Decorative Metal Mesh Screen

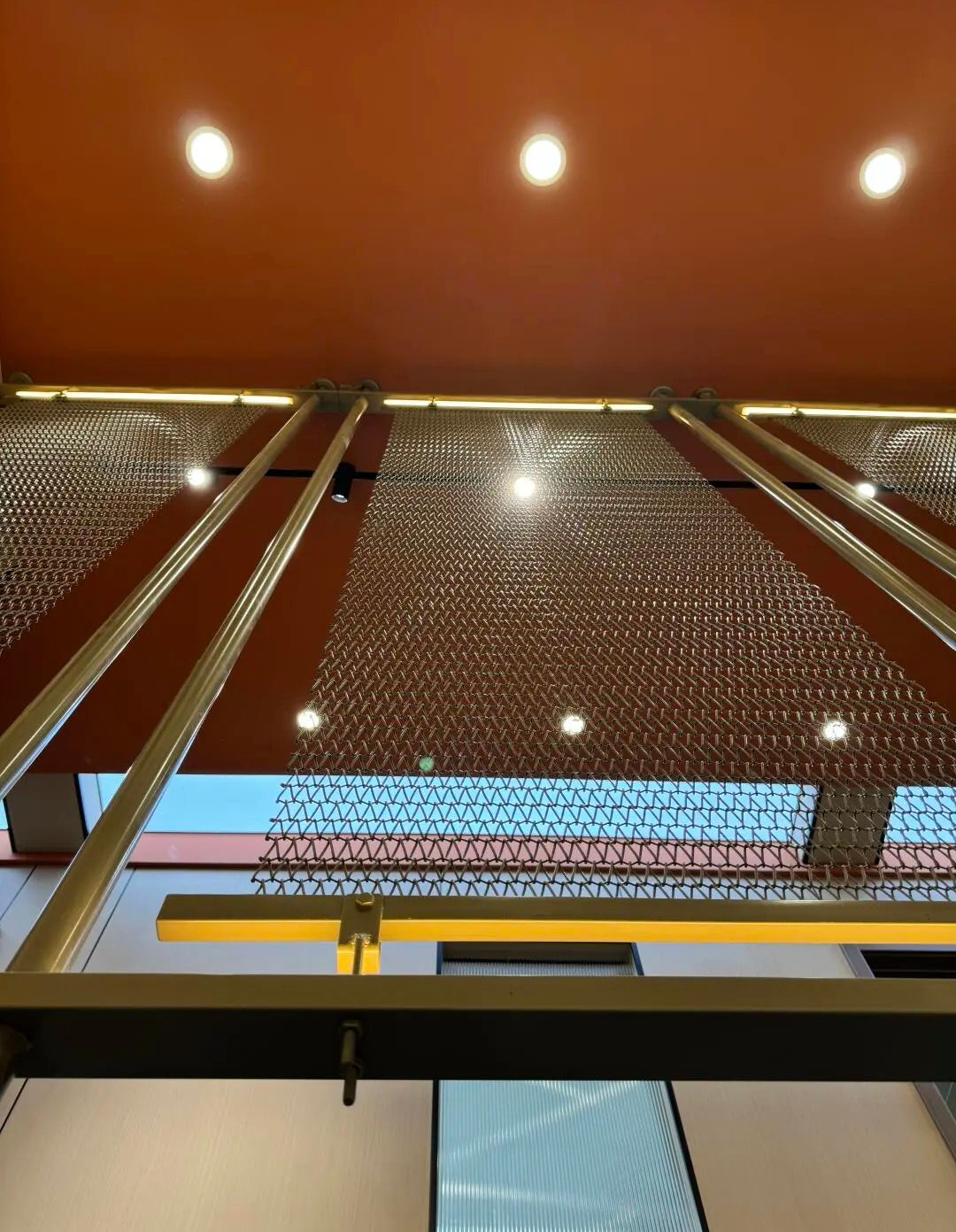

Architectural metal mesh screens that seamlessly integrate precision-woven stainless steel mesh with structural frames to create sophisticated space division solutions. Our metal mesh screens combine the transparency and airflow benefits of woven mesh with the structural integrity of welded tube frames, finished with advanced PVD titanium coatings for exceptional durability and contemporary aesthetics. These screens offer the perfect balance of visual separation and environmental connectivity, making them ideal for modern architectural applications where light transmission, air circulation, and design elegance are equally important.

Our metal mesh screens offer a sophisticated way to divide space, blending structural elegance with functional transparency for modern architecture.

- Corporate & Commercial Partitions: As elegant partitions in open-plan offices, lobbies, and commercial spaces to define functional zones while preserving light and an open-concept feel.

- Hospitality & Retail Space Division: For space division in restaurants, bars, and hotels, creating intimate areas without complete visual or acoustic isolation.

- Architectural & Exterior Elements: As functional architectural elements for facades, parking structures, and railings, providing safety and screening while allowing for essential airflow.

- Residential & Interior Features: In contemporary residences as stylish room dividers, staircase guards, or privacy screens that offer separation with a modern, airy aesthetic.

Elegant Transparency & Airflow

The precision-woven mesh provides visual separation while allowing light and air to pass through freely, maintaining a bright, open, and connected environment.

Refined Structural Design

Combines the delicate texture of woven mesh with the clean lines of a robust structural frame, creating a sophisticated architectural element that is both lightweight and strong.

