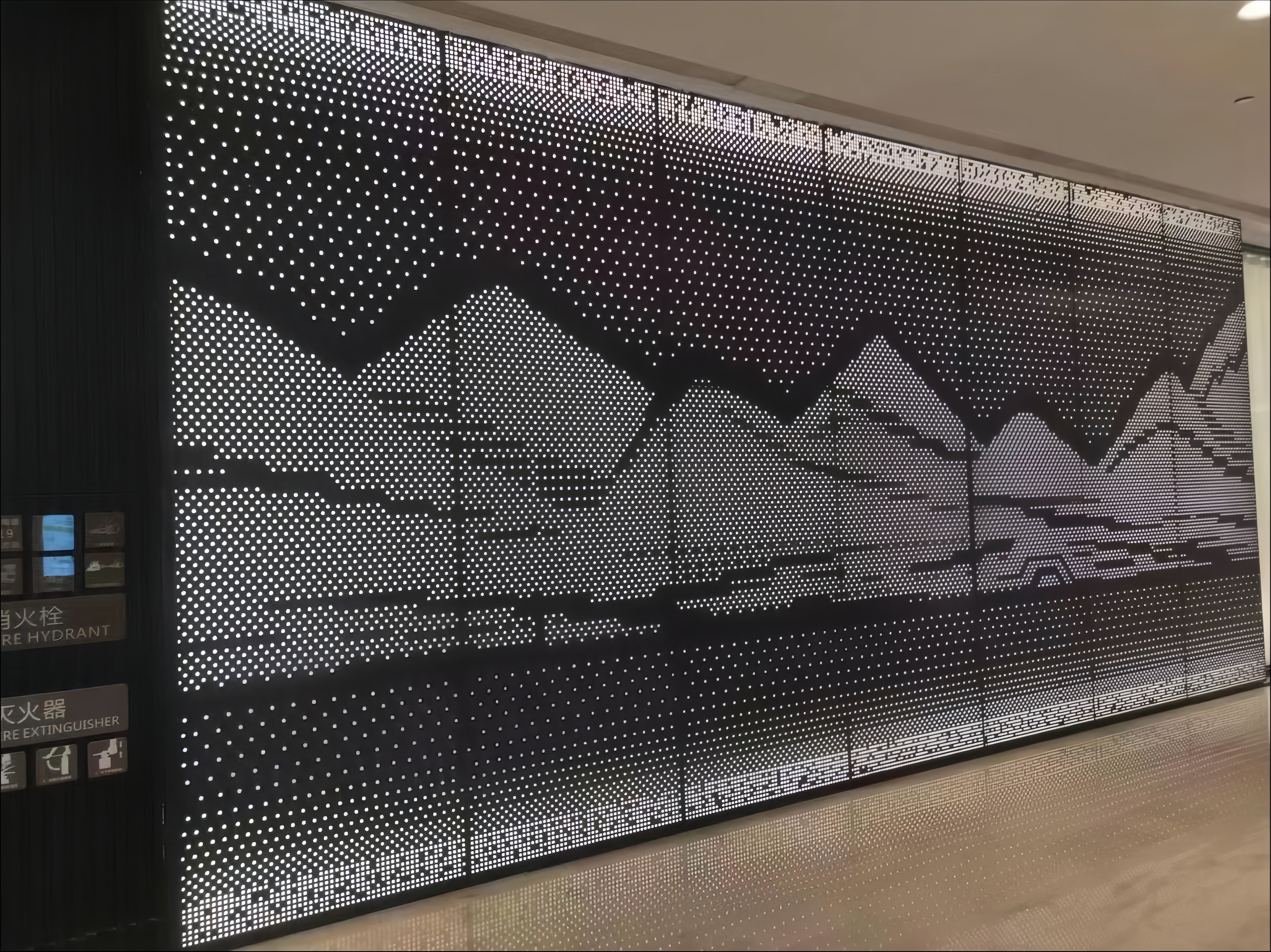

- Lighting integration - backlighting creates dramatic effects

- HVAC compatibility - allows air circulation while controlling sound

What Perforation Patterns Work Best for Different Interior Applications?

