Expanded sheet

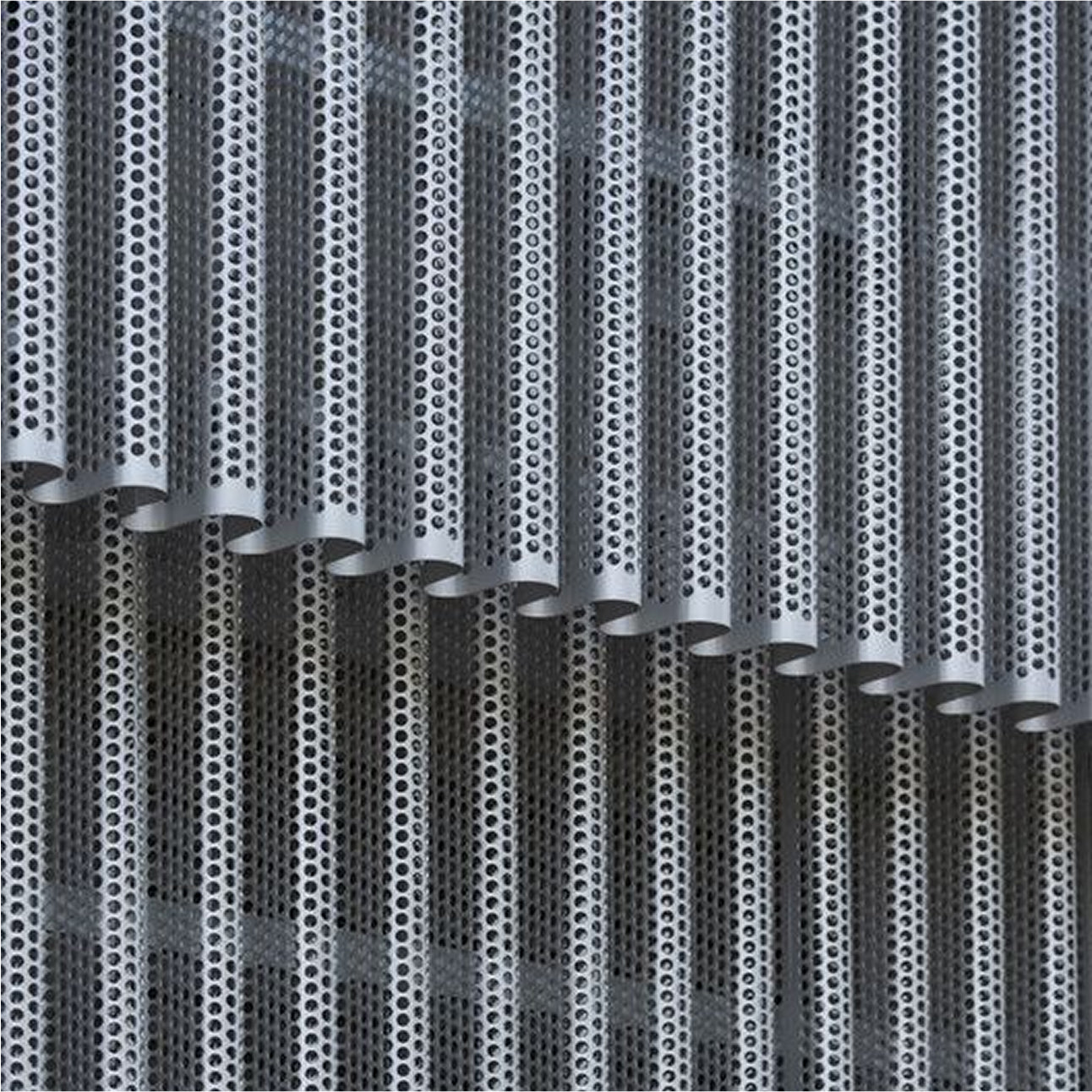

Expanded sheet, as a unique metal decorative mesh, is highly favored in the modern decoration field. It is usually made of metal sheets such as carbon steel, galvanized steel, aluminum, copper, or stainless steel. Through a special process, a row of cutting tools on an industrial die-cutting machine cuts the metal sheet. During the cutting process, the tools push down the newly cut parts and stretch them to form "strips". These "strips" are connected with the uncut parts to form diamond-shaped mesh holes, thus presenting a regular diamond-shaped opening pattern. This unique structure not only reduces its own weight and cost but also achieves the function of ventilation and air permeability. Its surface can be subjected to special treatments such as gold plating, silver plating, titanium plating, and tin plating, presenting a variety of colors. It has a rich variety of types, including the standard type, which can be used for making storage cabinets, warehouse enclosures, etc.; the raised type, whose staggered ridges form a diamond pattern with the overlapping metal strips, which is conducive to air circulation; and the flat type, which is about 5% lighter than the standard type, with a smooth surface. After cold rolling treatment, its anti-skid coating makes it suitable for building walkways and stairs, and it is also commonly used in scenarios such as enclosures, decoration, and ventilation. Expanded sheet is widely used in areas such as building facade decoration, indoor and outdoor partitions, stair and balcony railing protection, window safety protection, and air vents, adding unique decorative effects and practical functions to the space.

