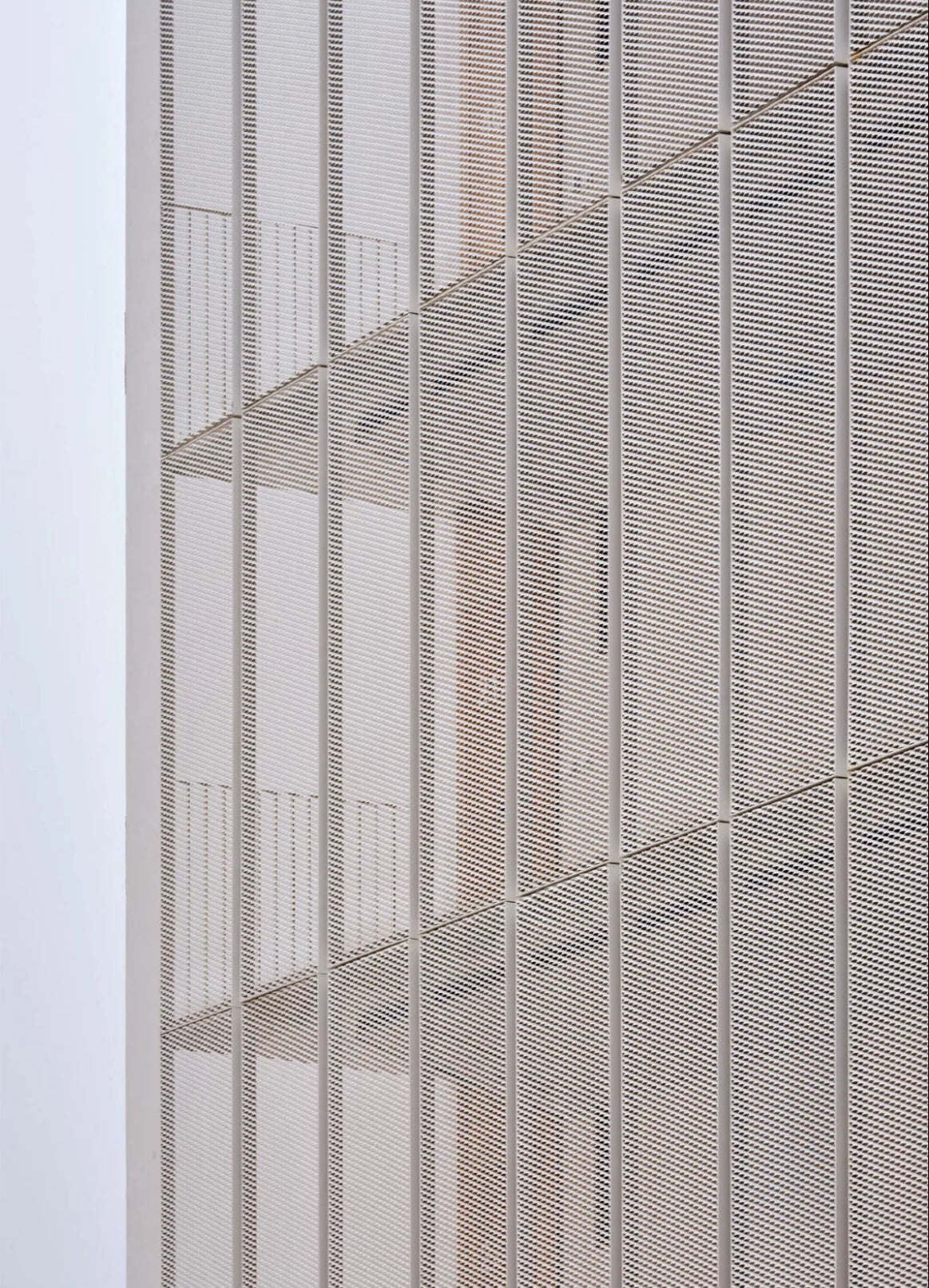

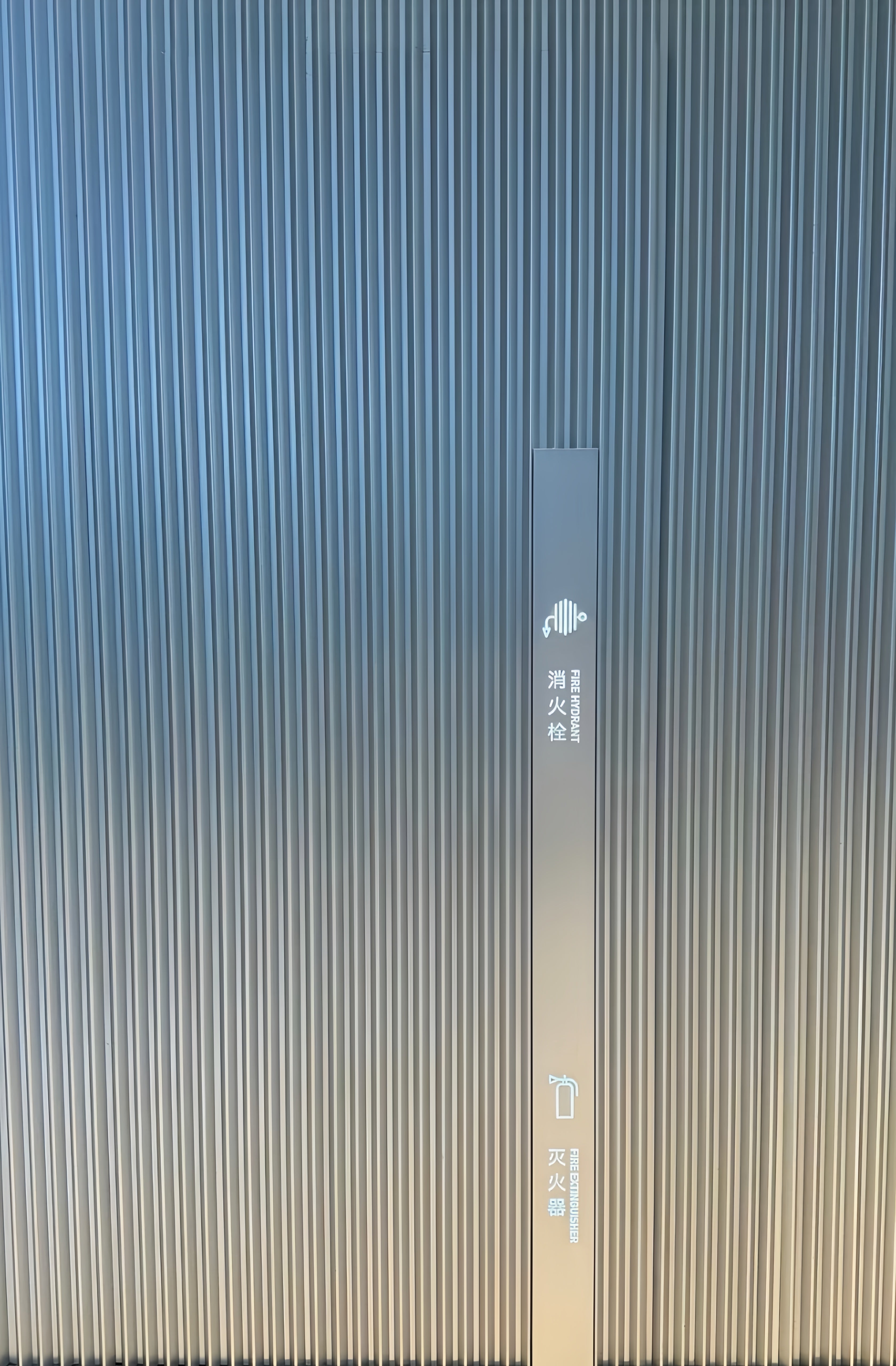

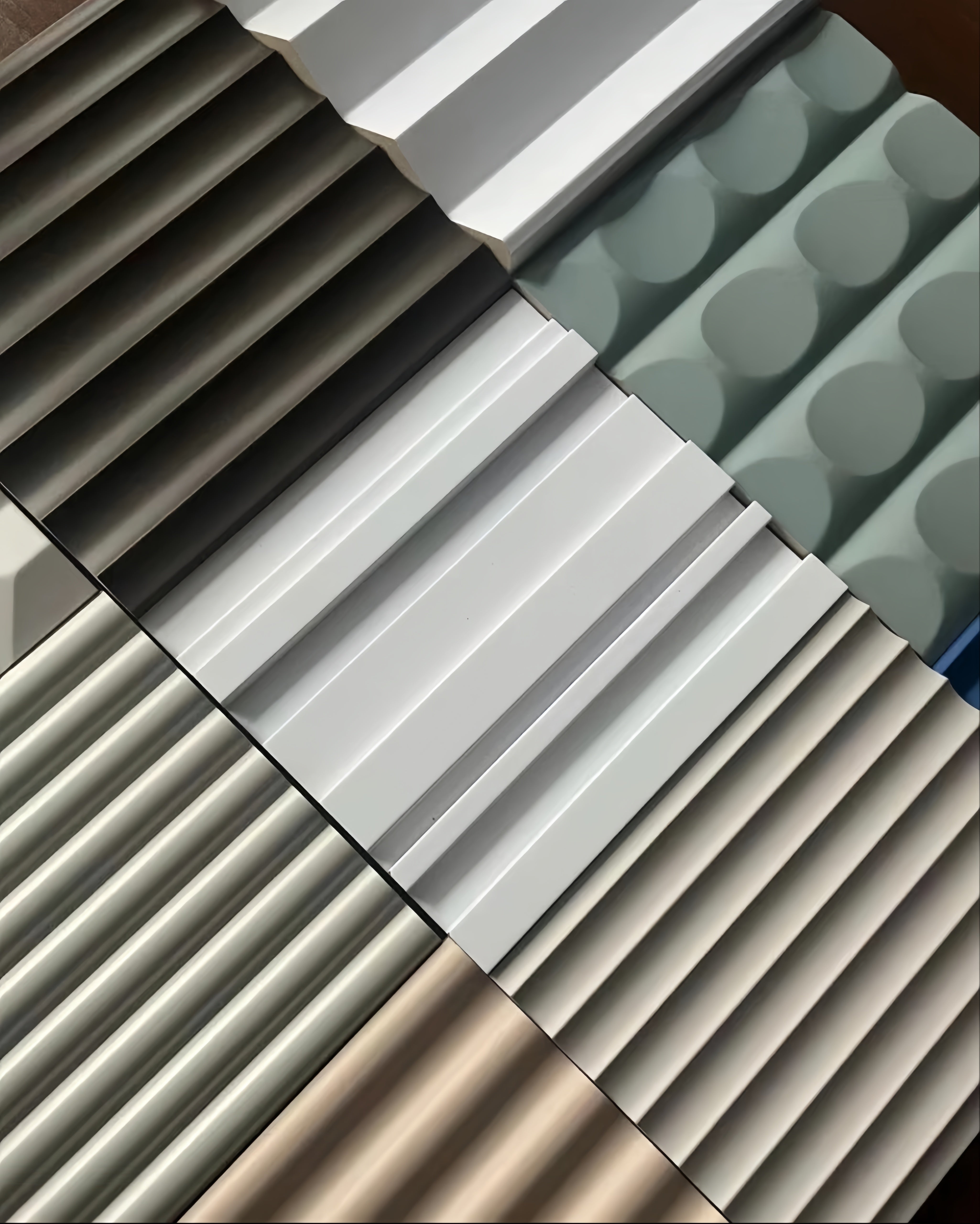

Corrugated Metal Panels for Cladding

High-performance corrugated metal cladding panels engineered for superior structural strength, weather resistance, and architectural versatility. These precision-formed panels feature continuous corrugated profiles that provide exceptional load-bearing capacity while maintaining lightweight construction. Our corrugated cladding systems deliver outstanding water shedding, thermal performance, and design flexibility for commercial, industrial, and residential applications.