Selecting the optimal perforation pattern depends on acoustic requirements, aesthetic goals, and functional needs for each specific interior application:

Office and Commercial Spaces:

Open Offices:

- Pattern: Ø4-6mm holes, 6-10mm centers, 30-45% open area

- Acoustic Goal: Speech privacy, reduce distractions (NRC 0.50-0.70)

- Aesthetic: Clean, professional appearance with subtle texture

- Installation: Wall-mounted panels or ceiling integration

Conference Rooms:

- Pattern: Ø3-5mm holes, 5-8mm centers, 25-40% open area

- Acoustic Goal: Speech clarity, eliminate echo (NRC 0.45-0.65)

- Aesthetic: Sophisticated, minimal visual impact

- Features: Often combined with integrated AV equipment

Reception Areas:

- Pattern: Ø6-10mm holes, 10-15mm centers, 40-55% open area

- Acoustic Goal: Ambient noise control, welcoming atmosphere (NRC 0.60-0.80)

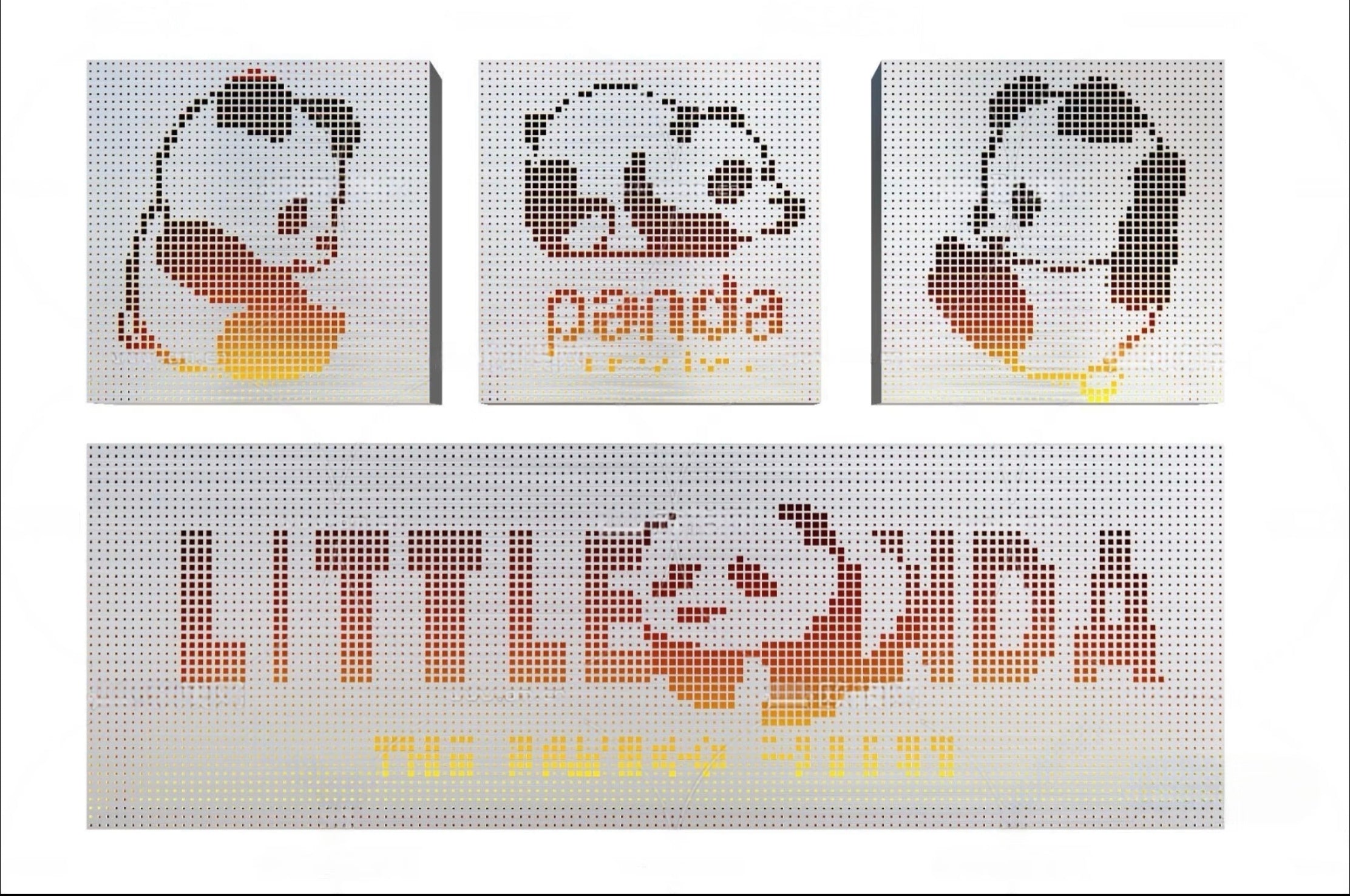

- Aesthetic: Decorative patterns, brand integration possible

- Features: Backlighting options for visual impact

Entertainment and Hospitality:

Restaurants:

- Pattern: Ø8-12mm holes, 12-18mm centers, 45-60% open area

- Acoustic Goal: Conversation comfort, reduce noise buildup (NRC 0.70-0.85)

- Aesthetic: Warm, inviting appearance with design flexibility

- Features: Easy cleaning, grease-resistant finishes

Hotels and Lobbies:

- Pattern: Custom decorative patterns, variable hole sizes

- Acoustic Goal: Luxurious quiet, sound masking (NRC 0.55-0.75)

- Aesthetic: High-end appearance, brand expression

- Features: Integrated lighting, artistic elements

Bars and Clubs:

- Pattern: Ø10-15mm holes, 15-25mm centers, 50-70% open area

- Acoustic Goal: Music clarity, crowd noise management (NRC 0.75-0.90)