Durable & Premium Finish

Constructed from high-grade stainless steel with an advanced PVD titanium coating, ensuring exceptional durability, corrosion resistance, and a lasting contemporary aesthetic.

| Grade | Composition | Properties | Corrosion Resistance | Applications |

|---|---|---|---|---|

| 304 | 18Cr-8Ni | General purpose, non-magnetic | Good | Interior, standard environments |

| 316 | 18Cr-10Ni-2Mo | Marine grade, superior corrosion resistance | Excellent | Exterior, coastal, high-humidity |

| 316L | Low carbon 316 | Enhanced weldability, reduced sensitization | Excellent | Critical applications, food service |

| 321 | 18Cr-9Ni-Ti | High temperature stability | Good | High-temperature applications |

| 430 | 17Cr (Ferritic) | Magnetic, economical | Fair | Budget applications, interior only |

| Frame Profile | Dimensions (mm) | Wall Thickness | Weight (kg/m) | Applications |

|---|---|---|---|---|

| Rectangular Tube | 20x40 to 50x100 | 1.5-3.0mm | 1.2-8.5 | Standard commercial, residential |

| Square Tube | 25x25 to 80x80 | 1.5-4.0mm | 1.4-9.2 | Architectural, symmetrical designs |

| Round Tube | Ø20 to Ø76 | 1.5-3.0mm | 1.1-6.8 | Contemporary, curved applications |

| Flat Bar | 20x3 to 100x10 | Solid profile | 0.5-7.8 | Minimalist, thin profile designs |

| Angle Frame | 25x25 to 75x75 | 2.0-6.0mm | 1.0-8.9 | Structural, mounting applications |

| Attachment Method | Description | Advantages | Applications |

|---|---|---|---|

| Welded Integration | Mesh welded directly to frame | Maximum security, permanent attachment | Security, high-stress applications |

| Clamped System | Mesh clamped between frame sections | Replaceable mesh, clean appearance | Commercial, maintenance access needed |

| Tensioned System | Mesh stretched and secured with tension | Optimal mesh flatness, professional appearance | Architectural, high-end applications |

| Mechanical Fastening | Screws or clips secure mesh to frame | Field replaceable, cost-effective | Industrial, utility applications |

| Adhesive Bonding | Structural adhesive bonds mesh to frame | Smooth appearance, vibration dampening | Specialty applications, clean rooms |

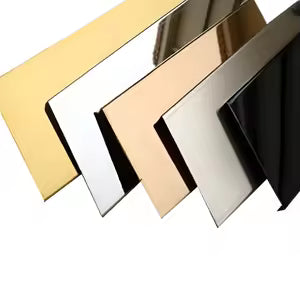

| Coating Type | Composition | Thickness (μm) | Color | Hardness (HV) | Applications |

|---|---|---|---|---|---|

| TiN | Titanium Nitride | 1.0-3.0 | Gold | 2000-2400 | Decorative, wear resistance |

| TiC | Titanium Carbide | 1.5-4.0 | Gray-black | 2800-3200 | High wear, industrial |

| TiCN | Titanium Carbonitride | 1.0-3.0 | Blue-gray | 2500-3000 | Balanced performance |

| TiAlN | Titanium Aluminum Nitride | 1.5-4.0 | Purple-bronze | 2800-3500 | High temperature, oxidation resistant |

| CrN | Chromium Nitride | 1.0-2.5 | Silver-gray | 1800-2200 | Corrosion resistance, decorative |

| Property | Test Method | Specification | Performance Level |

|---|---|---|---|

| Adhesion | ASTM D4541 | >50 N/mm2 | Excellent |

| Hardness | ASTM E384 | 1800-3500 HV | Superior |

| Corrosion Resistance | ASTM B117 | >1000 hours | Excellent |

| Wear Resistance | ASTM G99 | <0.1 mm3/Nm | Superior |

| Temperature Stability | Thermal cycling | -40°C to +400°C | Excellent |

| Panel Designation | Width (mm) | Height (mm) | Frame Depth (mm) | Total Weight (kg) | Applications |

|---|---|---|---|---|---|

| Compact | 600-900 | 1200-1800 | 25-40 | 8-18 | Residential, small commercial |

| Standard | 900-1200 | 1800-2400 | 30-50 | 15-32 | Commercial offices, retail |

| Large | 1200-1800 | 2400-3000 | 40-60 | 28-55 | Hotels, large commercial |

| Architectural | 1800-2400 | 3000-4000 | 50-80 | 45-85 | Lobbies, atriums, facades |

| Custom | Up to 3000 | Up to 6000 | 25-100 | Varies | Unique architectural applications |

| Parameter | Specification | Test Method | Performance Rating |

|---|---|---|---|

| Fire Rating | Non-combustible | ASTM E84 | Class A |

| Corrosion Resistance | 2000+ hours no degradation | ASTM B117 | Excellent |

| UV Stability | No color change | ASTM G154 | Excellent |

| Temperature Range | -40°C to +200°C continuous | Thermal cycling | Superior |

| Humidity Resistance | 100% RH no degradation | ASTM D2247 | Excellent |

| Mounting Type | Load Capacity | Adjustment | Installation Time | Applications |

|---|---|---|---|---|

| Floor-to-Ceiling | 400 kg/panel | ±20mm vertical | 2-4 hours/panel | Permanent partitions |

| Wall-Mounted | 250 kg/panel | ±10mm horizontal | 1-2 hours/panel | Semi-permanent screens |

| Suspended | 150 kg/panel | ±30mm all directions | 1-3 hours/panel | Flexible positioning |

| Track System | 200 kg/panel | Sliding capability | 3-5 hours/panel | Moveable partitions |

| Free-Standing | 300 kg/panel | Fixed position | 1-2 hours/panel | Portable applications |

FAQs

What's the difference between decorative metal screens and metal mesh screens?

Understanding the key differences between these two architectural screening solutions is crucial for selecting the right product for your project:

Decorative Metal Screens feature solid stainless steel or aluminum plates with precision laser-cut patterns, offering:

- Complete privacy with selective light transmission through cut-out designs

- Dramatic visual impact with bold geometric or artistic patterns

- 25-75% open area depending on pattern complexity

- PVD coatings in gold, rose gold, bronze, and custom colors

- Ideal applications: Hotel lobbies, corporate offices, luxury retail, residential room dividers.