| Profile Type | Pitch (mm) | Depth (mm) | Coverage Width (mm) | Effective Width (mm) | Min. Slope |

|---|---|---|---|---|---|

| 7/8" Corrugated | 19.1 | 4.8 | 660 | 610 | 1:4 (14°) |

| 1.5" Corrugated | 38.1 | 9.5 | 762 | 686 | 1:4 (14°) |

| 2.67" Corrugated | 67.7 | 19.1 | 762 | 686 | 1:8 (7°) |

| Box Rib 40 | 40.0 | 15.0 | 1000 | 950 | 1:8 (7°) |

| Trapezoidal 35 | 35.0 | 35.0 | 1000 | 910 | 1:10 (6°) |

| Standing Seam | Variable | 25.0 | 400-600 | 380-580 | 1:12 (5°) |

| Profile | Thickness | Max Span | Uniform Load | Moment of Inertia | Section Modulus |

|---|---|---|---|---|---|

| 7/8" Corrugated | 0.7mm | 2.5m | 1.2 kPa | 2.8 cm⁴/m | 1.2 cm³/m |

| 7/8" Corrugated | 1.0mm | 3.2m | 2.1 kPa | 4.0 cm⁴/m | 1.7 cm³/m |

| 1.5" Corrugated | 0.7mm | 3.8m | 1.8 kPa | 6.2 cm⁴/m | 2.6 cm³/m |

| 1.5" Corrugated | 1.0mm | 4.8m | 3.2 kPa | 8.9 cm⁴/m | 3.7 cm³/m |

| 2.67" Corrugated | 0.9mm | 6.5m | 2.8 kPa | 18.5 cm⁴/m | 5.8 cm³/m |

| Trapezoidal 35 | 0.7mm | 4.2m | 2.5 kPa | 12.8 cm⁴/m | 4.2 cm³/m |

| Parameter | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Profile Pitch | ±1.0mm | ±0.5mm |

| Profile Depth | ±0.5mm | ±0.3mm |

| Sheet Length | ±5mm | ±3mm |

| Sheet Width | ±3mm | ±2mm |

| Thickness | ±0.05mm | ±0.03mm |

| Straightness | ±3mm/m | ±2mm/m |

| Edge Squareness | ±2mm/m | ±1mm/m |

| Configuration | U-Value (W/m²K) | R-Value (m²K/W) | Thermal Bridge |

|---|---|---|---|

| Single Skin | 5.8-6.2 | 0.16-0.17 | Continuous |

| Insulated (50mm) | 0.6-0.8 | 1.25-1.67 | Reduced |

| Insulated (100mm) | 0.3-0.4 | 2.50-3.33 | Minimized |

| Double Skin | 0.4-0.6 | 1.67-2.50 | Eliminated |

| System Type | Sound Reduction (dB) | NRC | Applications |

|---|---|---|---|

| Single Skin | 25-30 | 0.05-0.10 | Industrial, agricultural |

| Insulated System | 35-45 | 0.15-0.25 | Commercial, residential |

| Double Skin | 45-55 | 0.20-0.30 | Noise-sensitive areas |

| Perforated + Insulation | 40-50 | 0.60-0.80 | Acoustic applications |

| Profile Type | Thickness | Span | Positive Pressure | Negative Pressure |

|---|---|---|---|---|

| 7/8" Corrugated | 0.7mm | 2.5m | 2.8 kPa | -2.2 kPa |

| 1.5" Corrugated | 0.7mm | 3.8m | 3.2 kPa | -2.8 kPa |

| 1.5" Corrugated | 1.0mm | 4.8m | 5.5 kPa | -4.8 kPa |

| 2.67" Corrugated | 0.9mm | 6.5m | 4.2 kPa | -3.8 kPa |

| Trapezoidal 35 | 0.7mm | 4.2m | 4.8 kPa | -4.2 kPa |

| Application | Fastener Type | Spacing | Edge Distance | Penetration |

|---|---|---|---|---|

| Wall Cladding | Self-drilling screws | 300-600mm | 15mm min | 20mm min |

| Roof Applications | Roofing screws + washers | 200-400mm | 20mm min | 25mm min |

| High Wind Areas | Structural screws | 200-300mm | 20mm min | 30mm min |

| Seismic Zones | Seismic-rated fasteners | 150-300mm | 25mm min | 35mm min |

| Test Condition | Performance Level | Test Standard |

|---|---|---|

| Static Water | No penetration at 300 Pa | ASTM E331 |

| Dynamic Water | No penetration at 150 Pa | ASTM E547 |

| Driving Rain | Class E4 (Excellent) | EN 12865 |

| Thermal Cycling | No degradation after 25 cycles | ASTM E1105 |

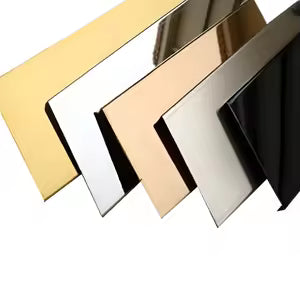

| Grade | Coating | Properties | Applications | Expected Life |

|---|---|---|---|---|

| G550 | Z275 (275g/m²) | High strength, good formability | Commercial, industrial | 25-30 years |

| G300 | Z350 (350g/m²) | Standard strength, excellent corrosion resistance | Residential, light commercial | 30-40 years |

| G450 | Z450 (450g/m²) | High strength, maximum corrosion protection | Marine, industrial | 35-45 years |