- Aesthetic: Dynamic, modern appearance

- Features: Vibration resistance, easy maintenance

Educational Institutions:

Classrooms:

- Pattern: Ø4-8mm holes, 6-12mm centers, 35-50% open area

- Acoustic Goal: Teacher voice clarity, student focus (NRC 0.55-0.75)

- Aesthetic: Durable, vandal-resistant appearance

- Features: Easy cleaning, impact resistance

Libraries:

- Pattern: Ø2-4mm holes, 4-6mm centers, 20-35% open area

- Acoustic Goal: Maximum quiet, whisper control (NRC 0.35-0.55)

- Aesthetic: Calm, scholarly appearance

- Features: Minimal visual distraction

Auditoriums:

- Pattern: Variable patterns for tuned acoustics

- Acoustic Goal: Optimal music and speech performance (NRC 0.80-0.95)

- Aesthetic: Professional, performance-appropriate

- Features: Engineered acoustic design required

Healthcare Facilities:

Patient Rooms:

- Pattern: Ø3-6mm holes, 5-10mm centers, 25-40% open area

- Acoustic Goal: Privacy, healing environment (NRC 0.45-0.65)

- Aesthetic: Clean, calming appearance

- Features: Antimicrobial coatings, easy disinfection

Waiting Areas:

- Pattern: Ø6-10mm holes, 10-15mm centers, 40-55% open area

- Acoustic Goal: Comfort, stress reduction (NRC 0.60-0.80)

- Aesthetic: Welcoming, professional appearance

- Features: Durable finishes, low maintenance

Pattern Selection Guidelines:

- Small holes (Ø2-6mm): Maximum sound absorption, subtle appearance

- Medium holes (Ø6-12mm): Balanced performance, moderate visual impact

- Large holes (Ø12mm+): Dramatic appearance, specialized acoustic tuning

- Custom patterns: Unique aesthetics, brand integration, artistic expression

How Do You Install Perforated Sheets for Interior Walls?

