Stainless steel feature walls combine durability with visual appeal in modern architecture. These installations use specially treated stainless steel metal panels to create focal points in homes and commercial spaces. Surface treatments like brushing, mirror polishing, and etching transform basic panels into artistic highlights that elevate any design.

What Are Stainless Steel Metal Panel Feature Walls?

Stainless steel metal panels have become essential architectural elements that blend functionality with design impact. Understanding their basic properties helps you make informed choices for your project.

Definition and Core Properties

Stainless steel metal panel feature walls are architectural installations using corrosion-resistant steel sheets as primary design elements.

- Panels typically fall somewhere in the roughly 1.0mm to 3.0mm thickness range for solid wall cladding, with some decorative applications using slightly thinner material depending on the application.

- Thinner sheets work well for interior accent walls, while thicker panels handle high-traffic commercial environments.

Panel Types and Grade Selection

Two main grades dominate feature wall projects: 304 and 316 stainless steel. Grade 304 handles most indoor applications and moderate outdoor conditions. Grade 316 adds molybdenum, making it tougher against saltwater and harsh chemicals.

Near coasts or industrial zones, the higher alloy content and corrosion resistance of 316 stainless typically come with a noticeable price premium over 304, often on the order of a few tens of percent for comparable products.

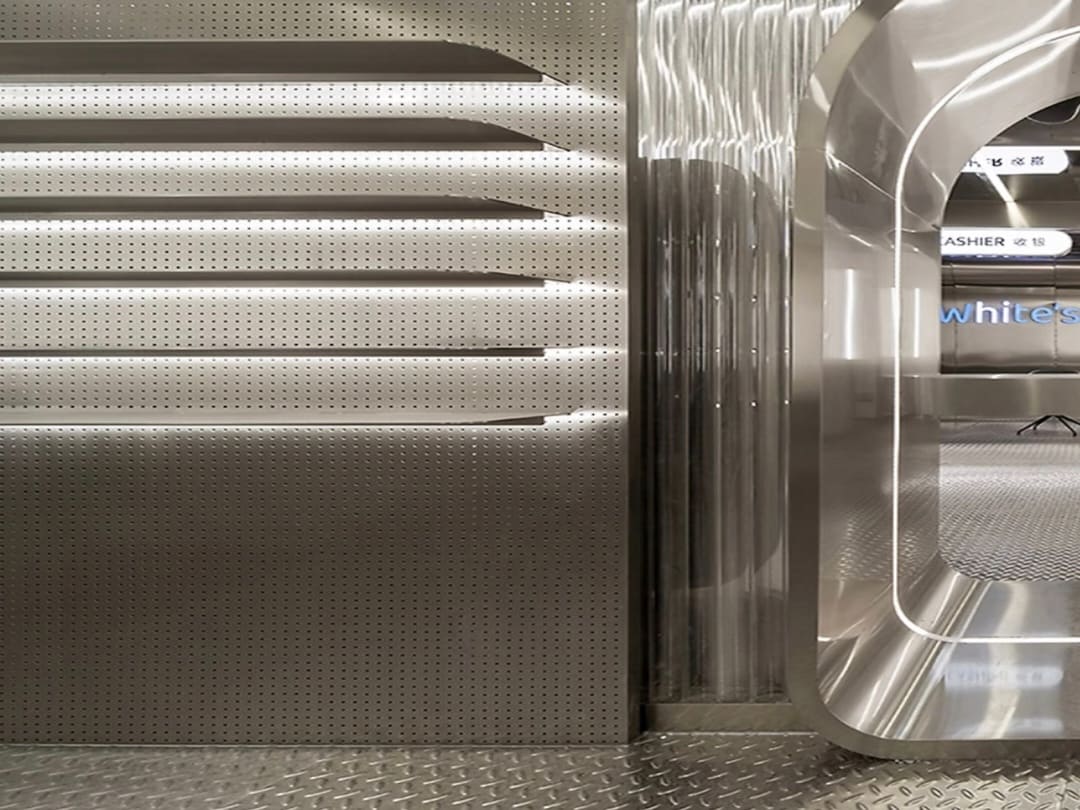

Panel formats vary—standard flat sheets offer clean looks, perforated panels allow light through, and textured panels add depth without special finishes.

Architectural Application Scenarios

Restaurants use stainless steel panels in open kitchens to project cleanliness. Corporate offices install them in lobbies for innovation appeal. Retail stores create striking backdrops that photograph well. Residential projects benefit too—feature walls behind beds or in home bars add sophistication.