| Grade | Composition | Properties | Best Applications |

|---|---|---|---|

| 304 | 18% Cr, 8% Ni | General purpose, non-magnetic | Food processing, architectural |

| 316 | 18% Cr, 10% Ni, 2% Mo | Marine grade corrosion resistance | Coastal, chemical environments |

| 321 | 18% Cr, 9% Ni, Ti stabilized | High temperature stability | Industrial, high-heat applications |

| duplex 2205 | 22% Cr, 5% Ni, 3% Mo | High strength and corrosion resistance | Extreme environments |

| Alloy | Temper | Properties | Applications |

|---|---|---|---|

| 3003 | H14/H16 | Good strength, excellent corrosion resistance | General cladding, residential |

| 3004 | H32/H34 | Higher strength than 3003, good formability | Commercial, architectural |

| 5052 | H32/H34 | Marine grade, high strength | Coastal, industrial applications |

| 6061 | T6 | Structural grade, heat treatable | High-performance applications |

| Coating Type | Thickness | Warranty | Color Retention | Chalk Rating | Best Applications |

|---|---|---|---|---|---|

| Polyester | 25μm | 10 years | Good | 8 (10 years) | General commercial, residential |

| Silicone Modified Polyester | 25μm | 15 years | Very Good | 8 (15 years) | Commercial, light industrial |

| PVDF (Kynar/Hylar) | 25μm | 20-35 years | Excellent | 9 (20 years) | Premium architectural, severe environments |

| Plastisol | 200μm | 15 years | Good | N/A | Industrial, high-abuse applications |

| Material/Coating | Marine Environment | Industrial Environment | Rural Environment |

|---|---|---|---|

| Galvanized Steel (Z275) | 15-20 years | 20-25 years | 25-30 years |

| Pre-painted Steel (PVDF) | 20-25 years | 25-30 years | 30-35 years |

| 304 Stainless Steel | 25+ years | 30+ years | 50+ years |

| 316 Stainless Steel | 40+ years | 50+ years | 100+ years |

| Aluminum (Anodized) | 30+ years | 35+ years | 50+ years |

FAQs

What Are the Key Differences Between Corrugated Profiles and How Do I Choose the Right One?

Corrugated panel profiles vary significantly in structural capacity, appearance, and application suitability, requiring careful selection based on project requirements:Profile Depth and Structural Performance:Shallow Profiles (7/8" - 4.8mm depth):

- Structural capacity: Suitable for spans up to 3.2m with standard loads

- Applications: Residential siding, accent walls, interior applications

- Advantages: Lower profile, traditional appearance, economical choice

- Limitations: Limited structural capacity, requires closer support spacing

- Best for: Light-duty applications, retrofit projects, decorative elements

Medium Profiles (1.5" - 9.5mm depth):

- Structural capacity: Spans up to 4.8m, excellent strength-to-weight ratio

- Applications: Commercial walls, agricultural buildings, industrial siding

- Advantages: Good structural performance, versatile appearance, cost-effective

- Characteristics: Most popular choice for general applications

- Best for: Standard commercial and industrial cladding projects

Deep Profiles (2.67" - 19.1mm depth):

- Structural capacity: Spans up to 6.5m, maximum load-bearing capability

- Applications: Large industrial buildings, warehouse walls, structural panels

- Advantages: Maximum strength, long spans reduce support structure

- Considerations: Higher profile creates bold shadow lines

- Best for: Heavy-duty applications, maximum span requirements

Trapezoidal Profiles (35mm depth):

- Structural capacity: Excellent in both directions, spans up to 4.2m

- Applications: Modern architectural projects, commercial buildings

- Advantages: Contemporary appearance, good structural performance

- Characteristics: Flat-topped ribs create distinctive linear appearance

- Best for: Architectural applications requiring modern aesthetic

Profile Selection Criteria:Structural Requirements:Load Capacity Comparison (1.0mm thickness):

- 7/8" Corrugated: 2.1 kPa uniform load, 3.2m max span

- 1.5" Corrugated: 3.2 kPa uniform load, 4.8m max span

- 2.67" Corrugated: 2.8 kPa uniform load, 6.5m max span

- Trapezoidal 35: 2.5 kPa uniform load, 4.2m max span

Aesthetic Considerations:

- Traditional appearance: 7/8" and 1.5" corrugated profiles

- Industrial/agricultural: 1.5" and 2.67" corrugated profiles

- Contemporary/modern: Trapezoidal and standing seam profiles

- Shadow lines: Deeper profiles create more dramatic shadow effects

- Scale relationship: Profile depth should relate to building size

Economic Factors:

- Material cost: Shallow profiles most economical per square meter

- Support structure: Deeper profiles allow wider spacing, reducing frame costs

- Installation efficiency: Standard profiles install faster than complex shapes

- Long-term value: Higher-performance profiles may justify premium cost

Environmental Suitability:

- Wind resistance: Deeper profiles provide better uplift resistance

- Water shedding: All profiles excellent, minimum slopes vary by profile

- Snow loading: Deeper profiles handle higher snow loads

- Thermal movement: All profiles accommodate expansion/contraction well

Application-Specific Selection:Residential Applications:

- Primary choice: 7/8" or 1.5" corrugated for traditional appearance

- Modern homes: Trapezoidal profiles for contemporary aesthetic

- Accent walls: Any profile based on architectural design intent

- Budget considerations: 7/8" corrugated most economical option

Commercial Buildings:

- Standard choice: 1.5" corrugated for balanced performance and cost

- Large buildings: 2.67" corrugated for maximum spans

- Architectural features: Trapezoidal or custom profiles for design impact

- Mixed-use: Consider different profiles for different building areas

Industrial/Agricultural:

- Heavy-duty: 2.67" corrugated for maximum structural performance

- Standard industrial: 1.5" corrugated for general applications

- Equipment protection: Deep profiles for impact resistance

- Maintenance access: Consider profile depth for cleaning and maintenance

Installation Considerations:

- Fastener requirements: Deeper profiles may require longer fasteners

- Flashing details: Profile depth affects flashing and trim requirements

- Handling: Deeper profiles more rigid but may require special handling

- Cutting: All profiles cut easily with standard metal cutting tools

How Do I Determine the Correct Material and Coating System for My Environment?