Professional installation of perforated interior wall sheets requires proper planning, mounting systems, and acoustic backing for optimal performance:

Pre-Installation Planning:

Site Assessment:

- Wall condition evaluation - ensure flat, stable mounting surface

- Acoustic requirements - determine backing material and air gap needs

- Electrical considerations - plan for integrated lighting or AV equipment

- HVAC integration - coordinate with air circulation requirements

- Access requirements - plan for future maintenance and modifications

Material Preparation:

- Accurate measurements and panel layout planning

- Custom cutting and edge finishing as required

- Quality inspection of panels and mounting hardware

- Acclimation period - allow materials to reach room temperature

- Safety equipment and proper handling procedures

Mounting System Options:

Direct Mount Installation:

- Best for: Small panels, solid backing walls, budget applications

- Process: Panels screwed directly to wall studs or solid substrate

- Advantages: Simple, cost-effective, minimal wall thickness

- Limitations: Limited acoustic performance, difficult panel replacement

- Backing: Acoustic insulation installed behind panels

Z-Clip System:

- Best for: Medium panels, accessible installation, moderate budgets

- Process: Z-clips attached to wall and panel backs for hanging installation

- Advantages: Easy panel removal, good acoustic performance, clean appearance

- Requirements: Precise clip alignment, adequate wall support

- Backing: Separate acoustic treatment behind mounting system

Cassette System:

- Best for: Large installations, premium applications, maximum performance

- Process: Panels mounted in frames, frames attached to wall grid system

- Advantages: Excellent acoustic performance, easy maintenance, professional appearance

- Requirements: Precision manufacturing, professional installation

- Backing: Integrated acoustic materials within cassette system

Grid Ceiling Integration:

- Best for: Ceiling applications, existing grid systems, flexible layouts

- Process: Panels sized to fit standard ceiling grid dimensions

- Advantages: Easy installation and replacement, system integration

- Requirements: Compatible grid system, proper panel support

- Backing: Above-ceiling acoustic treatment

Acoustic Backing Requirements:

Insulation Materials:

- Fiberglass batts (R-11 to R-19): Cost-effective, good performance

- Mineral wool (2-4 inch thickness): Fire-resistant, excellent acoustic properties

- Acoustic foam (1-3 inch): Lightweight, easy installation

- Recycled cotton (2-4 inch): Sustainable, good performance

Air Gap Specifications:

- Minimum gap: 25mm for basic acoustic improvement

- Standard gap: 50-100mm for good acoustic performance

- Premium gap: 150-200mm for maximum low-frequency absorption

- Variable gaps: Tuned acoustic response for specific applications

Installation Process:

Step 1: Wall Preparation

- Clean and inspect mounting surface

- Install acoustic backing material

- Mark panel layout and mounting points

- Install mounting system framework

Step 2: Panel Installation

- Handle panels carefully to avoid damage

- Install panels according to layout plan

- Ensure proper alignment and spacing

- Check acoustic backing integrity

Step 3: Finishing Work

- Install trim and edge treatments

- Seal gaps and joints as required

- Integrate lighting or other systems

- Clean panels and inspect installation

Quality Control:

- Acoustic testing to verify performance

- Visual inspection for alignment and finish quality

- Safety check of mounting system security

- Documentation of installation details for future reference

Maintenance Access:

- Removable panels for behind-wall access

- Service openings for HVAC and electrical systems

- Cleaning procedures and recommended schedules

- Replacement planning for damaged or worn panels

What Are the Maintenance Requirements for Interior Perforated Wall Panels?

