Aluminum Interior Wall Panels

Premium aluminum interior wall panels engineered for modern commercial and residential applications that combine exceptional durability, aesthetic versatility, and functional performance. These lightweight, high-strength panels feature advanced surface treatments and precision manufacturing to deliver superior interior cladding solutions for demanding environments.

Our premium aluminum interior wall panels are engineered for demanding interior environments where durability, hygiene, and modern aesthetics are paramount.

- Healthcare & Clean Environments: Hospitals, clinics, laboratories, and clean rooms requiring non-porous, easy-to-disinfect surfaces.

- Commercial & Corporate Spaces: Corporate lobbies, conference rooms, office partitions, and high-end retail stores for a sleek, professional finish.

- Public & Transportation Hubs: Airports, transit stations, and schools where superior durability and resistance to high traffic are essential.

- Hospitality & Food Service: Hotel interiors, restaurants, and commercial kitchens demanding a combination of sophisticated aesthetics and robust, easy-to-clean performance.

Unmatched Durability & Safety

Engineered for high-traffic areas, our panels are Class A fire-rated, impact-resistant, and corrosion-proof, ensuring decades of performance in the most demanding environments.

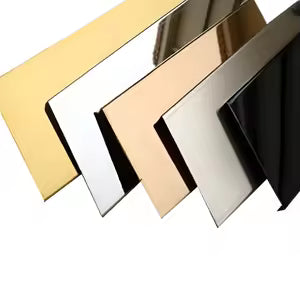

Sleek Aesthetics & Design Freedom

Delivers a sophisticated, contemporary look with an extensive selection of finishes—from anodized and PVD coatings to realistic wood grains—offering limitless creative possibilities.

Hygienic & Easy to Maintain

The non-porous surface is exceptionally easy to clean and disinfect, preventing bacterial growth. It's the ideal, low-maintenance solution for healthcare, food service, and public spaces.

| Alloy Type | Designation | Properties | Best Applications |

|---|---|---|---|

| 3003-H14 | Commercial Grade | Good formability, corrosion resistance, cost-effective | Standard interior applications |

| 3105-H25 | Architectural Grade | Enhanced strength, excellent surface quality | Premium commercial installations |

| 5005-H34 | High Corrosion Resistance | Superior corrosion protection, good formability | Humid environments, coastal areas |

| 5052-H32 | High Strength | Maximum strength, excellent corrosion resistance | High-traffic, impact-prone areas |

| Property | 3003-H14 | 3105-H25 | 5005-H34 | 5052-H32 | Test Standard |

|---|---|---|---|---|---|

| Tensile Strength | 145-185 MPa | 150-195 MPa | 160-200 MPa | 230-280 MPa | ASTM B557 |

| Yield Strength | 125-165 MPa | 130-170 MPa | 140-180 MPa | 195-240 MPa | ASTM B557 |

| Elongation | 8-12% | 6-10% | 6-9% | 6-10% | ASTM B557 |

| Hardness | 40-50 HB | 45-55 HB | 50-60 HB | 60-75 HB | ASTM E10 |

| Property | Value | Units | Test Standard |

|---|---|---|---|

| Density | 2.70 | g/cm3 | ASTM B311 |

| Melting Point | 660 | °C | - |

| Thermal Conductivity | 237 | W/m·K | ASTM E1461 |

| Thermal Expansion | 23.6×10-6 | /°C | ASTM E228 |

| Electrical Conductivity | 37.7 | MS/m | ASTM B193 |

| Modulus of Elasticity | 70 | GPa | ASTM B557 |

| Thickness | Weight | Max Panel Size | Typical Span | Applications |

|---|---|---|---|---|

| 1.5mm | 4.1 kg/m² | 1200×3000mm | 400mm | Light-duty, decorative |

| 2.0mm | 5.4 kg/m² | 1500×3000mm | 600mm | Standard commercial |

| 2.5mm | 6.8 kg/m² | 1500×4000mm | 800mm | High-traffic areas |

| 3.0mm | 8.1 kg/m² | 2000×4000mm | 1000mm | Structural applications |

| 4.0mm | 10.8 kg/m² | 2000×5000mm | 1200mm | Heavy-duty installations |

| 6.0mm | 16.2 kg/m² | 2000×6000mm | 1500mm | Maximum strength required |

| Property | Performance | Test Standard |

|---|---|---|

| Fire Rating | Class A Non-combustible | ASTM E84 |

| Smoke Development | 0-10 (Excellent) | ASTM E84 |

| Flame Spread | 0-5 (Excellent) | ASTM E84 |

| VOC Emissions | <0.25 mg/m2·h | GREENGUARD Gold |

| Humidity Resistance | Excellent | ASTM D2247 |

| Temperature Range | -40°C to +150°C | Interior applications |

| Thermal Shock | Excellent | ASTM C1026 |

| Coating Type | Thickness | Adhesion | Impact Resistance | Warranty | Applications |