- The material adapts remarkably well to different styles.

- Industrial spaces embrace raw metal aesthetics.

- Luxury environments combine polished stainless steel with marble or wood.

- Minimalist designs let panels speak for themselves.

For example, when designers want a consistent metal language across both exterior façades and interior reception feature walls, they can select matching surface finishes and color tones from Ansus Metal’s façade panel and interior cladding series, achieving a unified spatial experience.

Advantages Over Traditional Wall Materials

Stainless steel outlasts painted drywall, wallpaper, and most stone. It doesn't absorb moisture, preventing mold growth. Fire ratings are excellent—the material won't burn or release toxic fumes. Maintenance beats porous materials that trap dirt.

- Environmentally, stainless steel often averages around 60% recycled content in many markets and is effectively 100% recyclable at the end of life.

- This circular economy benefit appeals to LEED-certified projects.

What Are the Current Design Trends for Stainless Steel Metal Panels?

Today's stainless steel installations reflect evolving aesthetic preferences and environmental consciousness. These trends shape how designers and architects approach metal panel projects.

Minimalism and Industrial Aesthetics

The "less is more" approach dominates current projects. Designers install large, uninterrupted panels rather than busy patterns. The material's natural texture provides sufficient interest. This trend shows up in tech offices and modern residences where clean lines matter.

- Industrial style has moved mainstream.

- Exposed fasteners and raw edges, once hidden, now serve as intentional details, resonating with clients wanting authentic spaces.

Mixed Material Combinations

Stainless steel pairs well with other materials. Metal with reclaimed wood creates a warm-cool contrast. Glass and steel together maximize natural light. Concrete and steel share industrial DNA but offer different textures.

Textured and Patterned Surfaces

Three-dimensional patterns replace flat surfaces in high-end projects. Geometric reliefs catch light differently throughout the day. Organic patterns mimicking water ripples bring unexpected softness to metal.

- Custom perforations let designers control transparency.

- Gradient perforation patterns transition from solid to see-through across single panels, creating architectural drama.

- These gradient perforations or textured patterns can be realized through the perforated or expanded metal product lines offered by Ansus Metal, allowing control over daylighting and ventilation while delivering strong façade expression.

Sustainable and Eco-Friendly Design

Clients increasingly ask about material origins and lifecycle impacts. Stainless steel's recyclability helps meet sustainability goals. Some manufacturers offer panels with verified recycled content percentages.

Colored Stainless Steel Applications

Physical Vapor Deposition (PVD) coating opens color possibilities. Golds, bronzes, blacks, and blues maintain metallic character while adding personality. These finishes resist fading better than paint, and in typical indoor decorative use are designed to stay color-stable for many years under normal cleaning and wear.

- Colored panels work especially well for branding, where companies want specific color palettes.

- The metal provides durability, while the coating delivers the desired look.

What Surface Treatment Options Exist for Stainless Steel Metal Panels?

Surface treatments dramatically transform how stainless steel metal panels look and perform. Each finishing technique offers distinct visual characteristics and practical benefits.

Brushed and Satin Finishes

- Brushed finishes run abrasive material across steel in one direction, creating subtle linear patterns. This hides fingerprints and minor scratches better than polished surfaces. The look reads as sophisticated without being flashy—perfect for professional environments.

- Satin finishes create finer, softer textures. Surfaces reflect light diffusely, giving a warm, touchable quality. Architects specify satin for spaces where people interact closely with walls.

Mirror and High-Polish Surfaces

Mirror polishing creates highly reflective surfaces that bouncing light around spaces. Small rooms feel larger, dark areas brighten. The effect is dramatic but demands commitment—fingerprints show clearly.

Etched and Embossed Textures

- Chemical etching creates permanent patterns by selectively removing surface material. The process allows intricate designs that are impossible to achieve mechanically. Logos, decorative motifs, and artistic imagery transfer well to etched stainless steel.

- Embossing physically deforms metal, creating raised and recessed patterns. This three-dimensional quality adds tactile interest, working beautifully as room dividers where people view from multiple angles.

PVD Coating and Coloring Processes

PVD coating applies thin metallic compound layers in vacuum chambers. Results bond molecularly, creating finishes that won't chip or peel like paint. Colors remain stable with regular cleaning.

Aged and Vintage Effects

Controlled oxidation creates weathered appearances without sacrificing corrosion resistance. Treatments appeal to projects wanting character in new construction, mimicking decades of aging while remaining stable.

How Do You Select and Maintain Stainless Steel Metal Panels?