Perforated interior wall panels require minimal maintenance when properly installed, but regular care ensures optimal performance and appearance:

Routine Cleaning Procedures:

Daily/Weekly Maintenance:

- Dust removal using soft-bristle brush or vacuum with brush attachment

- Spot cleaning of fingerprints and minor stains with damp cloth

- Visual inspection for damage or loose mounting hardware

- Air circulation check to ensure perforations remain unobstructed

Monthly Cleaning:

- Compressed air cleaning to remove dust from perforations

- Mild detergent washing with soft cloth for surface cleaning

- Mounting system inspection for loose fasteners or clips

- Acoustic backing check for settling or displacement

Quarterly Deep Cleaning:

- Complete panel cleaning with appropriate cleaning solutions

- Perforation clearing using soft brushes or compressed air

- Hardware tightening and mounting system maintenance

- Performance assessment for acoustic and visual quality

Material-Specific Maintenance:

Aluminum Panels:

- Cleaning agents: Mild soap and water, avoid abrasive cleaners

- Finish protection: Use pH-neutral cleaners to preserve coatings

- Corrosion prevention: Immediate cleaning of spills and stains

- Scratch repair: Touch-up paint for minor coating damage

Stainless Steel Panels:

- Cleaning agents: Stainless steel cleaners, avoid chloride-based products

- Grain direction: Clean following brush grain pattern

- Water spots: Dry immediately after cleaning to prevent spotting

- Fingerprint removal: Regular cleaning with appropriate stainless cleaners

Painted Steel Panels:

- Cleaning agents: Mild detergents, avoid harsh chemicals

- Paint protection: Gentle cleaning to preserve finish integrity

- Touch-up procedures: Keep matching paint for minor repairs

- Rust prevention: Immediate attention to any coating damage

Healthcare and Food Service Applications:

Disinfection Procedures:

- EPA-approved disinfectants suitable for metal surfaces

- Contact time compliance following manufacturer recommendations

- Rinse procedures to remove disinfectant residues

- Drying protocols to prevent water damage or staining

Antimicrobial Maintenance:

- Specialized cleaning to maintain antimicrobial coating effectiveness

- Gentle procedures to avoid coating damage

- Regular testing of antimicrobial properties if required

- Replacement planning when coating effectiveness diminishes

Acoustic Performance Maintenance:

Perforation Care:

- Obstruction removal - clear dust, debris, or paint from holes

- Backing material check - ensure acoustic insulation remains in place

- Air gap maintenance - verify proper spacing behind panels

- Performance testing - periodic acoustic measurements if critical

Common Issues and Solutions:

Dust Accumulation:

- Cause: Normal air circulation through perforations

- Prevention: Regular cleaning schedule, air filtration improvement

- Solution: Compressed air cleaning, vacuum with brush attachment

Staining:

- Cause: Spills, fingerprints, environmental contamination

- Prevention: Protective coatings, prompt spill cleanup

- Solution: Appropriate cleaning agents, professional restoration if severe

Mounting System Issues:

- Cause: Building settlement, thermal expansion, vibration

- Prevention: Proper installation, quality hardware, expansion joints

- Solution: Hardware tightening, clip adjustment, professional inspection

Acoustic Degradation:

- Cause: Backing material settling, perforation obstruction

- Prevention: Quality installation, regular maintenance

- Solution: Backing replacement, perforation cleaning, system upgrade

Maintenance Schedule Recommendations:

High-Traffic Areas (Offices, Schools, Hospitals):

- Daily: Visual inspection, spot cleaning

- Weekly: Dust removal, basic cleaning

- Monthly: Deep cleaning, system check

- Annually: Professional inspection, performance testing

Standard Applications (Conference rooms, Restaurants):

- Weekly: Basic cleaning, visual inspection

- Monthly: Thorough cleaning, hardware check

- Quarterly: Deep cleaning, system maintenance

- Annually: Professional assessment

Low-Traffic Areas (Private offices, Residential):

- Monthly: Basic cleaning and inspection

- Quarterly: Thorough cleaning

- Annually: Complete maintenance and assessment

Professional Maintenance Services:

- Annual inspections by qualified technicians

- Performance testing for critical acoustic applications

- System upgrades and component replacement

- Warranty compliance maintenance documentation

How Do Perforated Interior Panels Compare to Other Acoustic Wall Treatments?