Material and coating selection must consider environmental exposure, service life requirements, maintenance expectations, and budget constraints:

Environmental Risk Assessment:

Coastal/Marine Environments (High Corrosion Risk):

- Primary concerns: Salt spray, high humidity, chloride exposure

- Material recommendations: 316 stainless steel, aluminum 5052, or galvanized steel with premium coatings

- Coating requirements: PVDF minimum, 25-35 year warranty systems

- Distance considerations: <1km from ocean requires marine-grade materials

- Maintenance: Regular fresh water rinsing, annual inspection

Industrial Environments (Chemical Exposure):

- Primary concerns: Chemical emissions, acid rain, particulate contamination

- Material recommendations: Stainless steel grades based on specific chemicals present

- Coating requirements: Chemical-resistant coatings, may require specialty systems

- Assessment needs: Chemical compatibility analysis required

- Monitoring: Regular inspection for coating degradation and chemical attack

Urban/Suburban Environments (Moderate Exposure):

- Primary concerns: Air pollution, temperature cycling, UV exposure

- Material recommendations: Pre-painted galvanized steel, aluminum with quality coatings

- Coating requirements: Silicone-modified polyester minimum, PVDF for premium applications

- Service life: 20-30 years with standard systems, 30-40 years with premium

- Maintenance: Periodic cleaning, coating inspection every 5-10 years

Rural/Agricultural Environments (Low-Moderate Exposure):

- Primary concerns: Temperature extremes, moisture, agricultural chemicals

- Material recommendations: Galvanized steel with polyester coatings

- Coating requirements: Standard polyester adequate for most applications

- Special considerations: Fertilizer and pesticide compatibility

- Cost optimization: Standard systems provide excellent value

Material Selection Matrix:

Budget-Conscious Projects:

Environment: Rural/Suburban

Material: G550 galvanized steel, Z275 coating

Paint system: Polyester, 25μm thickness

Expected life: 15-20 years

Maintenance: Moderate, recoating at 10-15 years

Total cost of ownership: Lowest initial cost

Standard Performance Projects:

Environment: Urban/Light Industrial

Material: G550 galvanized steel, Z350 coating

Paint system: SMP (Silicone Modified Polyester), 25μm

Expected life: 20-25 years

Maintenance: Low, inspection every 5 years

Total cost of ownership: Good balance of cost and performance

Premium Performance Projects:

Environment: Marine/Heavy Industrial

Material: 316 stainless steel or aluminum 5052

Paint system: PVDF, 25μm thickness (if painted)

Expected life: 35-50+ years

Maintenance: Minimal, cleaning as needed

Total cost of ownership: Highest initial cost, lowest lifecycle cost

Coating System Comparison:

Polyester Coatings:

- Performance: Good color retention, moderate durability

- Warranty: 10 years typical

- Cost: Most economical option

- Applications: Rural, residential, budget-conscious projects

- Limitations: Moderate chalk and fade resistance

Silicone Modified Polyester (SMP):

- Performance: Improved durability over standard polyester

- Warranty: 15-20 years typical

- Cost: 15-25% premium over polyester

- Applications: Commercial, light industrial, suburban

- Benefits: Better chalk resistance, improved color retention

PVDF (Kynar/Hylar) Coatings:

- Performance: Excellent durability, superior color retention

- Warranty: 20-35 years depending on environment

- Cost: 40-60% premium over polyester

- Applications: Architectural, marine, premium projects

- Benefits: Outstanding weathering resistance, easy cleaning

Specialty Coating Considerations:

High-Temperature Applications:

- Silicone coatings: Service to 300°C continuous

- Ceramic coatings: Extreme temperature resistance

- Heat-resistant primers: Essential for high-temperature service

- Color limitations: Limited color options for high-temperature coatings

Food Processing/Clean Environments:

- FDA-approved coatings: Food-safe formulations available

- Easy-clean surfaces: Smooth finishes resist contamination

- Antimicrobial coatings: Copper-based systems available

- Chemical resistance: Cleaning chemical compatibility essential

Aesthetic Requirements:

- Color matching: Custom colors available for architectural projects

- Texture options: Smooth, embossed, or wood-grain textures

- Metallic finishes: Copper, bronze, zinc appearances available

- Fade resistance: PVDF systems maintain color best over time

Decision Framework:

Step 1: Environmental Assessment

- Identify primary environmental challenges

- Assess exposure severity and duration

- Consider microclimate effects (building orientation, shading)

- Evaluate maintenance access and capabilities

Step 2: Performance Requirements

- Define minimum acceptable service life

- Establish appearance retention requirements

- Determine maintenance budget and capabilities

- Consider building use and occupancy requirements

Step 3: Economic Analysis

- Calculate initial cost differences

- Project maintenance and replacement costs

- Consider financing and cash flow impacts

- Evaluate total cost of ownership over building life

Step 4: Final Selection

- Balance performance requirements with budget constraints

- Consider warranty terms and manufacturer reputation

- Verify local availability and support

- Plan for future maintenance and replacement needs

What Are the Installation Requirements and Best Practices for Corrugated Cladding?