Making smart choices about stainless steel panels and caring for them properly ensures long-term satisfaction. Consider these practical factors for successful installation and upkeep.

Space and Environmental Considerations

Room function dictates finish choice. High-traffic areas need durable treatments that hide wear. Kitchens require surfaces that resist grease and cleaning chemicals. Outdoor installations must withstand UV, temperature swings, and precipitation.

- Lighting plays a huge role.

- Mirror finishes amplify light but can create glare opposite windows.

- Brushed finishes work better in spaces with challenging lighting.

Budget and Cost Planning

Material costs vary widely. Recent cost guides for stainless steel wall cladding place many standard 304-grade brushed systems in an approximate mid-hundreds-of-dollars-per-square-metre band (roughly the mid-teens per square foot) for material and fabrication, depending heavily on thickness, panel size, and finish complexity. Custom surface treatments, intricate patterns, or switching to 316-grade stainless can move total panel costs into substantially higher price brackets per square metre or square foot, especially on smaller bespoke runs. Installation labour for stainless wall panels is often budgeted in the tens of dollars per square foot in North American markets, reflecting the need for skilled installers, careful substrate preparation, and precise handling.

Installation Essentials and Key Points

Wall preparation matters critically. Stainless steel panels telegraph every substrate imperfection. Level, flat backing is non-negotiable. Most installers use plywood or drywall as substrates with proper framing behind.

Mounting methods vary. Adhesives work for small panels in protected locations. Mechanical fasteners provide security for larger installations. Concealed systems deliver the cleanest looks but cost more.

Daily Cleaning and Care Procedures

Regular cleaning prevents damaging buildup. Microfiber cloths with warm water handle routine maintenance. For tougher grime, pH-neutral stainless steel cleaners work best. Always wipe with the grain on brushed finishes.

Avoid chlorine-based cleaners and abrasive pads—they damage protective chromium layers. Even specialty cleaners need checking for harsh chemicals.

Long-Term Maintenance for Different Surfaces

Mirror finishes demand the most attention—weekly cleaning in normal conditions. Brushed and satin finishes hide marks better, stretching intervals to monthly or as-needed.

PVD-coated surfaces resist fingerprints and staining better than bare metal. Etched and embossed panels trap dirt in recesses, requiring occasional deep cleaning with soft brushes.

Frequently Asked Questions

Q1. How Does Climate Affect Outdoor Stainless Steel Panel Performance?

Climate significantly impacts outdoor panel longevity and appearance. Coastal environments require 316-grade stainless steel due to salt air causing corrosion on standard 304 grade stainless steel. High-humidity regions benefit from brushed or textured finishes that hide water spots better than mirror polish. Extreme temperature zones need proper expansion gap planning—panels expand and contract with temperature swings. Desert climates with intense UV exposure work well with PVD-coated panels that resist fading. Industrial areas with air pollutants may need more frequent cleaning to prevent chemical buildup. Always consult local fabricators familiar with regional conditions.

Q2. What Thickness Works Best for Different Wall Applications?

Panel thickness depends on installation type and traffic levels. Interior accent walls in commercial decorative sheet guidance are commonly in the 1.0–1.5mm range, providing adequate rigidity while still keeping weight and cost under control. High-traffic commercial lobbies often step up to around 1.2–1.5mm panels that better resist denting from carts and luggage impacts. Exterior facades typically use roughly 1.5–2.0mm solid sheets or composite systems with thin stainless faces but thicker structural cores to handle wind loads and temperature cycling. Ceiling applications frequently use slightly thinner material—around 0.6–1.0mm—since impact resistance matters less than weight.

Q3. Can You Install Stainless Steel Panels Over Existing Walls?

Yes, existing walls can serve as substrates if properly prepared. The existing surface must be clean, dry, level, and structurally sound. Minor imperfections telegraph through thin panels, so repair cracks and fill holes before installation. Painted walls need deglossing for adhesive bonding. Textured surfaces like stucco require smoothing or installing plywood underlayment. Check wall framing capacity—stainless steel adds 3-8 pounds per square foot, depending on thickness. Uneven walls may need furring strips to create a level mounting surface. Professional assessment determines if existing walls work or require replacement for quality results.

Conclusion

Stainless steel feature walls offer lasting beauty and performance when matched correctly to your space. Ready to start your project? Request samples from qualified fabricators to see different surface treatments in person and discuss installation requirements for your specific application.

Share:

Choosing Metal Interior Wall Panels For Commercial Spaces

Metal Surface Maintenance: Best Cleaning Techniques For Buildings