Product Features

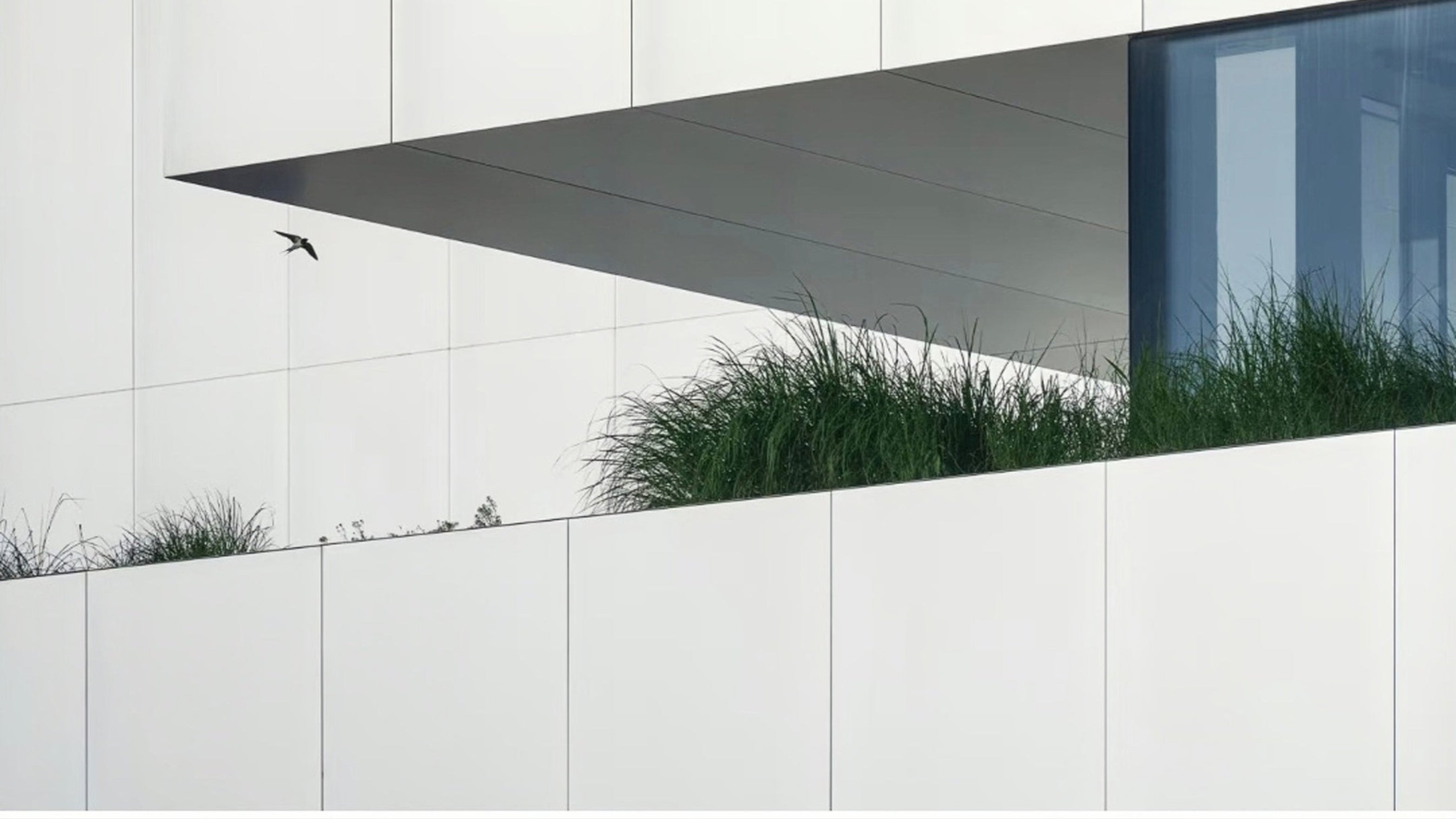

Relevant case

Technical data

Detail Parameter

Material Standard ASTM B209 / GB/T 3880

Alloy Grades 1050, 3003, 5052, 6061, 7075 (or customized)

Thickness 0.2mm–150mm (cold-rolled/hot-rolled)

Width 100mm–2500mm

Length 500mm–12000mm (coils or cut-to-size sheets)

Temper O (annealed), H12/H14/H16/H18 (work-hardened), T6 (heat-treated)

Surface Finish Mill finish, brushed, anodized, PVDF-coated, or mirror polish.

| Property | Aluminum | Stainless Steel | Galvanized Steel | Test Standard |

|---|---|---|---|---|

| Thermal Conductivity | 237 W/m·K | 16.3 W/m·K | 50 W/m·K | ASTM E1461 |

| Thermal Expansion | 23.6×10⁻⁶/°C | 17.3×10⁻⁶/°C | 11.7×10⁻⁶/°C | ASTM E228 |

| Melting Point | 660°C | 1400-1450°C | 1538°C | - |

| Density | 2.70 g/cm³ | 8.0 g/cm³ | 7.85 g/cm³ | ASTM B311/A751 |

| Property | Aluminum | Stainless Steel |

|---|---|---|

| Thermal Conductivity | 237 W/m·K | 16.3 W/m·K |

| Thermal Expansion | 23.6×10⁻⁶/°C | 17.3×10⁻⁶/°C |

| Melting Point | 660°C | 1400-1450°C |

| Density | 2.70 g/cm³ | 8.0 g/cm³ |

| Test Standard | ASTM Standards | ASTM Standards |

Sculpture

Lorem ipsum dolor sit amet consectetur adipisicing elit. Dolorem vero omnis hic cupiditate cumque sunt corporis quas excepturi, labore, libero quam enim voluptatem magnam animi temporibus exercitationem ex culpa eligendi.

Lorem ipsum dolor sit amet consectetur adipisicing elit. Dolorem vero omnis hic cupiditate cumque sunt corporis quas excepturi, labore, libero quam enim voluptatem magnam animi temporibus exercitationem ex culpa eligendi.

Other recommendations

FAQs

What are architectural metal screens used for?

Use this text to answer questions in as much detail as possible for your customers.

What are architectural metal screens used for?

Use this text to answer questions in as much detail as possible for your customers.

What are architectural metal screens used for?

Use this text to answer questions in as much detail as possible for your customers.

What are architectural metal screens used for?

Use this text to answer questions in as much detail as possible for your customers.

What are architectural metal screens used for?

Use this text to answer questions in as much detail as possible for your customers.