Perforated metal panels offer unique advantages compared to traditional acoustic treatments, providing superior durability, aesthetics, and performance in many interior applications:

Performance Comparison:

vs. Fabric-Wrapped Acoustic Panels:

- Durability: Metal panels last 20-40 years vs. 5-10 years for fabric

- Maintenance: Easy cleaning vs. replacement when soiled

- Fire safety: Class A non-combustible vs. potential fire concerns

- Hygiene: Washable, antimicrobial options vs. dust/allergen accumulation

- Aesthetics: Modern, professional appearance vs. limited design options

- Cost: Higher initial cost, lower lifecycle cost

vs. Acoustic Foam Treatments:

- Longevity: Permanent installation vs. degradation over time

- Performance: Broadband frequency control vs. limited high-frequency absorption

- Appearance: Architectural integration vs. industrial appearance

- Safety: Non-combustible vs. potential fire hazard

- Installation: Professional mounting vs. adhesive application

- Versatility: Customizable patterns vs. standard shapes only

vs. Wood Acoustic Panels:

- Moisture resistance: Excellent vs. susceptible to humidity damage

- Maintenance: Minimal vs. refinishing requirements

- Consistency: Uniform performance vs. natural material variation

- Fire rating: Superior vs. combustible material concerns

- Cost: Competitive vs. premium hardwood pricing

- Sustainability: Recyclable vs. forest resource consumption

vs. Gypsum Board Acoustic Treatments:

- Impact resistance: Excellent vs. easily damaged

- Weight: Lighter installation vs. heavy construction

- Flexibility: Removable/replaceable vs. permanent installation

- Performance: Tunable acoustics vs. limited acoustic properties

- Aesthetics: Design flexibility vs. paint-only options

- Integration: HVAC compatible vs. solid barrier

Unique Advantages of Perforated Metal:

Functional Benefits:

- Dual-purpose design - acoustic treatment and architectural feature

- Air circulation - maintains HVAC efficiency while controlling sound

- Integrated systems - lighting, AV equipment, and access panels possible

- Customizable performance - engineered for specific acoustic requirements

- Easy modification - panels can be removed or replaced without major renovation

Aesthetic Advantages:

- Modern appearance - complements contemporary interior design

- Lighting effects - backlighting creates dramatic visual impact

- Brand integration - custom patterns for corporate identity

- Color options - wide range of finishes and coating systems

- Texture variety - from subtle to bold visual effects

Practical Benefits:

- Vandal resistance - difficult to damage compared to soft materials

- Accessibility compliance - smooth surfaces, no protruding elements

- Code compliance - meets fire, safety, and building code requirements

- Professional installation - standard mounting systems and procedures

- Warranty protection - manufacturer warranties typically 10-25 years

Application-Specific Comparisons:

Healthcare Facilities:

- Infection control: Washable, disinfectable surfaces

- Patient safety: No particle shedding, hypoallergenic

- Durability: Withstands frequent cleaning and disinfection

- Maintenance: Minimal disruption for cleaning procedures

Educational Institutions:

- Durability: Withstands student activity and potential abuse

- Safety: Non-toxic, fire-resistant materials

- Performance: Optimized for speech clarity and learning environments

- Cost-effectiveness: Long-term value despite higher initial cost

Commercial Offices:

- Professional appearance: Maintains corporate image standards

- Flexibility: Adaptable to changing space requirements

- Performance: Supports productivity through noise control

- Integration: Compatible with modern building systems

Cost-Benefit Analysis:Initial Investment:

- Higher upfront cost than basic acoustic treatments

- Professional installation requirements add to initial expense

- Custom engineering may be required for optimal performance

Lifecycle Value:

- 25-40 year lifespan vs. 5-15 years for alternative treatments

- Minimal replacement costs - panels can be individually replaced

- Low maintenance expenses - cleaning vs. replacement

- Energy savings - natural ventilation reduces HVAC costs

- Property value enhancement - permanent building improvement

Selection Criteria:

- Choose perforated metal for: permanent installations, high-traffic areas, modern aesthetics, integrated building systems

- Consider alternatives for: temporary installations, budget-constrained projects, traditional design preferences, specialized acoustic requirements