Metal Mesh Screens utilize precision-woven stainless steel wire mesh integrated into structural frames, providing:

- High transparency (60-85% open area) with excellent visual connectivity

- Superior airflow for natural ventilation and air circulation

- Lightweight construction while maintaining structural integrity

- PVD titanium coatings for enhanced durability and contemporary aesthetics

- Ideal applications: Commercial partitions, restaurant dining areas, industrial facilities, exterior building facades

Key Selection Criteria:

- Choose decorative screens when you need privacy, dramatic visual impact, and controlled light transmission

- Choose mesh screens when you require airflow, transparency, and environmental connectivity

- Both options offer custom sizing up to 3000×6000mm, 15-25 year coating lifespan, and Class A fire ratings

How long do PVD coatings last and what affects their durability?

PVD (Physical Vapor Deposition) coatings typically last 15-25 years in interior applications and 10-20 years in exterior applications, making them an excellent long-term investment for architectural screening projects.

Coating Longevity by Environment:

- Interior commercial spaces: 20-25 years with proper maintenance

- High-traffic interior areas: 15-20 years (hotels, retail, offices)

- Exterior protected locations: 15-20 years (covered walkways, atriums)

- Full exterior exposure: 10-15 years (building facades, balcony screens)

- Coastal/marine environments: 10-12 years (with 316 stainless steel substrate)

Factors Affecting PVD Coating Durability:

Environmental Factors:

- UV exposure intensity - Direct sunlight accelerates color fading

- Chemical exposure - Harsh cleaning agents or atmospheric pollutants

- Humidity levels - High humidity can affect coating adhesion over time

- Temperature cycling - Extreme temperature changes cause expansion/contraction stress

Maintenance Factors:

- Cleaning frequency - Regular gentle cleaning extends coating life significantly

- Cleaning methods - Proper pH-neutral cleaners vs. abrasive or acidic products

- Physical contact - High-touch areas experience more wear

Coating Specifications for Maximum Durability:

- Coating thickness: 1.0-3.0 μm for optimal balance of appearance and durability

- Substrate preparation: Precision cleaning and surface activation before coating

- Multi-layer systems: Base layers improve adhesion and top layers provide color/protection

- Quality control: X-ray fluorescence measurement ensures uniform coating thickness

Extending Coating Life:

- Use pH-neutral cleaners (pH 6-8) and avoid abrasive materials

- Implement regular cleaning schedules based on environmental exposure

- Apply protective treatments in high-wear areas

- Schedule professional inspections every 5 years for early issue detection

Can these screens be customized for specific architectural designs and branding?

Yes, both decorative metal screens and metal mesh screens offer extensive customization capabilities to match your unique architectural vision and branding requirements.

Custom Pattern Development for Decorative Screens:

Design Process:

- Consultation phase - Our design team works with architects to understand project vision

- CAD development - Advanced parametric design software creates precise patterns

- 3D visualization - Virtual reality preview shows finished installation appearance

- Prototype creation - Physical samples (150×150mm to full-size panels) for approval

- Engineering optimization - Patterns refined for manufacturing efficiency and structural performance

Pattern Customization Options:

- Corporate logos and branding - Integrate company logos seamlessly into patterns

- Architectural coordination - Match existing building elements, window patterns, or facade details

- Cultural motifs - Traditional patterns for cultural centers, hotels, or themed environments

- Artistic collaboration - Work with artists to create unique sculptural installations

- Parametric designs - Computer-generated patterns with mathematical precision and scalability

Custom Sizing and Configuration:

- Panel dimensions: Custom sizes up to 3000×6000mm for unique architectural requirements

- Modular systems: Coordinated panels that work together for large installations

- Curved configurations: Bent or segmented panels for curved walls and unique geometries

- Multi-panel assemblies: Complex installations spanning multiple floors or large spaces

PVD Coating Customization:

Color Matching Services:

- RAL and Pantone matching - Precise color reproduction using advanced PVD techniques

- Sample matching - Match existing architectural finishes or material samples

- Custom color development - Create unique brand colors for signature installations