Successful corrugated cladding installation requires proper planning, correct fastening techniques, and attention to weather sealing and thermal movement:

Pre-Installation Planning:

Structural Verification:

- Load calculations: Verify structure can support panel weight plus wind/snow loads

- Support spacing: Confirm purlins/girts spaced per panel span capabilities

- Structural alignment: Check frame for plumb, level, and square within tolerances

- Connection capacity: Verify adequate fastener pull-out and shear capacity

- Thermal movement: Plan for expansion/contraction of panels and structure

Material Handling and Storage:

- Delivery inspection: Check for damage, verify quantities and specifications

- Storage requirements: Flat storage on level supports, protect from moisture

- Handling procedures: Use appropriate lifting equipment, avoid surface damage

- Weather protection: Cover materials during storage and installation

- Inventory management: Install oldest material first, rotate stock properly

Installation Sequence and Methods:

Layout and Starting Point:

- Reference lines: Establish level and plumb reference lines

- Starting corner: Begin installation from predetermined corner or centerline

- Panel orientation: Verify correct orientation for structural and aesthetic requirements

- Overlap planning: Plan panel overlaps to shed water effectively

- Expansion joint locations: Position expansion joints per thermal analysis

Fastening Procedures:

Fastener Selection:

- Material compatibility: Stainless steel or coated fasteners to prevent galvanic corrosion

- Length requirements: Minimum 20mm penetration into structural member

- Washer requirements: EPDM washers for weather sealing

- Thread type: Self-drilling for steel structure, self-tapping for wood

- Head type: Hex head for power tools, painted to match panel color

Fastening Patterns:

Standard Fastening (Normal Wind Areas):

- End laps: Every corrugation

- Side laps: 300-450mm centers

- Intermediate supports: Every other corrugation

- Panel ends: Within 150mm of panel end

- Total fasteners: 8-12 per square meter typical

High Wind Fastening (Hurricane/Cyclone Areas):

- End laps: Every corrugation

- Side laps: 200-300mm centers

- Intermediate supports: Every corrugation

- Panel ends: Within 100mm of panel end

- Total fasteners: 12-18 per square meter

Fastener Installation:

- Pre-drilling: Not required for self-drilling screws in steel up to 6mm

- Driving technique: Drive perpendicular to panel surface

- Torque control: Compress washer without over-driving

- Sealant application: Apply sealant under washer if required

- Quality control: Inspect fastener installation regularly

Weather Sealing and Flashing:

Side Lap Sealing:

- Sealant tape: Butyl or EPDM tape between overlapping panels

- Structural sealant: Silicone sealant for permanent installations

- Mechanical sealing: Continuous fastening through both panels

- Drainage: Ensure water can drain from lap joints

- Inspection access: Provide access for future sealant maintenance

End Lap Details:

- Minimum overlap: 150mm minimum, 200mm in high-wind areas

- Sealant application: Full-width sealant tape or structural sealant

- Fastener placement: Fasten through both panels into structure

- Water shedding: Upper panel overlaps lower panel

- Capillary break: Use closure strips to prevent water infiltration

Flashing and Trim Installation:

- Eave flashing: Extend 25mm beyond panel edge, seal to prevent uplift

- Ridge flashing: Overlap panels minimum 150mm each side

- Wall intersections: Step flashing or continuous flashing as appropriate

- Penetrations: Flash all roof and wall penetrations with compatible materials

- Expansion joints: Use flexible flashing systems for thermal movement

Thermal Movement Accommodation:

Expansion Calculations:

Thermal Movement = Length × Coefficient × Temperature Change

Steel: 12 × 10⁻⁶ per °C

Aluminum: 23 × 10⁻⁶ per °C

Example: 20m steel panel, 50°C temperature range

Movement = 20,000mm × 12 × 10⁻⁶ × 50°C = 12mm

Movement Accommodation Methods:

- Sliding connections: Allow movement at one end of long panels

- Expansion joints: Provide joints every 30-40m for steel, 20-25m for aluminum

- Flexible sealants: Use movement-capable sealants (±25% minimum)

- Fastener slots: Slotted holes allow panel movement

- Floating attachment: Attach panels to allow thermal movement

Quality Control and Inspection:

Installation Checklist:

- Panel alignment: Verify straight lines and proper overlap

- Fastener inspection: Check proper installation and spacing

- Sealant continuity: Verify continuous sealing at all joints

- Flashing installation: Confirm proper overlap and sealing

- Drainage verification: Test water flow and drainage paths

Common Installation Errors:

- Over-driving fasteners: Damages washers and reduces sealing

- Inadequate overlap: Allows water penetration and reduces wind resistance

- Missing sealants: Creates potential leak paths

- Poor alignment: Creates appearance problems and potential performance issues

- Inadequate thermal provision: Can cause buckling or fastener failure

Safety Considerations:

Fall Protection:

- Safety harnesses: Required for work above 2m height

- Safety lines: Secure attachment points independent of cladding

- Roof brackets: Temporary brackets for steep slope work

- Weather restrictions: Avoid installation in high winds or wet conditions

- Training requirements: Ensure installers trained in safe work practices

Tool Safety:

- Power tools: Use appropriate tools with safety guards

- Cutting equipment: Proper ventilation when cutting coated materials

- Lifting equipment: Rated for panel weight and wind conditions

- Personal protective equipment: Safety glasses, gloves, hard hats required

Maintenance Access:

- Permanent access: Plan for future maintenance and inspection access

- Removable panels: Consider removable panels for equipment access

- Service platforms: Provide safe access for cleaning and maintenance

- Documentation: Provide installation drawings and maintenance instructions

How Do I Calculate Structural Requirements and Span Capabilities?

