Keeping metal parts alive used to be all about corrosion, throughput, and price. Now sustainability sits right beside those three. When people talk about sustainable metal treatment, they mean cleaner chemistries, smarter lines, and better data so steel and aluminum stay protected while plants cut emissions, water use, and hazardous waste. The sections below show what that looks like inside real factories, from basic ideas to everyday decisions.

What Is Sustainable Metal Treatment For Modern Plants

Sustainable metal treatment is a way of running the whole finishing chain so impact drops and quality still hits spec. To move that way, teams need a shared view of scope and the main forces pushing change.

Concept And Scope

In practice, sustainable metal treatment covers cleaning, pretreatment, plating or conversion coating, painting or powder coating, curing, and all the rinses in between.

Pollution-prevention programs describe it as “source reduction first, end-of-pipe second.”

If a shop replaces high-hazard pretreatments, switches to low-temperature powder, and redesigns rinses, all those moves sit under the same umbrella. A simple test is: parts still last in the field, and the line now uses less energy, water, and hazardous chemistry to get there.

Why is Sustainable Metal Treatment Becoming Crucial?

Environmental Rules And Policies

Regulation pushes hard in this direction. Coating rules and sector P2 programs focus on VOC cuts, safer cleaning agents, and lower toxic metals in wastewater. Climate policy adds pressure on high-energy steps like curing and heat treatment. Each update nudges plants toward cleaner options and gives management a concrete reason to modernize metal treatment.

Customer Demand And Supply Chain Needs

Big buyers add their own layer. Automotive, appliance, and electronics brands now ask for VOC numbers, carbon estimates, and restricted-substance lists. For smaller job shops, sustainable metal treatment often starts as a way to keep a key customer and ends up as a way to stabilize quality and cost over several years.

How Does Sustainable Metal Treatment Affect Metal Material Choices?

Material decisions often decide how “green” a line can ever become. Once the wrong chemistry or substrate is in play, it is hard to clean up the impact downstream.

Low-Toxic Pretreatment And Eco Coatings

Traditional systems leaned on hexavalent chromium, cyanide, and similar high-hazard ingredients. Modern guidance promotes alternatives such as zirconium or titanium pretreatments and trivalent chromium, where performance allows. These options usually create less hazardous sludge and still meet corrosion targets when paired with good coatings.

Waterborne And Solvent-Free Coatings

Coatings are a major lever. Solvent-borne systems often carry VOC levels around 700–900 g/L, while many waterborne metal coatings sit closer to 100–300 g/L. Lower VOC means easier compliance and better air for workers on the line. That is why sustainable metal treatment tends to favor waterborne, powder, and other low-solvent options whenever product specs allow.

Recycled Metals And Low-Carbon Substrates

The metal itself arrives with a carbon footprint. Studies on steel and aluminum show big differences between conventional materials and low-carbon or high-recycled grades. When purchasing and processing teams work together, they can choose substrates that behave well in existing pretreatments and still cut upstream emissions.

Heavy Metal And Hazardous Chemical Reduction

Sustainable metal treatment also aims to shorten the list of truly nasty substances on-site. That can mean phasing out cadmium, reducing nickel exposure, or redesigning lines so fewer baths rely on persistent or carcinogenic organics highlighted in metal-finishing guidance. Once pretreatments, coatings, and substrates get cleaner, every later step on the line has a better chance of hitting both quality and sustainability goals.

How Does Sustainable Metal Treatment Change Metal Process Flows?

Even with better chemistries, a line can still waste energy and water. Sustainable metal treatment looks closely at ovens, rinses, and how tanks are arranged and controlled.

Energy-Saving Heat Treatment And Curing

Ovens and curing zones often dominate the energy bill in coating lines. Low-temperature-cure powders, UV-assisted curing, and better oven control are three common tools. Case studies on low-bake powders report energy savings that can reach roughly 50% in some jobs when both cure temperature and time are reduced. Those gains help both carbon numbers and fuel costs.

Closed-Loop Washing And Wastewater Control

Rinsing is the other big target. Moving from single-stage rinses to multi-stage counter-flow systems can cut fresh-water demand by about 70–80% while still delivering clean parts. When plants add conductivity-based controls to adjust flow, they often see lower water and sewer bills plus less sludge in treatment.