|---|---|---|---|---|---|

| Mill Finish | Natural oxide | Excellent | Good | 5-10 years | Utility areas |

| Anodized | 15-25μm | Excellent | Very Good | 20-30 years | Standard commercial |

| Powder Coat | 60-100μm | Excellent | Excellent | 15-25 years | Color applications |

| PVDF | 25-30μm | Excellent | Excellent | 20+ years | Premium installations |

| System Type | Panel Thickness | Max Span | Installation | Accessibility |

|---|---|---|---|---|

| Mechanical Fasteners | 2.0-6.0mm | 1200mm | Simple | Limited |

| Adhesive Mount | 1.5-3.0mm | 800mm | Clean appearance | None |

| Clip Systems | 2.0-4.0mm | 1500mm | Professional | Good |

| Cassette Systems | 1.5-3.0mm | 2000mm | Premium | Excellent |

| Curtain Wall | 3.0-6.0mm | 3000mm | Structural | Moderate |

| Environmental Factor | Performance | Certification |

|---|---|---|

| Recycled Content | 75-95% | ASI Certified |

| Recyclability | 100% | Infinitely recyclable |

| Embodied Energy | Low | LCA verified |

| Carbon Footprint | Reduced | EPD available |

| LEED Credits | Multiple categories | LEED v4 compliant |

| BREEAM Rating | Excellent | A+ rating |

FAQs

How should I clean and maintain Aluminum Wall Panels Interior?

Maintenance for our interior aluminum panels is straightforward, ensuring the finish remains pristine for years. For routine cleaning:

Dust Removal: Use a soft, dry cloth or a duster to remove any loose dust from the surface.

Washing: If needed, wipe the panels with a soft cloth dampened with a mild solution of soap or neutral detergent and warm water.

Rinsing: Immediately rinse the surface with a clean, damp cloth to remove any soap residue.

Precaution: Never use abrasive cleaners, scouring pads, or strong solvents, as these can permanently damage the panel’s surface finish.

Are aluminum panels fire-resistant?

Yes, aluminum panels are designed to be fire-resistant, especially made for commercial or residential projects. Special coatings or treatments can enhance their ability to withstand heat. Making them a safe and reliable option.

What Are the Key Advantages of Aluminum Interior Wall Panels?

Aluminum interior wall panels offer exceptional advantages that make them ideal for modern commercial and institutional applications requiring durability, hygiene, and aesthetic appeal:

Performance Advantages:

Durability and Longevity:

- 25-40 year service life with proper installation and maintenance

- Impact resistance - withstands daily wear and abuse in high-traffic areas

- Dimensional stability - no warping, shrinking, or expanding like organic materials

- Fatigue resistance - handles vibration and thermal cycling without degradation

- Corrosion immunity - unaffected by moisture, chemicals, and environmental factors

Fire Safety and Building Code Compliance:

- Class A non-combustible rating - will not contribute to fire spread

- Zero flame spread and smoke development in standard configurations

- No toxic gas emission during fire exposure

- Meets stringent building codes for hospitals, schools, and public buildings

- Insurance benefits - may reduce premiums due to fire safety properties

Hygiene and Health Benefits:

- Non-porous surface prevents bacterial growth and contamination

- Easy disinfection with standard cleaning agents and procedures

- Antimicrobial coating options for enhanced infection control

- No off-gassing - GREENGUARD Gold certified for indoor air quality

- Allergen-free - no dust mites, mold, or organic allergen accumulation

Maintenance and Lifecycle Advantages:

- Minimal maintenance requirements - periodic cleaning maintains appearance

- Stain and graffiti resistance - most marks easily removed

- No painting or refinishing required during service life

- Individual panel replacement possible without major renovation

- Cost-effective lifecycle - low maintenance and replacement costs

Design and Aesthetic Benefits:

Visual Appeal:

- Modern, professional appearance enhances interior environments

- Extensive color and finish options - unlimited design possibilities

- Consistent appearance - no natural material variation or fading

- Light reflection properties - can brighten interior spaces

- Integration capability - works with various architectural styles

Installation Flexibility:

- Lightweight construction - 60-70% lighter than comparable materials

- Large panel sizes reduce installation time and joint lines

- Multiple mounting systems accommodate various substrate conditions

- Curved surface capability with composite panel construction

- Modular design allows for easy modifications and reconfigurations

Environmental and Sustainability Benefits:

- High recycled content (75-95%) reduces environmental impact

- 100% recyclable at end of service life

- Energy efficient manufacturing compared to alternative materials

- LEED credits contribute to green building certification

- Local availability reduces transportation environmental impact

Economic Advantages:

- Competitive initial cost when considering performance and longevity

- Reduced labor costs due to lightweight and easy installation

- Lower insurance premiums due to fire safety properties

- Energy savings through reflective properties and thermal performance

- Property value enhancement - permanent building improvement

How Do You Select the Right Aluminum Alloy and Thickness for Interior Applications?

Selecting the optimal aluminum alloy and thickness requires careful consideration of application requirements, environmental conditions, and performance expectations:

Alloy Selection Guidelines:

3003-H14 (Standard Commercial Grade):

- Best for: General office environments, retail spaces, standard commercial applications

- Advantages: Cost-effective, good formability, adequate corrosion resistance

- Strength: Moderate (145-185 MPa tensile strength)

- Applications: Conference rooms, lobbies, retail displays, office partitions

- Environment: Normal indoor conditions, low to moderate humidity

3105-H25 (Architectural Grade):

- Best for: Premium commercial installations, architectural feature walls

- Advantages: Enhanced strength, superior surface quality, excellent finish retention

- Strength: Good (150-195 MPa tensile strength)

- Applications: Executive offices, hotel lobbies, high-end retail, corporate headquarters

- Environment: Standard indoor conditions with aesthetic requirements

5005-H34 (High Corrosion Resistance):

- Best for: Humid environments, coastal areas, food service applications

- Advantages: Superior corrosion resistance, good strength, excellent anodizing response

- Strength: Good (160-200 MPa tensile strength)

- Applications: Restaurants, commercial kitchens, pool areas, coastal buildings

- Environment: High humidity, chemical exposure, marine environments

5052-H32 (High Strength):

- Best for: High-traffic areas, impact-prone locations, structural applications

- Advantages: Maximum strength, excellent corrosion resistance, superior durability

- Strength: High (230-280 MPa tensile strength)

- Applications: Schools, hospitals, transportation hubs, sports facilities

- Environment: Heavy use, potential impact, demanding service conditions

Thickness Selection Criteria:

1.5mm Thickness:

- Applications: Decorative panels, low-impact areas, budget applications

- Span capability: 400mm maximum between supports

- Weight: 4.1 kg/m² - minimal structural load

- Best for: Residential applications, private offices, decorative elements

- Limitations: Limited impact resistance, smaller panel sizes

2.0mm Thickness (Most Popular):

- Applications: Standard commercial installations, office environments

- Span capability: 600mm between supports

- Weight: 5.4 kg/m² - good strength-to-weight ratio

- Best for: Conference rooms, retail spaces, general commercial use

- Benefits: Optimal balance of cost, performance, and installation ease

2.5-3.0mm Thickness:

- Applications: High-traffic areas, institutional buildings, premium installations

- Span capability: 800-1000mm between supports

- Weight: 6.8-8.1 kg/m² - substantial feel and performance

- Best for: Schools, hospitals, airports, corporate lobbies

- Benefits: Enhanced impact resistance, larger panel capabilities

4.0-6.0mm Thickness:

- Applications: Heavy-duty installations, structural panels, extreme conditions

- Span capability: 1200-1500mm between supports

- Weight: 10.8-16.2 kg/m² - maximum strength and durability

- Best for: Industrial facilities, high-security areas, architectural features

- Benefits: Maximum impact resistance, structural capability

Application-Specific Recommendations:

Healthcare Facilities:

- Alloy: 5005-H34 or 5052-H32 for corrosion resistance

- Thickness: 2.5-3.0mm for durability and impact resistance

- Finish: Antimicrobial powder coating or anodized

- Considerations: Easy cleaning, infection control, impact resistance

Food Service Environments:

- Alloy: 5005-H34 for moisture and chemical resistance

- Thickness: 2.0-3.0mm depending on application

- Finish: PVDF or hard anodized for chemical resistance

- Considerations: Grease resistance, easy cleaning, food safety compliance

Educational Institutions:

- Alloy: 5052-H32 for maximum impact resistance

- Thickness: 3.0-4.0mm for high-traffic durability

- Finish: Powder coating for color options and durability

- Considerations: Vandal resistance, safety, maintenance ease

Corporate Offices:

- Alloy: 3105-H25 for premium appearance

- Thickness: 2.0-2.5mm for standard applications

- Finish: PVDF or premium powder coating

- Considerations: Aesthetic appeal, professional appearance, design flexibility

Selection Decision Matrix:

- Determine environmental conditions (humidity, chemicals, temperature)

- Assess impact and traffic requirements (foot traffic, potential abuse)

- Consider span requirements (support spacing, panel sizes)

- Evaluate aesthetic goals (finish options, appearance standards)

- Balance cost vs. performance (initial cost, lifecycle value)

What Installation Methods Work Best for Aluminum Interior Wall Panels?

Professional installation of aluminum interior wall panels requires selecting the appropriate mounting system based on panel specifications, substrate conditions, and performance requirements:

Installation System Options:

Mechanical Fastener Systems:

- Best for: Solid substrates, permanent installations, cost-effective solutions

- Panel thickness: 2.0-6.0mm suitable

- Process: Direct attachment through panel face or concealed fastening

- Advantages: Simple installation, maximum holding power, field adjustable

- Disadvantages: Visible fasteners (face-fixed), potential thermal bridging

- Applications: Utility areas, industrial settings, budget installations

Adhesive Mounting Systems:

- Best for: Smooth substrates, clean appearance requirements, lightweight panels

- Panel thickness: 1.5-3.0mm recommended

- Process: Structural adhesive bonding to prepared substrate

- Advantages: No visible fasteners, smooth appearance, quick installation

- Disadvantages: Permanent installation, substrate preparation critical

- Applications: Retail displays, decorative features, smooth wall surfaces

Clip and Rail Systems:

- Best for: Professional installations, panel replacement capability, large areas

- Panel thickness: 2.0-4.0mm optimal

- Process: Panels hang on wall-mounted rail systems via clips

- Advantages: Concealed fastening, easy panel removal, professional appearance

- Disadvantages: Higher material cost, precision installation required

- Applications: Commercial offices, healthcare facilities, institutional buildings

Cassette Systems:

- Best for: Premium installations, maximum accessibility, large format panels

- Panel thickness: 1.5-3.0mm in frame systems

- Process: Panels mounted in frames, frames attached to wall grid

- Advantages: Easy maintenance access, excellent appearance, system integration

- Disadvantages: Highest cost, complex installation, wall thickness required

- Applications: High-end commercial, hospitals, clean rooms, airports

Installation Process Overview:

Pre-Installation Planning:

- Site survey and substrate condition assessment

- Panel layout and cutting plan development

- Utility coordination (electrical, HVAC, plumbing integration)

- Access planning for installation equipment and materials

- Quality control procedures and inspection points

Substrate Preparation:

- Surface cleaning and contamination removal

- Flatness verification (±3mm over 3m typically required)

- Moisture content check and vapor barrier installation if needed

- Primer application for adhesive systems

- Mounting system installation and alignment verification

Panel Installation Sequence:

- Starting point establishment and reference line layout

- First panel installation with careful alignment and leveling

- Progressive installation maintaining consistent gaps and alignment

- Utility integration for electrical outlets, switches, and fixtures

- Trim and edge finishing for professional appearance

- Final inspection and touch-up work

Critical Installation Factors:

Thermal Expansion Management:

- Expansion joints every 12-15 meters for large installations

- Floating attachment allows panel movement

- Sealant selection compatible with thermal cycling

- Panel sizing considers temperature range and expansion coefficients

Substrate Requirements:

- Flatness tolerance: ±3mm over 3m span

- Structural adequacy: Support panel weight plus wind/seismic loads

- Moisture control: Vapor barriers where required

- Compatibility: Chemical compatibility between materials

Quality Control Measures:

- Panel inspection before installation for damage or defects

- Installation verification using laser levels and measuring tools

- Joint consistency maintained throughout installation

- Final cleaning and protection during construction completion

Installation Best Practices:

Panel Handling:

- Protective film maintained until installation completion

- Proper lifting techniques prevent panel damage and worker injury

- Storage requirements keep panels flat and protected

- Transportation in appropriate racks or crates

Tool and Equipment Requirements:

- Precision cutting tools for field modifications

- Lifting equipment for large or heavy panels

- Measuring instruments for accurate layout and alignment

- Safety equipment for working at height and material handling

Common Installation Challenges:

- Out-of-plumb walls require shimming and adjustment

- Utility integration needs careful planning and coordination

- Panel damage during installation requires replacement procedures

- Weather protection during installation in unconditioned spaces

Post-Installation Requirements:

- Protective film removal and surface cleaning

- Joint sealing where required for moisture or air barriers

- System testing for removable panel systems

- Documentation of installation details and warranty information

How Do Aluminum Panels Perform in Different Interior Environments?

Aluminum interior wall panels excel across diverse interior environments due to their inherent material properties and advanced surface treatments:

Healthcare and Medical Facilities:

Performance Advantages:

- Infection control - non-porous surfaces prevent bacterial harboring

- Easy disinfection - compatible with hospital-grade cleaning agents

- Impact resistance - withstands equipment contact and daily abuse

- Chemical resistance - unaffected by medical cleaning chemicals

- Fire safety - Class A non-combustible rating for patient safety

Specific Applications:

- Patient rooms: Easy cleaning, infection control, impact resistance

- Operating theaters: Seamless surfaces, easy sterilization, chemical resistance

- Corridors: High-traffic durability, wheelchair and gurney impact resistance

- Laboratories: Chemical resistance, easy decontamination, static control options

Recommended Specifications:

- Alloy: 5005-H34 or 5052-H32 for corrosion resistance

- Thickness: 2.5-3.0mm for impact resistance

- Finish: Antimicrobial powder coating or hard anodized

- Installation: Clip systems for easy panel replacement and cleaning access

Food Service and Commercial Kitchens:

Performance Requirements:

- Grease and oil resistance - easy cleaning of cooking residues

- Temperature stability - withstands kitchen heat and steam

- Chemical resistance - compatible with commercial cleaning products

- Hygiene compliance - meets health department requirements

- Fire resistance - critical safety requirement in cooking areas

Environmental Challenges:

- High humidity from cooking and dishwashing operations

- Temperature fluctuations from cooking equipment and refrigeration

- Chemical exposure from cleaning agents and food acids

- Physical impact from equipment and utensil contact

Recommended Specifications:

- Alloy: 5005-H34 for superior corrosion resistance

- Thickness: 2.0-3.0mm depending on impact exposure

- Finish: PVDF fluoropolymer or hard anodized for chemical resistance

- Installation: Sealed systems to prevent moisture infiltration

Educational Institutions:

Durability Requirements:

- Vandal resistance - withstands intentional and accidental damage

- Impact resistance - handles student activity and equipment contact

- Easy maintenance - simple cleaning procedures for custodial staff

- Safety compliance - meets educational facility safety standards

- Acoustic properties - can integrate with sound control systems

High-Traffic Challenges:

- Constant use throughout school days and events

- Potential abuse from students and equipment

- Maintenance windows limited to evenings and weekends

- Budget constraints require long-term value and durability

Recommended Specifications:

- Alloy: 5052-H32 for maximum impact resistance

- Thickness: 3.0-4.0mm for heavy-duty applications

- Finish: Powder coating for color options and durability

- Installation: Mechanical fasteners for permanent attachment

Corporate and Office Environments:

Performance Expectations:

- Professional appearance - maintains corporate image standards

- Acoustic integration - compatible with sound control systems

- Design flexibility - supports various architectural styles

- Low maintenance - minimal disruption to business operations

- Indoor air quality - no off-gassing or allergen concerns

Environmental Conditions:

- Climate controlled - stable temperature and humidity

- Moderate traffic - normal office activity levels

- Aesthetic focus - appearance and design critical

- Technology integration - compatibility with AV and IT systems

Recommended Specifications:

- Alloy: 3105-H25 for premium appearance and finish quality

- Thickness: 2.0-2.5mm for standard office applications

- Finish: PVDF or premium powder coating for appearance retention

- Installation: Clip systems for professional appearance and accessibility

Transportation and Public Facilities:

Extreme Conditions:

- High traffic volume - thousands of people daily

- Security concerns - vandal and tamper resistance required

- Weather exposure - potential moisture and temperature extremes

- Maintenance challenges - limited access windows for service

- Code compliance - stringent fire and safety requirements

Performance Requirements:

- Maximum durability - withstand extreme use conditions

- Easy cleaning - efficient maintenance procedures

- Security features - difficult to damage or remove

- Fire safety - critical for public safety and egress

- Accessibility compliance - ADA and universal design requirements

Recommended Specifications:

- Alloy: 5052-H32 for maximum strength and durability

- Thickness: 4.0-6.0mm for heavy-duty applications

- Finish: PVDF or hard anodized for maximum durability

- Installation: Mechanical fasteners with security hardware

Clean Room and Laboratory Environments:

Special Requirements:

- Particle control - surfaces must not shed or accumulate particles

- Chemical compatibility - resistance to laboratory chemicals and solvents

- Static control - conductive options for sensitive applications

- Easy decontamination - compatible with sterilization procedures

- Seamless installation - minimal joints and crevices

Critical Performance Factors:

- Surface smoothness - no texture to trap contaminants

- Chemical inertness - no reaction with process chemicals

- Outgassing control - minimal volatile emissions

- Electrostatic properties - controlled for sensitive processes

Recommended Specifications:

- Alloy: 5005-H34 or 3105-H25 for surface quality

- Thickness: 2.0-3.0mm for adequate strength with smooth surfaces

- Finish: Hard anodized or specialized clean room coatings

- Installation: Sealed cassette systems with accessible backing

What Are the Cost Factors and Lifecycle Economics of Aluminum Interior Panels?

Understanding the complete cost structure and lifecycle economics of aluminum interior panels is essential for making informed decisions about interior wall systems:

Initial Cost Components:

Material Costs:

- Base aluminum pricing varies with alloy type and market conditions

- Thickness impact - heavier gauges cost more per square meter

- Finish selection significantly affects material cost

- Panel size - larger panels may have premium pricing

- Quantity discounts available for large projects

Cost Hierarchy by Finish Type:

- Mill finish - Lowest cost, basic protection

- Anodized - Moderate cost, excellent durability

- Powder coating - Moderate to high cost, color flexibility

- PVDF coating - Highest cost, premium performance

Manufacturing and Fabrication:

- Standard sizes most economical

- Custom cutting adds 10-20% to material cost

- Special edge treatments increase fabrication costs

- Complex shapes require specialized tooling and setup

- Quality control and testing add to manufacturing cost

Installation Cost Factors:

Labor Requirements:

- Installation complexity varies by mounting system

- Panel size and weight affect handling requirements

- Site conditions impact installation efficiency

- Substrate preparation may require additional work

- Coordination with other trades affects scheduling

Installation Cost by System Type:

- Adhesive mounting: Lowest labor cost, fastest installation

- Mechanical fasteners: Moderate cost, straightforward installation

- Clip systems: Higher cost, requires precision and skill

- Cassette systems: Highest cost, specialized installation required

Supporting Infrastructure:

- Substrate preparation and repair work

- Mounting system materials and hardware

- Electrical integration for lighting and outlets

- HVAC coordination for air circulation requirements

- Safety equipment and access requirements

Lifecycle Cost Analysis:

Maintenance and Operating Costs:

- Cleaning requirements - minimal for aluminum panels

- Repair costs - individual panel replacement possible

- Refinishing - not required during typical service life

- Energy impact - reflective surfaces can reduce lighting costs

- Insurance benefits - fire-resistant properties may reduce premiums

Durability and Replacement:

- Service life - 25-40 years typical for interior applications

- Wear resistance - maintains appearance throughout service life

- Damage resistance - withstands impact and abuse better than alternatives

- Obsolescence risk - timeless appearance reduces replacement pressure

- Salvage value - aluminum retains significant scrap value