Structural analysis of corrugated cladding requires understanding profile properties, load combinations, and deflection limits for safe and economical design:

Basic Structural Principles:Section Properties of Corrugated Profiles:

- Moment of inertia: Resistance to bending, increases with profile depth

- Section modulus: Bending strength capacity, critical for stress calculations

- Effective area: Cross-sectional area for axial loads and weight calculations

- Radius of gyration: Important for buckling calculations

- Shear area: Effective area for shear force resistance

Profile Efficiency Comparison:

Structural Efficiency vs. Flat Sheet (same material thickness):

- 7/8" Corrugated: 8-12 times stronger in bending

- 1.5" Corrugated: 15-25 times stronger in bending

- 2.67" Corrugated: 40-60 times stronger in bending

- Weight increase: 0% (same material thickness)

Load Types and Combinations:

Dead Loads:

- Panel weight: 3.5-7.8 kg/m² depending on material and thickness

- Insulation weight: 1-5 kg/m² for typical insulation systems

- Support structure: Distributed load from purlins, girts, and framing

- Equipment loads: HVAC units, signs, maintenance equipment

- Snow loads: Regional snow load requirements per building codes

Live Loads:

- Maintenance loads: 1.0 kPa minimum for accessible areas

- Equipment loads: Actual loads from building equipment

- Construction loads: Temporary loads during installation

- Seismic loads: Earthquake-induced forces per seismic design codes

- Impact loads: Accidental impact from equipment or debris

Wind Loads:

- Basic wind speed: Regional design wind speeds per building codes

- Exposure category: Building surroundings affect wind pressures

- Building height: Wind pressure increases with height above ground

- Roof slope: Affects wind pressure coefficients

- Internal pressure: Building air leakage affects net pressures

Wind Pressure Calculation Example:

Design Wind Pressure = qz × Gh × Cp - qi × (GCpi)

Where:

qz = Velocity pressure at height z

Gh = Gust effect factor

Cp = External pressure coefficient

qi = Internal velocity pressure

GCpi = Internal pressure coefficientTypical Values:

- External pressure: +0.8 to -1.8 kPa depending on location

- Internal pressure: ±0.2 to ±0.4 kPa depending on building tightness

- Net design pressure: -2.2 to +1.2 kPa typical range

Structural Analysis Methods:

Simple Span Analysis:

Maximum Moment: M = wL²/8 (uniform load)

Maximum Deflection: δ = 5wL⁴/(384EI)

Where:

w = Uniform load per unit width

L = Span length

E = Modulus of elasticity

I = Moment of inertia per unit width

Continuous Span Analysis:

- Moment reduction: 20-30% reduction in maximum moments

- Deflection reduction: 40-60% reduction in maximum deflections

- Support reactions: Higher reactions at intermediate supports

- Construction considerations: Requires temporary support during installation

Load Capacity Tables (1.0mm thickness, simply supported):

Deflection Control:

Deflection Limits:

- Serviceability: L/300 for general applications

- Appearance: L/500 for architectural applications where appearance is critical

- Drainage: L/240 minimum to maintain roof slope

- Equipment: L/600 for sensitive equipment platforms

- Ponding: Additional analysis required for flat or low-slope roofs

Deflection Calculation Example:

Given: 1.5" corrugated, 1.0mm thick, 4.0m span, 1.5 kPa uniform load

Section properties: I = 8.9 cm⁴/m, E = 200,000 MPa

Deflection = (5 × 1.5 × 4000⁴) / (384 × 200,000 × 89,000)= 9.4mm

Deflection ratio = 9.4mm / 4000mm = L/426 ✓ (acceptable for L/300 limit)

Special Design Considerations:

Uplift Resistance:

- Fastener capacity: Critical for negative wind pressures

- Edge details: Enhanced fastening required at building edges

- Corner effects: Higher pressures at building corners

- Continuous attachment: Prevents progressive failure

- Safety factors: Minimum 2.5 for ultimate strength design

Concentrated Loads:

- Load distribution: Concentrated loads spread through corrugations

- Local effects: Check for local crippling under point loads

- Support details: May require local reinforcement or load distribution

- Dynamic effects: Impact factors for moving loads

- Equipment attachment: Special consideration for heavy equipment

Thermal Stress Analysis:

- Restrained expansion: Calculate thermal stresses in restrained panels

- Temperature differentials: Consider temperature differences across panel

- Material properties: Thermal expansion coefficients vary by material

- Connection flexibility: Design connections to accommodate movement

- Expansion joints: Required for long continuous runs

Buckling Analysis:

Local Buckling:

- Flange buckling: Compression flanges of corrugations

- Web buckling: Vertical webs under shear or compression

- Interactive buckling: Combined local and global effects

- Post-buckling strength: Some capacity retained after local buckling

- Design provisions: Building codes include buckling provisions

Global Buckling:

- Lateral-torsional buckling: Out-of-plane instability

- Panel buckling: Overall panel stability under compression

- Support conditions: Continuous support prevents most buckling modes

- Bracing requirements: Temporary bracing during construction

- Slenderness limits: Maximum unsupported lengths for stability

Computer Analysis:Software Options:

- Finite element analysis: ANSYS, ABAQUS for complex geometries

- Structural analysis: SAP2000, ETABS for building analysis

- Manufacturer software: Specialized programs for metal building design

- Spreadsheet tools: Excel-based calculators for routine analysis

Modeling Considerations:

- Boundary conditions: Accurate representation of support conditions

- Load application: Proper distribution of loads across panel width

- Material properties: Include non-linear effects if significant

- Connection modeling: Represent actual connection stiffness and strength

- Dynamic analysis: Required for seismic and wind-induced vibrations

Design Verification:

Code Compliance:

- Building codes: IBC, NBC, Eurocode requirements

- Material standards: ASTM, CSA, EN specifications

- Wind standards: ASCE 7, NBCC wind provisions

- Seismic standards: Earthquake design requirements

- Professional review: Licensed engineer review and approval

Testing and Validation:

- Material testing: Verify material properties and section properties

- Load testing: Physical testing for unusual or critical applications

- Performance monitoring: Field measurement of actual deflections

- Quality assurance: Regular inspection during construction

- Long-term monitoring: Periodic assessment of structural performance

What Are the Maintenance Requirements and Expected Service Life for Different Systems?