Low-Emission Line Design

Line design also matters. Best-practice documents for metal finishing encourage better fume capture, high-transfer-efficiency spray equipment, and enclosed sections in high-emission zones. These changes reduce fugitive emissions and paint loss and make it easier to prove compliance when inspectors arrive.

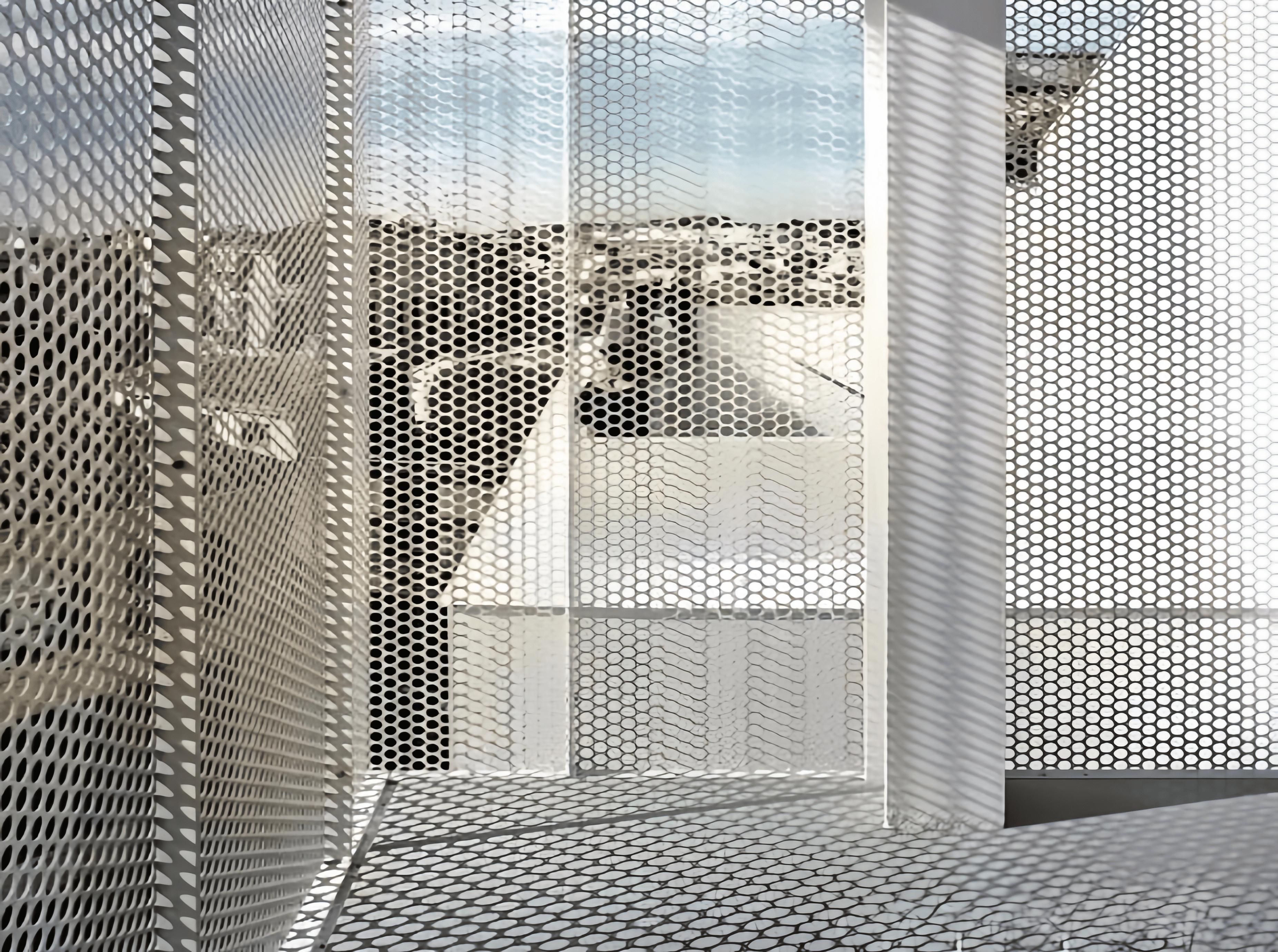

Suppliers that serve demanding architectural markets, such as Ansus Metal with its perforated and expanded metal façade systems, depend on this kind of low-emission, high-consistency finishing to deliver both visual quality and a credible sustainability story.