- Multi-tone effects - Gradient or transition effects within single panels

- Texture coordination - Brushed, hammered, or embossed surface treatments

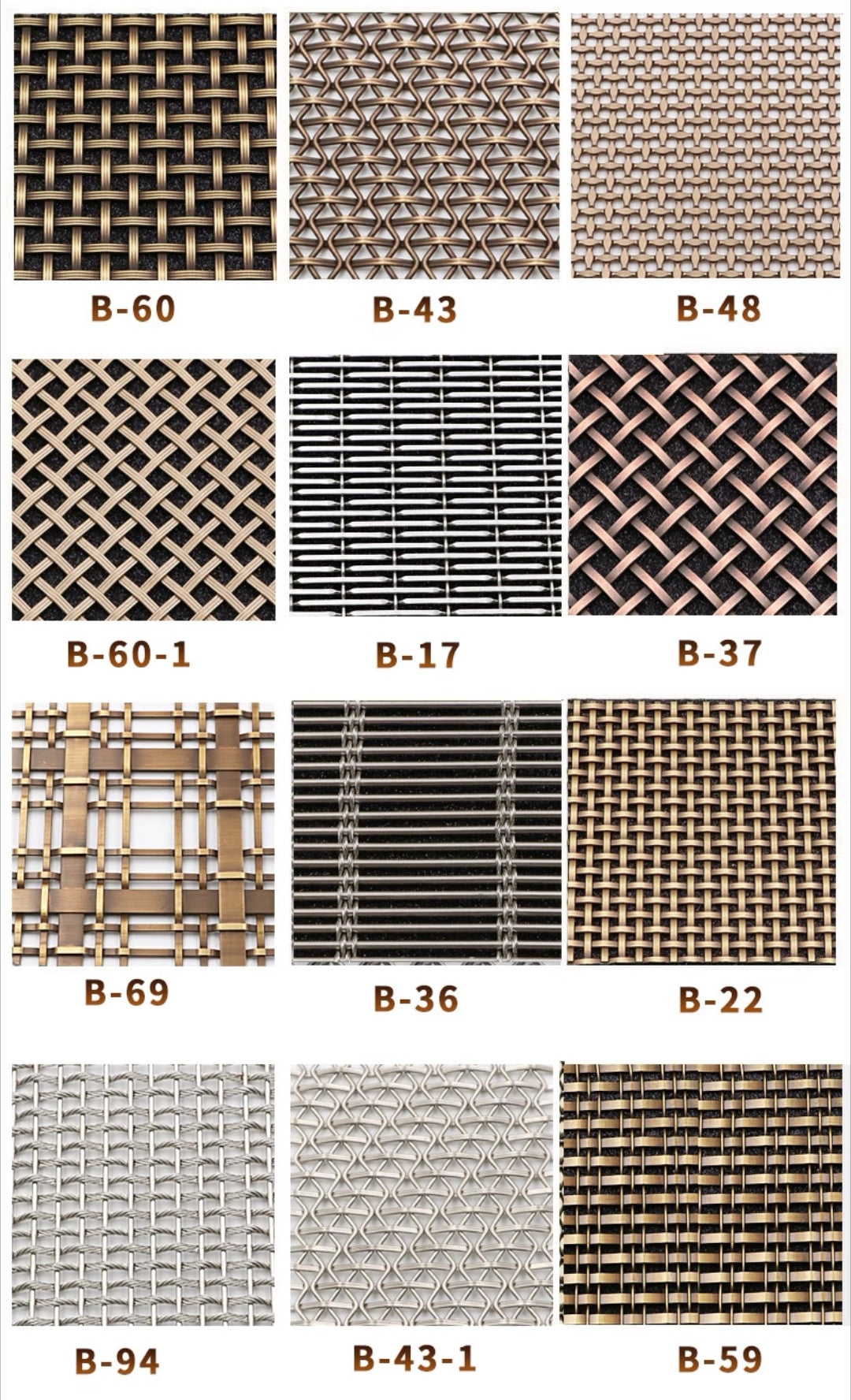

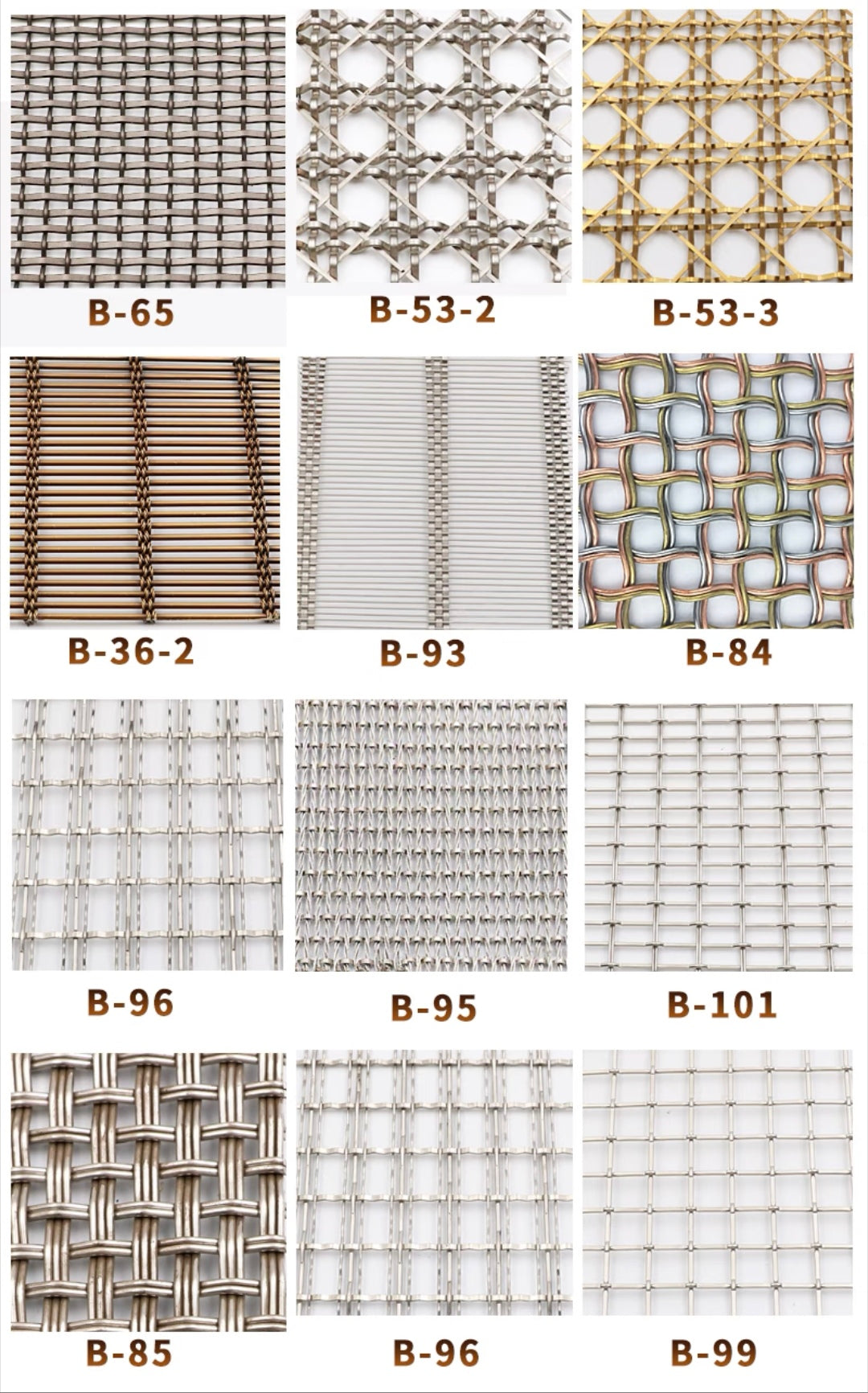

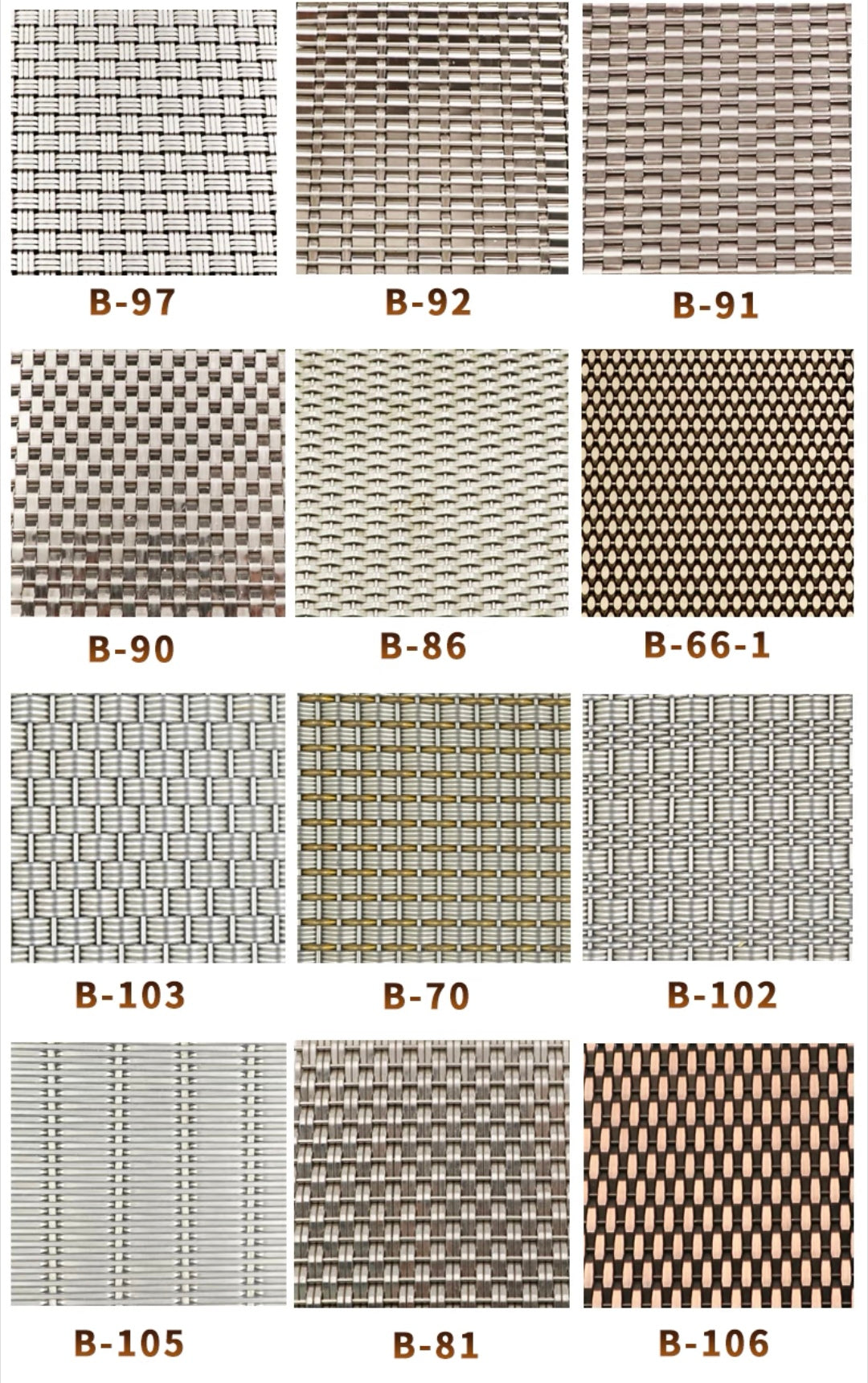

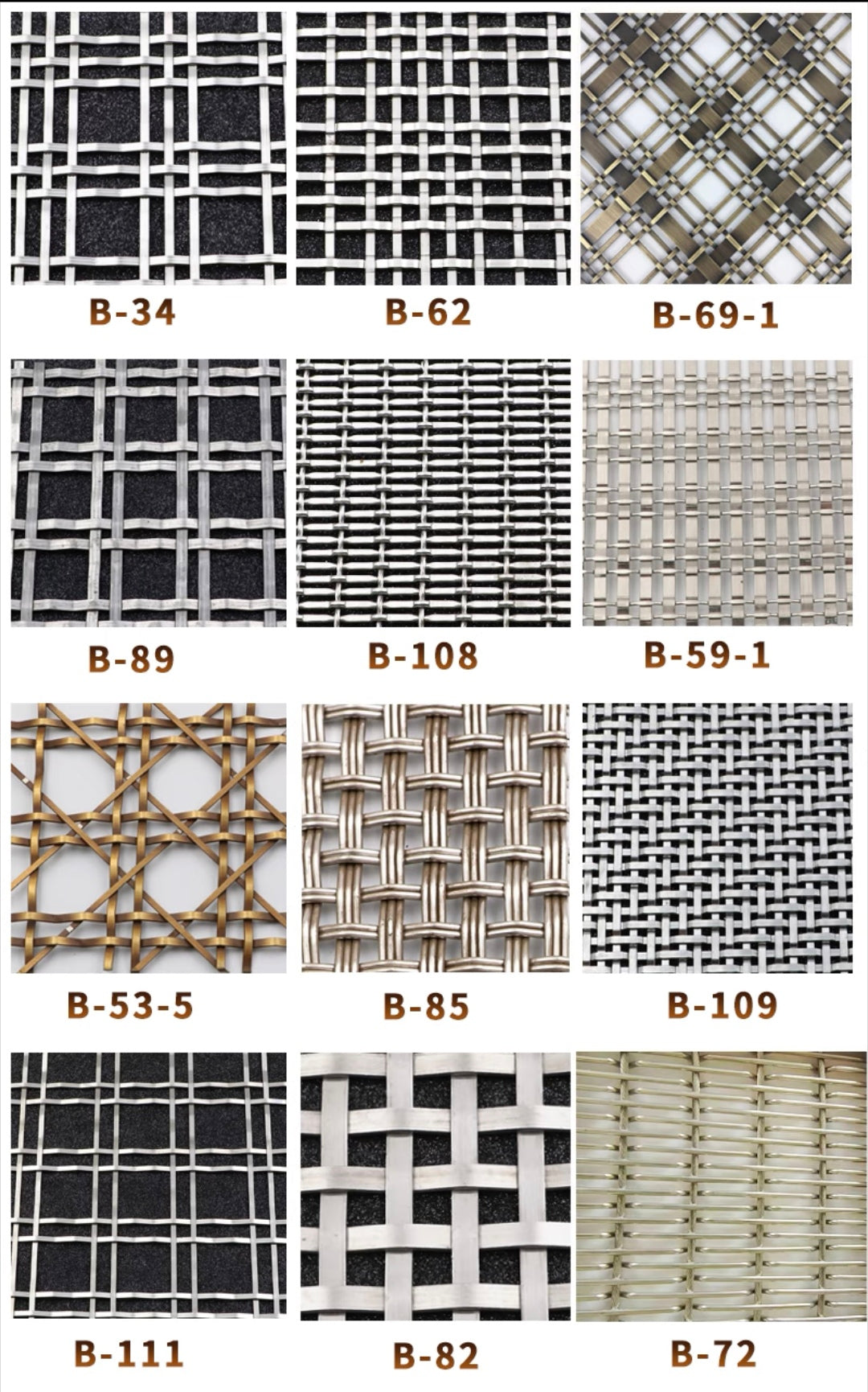

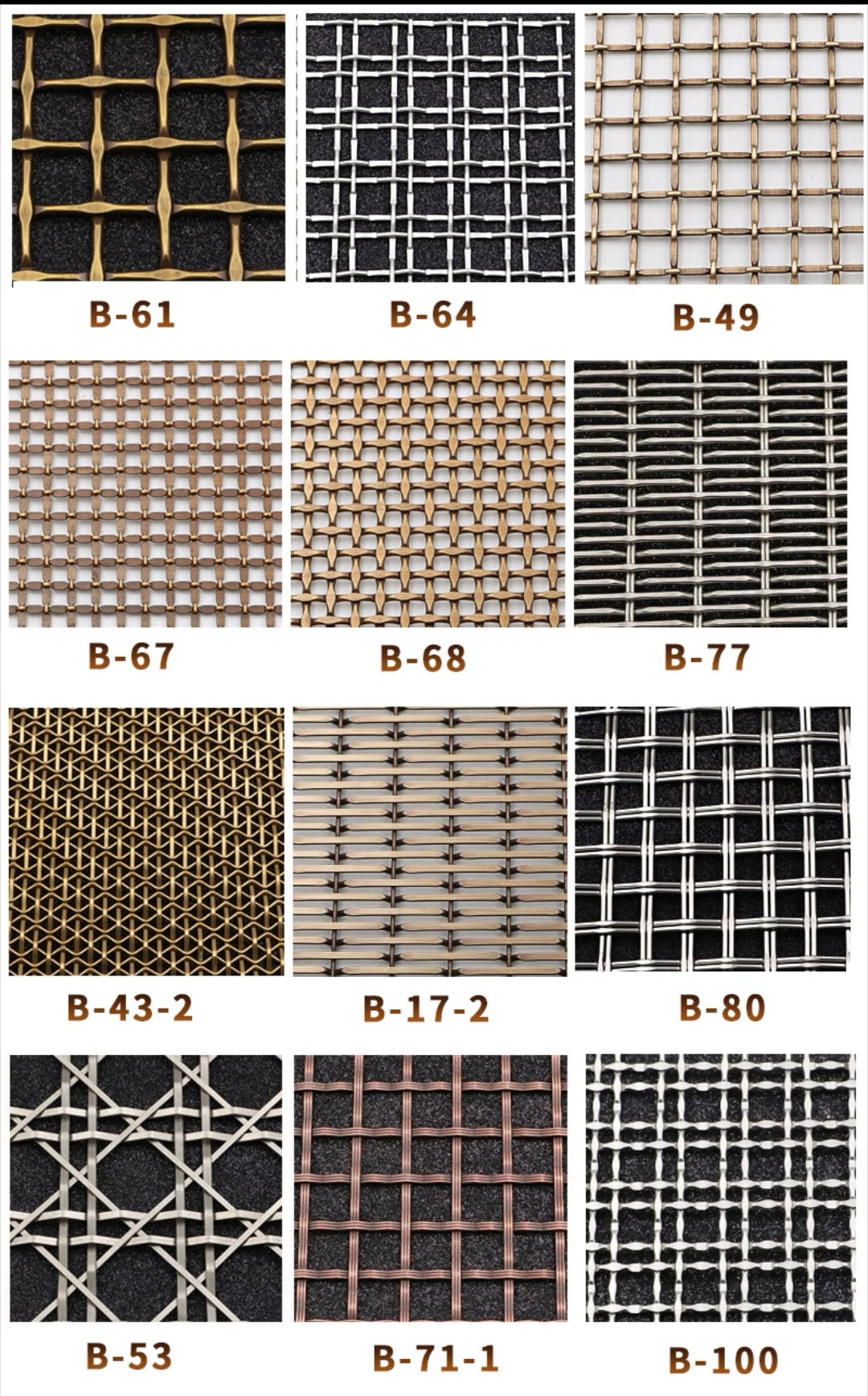

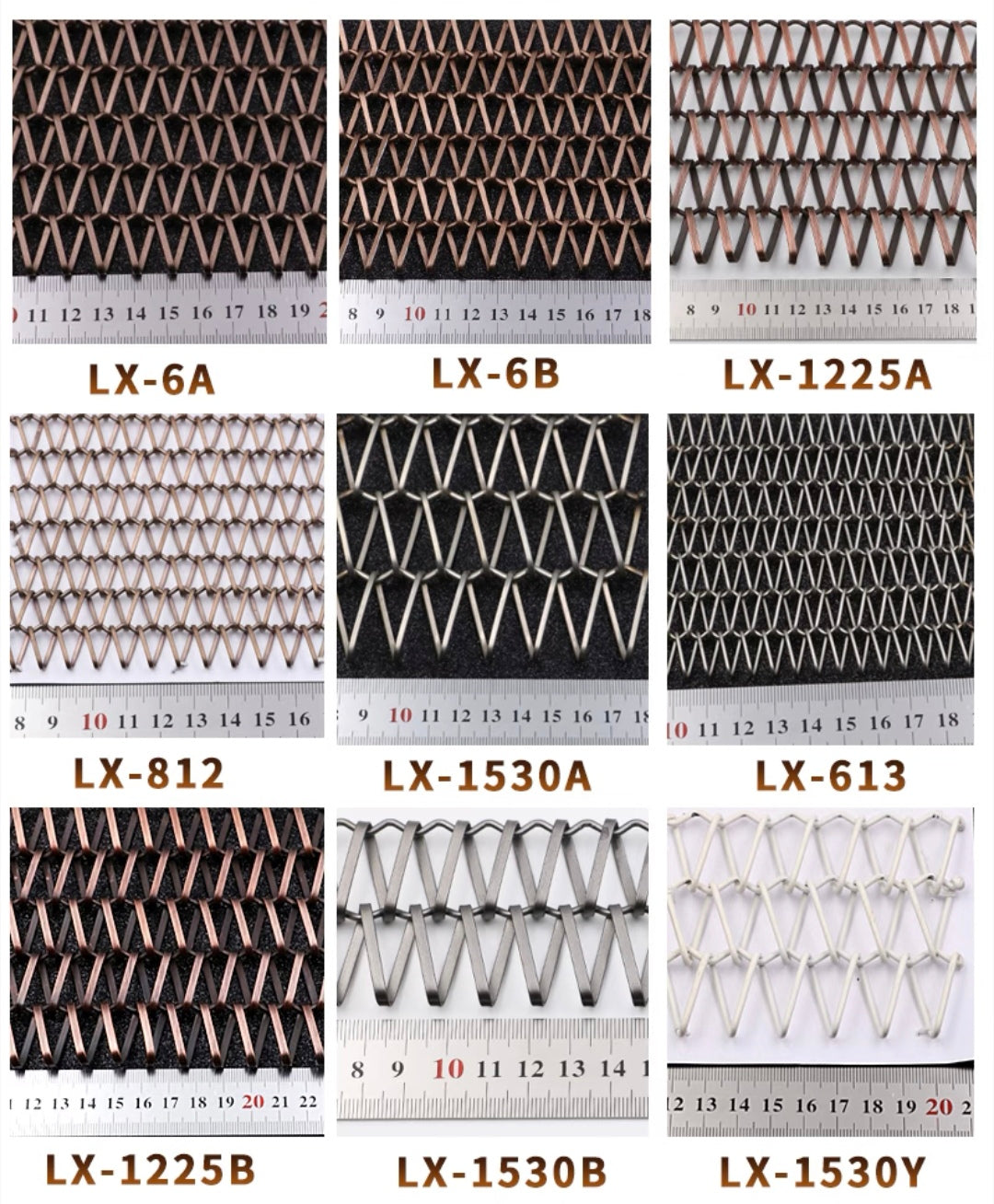

Metal Mesh Screen Customization:

- Mesh pattern variations - Square, rectangular, diamond, hexagonal, or custom geometric patterns

- Wire gauge selection - 0.5mm to 3.0mm wire diameter for different visual and performance characteristics

- Aperture sizing - 2mm to 20mm openings optimized for specific transparency and airflow requirements