Maintenance requirements and service life vary significantly based on material selection, coating systems, environmental exposure, and building use, requiring planned maintenance programs for optimal performance:Service Life Expectations by System:

Economy Systems (Galvanized Steel + Polyester Coating):

- Expected service life: 15-25 years depending on environment

- First maintenance: 8-12 years (cleaning and touch-up)

- Major maintenance: 12-18 years (partial recoating)

- Replacement consideration: 20-25 years

- Best applications: Rural, residential, budget-conscious projects

Standard Systems (Galvanized Steel + SMP Coating):

- Expected service life: 20-30 years depending on environment

- First maintenance: 10-15 years (cleaning and inspection)

- Major maintenance: 18-25 years (selective recoating)

- Replacement consideration: 25-35 years

- Best applications: Commercial, suburban, standard industrial

Premium Systems (Stainless Steel or PVDF Coated Steel):

- Expected service life: 35-50+ years depending on material

- First maintenance: 15-20 years (cleaning only)

- Major maintenance: 25-35 years (minor repairs only)

- Replacement consideration: 40-60+ years

- Best applications: Architectural, marine, severe environments

Maintenance Program Development:

Inspection Schedules:

Annual Inspections (All Systems):

- Visual assessment: Overall condition, color retention, chalking

- Fastener inspection: Loose fasteners, washer condition, corrosion

- Sealant evaluation: Joint sealant condition and adhesion

- Drainage check: Gutters, downspouts, and drainage paths

- Documentation: Photo documentation and condition reports

Detailed Inspections (Every 3-5 Years):

- Coating assessment: Gloss retention, color measurement, adhesion testing

- Corrosion evaluation: Red rust, white rust, and coating breakdown

- Structural assessment: Panel attachment, structural integrity

- Thermal movement: Expansion joint condition and function

- Professional evaluation: Qualified inspector assessment

Cleaning Procedures by Environment:

Rural/Suburban Environments:

- Frequency: Annual cleaning or as needed for appearance

- Method: Low-pressure wash with mild detergent

- Equipment: Garden hose, soft brush, mild cleaning solution

- Timing: Spring cleaning after winter weather

- Cost: $0.50-1.50 per m² for professional cleaning

Urban/Industrial Environments:

- Frequency: Semi-annual cleaning, quarterly in heavy pollution areas

- Method: Pressure washing with specialized cleaners

- Equipment: Pressure washer (max 1500 PSI), appropriate detergents

- Timing: Spring and fall cleaning cycles

- Cost: $1.00-2.50 per m² for professional cleaning

Marine/Coastal Environments:

- Frequency: Quarterly cleaning, monthly in direct salt exposure

- Method: Fresh water rinse followed by detergent wash

- Equipment: Desalination cleaners, corrosion inhibitors

- Timing: Regular schedule regardless of appearance

- Cost: $1.50-3.00 per m² for professional cleaning

Cleaning Procedures:

Standard Cleaning Process:

- Pre-rinse: Remove loose dirt and debris with water

- Detergent application: Apply appropriate cleaning solution

- Dwell time: Allow 5-10 minutes for soil dissolution

- Agitation: Soft brush for stubborn soils

- Final rinse: Thorough rinse with clean water

- Inspection: Check for areas requiring additional attention

Specialized Cleaning:

- Grease removal: Alkaline degreasers for kitchen exhaust areas

- Mold/mildew: Biocide treatments for humid environments

- Industrial soils: Specialized cleaners for specific contaminants

- Salt removal: Desalination cleaners for marine environments

- Restoration cleaning: Aggressive cleaning for neglected surfaces

Preventive Maintenance:

Coating Protection:

- Regular cleaning: Prevents accumulation of damaging contaminants

- Touch-up painting: Address minor scratches and chips promptly

- Sealant maintenance: Replace deteriorated sealants before water penetration

- Drainage maintenance: Keep drainage systems clear and functional

- Protective measures: Install guards in high-abuse areas

Fastener Maintenance:

- Torque checking: Re-tighten loose fasteners annually

- Washer replacement: Replace deteriorated washers before leakage

- Corrosion treatment: Clean and treat corroded fasteners

- Upgrade considerations: Replace with stainless steel in corrosive environments

- Sealant renewal: Apply sealant under washers if needed

Repair Procedures:

Minor Repairs:

- Scratch repair: Clean, prime, and touch-up with matching paint

- Fastener replacement: Remove and replace with compatible fasteners

- Sealant renewal: Remove old sealant, clean, and apply new sealant

- Panel adjustment: Realign panels and adjust fastening

- Drainage improvement: Clear blockages and improve drainage paths

Major Repairs:

- Panel replacement: Replace severely damaged or corroded panels

- Structural repairs: Address support structure problems

- Coating restoration: Strip and recoat large areas or entire surfaces

- System upgrades: Upgrade to higher-performance materials

- Waterproofing renewal: Complete sealant and flashing replacement

Maintenance Optimization:

Preventive Strategies:

- Access improvement: Provide safe access for maintenance activities

- Material upgrades: Upgrade to higher-performance materials during repairs

- System improvements: Address design deficiencies during maintenance

- Training programs: Train maintenance staff in proper procedures

- Vendor relationships: Establish relationships with qualified service providers

Technology Integration:

- Condition monitoring: Use drones or sensors for remote monitoring

- Predictive maintenance: Analyze data to predict maintenance needs

- Digital documentation: Use mobile apps for inspection and documentation

- Performance tracking: Monitor energy performance and building envelope integrity

- Automated systems: Consider automated cleaning systems for large buildings

End-of-Life Considerations:

- Replacement planning: Plan replacement before system failure

- Material recycling: Ensure proper recycling of replaced materials

- Upgrade opportunities: Consider system upgrades during replacement

- Sustainability goals: Align replacement with sustainability objectives

- Performance improvements: Incorporate lessons learned into new systems