Automation And Online Monitoring

Modern sensors close the loop. When conductivity, pH, and temperature are tracked in real time, controls can trim water use and adjust dosing instead of relying on fixed setpoints and occasional manual checks. Programs that added conductivity control to rinses have seen sharp drops in water use and chemical loss with short payback times. Together, these upgrades turn sustainable metal treatment from a wish list into concrete changes on ovens, tanks, and controls.

How Should Companies Make Decisions About Sustainable Metal Treatment In Practice?

Knowing the options is one thing; choosing a path that fits the plant is another. A simple structure keeps sustainable metal treatment grounded in numbers instead of slogans.

Impact Metrics And Data Baseline

Most plants begin with a small set of metrics linked directly to metal treatment:

- Energy per unit area coated

- Fresh water per part

- VOC per kilogram of coating

- Hazardous waste per month

- Basic health and safety indicators

Looking at mature projects, typical improvement ranges look like this:

| Metric | Typical Improvement Range With Sustainable Metal Treatment |

| Fresh Water Use In Rinsing | About 70–80% lower with well-designed counter-flow rinses |

| VOC Emissions From Coatings | Roughly 50–80% lower VOC levels with waterborne systems |

| Curing Energy For Coated Parts | Around 15–50% savings with low-temp or UV-assisted curing |

Each plant will land at its own numbers, but this range keeps goals ambitious and still believable.

Implementation Steps And Technology Upgrade Planning

Instead of rebuilding everything at once, most teams move in steps. A common pattern is: map the current line and collect a few weeks of data; fix obvious “housekeeping” issues in rinses and ovens; pilot one new pretreatment or coating on a small product family; then lock in what works through updated procedures and training. Experience from metal-finishing programs shows that this mix of quick wins and focused upgrades usually delivers solid environmental and financial payback.

FAQs

Q1: How Can Sustainability Targets Be Built Into Metal Treatment Contracts With Suppliers?

A practical way is to treat sustainability like quality and delivery. Contracts can include a small set of clear metrics, such as maximum VOC per liter, recycled content in metal stock, or limits on specific hazardous substances. Suppliers then report against those items on a fixed schedule, using lab data or third-party documents. When new projects start, engineering and purchasing teams can score options on both technical fit and sustainability numbers instead of price alone. Over time, this creates a shared language, so suppliers know which improvements will actually matter in sourcing decisions.

Q2: What Organizational Changes Make Sustainable Metal Treatment Easier To Maintain?

Plants that keep progress going usually give metal treatment its own cross-functional owner. That person or team pulls in EHS, production, maintenance, and purchasing instead of leaving decisions inside one department. Regular short reviews, for example, each quarter, keep metrics visible and highlight lines that need help. It also helps to link at least one sustainability indicator to site bonuses or performance goals, so operators and supervisors see that better rinses, stable baths, and careful handling of chemicals are part of the day job, not a side project.

Q3: How Can Training Support Long-Term Sustainable Metal Treatment Goals?

Training works best when it connects daily tasks with actual outcomes. Instead of generic “green” sessions, operators see more value when someone explains how a specific change in pH, temperature, or conductivity affects rejects, rework, and compliance risk. Short toolbox talks at the line, simple visuals near tanks, and clear troubleshooting steps give people confidence to act before problems grow. Refresher sessions for new hires and for supervisors keep knowledge from fading. When staff understand why settings matter, sustainable metal treatment becomes a normal part of running the line well.

Conclusion

To turn ideas into action, pick one pilot area where sustainable metal treatment clearly supports your customers and compliance goals, set a few simple targets for energy, water, or hazardous waste, and run a time-boxed trial; once the results look solid, write those practices into your standards and repeat the pattern on the next line so improvement slowly becomes the default way you treat metal.

If you work with façades, ceilings, or decorative metal screens and want a partner that already builds sustainability into aluminum and stainless steel systems, We Ansus Metal is worth considering as you plan your next round of upgrades.

Share:

Design and Selection Guide for Metal Interior Wall Panels

Choosing Metal Interior Wall Panels For Commercial Spaces