- Frame integration - Custom frame profiles and finishes coordinated with mesh specifications

Minimum Order Quantities:

- Standard modifications: 10 panels minimum

- Custom patterns: 25-50 panels minimum depending on complexity

- New PVD colors: 100 panels minimum for color development

- Prototypes available: 1-5 sample panels for design verification

Timeline for Custom Projects:

- Simple modifications: 6-8 weeks

- Complex custom patterns: 10-16 weeks including design development

- New color development: 12-14 weeks including testing and approval

What are the structural requirements and load capacities for installation?

Understanding structural requirements is essential for safe and successful installation of architectural metal screens. Load capacities vary by material, panel size, and mounting method, with all specifications including appropriate safety factors for building code compliance.

Structural Load Capacities:

Decorative Metal Screens:

- Stainless steel panels: Wind loads up to 2.5 kPa, seismic loads up to 1.5 kPa

- Aluminum panels: Wind loads up to 2.0 kPa, seismic loads up to 1.2 kPa

- Impact resistance: 150J for stainless steel, 120J for aluminum per ASTM D3763

- Deflection limits: L/300 under design loads to prevent visible deformation

- Safety factors: 2.5 for wind loads, 2.0 for seismic loads per building codes

Metal Mesh Screens:

- Wind load capacity: 2.0 kPa typical for standard frame construction

- Seismic load capacity: 1.2 kPa with appropriate mounting systems

- Mesh tension: 500-1500 N/m depending on wire gauge and panel size

- Frame rigidity: L/400 deflection limit for optimal mesh performance

Mounting System Capacities:

Floor-to-Ceiling Systems:

- Load capacity: 400-500 kg per panel depending on panel size

- Adjustment range: ±25mm vertical for installation tolerances

- Substrate requirements: 20 MPa concrete or 16-gauge steel framing minimum

- Installation time: 2-4 hours per panel with experienced crews

Wall-Mounted Systems:

- Load capacity: 250-300 kg per panel with proper substrate attachment

- Adjustment range: ±15mm horizontal for alignment corrections

- Fastener requirements: 316 stainless steel anchors rated for substrate type

- Installation time: 1-2 hours per panel for standard configurations

Suspended Systems:

- Load capacity: 150-200 kg per panel depending on suspension method

- Adjustment range: ±50mm all directions for precise positioning

- Cable/rod systems: 7×19 stainless steel cable or solid stainless steel rods

- Safety factors: 8:1 for suspension cables, 4:1 for support structures

Substrate Requirements by Type:

Concrete Substrates:

- Minimum strength: 20 MPa compressive strength

- Minimum thickness: 150mm for heavy panel applications

- Anchor specifications: Wedge or epoxy anchors rated for seismic loads

- Edge distances: Minimum 100mm from concrete edges

Steel Frame Substrates:

- Minimum gauge: 16-gauge (1.5mm) for standard applications

- Connection methods: Through-bolts preferred, structural screws acceptable

- Backing requirements: Solid backing plates for distributed loading

- Thermal considerations: Expansion joints for large installations

Masonry Substrates:

- Unit requirements: Solid masonry units, avoid hollow block without grouting

- Anchor types: Expansion anchors or epoxy-set threaded rods

- Mortar joints: Avoid anchoring in mortar joints when possible

- Load distribution: Backing plates required for point loads

Engineering Services:

- Structural calculations provided for complex applications

- Seismic analysis for high seismic zones (Seismic Design Categories D, E, F)

- Wind load analysis for high-rise or exposed installations

- Connection design for unusual substrate conditions

- Thermal movement analysis for large installations or extreme temperature ranges

Code Compliance:

- Building codes: IBC, ASCE 7, local amendments

- Seismic standards: ASCE 7 seismic design provisions

- Fire codes: NFPA 101, local fire marshal requirements

- Accessibility: ADA compliance for accessible routes

- Safety standards: OSHA requirements for installation procedures

How do I maintain these screens and what cleaning products are safe to use?

Proper maintenance is crucial for maximizing the 15-25 year lifespan of PVD coatings and ensuring optimal performance of your architectural metal screens. Regular cleaning with appropriate products prevents damage and maintains appearance.

Maintenance Schedule by Environment:

Interior Commercial Spaces:

- High-traffic areas (lobbies, retail): Weekly cleaning recommended

- Office environments: Bi-weekly to monthly cleaning adequate

- Residential applications: Monthly cleaning typically sufficient

- Food service areas: Daily cleaning and sanitization required for health codes

Exterior Applications:

- Urban environments: Monthly cleaning due to pollution and dust accumulation

- Coastal locations: Bi-weekly cleaning essential due to salt air exposure

- Industrial areas: Weekly cleaning may be required depending on airborne contaminants

- Protected exterior (covered walkways): Monthly to quarterly cleaning adequate

Safe Cleaning Products and Methods:

Recommended Cleaning Agents:

- Mild dish soap solution (1-2% concentration) - Safe for all PVD coatings

- pH-neutral cleaners (pH 6-8) - Prevent coating damage from acidic or alkaline products

- Isopropyl alcohol (70% solution) - Excellent for removing fingerprints and oils

- Specialized stainless steel cleaners - Follow manufacturer's compatibility guidelines

- Microfiber cloths - Prevent scratching during cleaning process

Cleaning Process Steps:

- Dust removal - Use soft brushes or compressed air to remove loose debris

- Pre-rinse - Light water rinse to remove surface contamination

- Cleaning solution application - Apply appropriate cleaner with soft cloth or sponge

- Gentle agitation - Use soft brushes for stubborn soils, avoid abrasive scrubbing

- Thorough rinse - Remove all cleaning residue with clean water

- Drying - Air dry or use clean, lint-free cloths to prevent water spots

Products to Avoid:

- Abrasive cleaners or steel wool - Can scratch PVD coatings permanently

- Chlorine bleach - Causes pitting and corrosion of stainless steel

- Strong acids (pH <4) - Muriatic acid, phosphoric acid can damage coatings

- Strong alkalis (pH >10) - Caustic cleaners can cause coating delamination

- Ammonia-based products - Can react with certain PVD coating chemistries

Specialized Cleaning by Application:

Healthcare Environments:

- Hospital-grade disinfectants - Verify compatibility with PVD coatings

- Contact time requirements - Follow EPA label instructions for efficacy

- Frequency: Multiple daily cleaning cycles per infection control protocols

- Documentation - Maintain cleaning logs for regulatory compliance

Food Service Areas:

- Food-safe cleaners - NSF-approved products for food contact surfaces

- Sanitizer compatibility - Ensure cleaning agents don't interfere with sanitizers

- Temperature considerations - Hot water cleaning (up to 60°C) acceptable

- Grease removal - Alkaline degreasers safe at proper dilution ratios

Troubleshooting Common Issues:

Water Spots and Mineral Deposits:

- Cause: Hard water or inadequate drying after cleaning

- Solution: Use distilled water for final rinse, dry immediately with soft cloths

- Prevention: Install water softening systems in hard water areas

Fingerprints and Smudges:

- Cause: Natural oils from skin contact

- Solution: Isopropyl alcohol (70%) on microfiber cloth

- Prevention: Apply anti-fingerprint coatings in high-touch areas

Coating Wear or Discoloration:

- Cause: Improper cleaning agents or excessive abrasion

- Solution: Professional assessment and potential recoating

- Prevention: Use only approved cleaning products and gentle techniques

Professional Maintenance Services:

- Annual inspections - Professional assessment of coating condition and structural integrity

- Deep cleaning services - Specialized equipment for large installations

- Coating restoration - Touch-up or complete recoating when needed

- Preventive treatments - Anti-fingerprint or protective coatings for high-wear areas

Maintenance Cost Considerations:

- Routine cleaning: $2-5 per square meter annually for professional service

- Deep cleaning: $5-10 per square meter for annual professional deep cleaning

- Coating touch-up: $15-25 per square meter for localized repairs

- Complete recoating: $30-50 per square meter after 15-20 years service life

Documentation and Warranty:

- Maintenance logs - Keep records for warranty compliance

- Product compatibility - Verify cleaning products don't void warranty

- Professional services - Use certified maintenance providers when possible

- Warranty coverage - 10-year limited warranty on PVD coating performance with proper maintenance